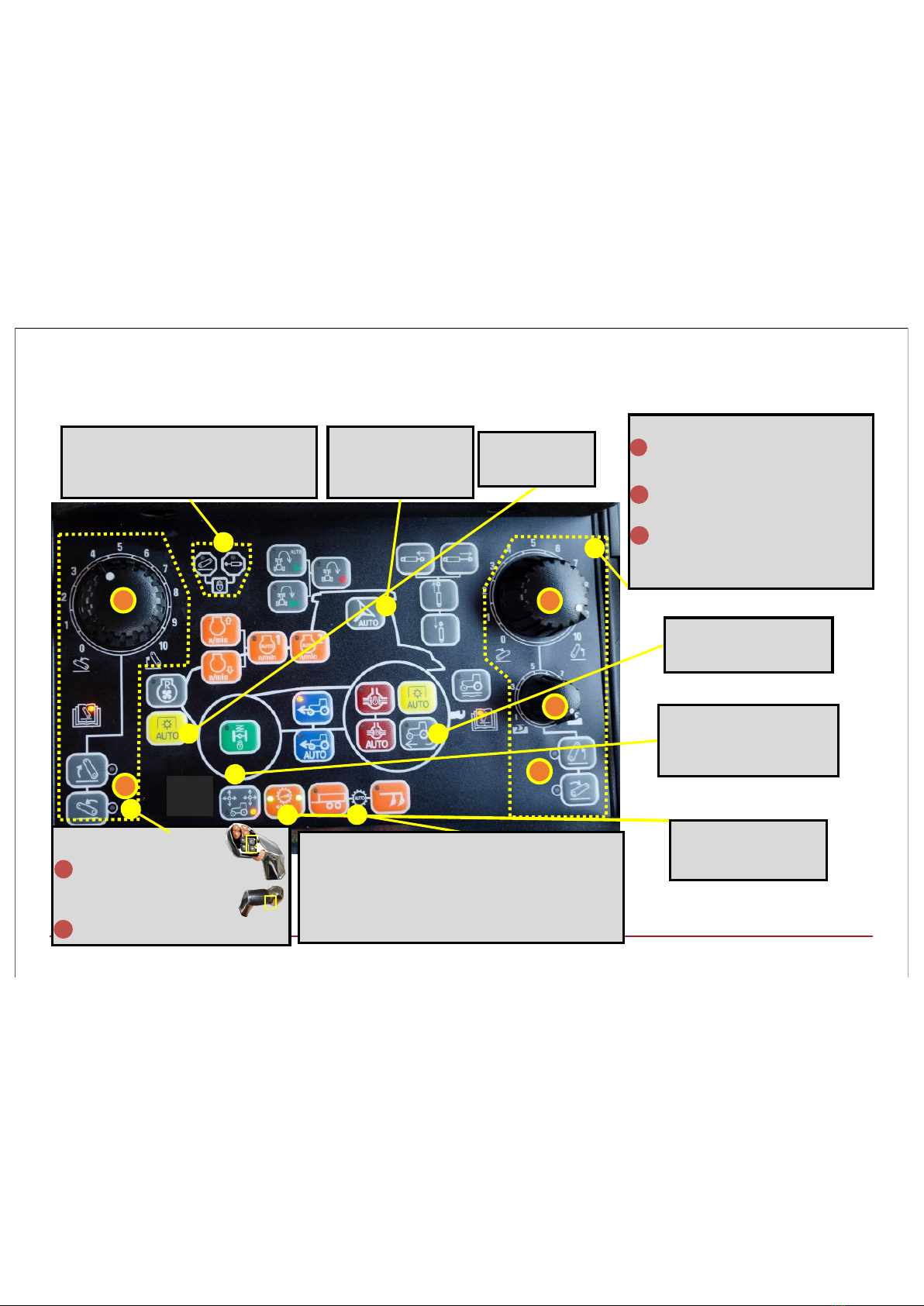

Engine coolant

temperature

Fuel level

Warning Light

Panel

Engine speed

Actual gear

Reverse gear

Transmission status

Ground speed

AdBlue level

Clock

Change/Scroll 1

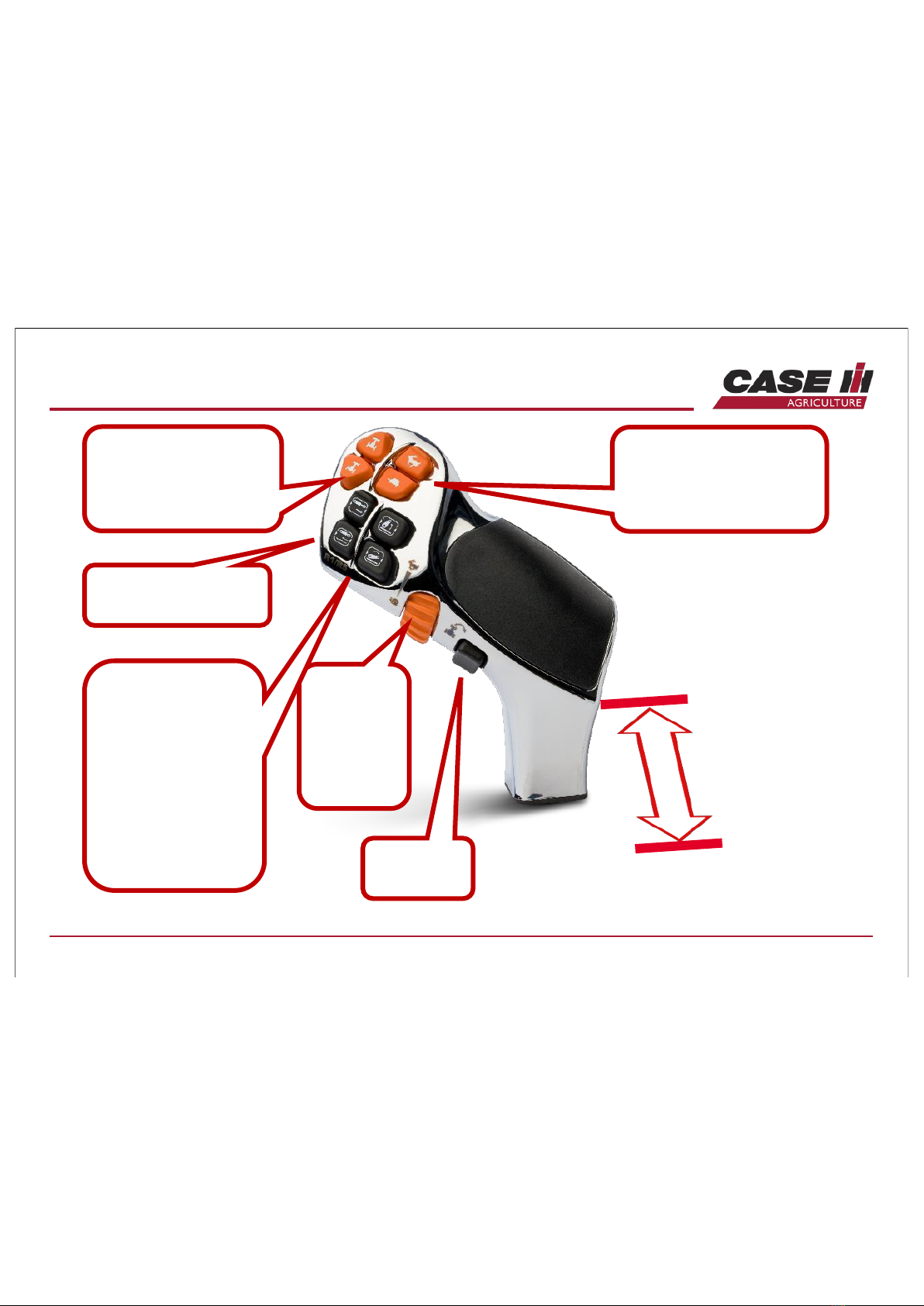

Raise

Change/Scroll 2

Program / Input of data

Lower

Reset

Engine oil / air pressure

Wheel slip

Front & rear PTO speed /

Lift height front & rear hitch

Performance data of the tractor

Driven distance

Area counter

Service interval / operating hours

Air condition

Remote valve settings

MULTI FUNCTION DISPLAY:

- configuration menu

- engine load [%]

- engine oil pressure [bar/%]

- engine oil temperature [°C]

- charge air temperature [°C]

- AdBlue temperature [°C]

- transmission oil pressure [bar]

- transmission oil temp. [°C]

- battery voltage [V]

- pneumatic air pressure [%]

- climate control settings

- slip value [%]

- work performance [ha]

- work performance [ha/h]

- fuel level [litres]

- fuel rate [l/h]

- remaining working time at

present fuel rate [h]

- distance counter [km]

- slow speed indicator [m/min]

- working time [h:min]

- PTO speed front / rear [rpm]

- lift height front / rear hitch [%]

- hydraulic remote valve settings