flipIT Tech Line: 800 770-7042 3

©2009 CBT Supply Inc.

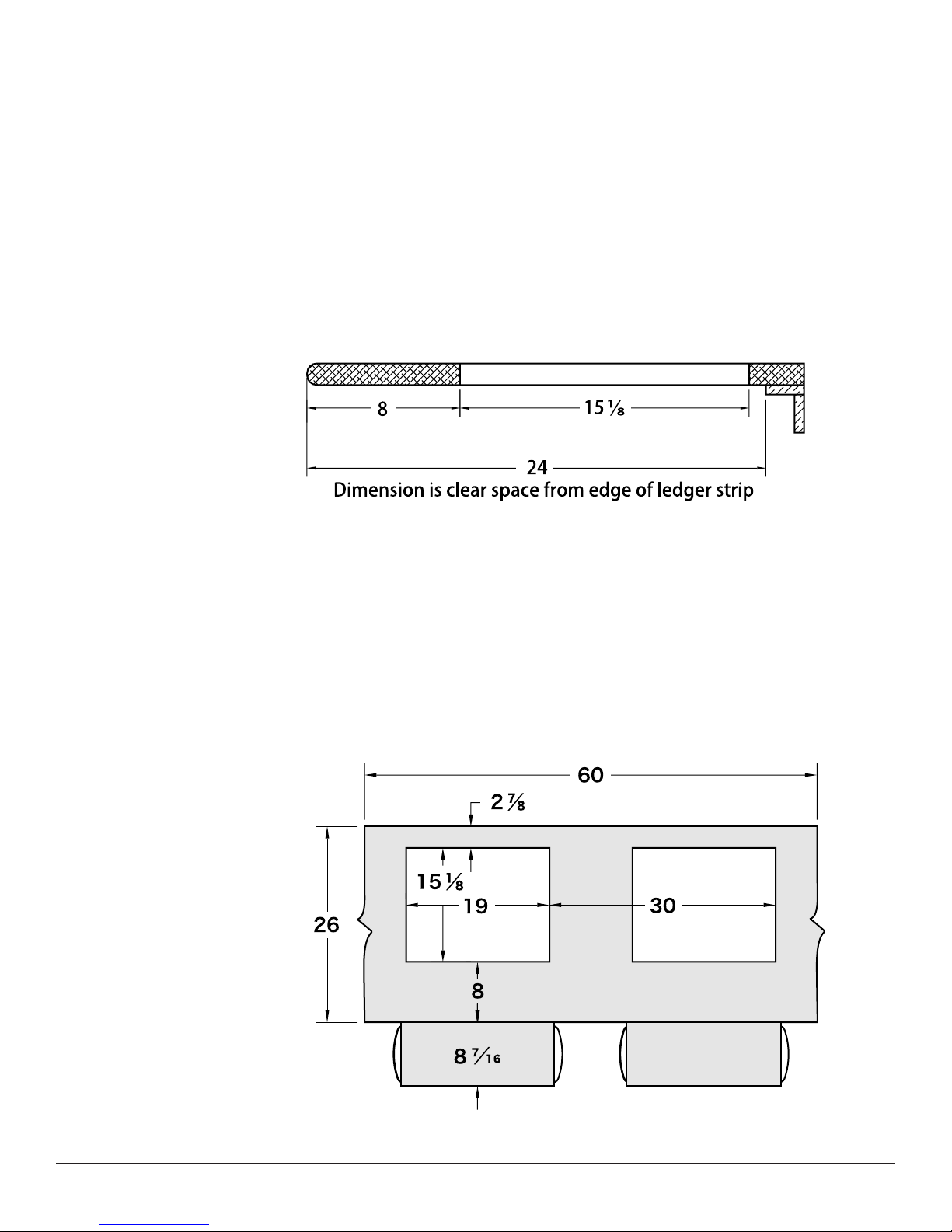

These instructions make certain assumptions about the working space. You can

make variations in these based on your application, but here is a reference of the

space allocation as designed for a standard installation. If you are placing two or

more flipIT units side-by-side, 30” spacing is recommended as a minim um.

The mouse tray extends on left or r ight. Seat users so left- and r ight-handed

do not conflict.

IMPORTANT:

Planning Ahead

Whenever possible, install the flipIT mechanism FIRST, before assembling the

desk. It’s easier and more efficient to w ork this way.

If you are installing flipIT into an assemb led desk, see if it is possib le to remove the

desktop to make the cut-out. If that is not possible, take care to make a work envi-

ronment that will protect the surface finish of your furniture and will be safe for oper-

ating power tools.

The recommended placement of the cutout f or the flipIT unit is 8 inches from the

user’s edge. This assumes a straight edge; not a round or contoured edge. If you

are experimenting with placement for an unusual application, we recommend

requesting additional templates and making dry-fit installations into scrap.

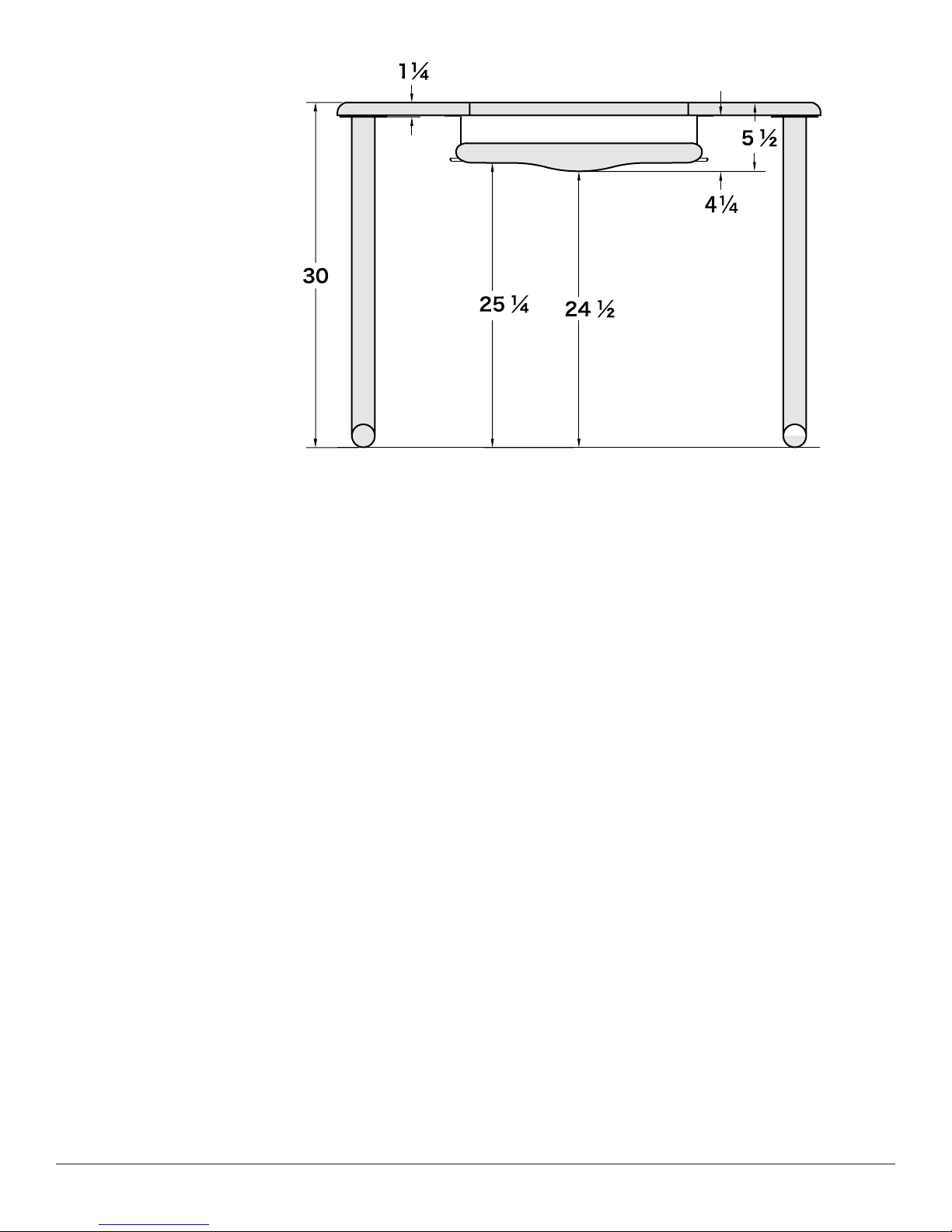

Based on this profile, a minimum of 24 inches of clearance, front to back, must be

allowed for the mechanism and LCD monitor. If you are installing modesty panels,

make sure you allow this clearance, as well.

Counter Top Depth

Workstation Spacing

Use 30 inch spacing from

centerline to centerline, or from

common reference point as shown

on the drawing (from right edge of

cut-out to right edge of cut-out).

This drawing depicts a segment of

table top and does not

indicate a minimum table top

width.

FIK/FIH-23 for widescreens

cutout is 15-5/16” x 25” and

Keyboard is 26” wide including

mouse surface.

FIK/FIH-19 for widescreens

cutout is 15-5/16” x 20.62” and

Keyboard is 26” wide including

mouse surface.