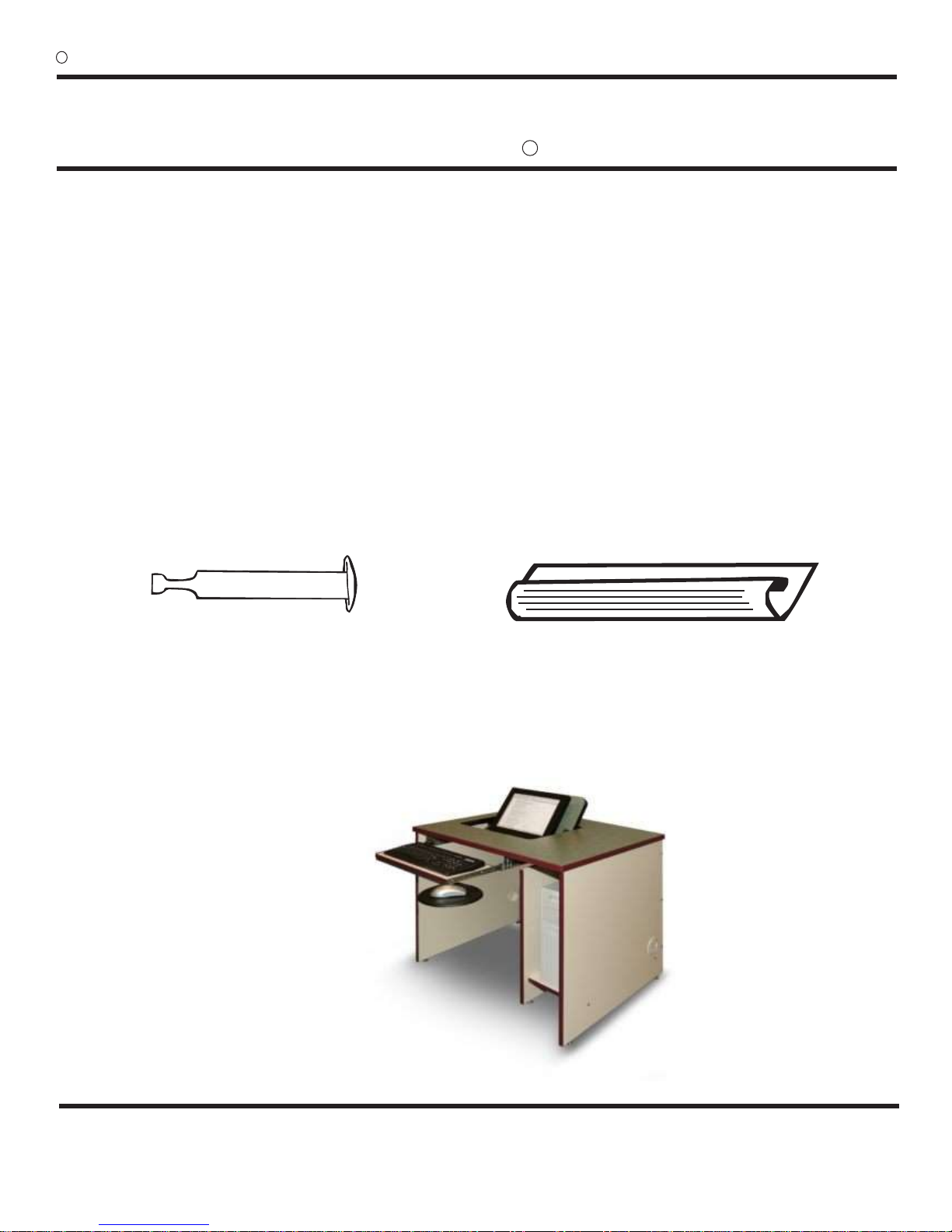

STEP 1 - Desk Panel & Side PanelAssembly

NOTE: 1 person assembly required for proper fit.

NOTE: DO NOT CUT THE NYLON CABLE TIE FROM THE KEYBOARD

HINGE UNTIL THE DESK IS ASSEMBLED AND UPRIGHT.

In a clean work area lay Desk Top Panel facing down on

the floor on cardboard or carpet/packing quilt. (Fig. 1)

Lift and place Right Side Panel into 90overtical position

with fittings facing in. While holding right panel in vertical

position, match RV Fittings to one another and snap

panel into place. Use power drillto tighten the screw

contained in the RV Fitting. (Fig.2) Each RV Fitting

contains a screw to lock the hardware once the panels

have been snapped into place. Warranty is void if all

locking screws have not been tightened. RV Fittings

come preinstalled in panels and are equally spaced along

Desk Top edge. Tighten all remaining RV Fittings along

panel edge. (Fig.3)

Repeat STEP 1 for the installation of the Left Side Panel.

STEP 2 - Back Panel To Sides Assembly

NOTE: 2 person assembly required for proper fit.

Slide Back Panel into position between two Side Panels

matching the cam fittings to the holes at top. It is necessary

for 2 people to accomplish this assembly. Vertical panels

cannot be left standing unsupported (Fig.4) Insert top

2 Cam Pins through Left and Right End Panels into cam

fittings. (Fig. 5) Start at the top cam of each end panel

when inserting Cam Pins and move down each end

panel alternating as Cam Pins are inserted. Make sure

arrows on Cam Pins are facing out (3 pm clock position).

Tighten about 1/4 turn with screwdriver until it locks into

place.(Fig. 6) Repeat this step for remaining 4 Cam

Pins. The Cam Pin is a steel to steel assembly which

ensures heavy duty strength when assembled.

Figure 1

Figure 2

Figure 3 Check to verify that arrow is

pointing perpendicular to pin

when cam is locked.

Figure 4

Figure 5

cCBT Supply Inc.

Cam pin is inserted through

panel into preinstalled fitting.

(Once Back Panel is secured to Left

and Right Side Panels, the “shell” of

the desk is assembled. See Figure 7

on next page)

Figure 6

SFI Single Workstations Flip-it Single Series Page 3