SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 6/2020)

TABLE OF CONTENTS

SECTION 1 – SAFETY INFORMATION............................................................................................................. 4

1.1 – CAUTION .......................................................................................................................................... 4

1.2 – PRECAUTIONS .................................................................................................................................. 5

SECTION 2 – THE SUMP CLEANER................................................................................................................. 6

2.1 – UNIT IDENTIFICATION ...................................................................................................................... 6

2.2 – MODEL & SERIAL NUMBER .............................................................................................................. 7

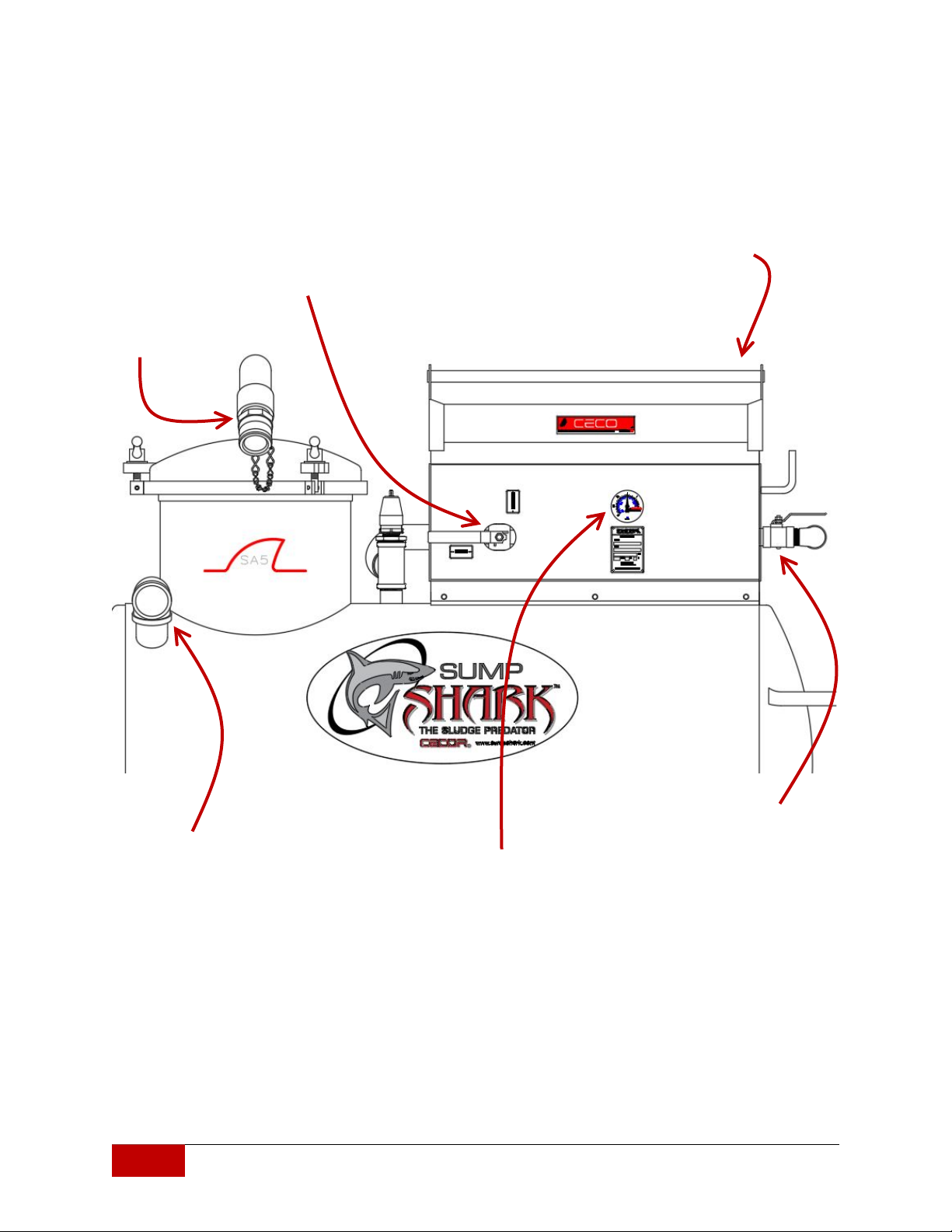

2.3 – SUMP CLEANPER FEATURES............................................................................................................. 8

SECTION 3 – INSTALLATION .......................................................................................................................... 9

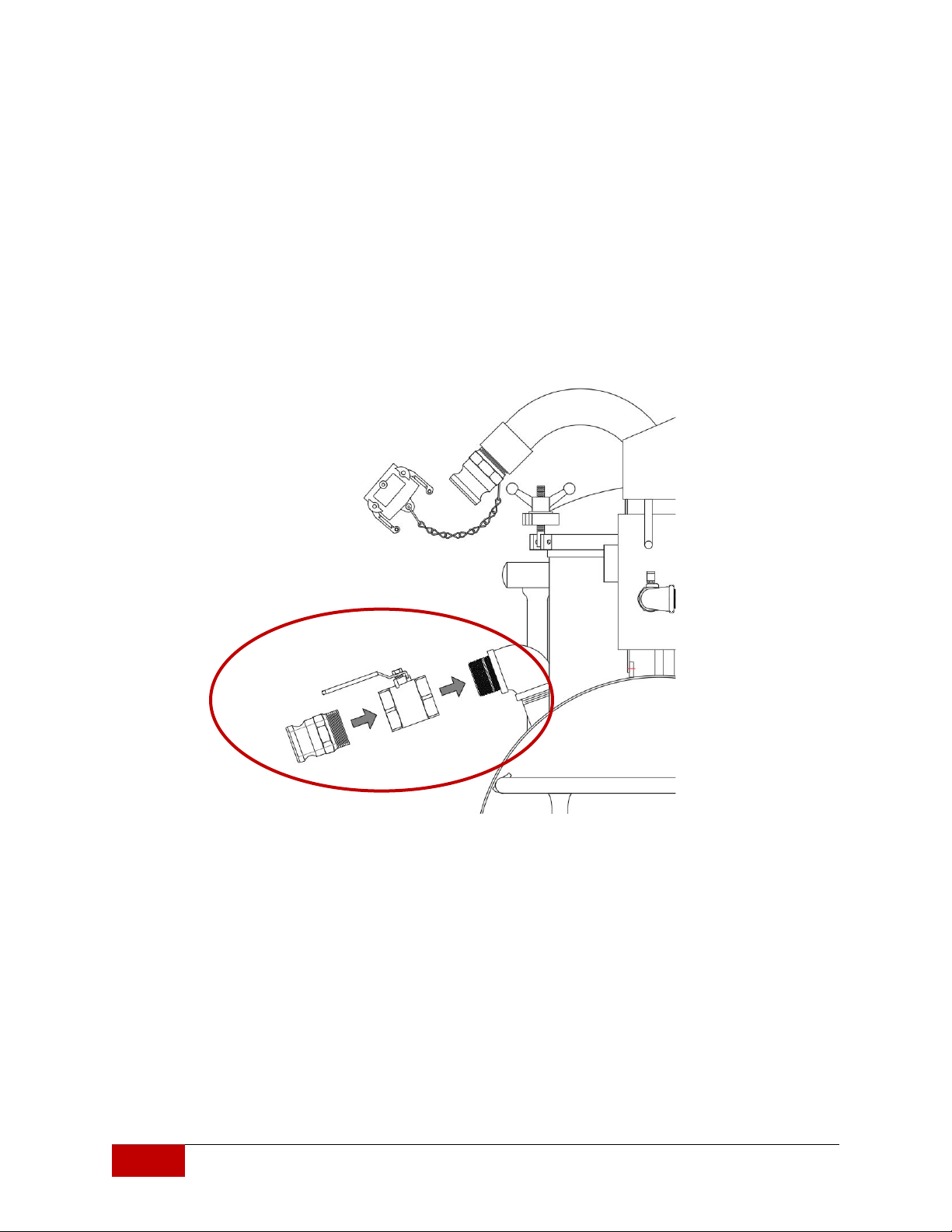

3.1 – ASSEMBLE DISCHARGE CONNECTION.............................................................................................. 9

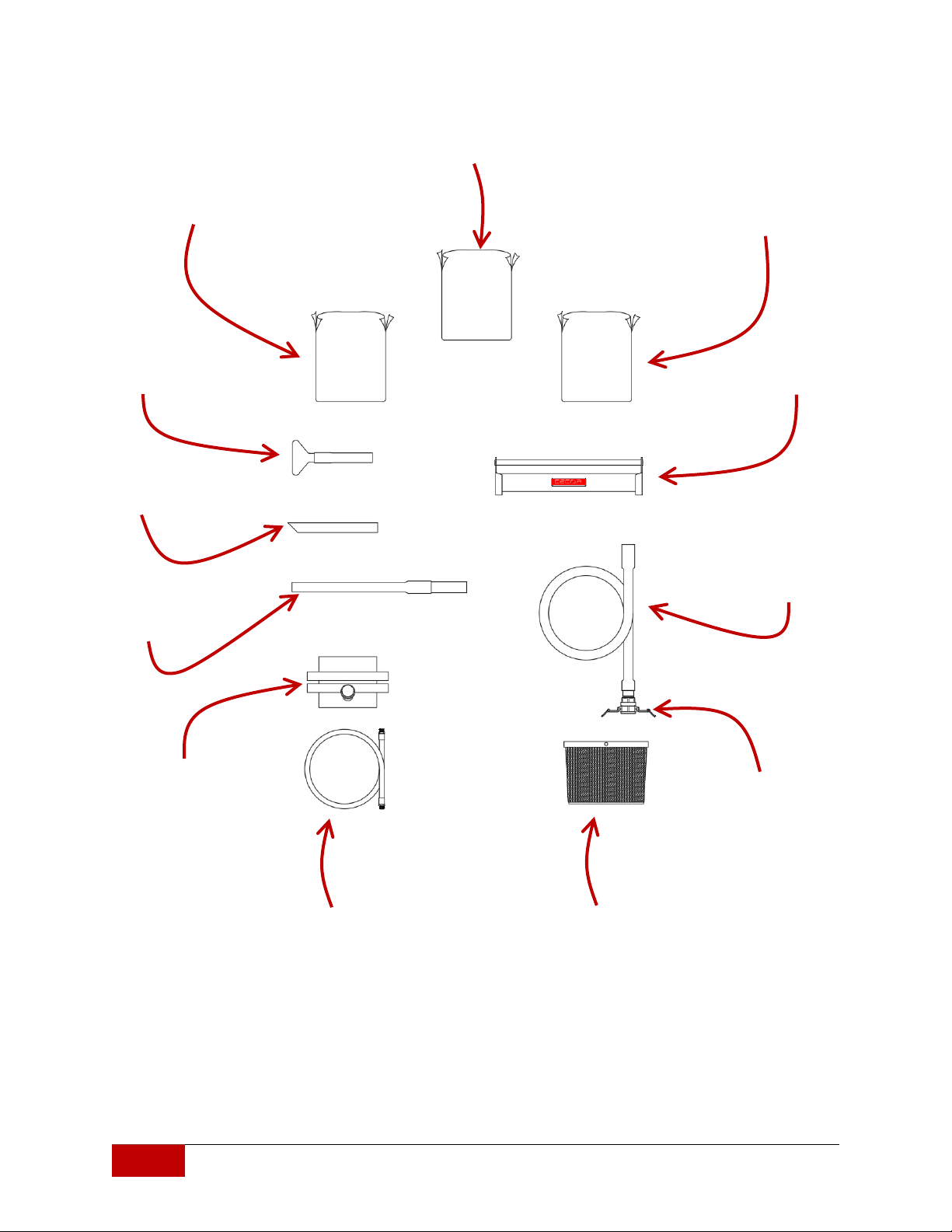

3.2 – LOOSE ITEMS.................................................................................................................................... 9

3.3 – INITIAL STARTUP ............................................................................................................................ 11

SECTION 4 – OPERATION ............................................................................................................................15

4.1 – CLEANING A SUMP......................................................................................................................... 15

4.2 – DISCHARGING FLUID FROM THE SUMP CLEANER.......................................................................... 16

4.3 – FILTER ............................................................................................................................................. 16

4.3.1 – F10 FILTER ...............................................................................................................................17

4.3.2 – F23 FILTER ...............................................................................................................................19

4.4 – CLEANING THE SUMP CLEANER .....................................................................................................23

SECTION 5 – MAINTENANCE ....................................................................................................................... 24

5.1 – DAILY MAINTENANCE..................................................................................................................... 25

5.2 – WEEKLY MAINTENANCE................................................................................................................. 25

5.3 – MONTHLY MAINTENANCE ............................................................................................................. 25

5.4 – SEMI ANNUAL.................................................................................... Error! Bookmark not defined.

SECTION 6 – TROUBLESHOOTING............................................................................................................... 26

SECTION 7 – REPAIR PARTS LIST .................................................................................................................27

7.1 – WHEELS & CASTER ......................................................................................................................... 27

7.1.1 “PTL” PUSH TOW LIFT WHEEL TRANSPORT 90-200 GAL............................................................27

7.1.3 “TW” TOW WHEEL TRANSPORT 300 & 400 GAL........................................................................28

7.1.4 “TW” TOW WHEEL TRANSPORT 500 GAL .................................................................................. 29

7.2 – TANK & PUMP ................................................................................................................................ 30

7.3 – FILTER, TOOLS & HOSE ...................................................................................................................31