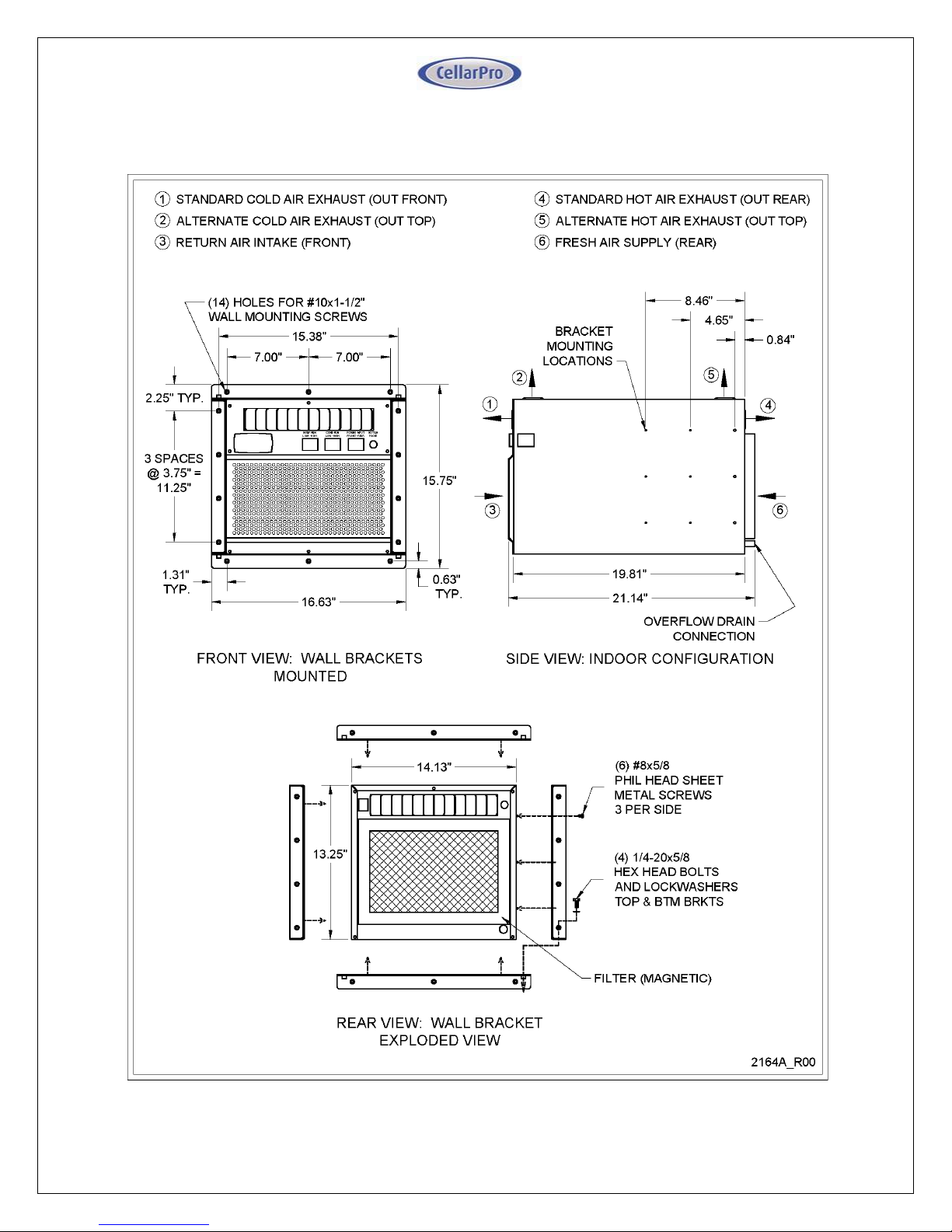

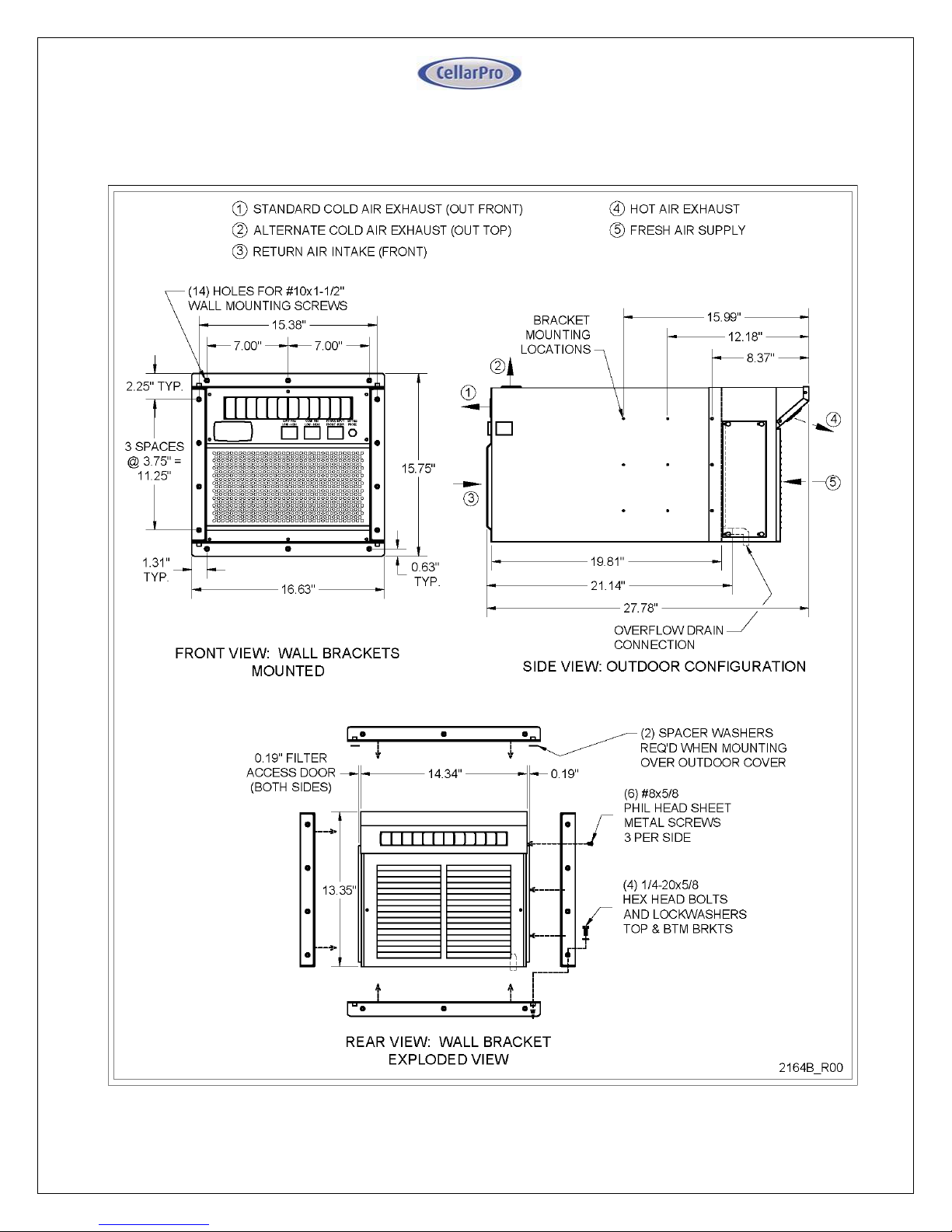

•Placement

CellarPro2000VS Seriescooling units are designed to be installed THROUGH THE WALL, so that the rear and the

front of the cooling unit DO NOT SHARE THE SAME AIR SPACE.

Wheninstalling this unit,youmustselect fromthepre-drilledholes to attach the mounting brackets. If you drill

newholesintothecase,youwill damagethe internalcomponentsofthecoolingunit.

The rear of the cooling unit must be installed in a space that is at least as large as the wine cellar unless the rear

intakeandexhaustareducted. Boththefrontandtherearofthecoolingunitrequireaminimumclearanceof12

inches.

Theseunits also canbe placedcompletelyINSIDE or OUTSIDE thecellarwhenusedincombinationwithourduct

kits.

•Ambient Environment

2000VSi - designed for internal use only (ie sheltered from outdoor weather), the rear of the unit

can be exposed to temperature conditions ranging from 40 to 110°F.

2000VSx –designed for external use, the rear of the unit can be exposed to temperature

conditions ranging from 40 to 110°F. Refer to the Installation section for additional requirements

for outdoor exposures.

PLEASE NOTE: With our (optional) compressor heater, all of our cooling units can be used in

environments down to 20°F, and with our (optional) fan cycling switch, all of our cooling units can be

used in environments down to -20°F.

CellarPro cooling units are not designed to heat the cellar space, so if temperatures inside the cellar

drop below proper wine storage

temperatures, the cooling unit cannot

create heat inside the cellar.

•Insulation

CellarPro cooling units are designed

to be installed inside wine cellars that

have proper insulation, moisture

barriers and an airtight seal from the

environment outside the cellar.

Interior walls and floor should

have a minimum of R-11 insulation,

and a vapor barrier on the warm side

of the insulation. The ceiling should

have a minimum of R-19 insulation

and a vapor barrier on the warm side

of the insulation. Doors also should be insulated and tightly sealed with weather s t r i p p i n g

a r o u n d t h e peri me ter o f the door. Surface-mounted fixtures are recommended

over recessed lighting, which can allow air to leak into the cellar.