Index

1

POLO 20-30-50/L POST-MIX

Index

1 - Safety .....................................................................................................................3

1.1 Intended use ..................................................................................................................... 3

1.2 Improper use .................................................................................................................... 3

1.3 List of hazards ................................................................................................................... 4

1.4 Residual risks .................................................................................................................... 6

2 - General information ............................................................................................... 7

2.1 Manufacturer’s details ........................................................................................................ 7

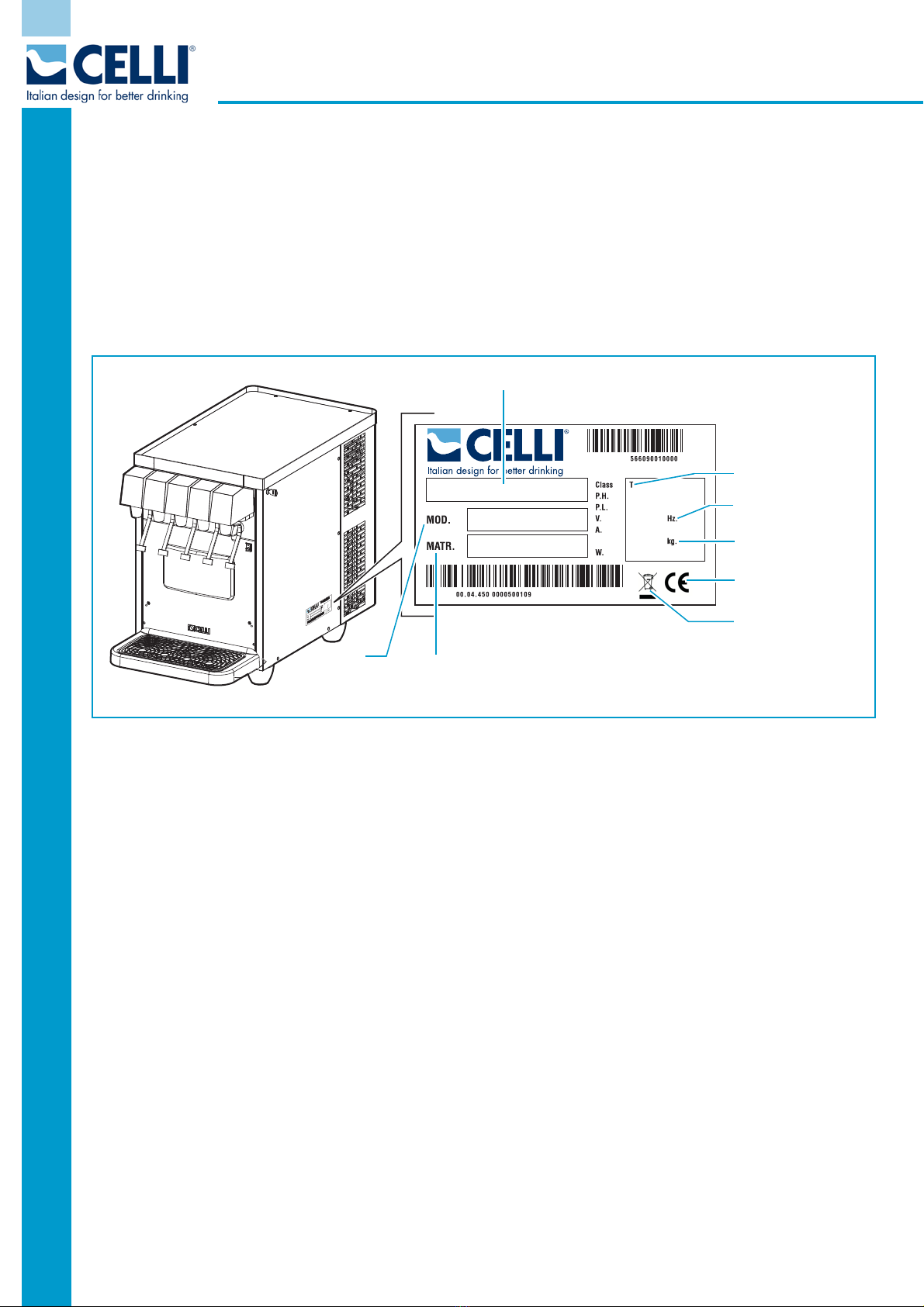

2.2 Machine identification......................................................................................................... 8

2.3 Warranty........................................................................................................................... 8

2.4 Symbols used in the manual ............................................................................................... 9

2.5 Staff qualification............................................................................................................... 9

3 - Description of the machine .................................................................................. 10

3.1 Main components of the POLO L POST-MIX range...............................................................11

3.2 Operating principle............................................................................................................13

3.2.1 Sound emissions ......................................................................................................16

3.3 Dimensions in mm (inches)................................................................................................17

3.3.1 POLO 20-L ...............................................................................................................17

3.3.2 POLO 30-L ...............................................................................................................17

3.3.3 POLO 50-L ...............................................................................................................17

3.4 Differential-switch power cord (optional) ............................................................................18

4 - Installation ........................................................................................................... 19

4.1 Checks and Unpacking ......................................................................................................19

4.2 Positioning .......................................................................................................................20

4.3 Environmental conditions...................................................................................................21

4.4 Electrical requisites ...........................................................................................................21

4.5 Connections .....................................................................................................................22

4.5.1 Preparing the machine..............................................................................................22

4.5.2 Water intake connection ...........................................................................................23

4.5.3 Connecting the syrup lines ........................................................................................25

4.5.4 Carbon dioxide (CO2) connection ...............................................................................26

4.5.5 Electrical connection .................................................................................................28

4.6 Adjusting the carbon dioxide (CO2) supply..........................................................................29

4.7 Checking for leaks.............................................................................................................29

4.8 Adjusting the dispensing valves .........................................................................................30

4.9 First start-up ....................................................................................................................31

5 - Using the machine................................................................................................ 32

5.1 Stopping the machine .......................................................................................................33

6 - Maintenance ......................................................................................................... 34

6.1 Scheduled maintenance.....................................................................................................34

6.1.1 Cleaning ..................................................................................................................35

6.2 Table of procedures ..........................................................................................................36