CENTENT COMPANY

iii

CONTENTS

GENERAL DESCRIPTION ...................................................................................1

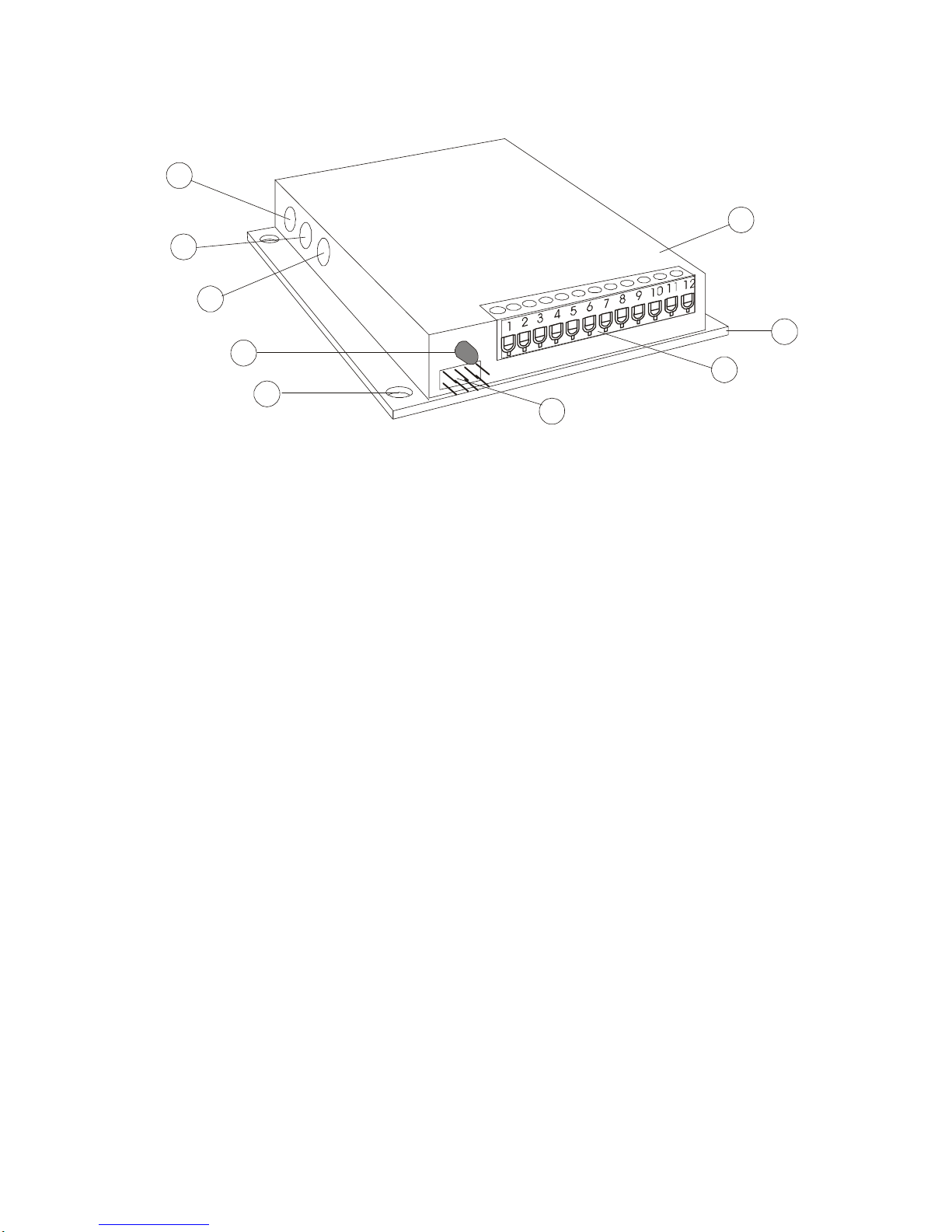

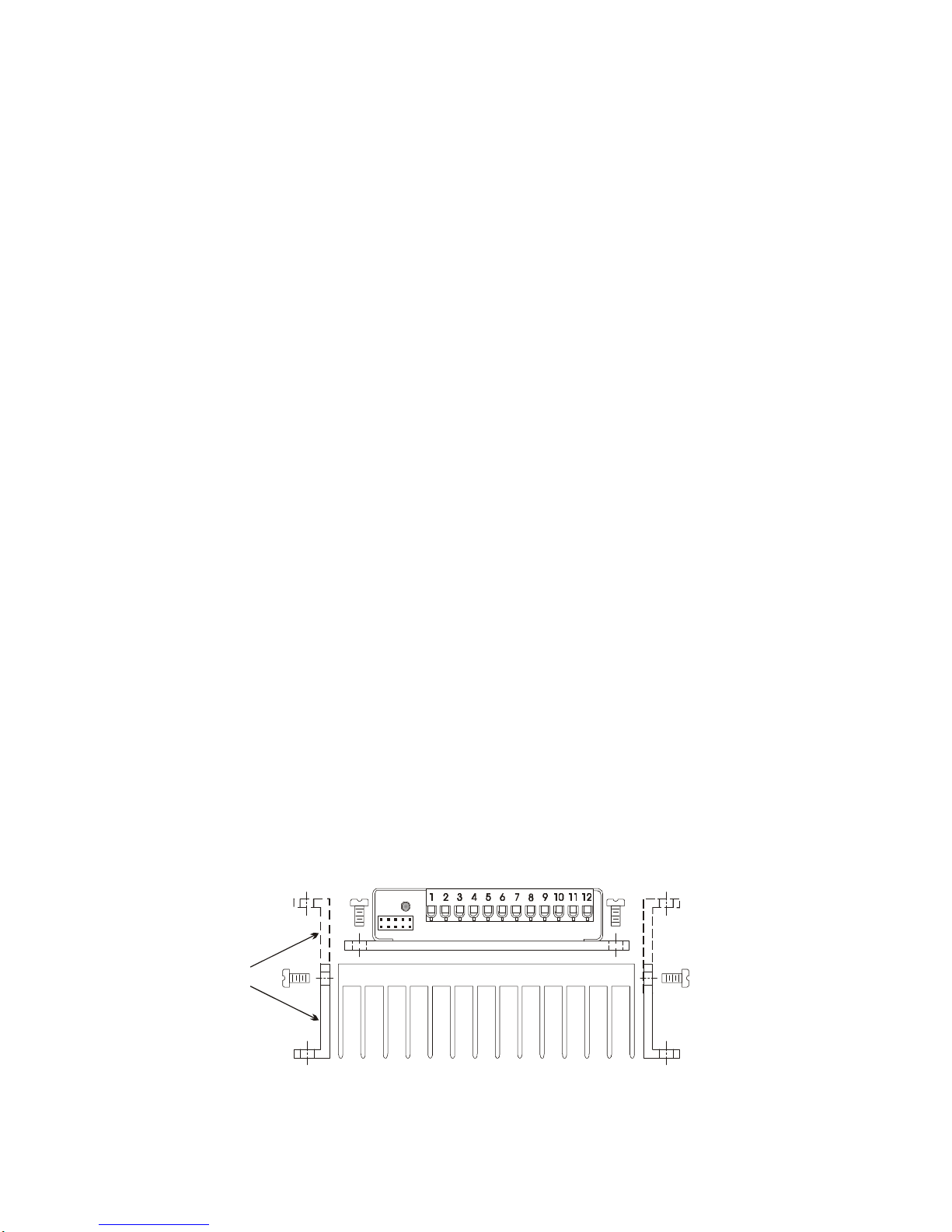

LOCATION OF COMPONENTS..........................................................................2

GETTING STARTED.............................................................................................. 3

QUICK SETUP........................................................................................................3

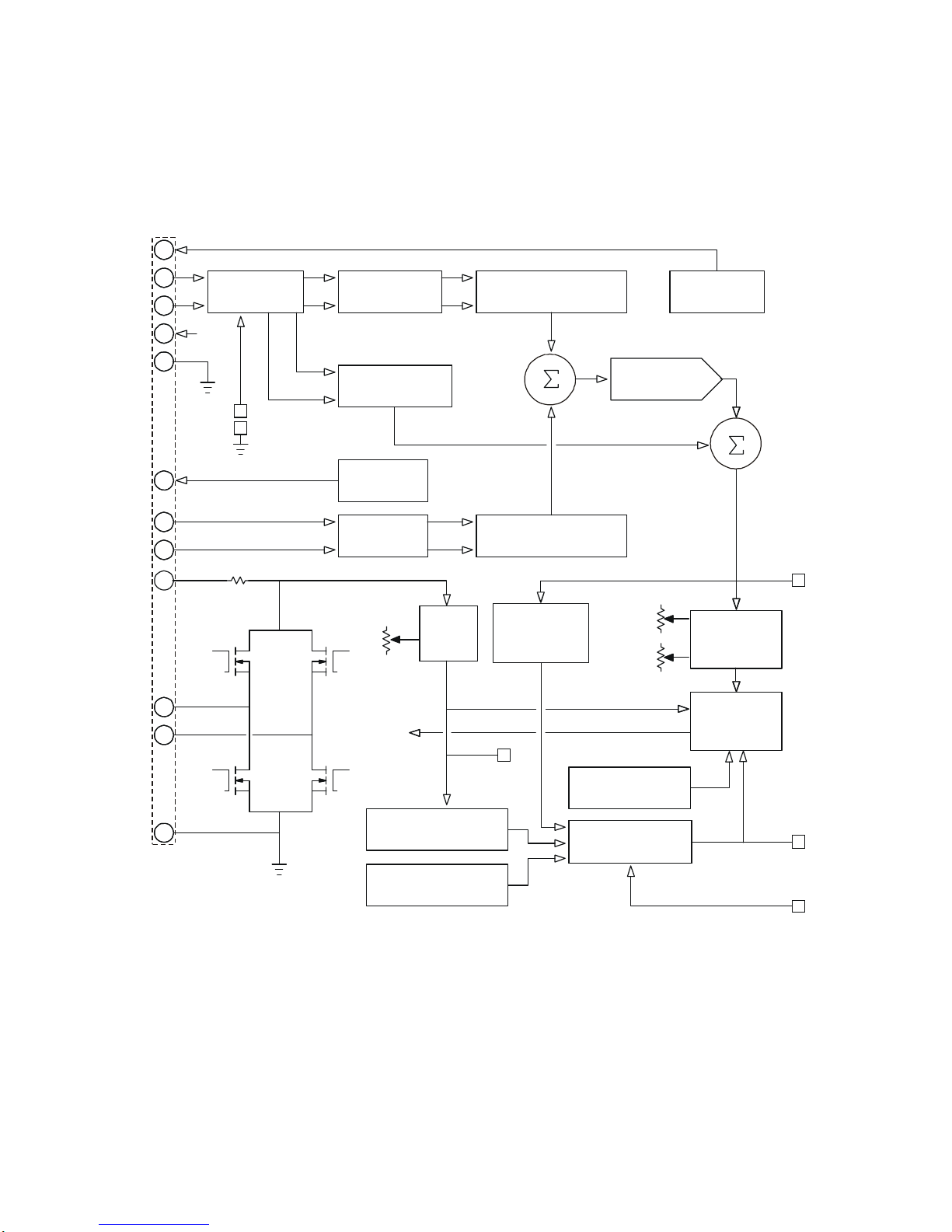

THEORY OF OPERATION...................................................................................4

Main Elements..................................................................................................... 4

Auxiliary Elements ..............................................................................................5

Current Limit ........................................................................................................7

Protection Circuits............................................................................................... 8

TERMINAL BLOCK FUNCTIONS

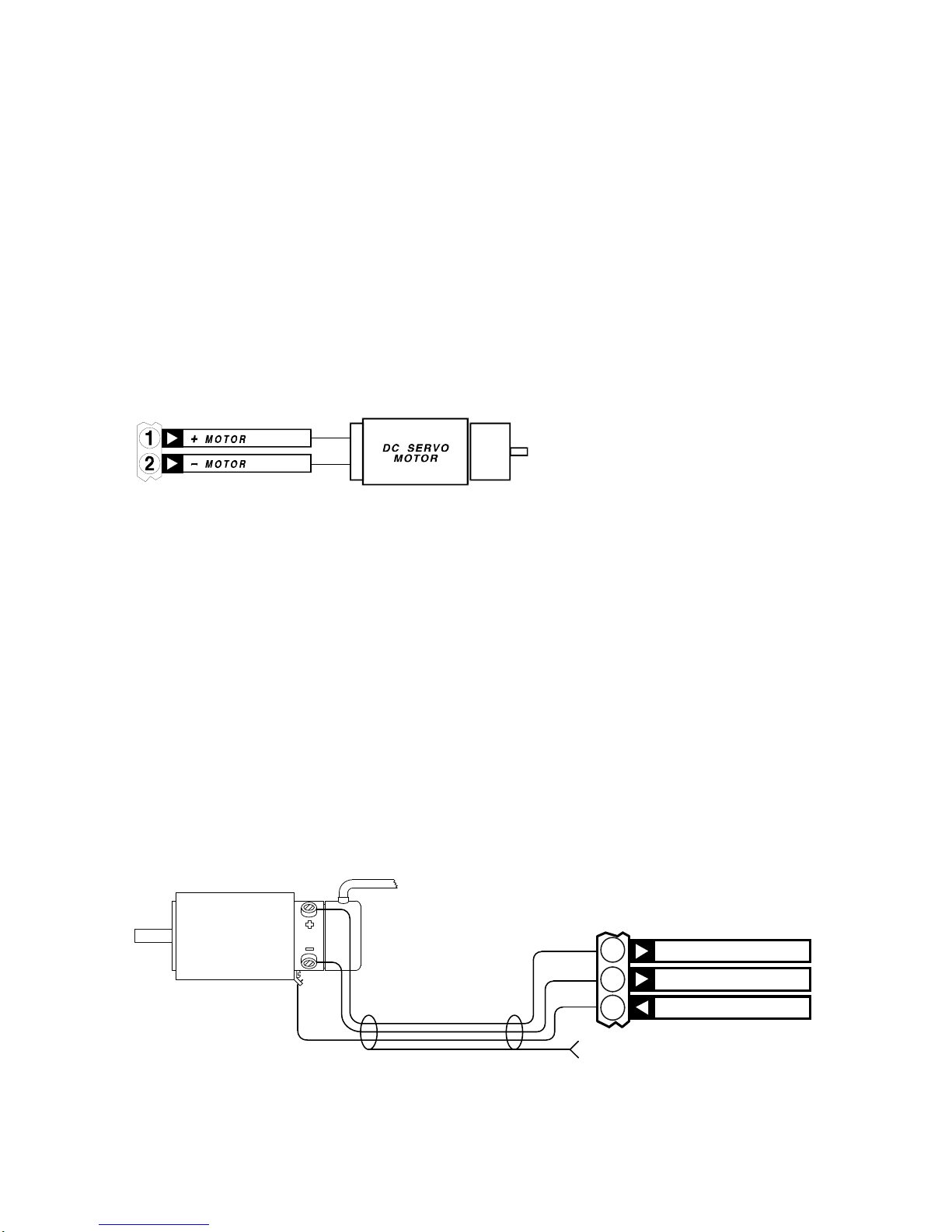

Motor Group.......................................................................................................10

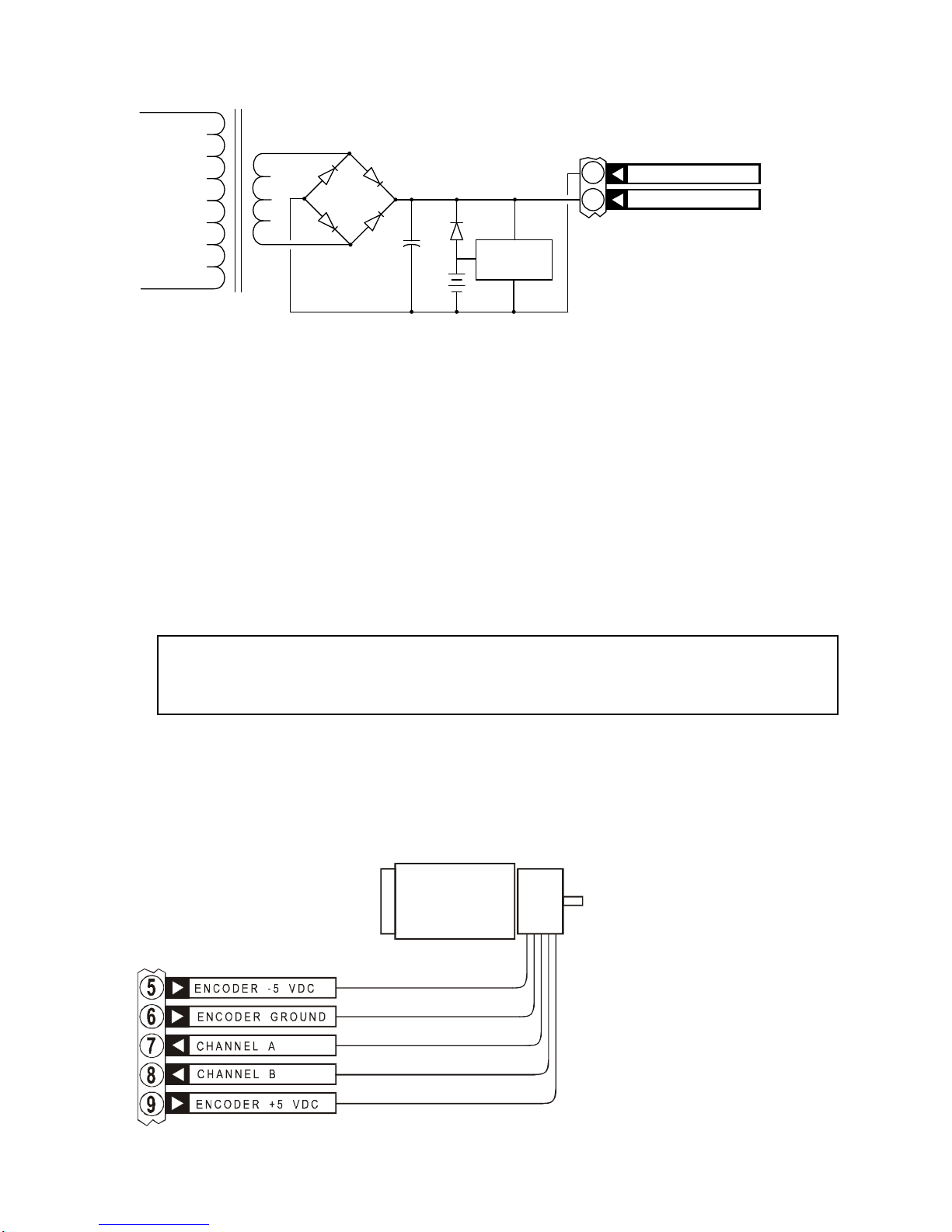

Power Supply Group ........................................................................................11

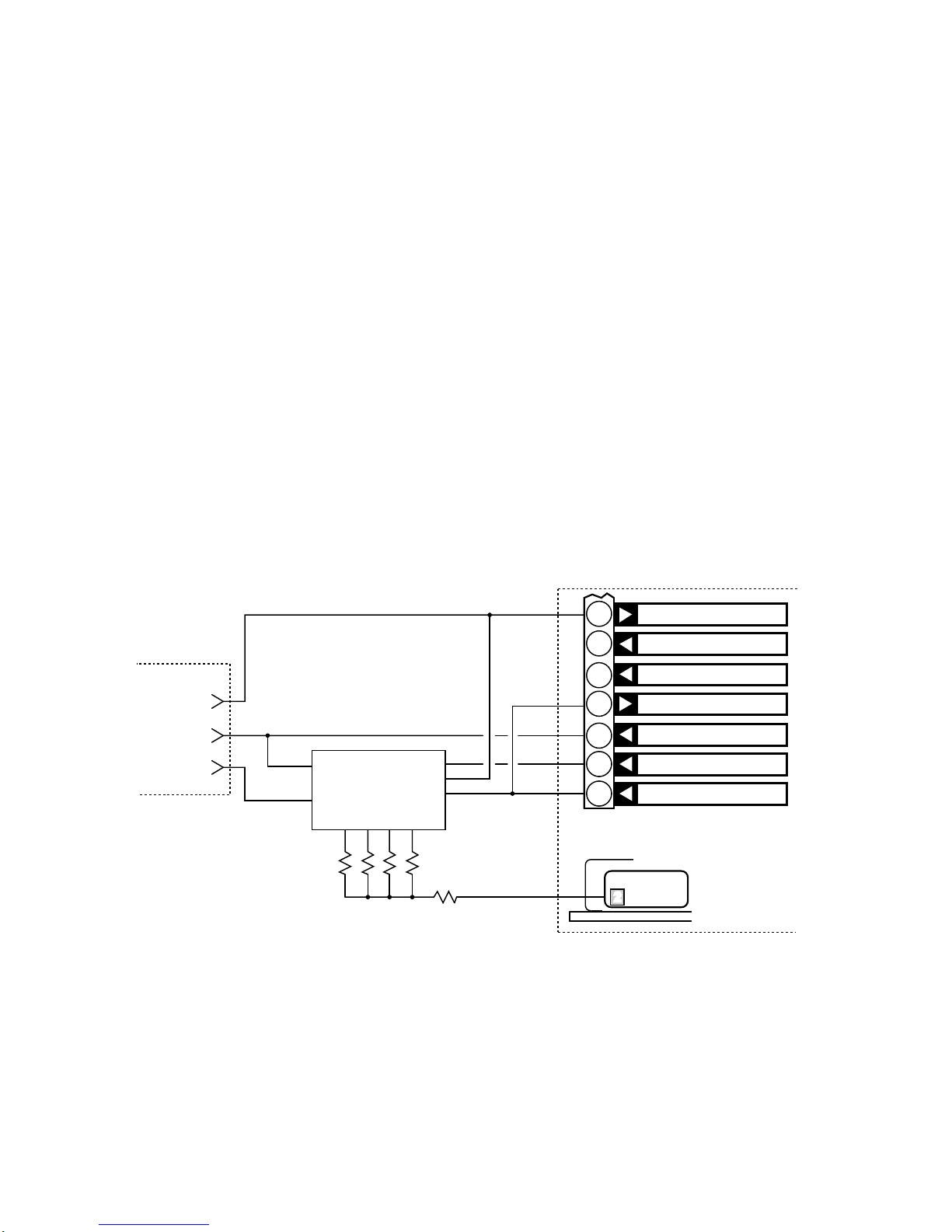

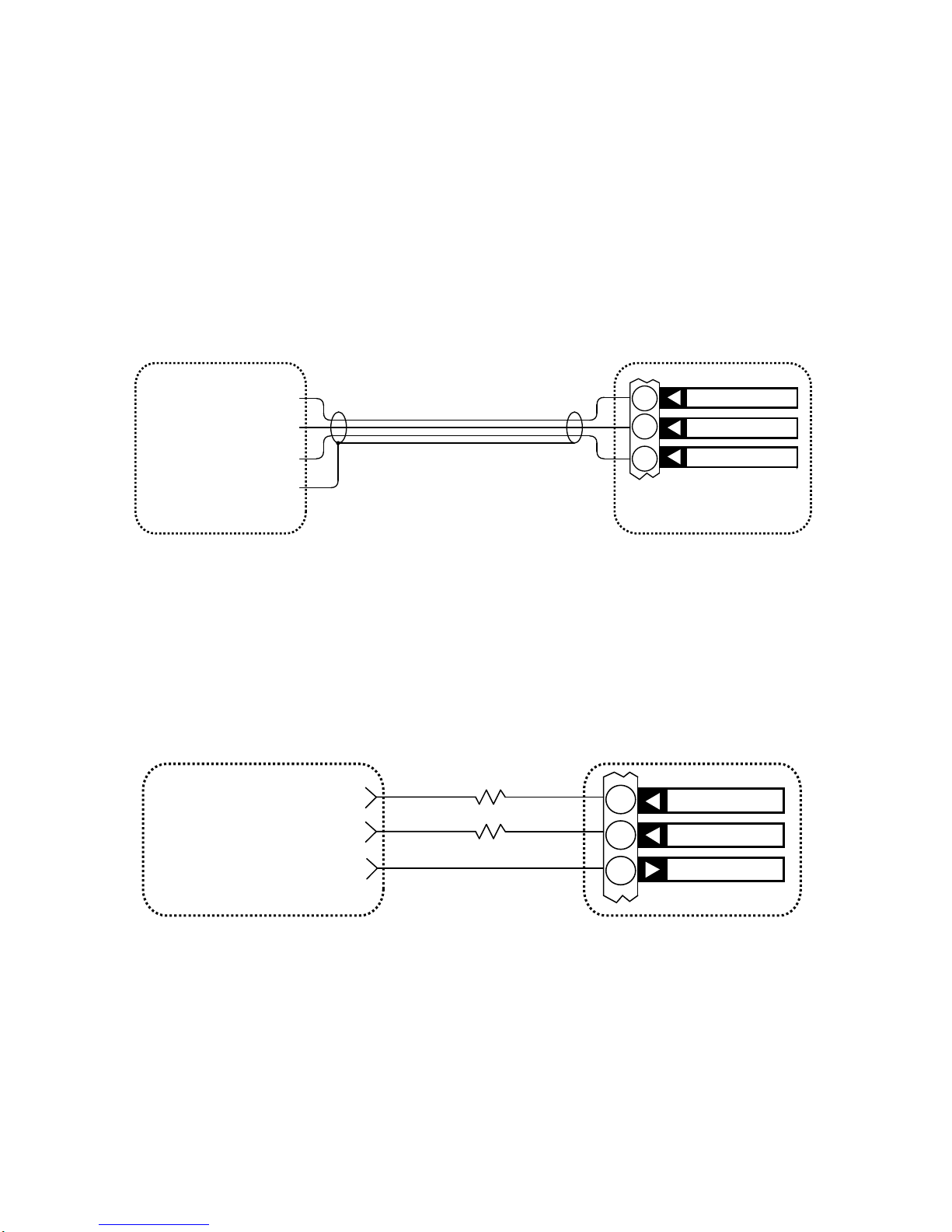

Encoder Group.................................................................................................. 12

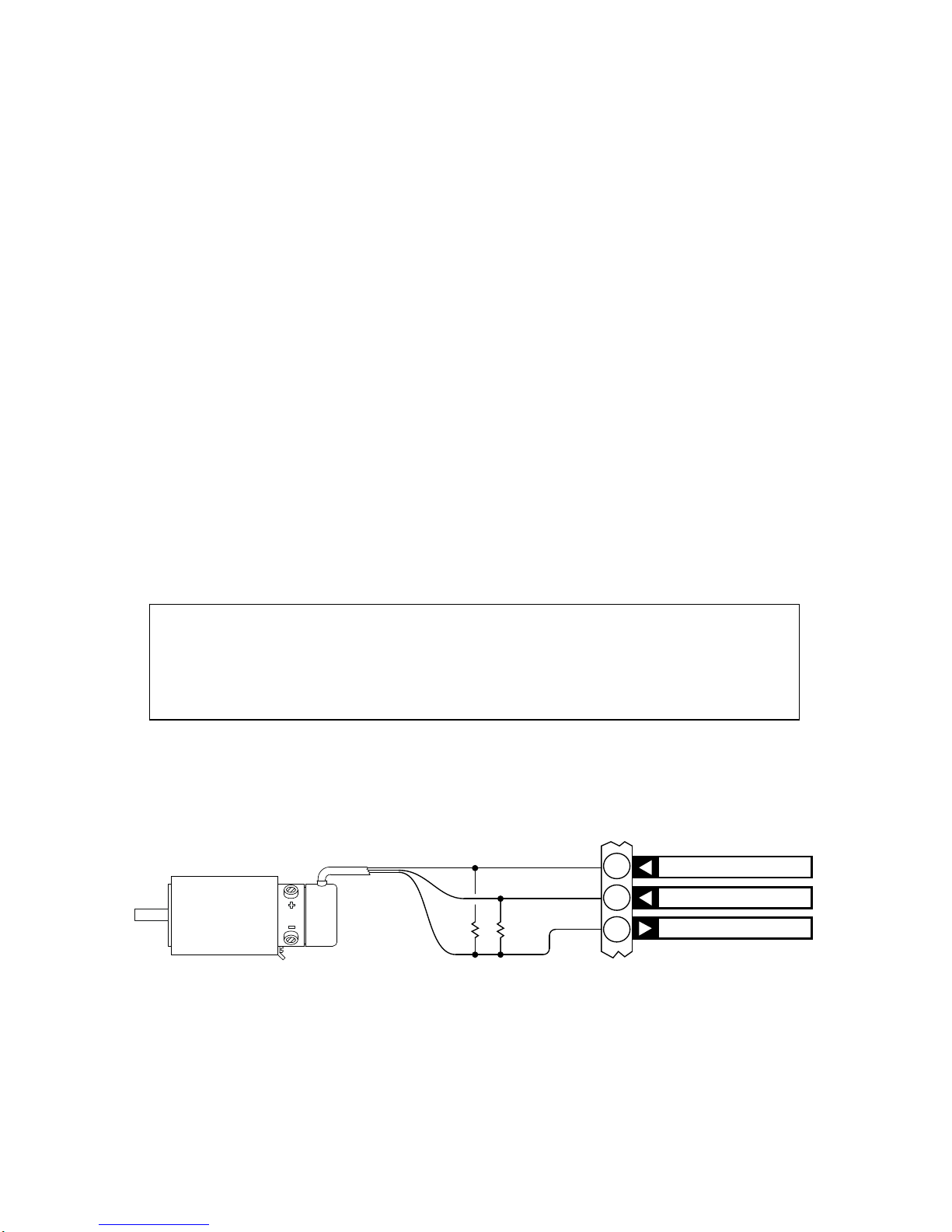

Sine-Cosine Encoders................................................................................................14

TTL Encoders ..............................................................................................................14

Command Group............................................................................................... 15

OPTION HEADER................................................................................................ 17

System Inertia....................................................................................................17

Position Error..................................................................................................... 18

+2.5V Reference...............................................................................................18

Current Monitor ................................................................................................. 18

Fault Output....................................................................................................... 19

Reset Input.........................................................................................................20

+12 Volt Test...................................................................................................... 20

Encoder Jumper................................................................................................ 20

Ground................................................................................................................ 20

TUNING THE CN0182 SERVO DRIVE

Current Trimpot................................................................................................. 21

Gain Trimpot......................................................................................................22

Damping Trimpot...............................................................................................22

Integral Coefficient............................................................................................ 23

Servo Loop Tuning ...........................................................................................23

Interpreting Figure 12 – Optimum Damping.................................................. 27

Picking A Motor................................................................................................. 27

Motor Fundamentals......................................................................................... 28

SPECIFICATIONS................................................................................................31

FULL SCALE DRAWING....................................................................................32