9

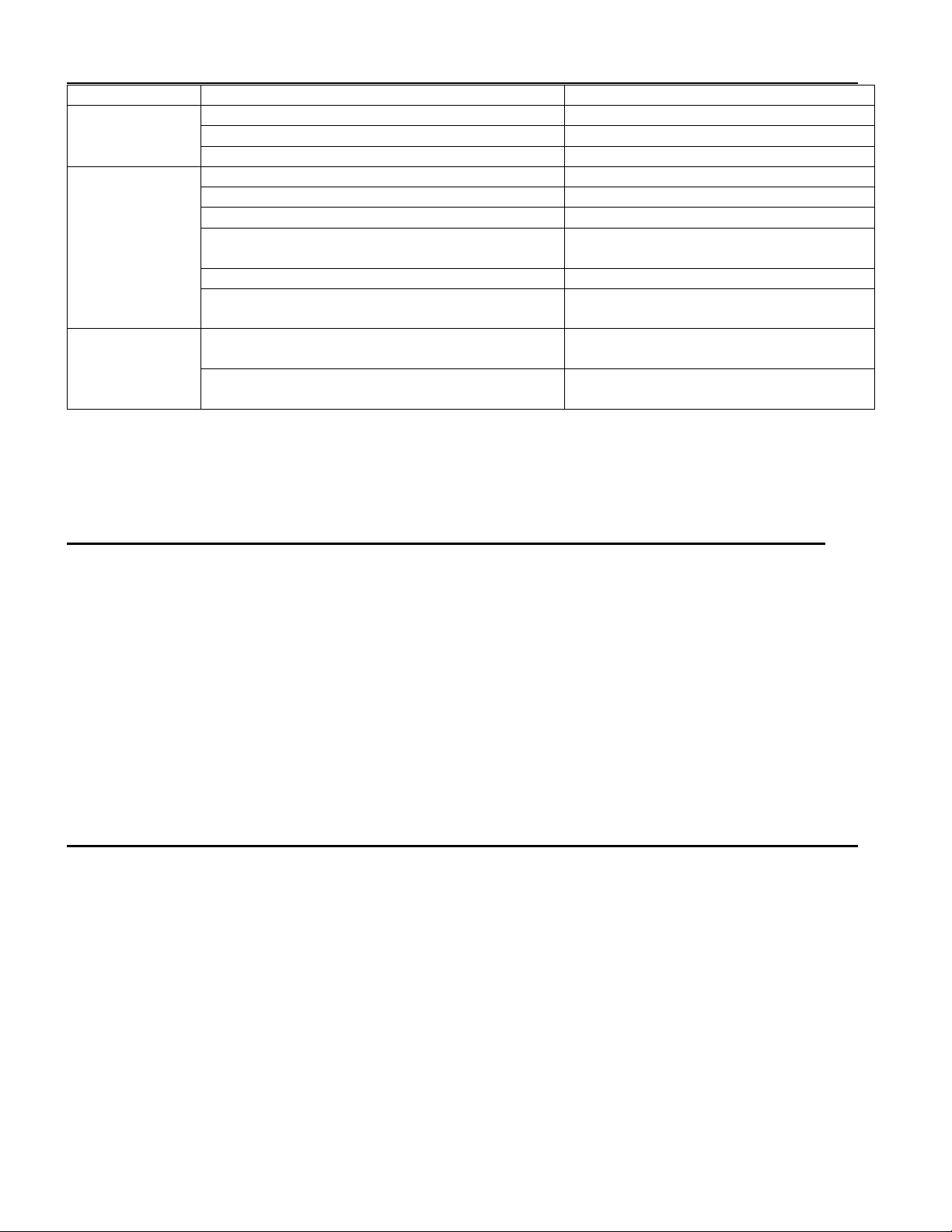

TROUBLESHOOTING:

Product thawing

/ not freezing

Temperature control is on the highest point

Plug and outlet not connected well

Securely connect the plug to the outlet

Blown fuse or tripped breaker

Change the fuse / Reset the breaker

Compressor

Continues to

Run

Temperature control is on the lowest point

Adjust temperature control

Too much product stored in the cabinet

Lid is open for extended periods of time.

Lid is open too frequently.

Reduce the length of time

or the frequency of the lid being open.

Reposition unit 4" from the wall

Close to a hot source or in the sun

Change the unit's location

or remove the heat source

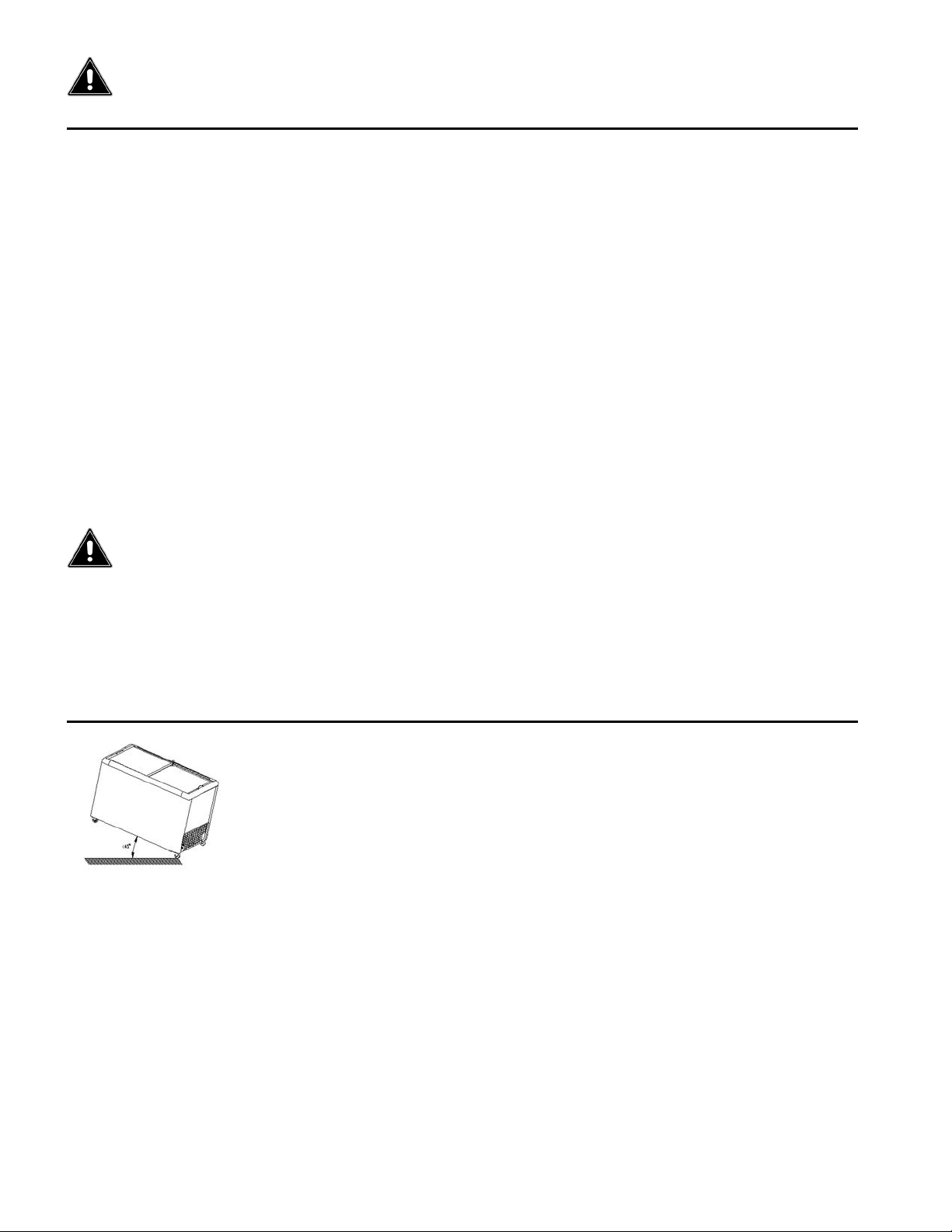

Ground is not flat so unit doesn't sit level and

is making a vibrating noise

Change the unit's location to a flat surface

Refrigerant lines are connected

or too close together

Separate the refrigerant lines

NOTE: If the unit continues to have issues and you cannot solve the troubles according to the above-mentioned

troubleshooting information or guidelines, please contact an authorized service agent. Do not handle it yourself

unless you are a trained and licensed refrigeration technician.

GENERAL MAINTENANCE AND CLEANING:

1. To save energy, keep the door closed as much as possible. Do not open the door frequently or leave it open for

extended periods of time. This will conserve energy and preserve the quality of the food in the cabinet.

2. Never place heavy or hot items on the top of the freezer to avoid damage to the appliance.

3. Turn OFF the power before cleaning.

4. To clean the freezer, use a soft cloth with mild detergent and hot water.

5. Use warm water to clean the magnetic gasket in order to maintain its elasticity. Apply some talcum powder to it to

prolong its service life. If the gasket is damaged, replace it immediately.

6. The freezer should not be left unused for a long time. To stop using the freezer and to store it, safely disconnect the

main power first, then clean the inside and leave the door open for 2-3 days with an open box of baking soda in the

cabinet. Make sure the inside of the cabinet is dry before storing.

7. To return the freezer to use, clean the inside cabinet with a sanitizing solution. Wipe thoroughly with a damp cloth.

Allow the unit to air dry, leaving the door open for 2-3 days.

CLEANING THE CONDENSER (Related Warranty Information)

•Condensers will accumulate dirt and require cleaning every 30 days.

•Dirty condensers result in compressor failure, product loss, and lost sales, which are not covered by warranty.

•If you keep the Condenser clean you will minimize your service expense and lower your electrical costs.

•The Condenser requires scheduled cleaning every thirty days or as needed.

•Air is pulled through the Condenser continuously, along with dust, lint, grease, etc.

•A dirty Condenser can result in voiding the unit's warranty coverage, as well as, compressor failure, product loss

and loss of product sales.

•Proper cleaning involves removing dust from the Condenser. By using a soft brush, or vacuuming the Condenser

with a shop vac, or using CO2, nitrogen, or pressurized air.

•If you cannot remove the dirt adequately, please call our technical service number and we will refer you to local

companies.

•On most of the units the condenser is accessible in the rear of the unit. You may need to remove the cabinet grill to

expose the refrigeration system and piping network.

•The Condenser looks like a group of vertical fins. You need to be able to see through the condenser for the unit to

function at maximum capacity. Do not place filter material in front of condensing coil. This material blocks

air-flow to the coil similar to having a dirty coil.