5

1 Implementation

Dear customers,

With the CENPAC product from Centrosolar AG, you have

acquired a strong, high-quality product.

This reliable complete system combines the benets of

a customized PV installation with the possibilities of an

immediately available standard solution and guarantees

optimal returns under nearly all conditions. It is also un-

complicated and quick to mount.

1.1 Notes on these instructions

If you have any questions on the installation or any com-

ponents of the installation, please contact your local Cen-

trosolar ofce.

Repairing and operating a PV installation require solid

expert knowledge. This is why all work on the installation

should only be carried out by correspondingly qualied

and authorized specialist personnel. Read these mount-

ing instructions carefully and attentively before installing

and commissioning the system. Keep the instructions in

an easily accessible place. The instructions are part of the

product, they only apply to the complete CENPAC sys-

tems of Centrosolar AG. Pay special attention to the notes

on safe use. Centrosolar will not accept liability for dam-

age arising due to failure to observe these instructions.

Please observe:

Ensure that the correct safety instructions are followed for

mounting and operation. Pay attention to the relevant gen-

eral preliminary remarks from Centrosolar AG, available at

www.centrosolar.com.

Failure to observe the requirements in these mounting in-

structions can lead to the exclusion of all guarantees, war-

ranties and product liability.

The following details, notes and recommendations for

action may not be complete and should be constantly

checked to see whether they are complete and up-to-date.

1.2 Description of the mounting system

The bearing capacity of the roof in connection with the as-

sembly of a Centrosolar photovoltaic installation and the

arrangement of the fastening points are to be shown in a

structural analysis for which the building owner is respon-

sible. There is no liability on the part of Centrosolar AG for

the structural suitability of the mounting construction.

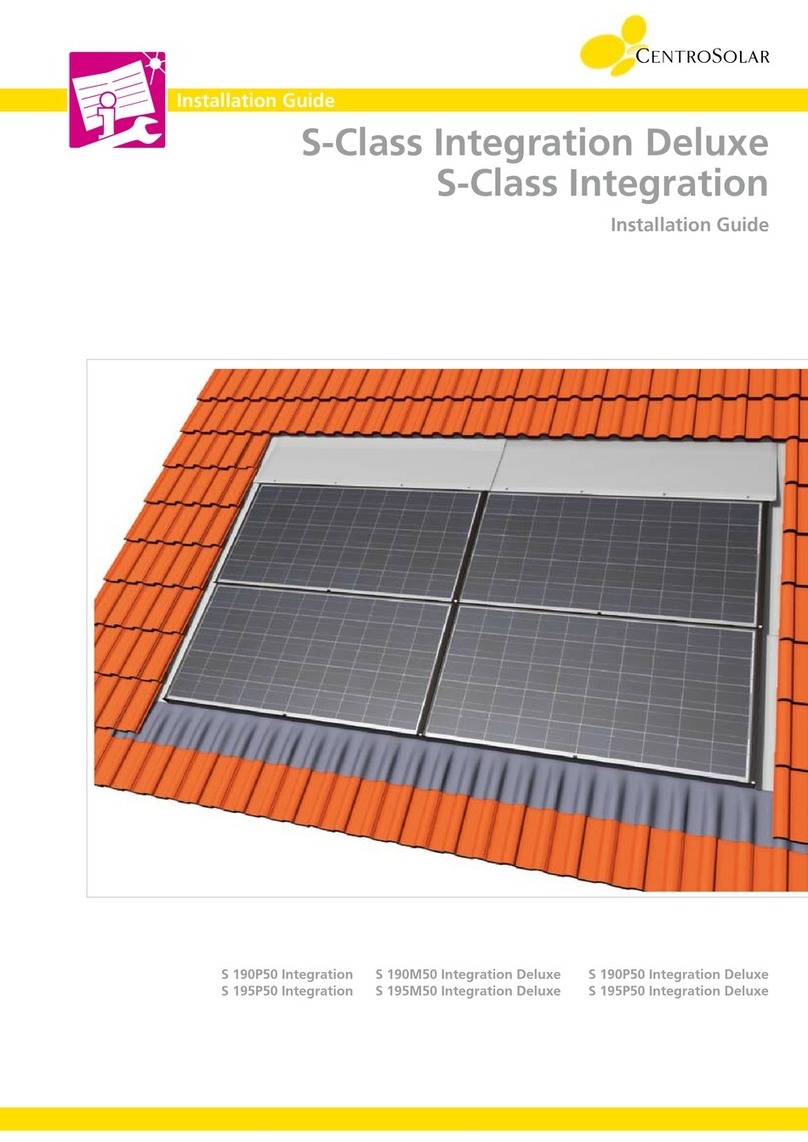

The MS Constocc Excellent mounting system basically

consists of module support proles and 2-C groove pro-

les. Please see the summary of the mounting materials

(chapter 2) for an exact overview of the necessary com-

ponents. Assembly takes place in a cross-cross arrange-

ment. This is mechanically the most stable and safe in-

stallation of photovoltaic modules. The 2-C groove proles

are constructed vertically. The module support proles are

inlaid proles fastened horizontally onto the 2-C groove

proles.

All connecting elements and system parts are manufac-

tured from aluminium or stainless steel. The system pro-

les are delivered anodized in black.

For the suitable rafter conguration of your complete

CENPAC system, please see the rafter conguration

plans in the document folder.

In case of different rafter distances, congure your rafters

according to chapter 3.3 or contact your local Centrosolar

ofce.

Proper use

Check the delivery is complete by way of packing list and

parts list before commencing the mounting. Electrical in-

stallation work that may exceed the range of the safety

extra low voltage may only be carried out by electrotechni-

cal specialists.

The mounting system MS Constocc Excellent was de-

signed solely for holding the PV modules. Any other use

is regarded as improper. Proper use also includes adher-

ing to the mounting instructions Centrosolar AG cannot be

held liable for damage resulting from failure to observe the

mounting instructions, in particular, the safety instructions

or improper use of the product.