Installation guide

1 Notesonthisguide

Thank you for choosing Centrosolar S-Class Integration/S-

Class Integration Deluxe modules. If you have any ques-

tions regarding the system components please contact

our technical support: +49 (0) 5251 500 500.

The maintenance and operation of a PV system require

a sound technical knowledge. Therefore, any work on the

system may only be carried out by qualied and authorized

personnel. Make sure to read these assembly instructions

carefully before installing, commissioning or servicing the

system, and store these instructions in a well accessible

location. This guide is part of the product. It is applicable

only to S-Class Integration/S-Class Integration Deluxe so-

lar modules by Centrosolar AG. Please pay special atten-

tion to the notes on the safe use of the system. Centroso-

lar is not liable for any damage resulting from disregarding

this guide.

Targetgroups

The target group of this guide, especially chapter 5 (Safe

installation) are skilled craftsmen. All relevant informa-

tion for the operator can be found in section 8 (Mainte-

nance and cleaning).

Information regarding your safety

and the protection of the device is

highlighted.

Pleasenote:

Disregarding the instructions of this installation guide may

void any warranties, guaranties and product liabilities.

2 SystemS-ClassIntegration(Deluxe)

2.1 Description

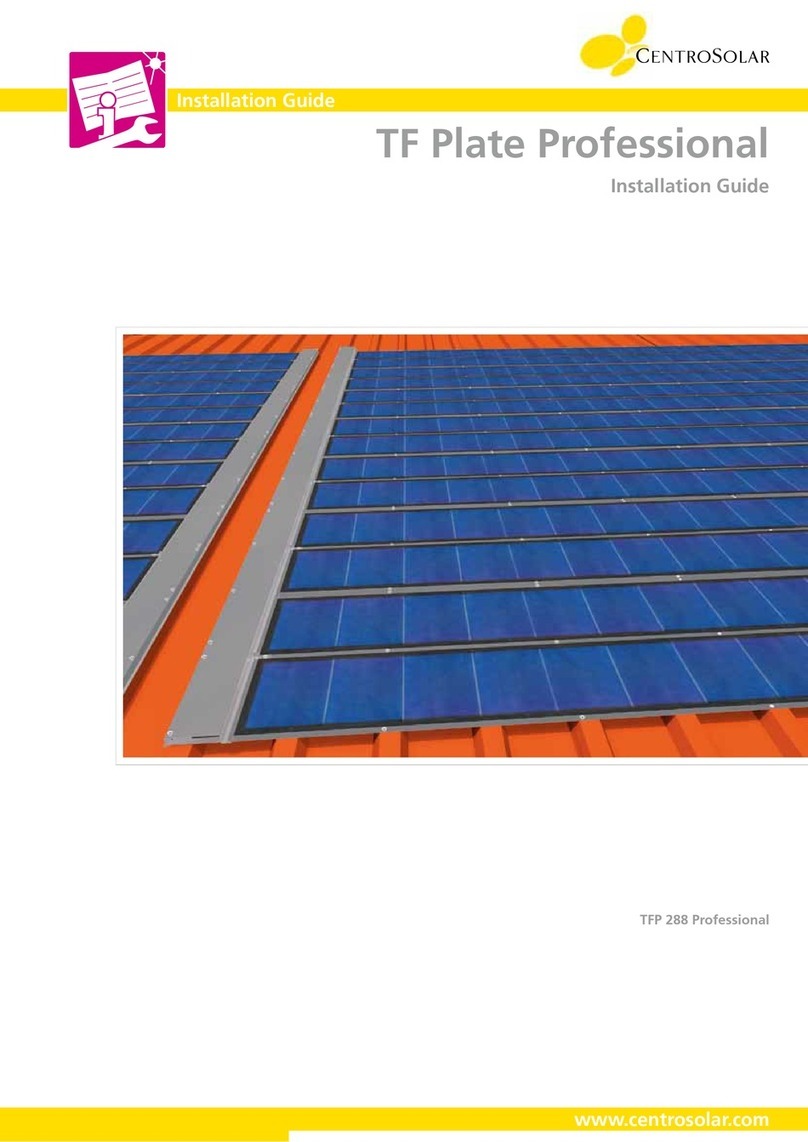

The S-Class Integration (Deluxe) mounting system replac-

es the conventional roong of pitched roofs and is used for

a roof inclination of more than 10 degrees. It is laid onto

the existing roof lathing and is suitable for old and new

buildings alike.

Due to the arrangement of the system lathing, the S-Class

Integration (Deluxe) mounting system provides for a back-

side ventilation in order to cool the modules from the back.

For the electrical connection, HUBER+SUHNER prefabri-

cated connectors are used.

2.2 Tightness

The S-Class Integration (Deluxe) mounting system offers

a rain resistance which is comparable to a standard pan-

tiled roof. It does not mean that a roof is water tight! Under

certain climatic conditions, snow akes, driving rain oder

water may penetrate under the modules from the eaves.

For a proper drainage of ingressed water or condensate,

an intact sub-roof is required. If not available, such a roof

must be erected/retrotted prior to installation of the mod-

ules.

2.3 Sub-roof

The general rules, which are valid for roofers, shall ap-

ply to the design and the backside ventilation of the sub-

roof. In order to extend the lifetime of the substructure, the

backside ventilation should be enhanced by means of the

module lathing and ventilation orices at the eaves and

ridge. In addition, backside-ventilated crystalline modules

will offer a higher yield.

A structural stability of the roof and/or the roof substructure

with regard to wind and snow load, which allows the re-

sulting loads and forces to be absorbed and transfered by

the roof substructure – the rafters, lathing and connecting

elements – is a basic requirement for the installation of a

photovoltaic system .

2