CenturionPro GC MINI User manual

OWNERS MANUAL

GC MINI BUCKER

G

o

o

d

M

a

n

u

f

a

c

t

u

r

i

n

g

P

r

a

c

t

i

c

e

C

o

m

p

l

i

a

n

t

2

2cprosolutions.com1 855 535 0558

LIABILITIES

LEGALITIES

CenturionPro Solutions (the manufacturer) will repair or replace, without charge, any

parts proven defective in material or workmanship for a period of 2 years. Regular

wear and tear of consumable parts, including but not limited to cut plates, entry feed

cover and blades will not be covered under this warranty.

The warranty period will begin on the date the machine(s) is purchased by the initial

purchaser. Product or component warranty defects can be remedied at any authorized

service dealer, or directly at the manufacturer. Any service work performed, and deemed

valid due to a defective part, will be free of charge. CenturionPro Solutions reserves the

right to use any manufacturer-approved replacement part for the warranty repair.

The machine or defective part must be returned to the manufacturer for analysis or

replacement at the cost of the owner. Parts deemed to be covered under the warranty

will be provided for free excluding shipping costs.

Do not return the machine to the place of purchase for repair or warranty claims, unless

you have been authorized by CenturionPro Solutions to do so. The place of purchase can

only sell replacement parts and will not repair any warranty issues, unless it is noted as

an authorized repair dealer and has been authorized to work on your machine.

CenturionPro Buckers are intended for use on legal aromatic herbs and hops. Please check all municipal, provincial/state and federal laws and regulations

before using these machines. CenturionPro Solutions does not promote or condone the use of these products in any way that may be deemed illegal.

To receive maximum performance and satisfaction from the Buckers, it is important that you read and understand the safety and manitenance precautions

before using the machine.

The manufacturer assumes no risk and shall be subject to no liability for damages or loss resulting from the specic use or application made of the

product. In no event will the manufacturer be liable for any special, incidental or consequential damages (including loss of use, loss of prot and claims of

third parties) however caused - whether by negligence of the manufacturer or otherwise. If you have any questions regarding your warranty rights and

responsibilities, please contact the manufacturer.

IF WARRANTY REPAIR IS REQUIRED, PLEASE CONTACT THE MANUFACTURER AT 1-855-535-0558 OR

1. Model and serial number - Located on the front of the bucker

2. Proof of purchase date

3. A copy of the original Warranty Registration Card or Online Submission

4. Details of the defect or problem (include photos and videos)

YOU MAY BE DENIED WARRANTY COVERAGE IF YOUR MACHINE HAS FAILED

DUE TO ANY OF THE FOLLOWING:

Product abuse Normal wear

Product neglect Accidental damage

Improper maintenance Unapproved modications

Improper electrical connection

WARR ANTY TERMS AND CONDITIONS

OWNERS MANUAL

THE TABLETOP

WARRANTY

!! IMPORTANT !!

cprosolutions.com/warranty

REGISTER NOW!

YOU MUST REGISTER YOUR BUCKER WITHIN 30 DAYS OF YOUR PURCHASE

YOU HAVE JUST MADE A SMART DECISION BY PURCHASING THE BEST BUCKER IN THE WORLD. FAILURE TO REGISTER YOUR BUCKER WITHIN 30

DAYS OF PURCHASE WILL VOID YOUR 2 YEAR WARRANTY. PROTECT YOUR INVESTMENT. THIS PROCESS WILL ONLY TAKE 3 MINUTES TO COMPLETE.

For more information or to watch our video tutorials visit cprosolutions.com

OWNERS MANUAL

GENTLE CUT - GCM BUCKER

3

G

o

o

d

M

a

n

u

f

a

c

t

u

r

i

n

g

P

r

a

c

t

i

c

e

C

o

m

p

l

i

a

n

t

2

RELIABLE•INDUSTRIAL

•SIMPLE• EFFICIENT

WITNESS THE RISE

GENERAL

• Do not move, disassemble, clean or inspect the Bucker while the power is still connected to the machine.

• The Buckers are very heavy - Never lift alone and always use proper lifting techniques.

• Replacement parts are specic to the Buckers and must be purchased from an authorized dealer only.

• Substituting factory parts with non-approved third-party replacements may result in damage to the

machine or bodily harm.

• Keep all individuals a safe distance from the work area. Do not operate the machine around children.

• Do not remove safety labels. Replace any and all labels if they become damaged or obscured

CONNECTION

• As with home appliances, GC Buckers must be used in connection with a properly

grounded receptacle.

• Never plug in or power up your Bucker machine if the protective shrouds are removed.

• Do not use extension cords smaller than 12 gauge or longer than 7.6m (25ft) in length

to power the Bucker.

• Using unrated extension cords can cause motor overheating and premature failure.

The GC Buckers are a high-powered machines that require special safety precautions to be practiced while in operation to reduce the risk of personal injury.

Improper use of the GC Bucker may cause serious or fatal injury. Please read the precautions and warning labels before using the GC Bucker.

IMPORTANT SAFETY INFORMATION

CENTURION PRO SOLUTIONS:

GC BUCKERS

OPERATION

• GC Buckers comes from the manufacturer set with the optimal blade rotation. The initial set up will

show assembly instructions.

• Safety glasses and dust masks must be worn at all times when operating Buckers.

• Do not operate any Bucker machine while tired or under the inuence of medication, drugs

or alcohol.

• Do not put anything other than plant material into the Bucker. Doing so may cause damage to the

machine or result in bodily harm.

• Operate the Bucker in a well ventilated area in order to prevent overheating.

MAINTENANCE

• Never leave the GC Bucking system running unattended.

• Never conduct maintenance or cleaning while the machine is plugged in.

• Do not modify or adapt any part of the Bucker or its accessories. Doing so may cause irreversible

damage to the machine or result in bodily harm.

DO NOT LEND OUT OR RENT YOUR GC BUCKER WITHOUT THIS OPERATING MANUAL.

A FIRST TIME USER SHOULD OBTAIN PROPER INSTRUCTION PRIOR TO USE.

0PERATING THE GC BUCKER WITHOUT READING THE INSTRUCTIONS THAT ACCOMPANY A CAUTIONARY LABEL

(IE. "DANGER", "CAUTION", "WARNING", OR "NOTICE" SYMBOL), MAY RESULT IN SERIOUS OR FATAL INJURY.

FOR OPTIMAL PERFORMANCE AND LIFE, THE BUCKER BLADE

MUST BE REMOVED AND CLEANED AFTER DAILY USE.

DRY BUCKING TIPS

3 STEPS FOR OPTIMAL PROCESSING

ENVIRONMENT PREPARATION

• Ensure adequate space

• Review electrical requirements

• Have adequate bins for product transport

• Cooler temperatures in processing room is

bene cial

PLANT PREPARATION

• Cut main stalk

• Seperate each individual stem

(no 'y' junctions)

• Leave 3" of stem for clearance into machine

• Ensure clean angled cuts for precise feeding

FEEDING

• Keep prepped product stem side up for

effi ciency

• Size the stem to t the ideal hole

• Feed end rst into machine

FOLLOW US ON:

1.855.535.0558 www.cprosolutions.com[email protected]om

MOISTURE CONTENT

• If fl owers are too dry, colas may fall apart

when destemmed

• Optimal moisture content: 12% - 14%

• Let the GC bucker gently slice stem from

fl ower, rather than pulling or popping

FLOWER CONSISTENCY

• Small stems should snap when bent, but

big stalks should remain pliable

• If stems are too brittle, they may break

upon entering the machine

• Buds should be “springy” and return to

their original shape when squeeze

FEED RATE

• Insert stalks slowly, controlling the feed rate

• Handle dry plants delicately

• Catch de-stemmed fl owers as they are

sliced from stalks

PLANT PREPPING 101

For more information or to watch our video tutorials visit cprosolutions.com

OWNERS MANUAL

GENTLE CUT - GCM BUCKER

5

TABLE OF CONTENTS

WARRANTY

IMPORTANT SAFETY INFORMATION

PLANT PREP 101 - 3 STEPS FOR OPTIMAL PROCESSING, DRY BUCKING TIPS

TABLE OF CONTENTS

COMPONENT OVERVIEW

CLEANING & MAINTENANCE

BUCKER SPECIFICATIONS

GENERAL OPERATIONS

TROUBLESHOOTING

FREQUENTLY ASKED QUESTIONS

RETURN/REFUND POLICY

NOTES

2

3

4

5

6

7

8

9

10

10

10

11

GCM ADDITIONAL REQUIREMENTS

EXTENSION CORD

14 AWG (min AWG SIZE)

7.6m/25ft MAX LENGTH

GCM BUCKER CONNECTIONS

CANADA, USA, MEXICO & JAPAN

CONNECTOR PLUG

REGULAR WALL OUTLET

GCM BUCKER CONNECTIONS

EUROPE, SOUTH AMERICA & ASIA

CONNECTOR PLUG

REGULAR WALL OUTLET

AMOUNT CONTENTS

1 x GC MINI BUCKER

1 x MANUAL

2 x COLLECTION BAG

1 x SAFETY GOGGLES

6cprosolutions.com1 855 535 0558

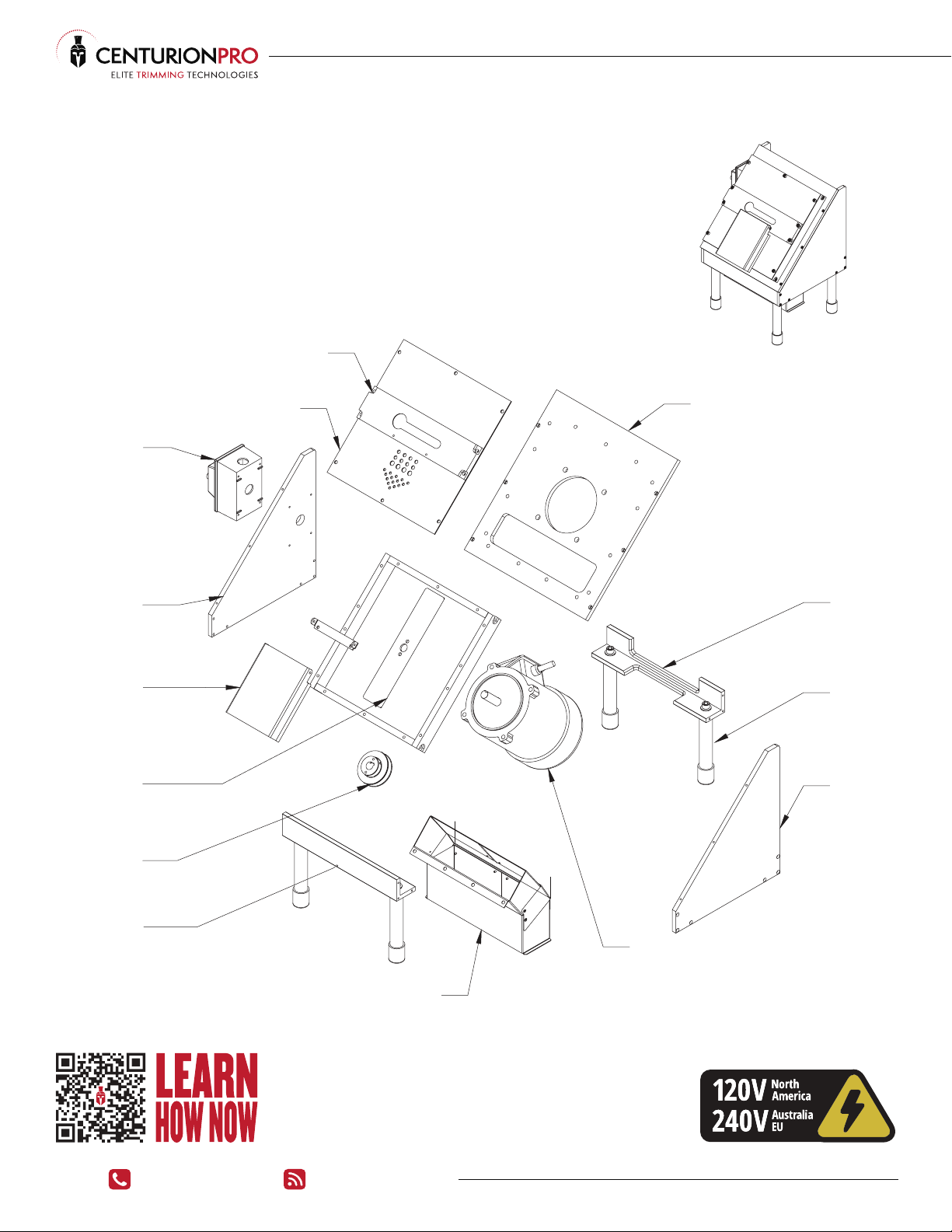

COMPONENT OVERVIEW

50863

BEARING

BAR

50866

TOP PLATE

20185

ELECTICAL

BOX

50880

SIDE PLATE

LEFT

50481

COVER

50897

CUTTING

BLADE

50484

PULLEY

AK27-5/8

50896

CROSS BAR

FRONT

50869

MOTOR PLATE

50895

CROSS BAR

BACK

51023

LEG

50879

SIDE PLATE

RIGHT

20327

CHUTE

20357

MOTOR

For more information or to watch our video tutorials visit cprosolutions.com

OWNERS MANUAL

GENTLE CUT - GCM BUCKER

7

STEP 4:

BLADE

CLEANING

Clean the BLADE of

debris by soaking

in warm water

and wiping down

with 70% isopropyl

alcohol.

Re-assemble bucker

in reverse order.

Remove bag from system

and empty contents. Turn

bag inside-out and pressure

wash. Allow bag to dry.

STEP 5:

CLEAN

BAG

STEP 6:

REASSEMBLE

BUCKER

FOR OPTIMAL PERFORMANCE AND LIFE,

THE BUCKER BLADE MUST BE REMOVED

AND CLEANED AFTER DAILY USE.

CLEANING & MAINTENANCE

STEP 1:

REMOVE

BEARING BAR

4 - 3/16" hex top x 0.75" bolts 10 - 3/16" hex top x

0.5" bolts

2 - 1/8" x 0.5" bolts

STEP 2:

REMOVE TOP

PLATE

STEP 3:

BLADE

REMOVAL

* Ensure machine is unplugged before cleaning.

Avoid getting bearings and motor wet.

IMPORTANT NOTE:

IT IS IMPERATIVE THAT YOU CLEAN THE MACHINE AFTER EVERY 30 MINUTES OF USE ON WET PRODUCT AND AFTER

EVERY HOUR OF USE ON DRY PRODUCT. LOOSE DEBRIS CREATES RESISTANCE ON THE BLADE, WHICH CAN CAUSE THE

MOTOR TO OVERHEAT AND POTENTIALLY BURN OUT. USER NEGLIGENCE IS NOT COVERED BY WARRANTY.

* Periodically check that

the collection bag is

not kinked and that

the waste material is

fully making its way

down into the bag.

8cprosolutions.com1 855 535 0558

GCM BUCKER SPECIFICATIONS

GCM BUCKER

Input Voltage NA: 120V, 60Hz Single Phase

EU, AUS: 240V, 50Hz Single Phase

Current Draw NA: < 6A Operating

EU, AUS: < 3A Operating

Motor 0.25HP

Motor RPM 1750 RPM

Weight 46lbs / 21kg

Length 15in / 38cm

Width 17in / 43cm

Height 19in / 48cm

Circuit Breaker Required NA: 15A/120V

EU, AUS: 15A/220V

Warranty 2 Years

GCM BUCKER FEATURES

Feed Types Dry/Wet

Feed Entry Sizes 3-hole (3/16”, 1/4”, 3/8”)

Feed Throughput +4lbs/hr (Dry) | +20lbs/hr (Wet)

Blade Length: 9-5/8”

GMP Compliant* Yes

UL Compliant* Yes

CE Compliant* Yes

RoHS Compliant* Yes

Primary Material 304 Stainless Steel / Aluminum

GCM ADDITIONAL REQUIREMENTS

EXTENSION CORD 14 AWG (min AWG SIZE)

7.6m/25ft MAX LENGTH

For more information or to watch our video tutorials visit cprosolutions.com

OWNERS MANUAL

GENTLE CUT - GCM BUCKER

9

Directions for cleaning:

A thorough cleaning of the GC Bucker should be performed after each use. Any resin build-

up on the machine attracts more resin, compounding the problem. Build-up can cause

decreased performance, overheating and could trip your circuit breaker. Future cleaning

also becomes more dicult if build-up is given a chance to dry out and harden. Operating

the GC Bucker in a cold environment will also reduce resin build-up.

After disassembly, all chutes, springs and guards can be soaked using hot water and, or

wiped with isopropyl alcohol. Soak all other surfaces with soap and warm water and let sit

for 5-10 minutes. Repeat 2-3 times to soften the resin, then powerwash to remove debris.

Be sure to wash the under side of the cartridge also. Any stubborn areas, such as the top

plate, may require scrubbing with a sti bristled or a plastic scraper (do not use a metal

scraper). Plant matter build-up is the most obvious sign that more attention is needed in a

particular area. Dry the machine with compressed air or a soft cloth.

• There are a series of holes located on the front of the top plate for bucking

• Stems are fed through the holes of the machine by hand

• Each plant must have 3 inches of base stem to clear the buckers

• Please note all strains run dierently and certain denser strains can need the top

colas taken o before being run

1. Make sure Bucker is turned o

2. Using provided tools, remove Bearing Bar and then the Top Plate

3. Clean Top Plate with isopropyl alcohol using brushes provided

4. Spray Top Plate liberally with isopropyl alcohol

5. Wipe down using a soft cloth, making sure the machine is dry completely

6. Clear out any debris on the bottom of the chute

7. Spray blade liberally with isopropyl alcohol

8. Wipe down using a soft cloth, making sure the machine is dry completely

The GC Bucker is a precision machine. It is essential that it is operated and maintained

with this in mind. The machine has been adjusted and tested by the manufacturer prior to

shipping to ensure optimal performance. However, it is important to inspect the machine at

initial start-up and after each use to ensure that no damage or plant material build-up has

occurred and that the blades spin freely.

In addition, it is highly recommended to clean the machine at the end of every use. This

ensures that the blades are kept lubricated and that resin does not build-up and aect

performance. This is especially important if the machine has been stored for an extended

period of time.

MACHINE MAINTENANCE

Inspection of the GC Bucker should be conducted prior to each use

following these steps:

1. Unplug the Bucker and visually inspect all of the components for wear, damage and plant

matter build-up

2. Remove the bearing plate, top plate. See disassembly section for instructions

3. Inspect the blade for damage or cracking

4. Ensure the blade spins freely

5. Visually inspect the bag and ensure the Bucker is free of loose debris

INSPECTION

CLEANING

NOTE

• Tool kit provided with Bucker

• Brush / Plastic scraper

• Spray bottle lled with 70% isopropyl alcohol

• Soft cloths

MATERIALS NEEDED

PREPPING YOUR PLANT:

2 STEPS FOR OPTIMAL PROCESSING

1) ENVIRONMENT PREPARATION

• Ensure adequate space

• Review electrical requirements

• Have adequate bins for product transport

• Cooler temperatures ( below 15˚C ) in processing room is benecial

2) PLANT PREPARATION

• Cut main stalk

• Seperate each individual stem (no 'Y' junctions)

• Leave 3" of stem for clearance into machine

• Ensure clean angled cuts for precise feeding

• Keep prepped product stem side up for eciency

• Size the stem to t the ideal hole

• Feed end rst into machine

GENERAL OPERATIONS

10 cprosolutions.com1 855 535 0558

FREQUENTLY ASKED QUESTIONS

WE ARE OPEN MONDAY THROUGH FRIDAY FROM 9AM TO 5PM PST - PH: 1-855-535-0558

FILLING OUT THE “CONTACT US” FORM ON THE WEBSITE, IS ANOTHER SURE WAY TO GET IN TOUCH.

1) MOTOR IS VERY HOT

The motor is designed to operate at higher temperatures, avoid contact with the motor during regular operation. The motor is thermally fused and will shut down automatically if

overheating occurs

2) MACHINE IS JAMMED, OR MISFED WITH PLANT MATTER

This can happen when too large of a branch is put through the machine. Shut the machine down and remove the top plate exposing the cutting blade. Clear this area of any

debris, reassemble the place and start the machine back up. You should be good to go. Be mindful that the cutting blade is extremely sharp and to avoid direct contact to arms or

hands without wearing proper safety protective gear.

3) THERE IS A GRINDING SOUND COMING FROM THE MACHINE

This can be caused by worn out bearings, misaligned gears or improperly installed components. We recommend contacting tech support for assistance.

4) DOES THE STEM HAVE TO BE A CERTAIN LENGTH TO FEED TO THE BUCKER?

Yes, there must be 3 inches of base stem to clear the cutters.

5) DO I NEED A SPECIAL OUTLET FOR THE BUCKER?

CenturionPro Buckers can be plugged into any standard 110V wall outlet (220V AUS/EU).

6) DO THE GC BUCKERS WORK BEST WITH A PARTICULAR STRAIN?

GC Buckers are extremely versatile and can handle any strain, but please note that all strains run dierently.

TROUBLESHOOTING

HOW EASY IS IT TO CLEAN?

Our machines can be taken apart and cleaned within 10-15 minutes. The Bucker must be cleaned

after daily use. Just spray the rollers liberally with isopropyl alcohol, then wipe with a soft cloth. We

recommend to clean every 4-6 hours of use, but it depends on your strain. We know the importance of

down time during a harvest so we wanted to make this process extremely quick and easy

WHAT IS THE OPTIMAL ROOM TEMPERATURE TO USE BUCKER?

Use your CenturionPro Bucker in 50-60 °F (10- 15 °C) room to get the best performance.

Cooler temperatures prevent excessive sticking to machine components.

DO YOUR BUCKERS PROCESS WET OR DRY PRODUCT?

The answer is both. CenturionPro Buckers can process both wet and dry product. See the Plant Prepping 101

section for more details.

ARE YOUR MACHINES BUILT TO AN INDUSTRIAL STANDARD?

We do not compromise quality for cost savings. All CenturionPro Solutions machines are composed

of the highest quality materials available in North America and each machine is put through a

comprehensive quality control inspection. We only use brand name components in the build out of

our Bucker machines which enables us to have the comfort in giving you a 2 year warranty. With proper

maintenance these machines will last you well over a decade.

MY MACHINE IS NOT WORKING LIKE IT DID WHEN IT WAS NEW, WHY?

Make sure to fully clean the machine and blades. If the machine is clean and the blades are free of

debris, then your machine should buck exactly like it was new.

RETURN/REFUND POLICY

Once the machinery/parts are opened and/or used they are no longer eligible for refund or exchange. Customers can only return if written notice of return has been provided to CenturionPro Solutions within 7

days of receiving their machine and the machine or any component of which have not been used. There will be a 20% restocking fee and the customer will be responsible for all shipping costs. Returns must be

packaged same as it arrived and CenturionPro is not liable for any shipping damage incurred on return. If damage occurs in transit on return, CenturionPro will refuse the return and customer will need to process

a claim with their shipping provider. Any missing or damaged items must be reported to CenturionPro within 14 business days of receiving the shipment.

For more information or to watch our video tutorials visit cprosolutions.com

OWNERS MANUAL

GENTLE CUT - GCM BUCKER

11

NOTES

cprosolutions.com

1 855 535 0558

sales@cprosolutions.com

FOLLOW US ON:

cprosolutions.com

1 855 535 0558

sales@cprosolutions.com

FOLLOW US ON:

Other CenturionPro Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Gis

Gis GKU 1250 Translation of the original instruction manual

SCHUNK

SCHUNK AOV-MC Assembly and operating manual

TNA

TNA TX7302 Installation and operation manual

ABB

ABB Turbocharger A130-M Original assembly instructions

Reflex

Reflex Reflexomat Original operating manual

Siemens

Siemens SIRIUS 3RA241-8X 3-1 Series Original operating instructions

Continental Refrigerator

Continental Refrigerator PC440i Series Operator's manual

SKF

SKF EP1000 Nstallation guide

PCB Piezotronics

PCB Piezotronics 394C06 Installation and operating manual

PA

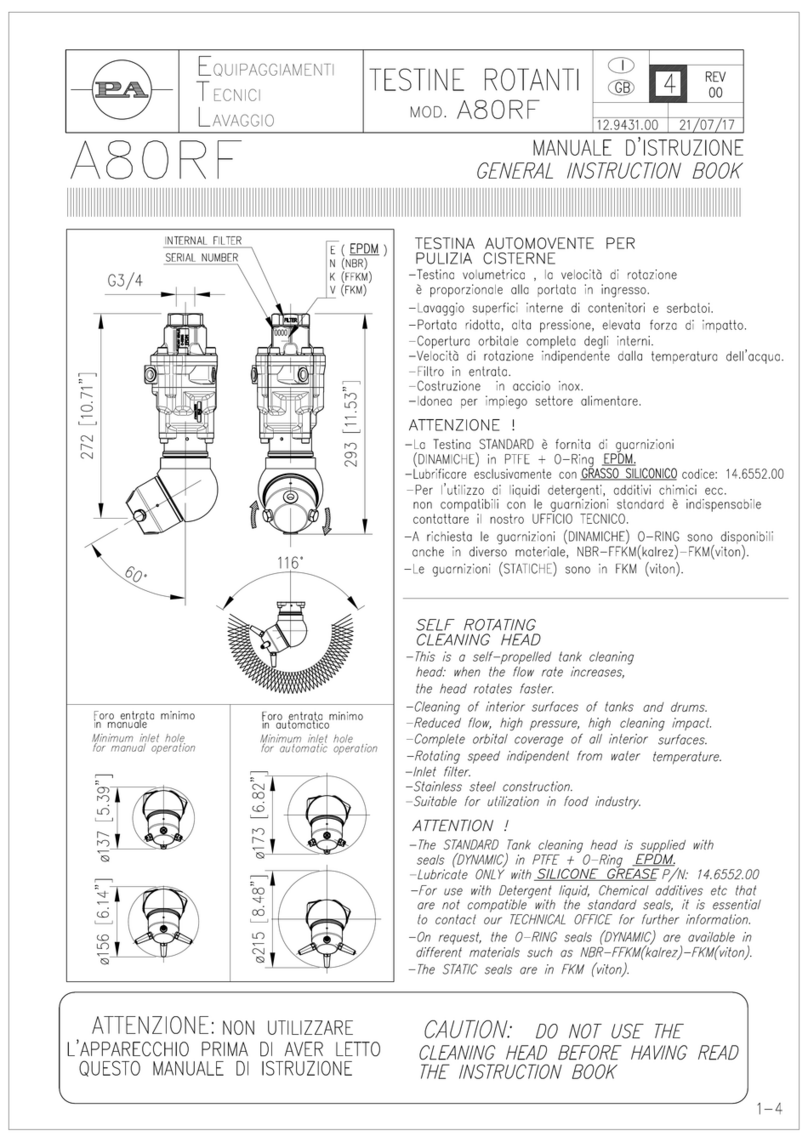

PA A80RF Instruction book

Dover

Dover Marathon V-4224 Operation, maintenance and installation manual

SCHUNK

SCHUNK TRIBOS SVP-2D Assembly and operating manual