CenturionPro DBT 4 User manual

OWNERS MANUAL

DBT MODEL 4

WITH VARIABLE SPEED CONTROL

2cprosolutions.com1 855 535 0558

CenturionPro Solutions (the manufacturer) will repair or replace, without charge, any

parts proven defective in material or in workmanship for a period of 3 years on the

Trimming Machine and 2 years on the Variable Speed Control.

Thewarrantyperiodwillbeginonthedatethemachine(s)ispurchasedbytheinitialpurchaser.

Product or component warranty defects can be remedied at any authorized service dealer, or

directlyat the manufacturer.Any service workperformed,anddeemed valid due toadefective

part, will be free of charge. CenturionPro Solutions reserves the right to use any manufacturer-

approved replacement part for the warranty repair.

The machine or defective part then must be returned to the manufacturer for analysis or

replacement at the cost of the owner. Parts deemed to be covered under the warranty will be

provided for free excluding shipping costs.

Do not return the machine to the place of purchase for repair or warranty claims, unless you

have been authorized by CenturionPro Solutions to do so. The place of purchase can only sell

replacement parts and will not repair any warranty issues, unless it is noted as an authorized

repair dealer and has been authorized to work on your machine.

CenturionPro trimming machines are intended for use on legal aromatic herbs and hops. Please check all municipal, provincial/state and

federal laws and regulations before using these machines. CenturionPro Solutions does not promote or condone the use of these products in

any way that may be deemed illegal. Allow only persons who understand this disclaimer to operate the machines.

The manufacturer assumes no risk and shall be subject to no liability for damages or loss resulting from the specic use or application made

of the product. In no event will the manufacturer be liable for any special, incidental or consequential damages (including loss of use, loss

of prot and claims of third parties) however caused - whether by negligence of the manufacturer or otherwise. If you have any questions

regarding your warranty rights and responsibilities, please contact the manufacturer.

YOU MUST REGISTER YOUR TRIMMER WITHIN 30 DAYS OF YOUR PURCHASE

WARRANTY

YOU HAVE JUST MADE A SMART DECISION BY PURCHASING THE BEST TRIMMER IN THE WORLD. FAILURE TO REGISTER YOUR MACHINE WITHIN 30

DAYS OF PURCHASE WILL VOID YOUR 10 YEAR WARRANTY. PROTECT YOUR INVESTMENT. THIS PROCESS WILL ONLY TAKE 3 MINUTES TO COMPLETE.

!! IMPORTANT !!

IF WARRANTY REPAIR IS REQUIRED, PLEASE CONTACT THE MANUFACTURER AT 1-855-535-0558 OR

1. Model and serial number - Located on outside of motor

2. Proof of purchase date

3. A copy of the original Warranty Registration Card or Online Submission

4. Details of the defect or problem (include photos and videos)

YOU MAY BE DENIED WARRANTY COVERAGE IF YOUR MACHINE HAS FAILED

DUE TO ANY OF THE FOLLOWING:

Product abuse Normal wear

Product neglect Accidental damage

Improper maintenance Unapproved modications

Improper electrical connection Water Damage

WARRANTY TERMS AND CONDITIONS

cprosolutions.com/warranty

REGISTER NOW!

LEGALITIES

LIABILITIES

3

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

The DBT Model 4 is a high-speed trimming system, requiring that specic safety precautions are practiced during operation to reduce the risk of personal injury.

Improper use of the DBT Model 4, or any CenturionPro product, may cause serious or fatal injury. Please ensure you read the operations manual and warning notes

before using the DBT Model 4 with Variable Speed Control.

IMPORTANT SAFETY INFORMATION

CENTURIONPRO SOLUTIONS:

DBT MODEL 4 WITH VARIABLE SPEED CONTROL

AUTOMATED TRIMMING SYSTEM

DO NOT LEND OUT OR RENT YOUR DBT MODEL 4 WITHOUT THIS OPERATING MANUAL. A FIRST TIME USER SHOULD OBTAIN PROPER INSTRUCTION PRIOR TO USE.

GENERAL

• Do not move, disassemble, clean or inspect the trimmer while the power is still

connected to the machine.

• Replacement parts are specic to DBT Model 4 and must be purchased from

an authorized dealer only. Substituting factory parts with non-approved third-

party replacements may result in damage to the machine or bodily harm.

• Keep all individuals a safe distance from the work area. Do not operate the

machine around children.

• Do not remove safety labels. Replace any and all labels if they become

damaged or obscured.

CONNECTION

• As with home appliances, the DBT Model 4 must be used in connection with a

properly grounded receptacle.

• Never plug in or power up your trimming machine if the protective shrouds are

removed.

• Do not use extension cords over 8m (25ft) in length to power the DBT Model 4.

OPERATION

• The initial set up will show assembly instructions to unpack and set-up your machine.

• Safety glasses should be worn at all times while operating theDBT Model 4.

• Do not operate any trimming machine while tired or under the inuence of

medication, drugs or alcohol.

• Do not put anything other than plant material into the tumbler. Doing so may cause

damage to the tumbler, the machine or result in bodily harm.

• Operate the trimmer in a well ventilated area in order to prevent overheating.

MAINTENANCE

• Never leave the DBT Model 4 system running unattended.

• Never conduct maintenance or cleaning while the machine is plugged in.

• Do not modify or adapt any part of the trimmer or its accessories. Doing so may

cause irreversible damage to the machine or result in bodily harm.

4cprosolutions.com1 855 535 0558

DBT MODEL 4 - WITH VARIABLE SPEED CONTROL

DBT MODEL 4 - WITH VARIABLE SPEED CONTROL

Input Voltage

3 Amp - 110V NA

1.5 Amp - 220V EU/AUS

Dimensions (L x W x H) 67in x 36in x 53in

170cm x 91cm x 135cm

Weight 240 lbs / 109 kg

Tumbler Diameter 20in / 51cm

Tumbler Length 66in / 168cm

Number of Tumblers 1

Processing Capacity (per hour) Dry: 108 lbs / 49 kg

Motor 1/4 HP

Warranty 3 years

VSC Warranty 2 years

DBT MODEL 4 - ADDITIONAL REQUIREMENTS

EXTENSION CORD

14 AWG (min AWG SIZE)

7.6m/25ft MAX LENGTH

ELECTRICAL POWER SUPPLY SET-UP

TEST YOUR ELECTRICAL CURRENT TO MAKE SURE IT

IS PRODUCING POWER. WE RECOMMEND HAVING A

CERTIFIED ELECTRICIAN SET UP THE PROPER POWER

SUPPLY. THIS WILL ENSURE YOUR POWER SOURCE IS

SUPPLYING THE CORRECT ELECTRICITY. IF YOU HAVE NOT

DONE THIS, HAVE A CERTIFIED ELECTRICIAN COME AND

TEST YOUR ELECTRICAL CURRENT.

5

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

TABLE OF CONTENTS

WARRANTY

IMPORTANT SAFETY INFORMATION

SPECIFICATIONS

TABLE OF CONTENTS

BEFORE YOU START

COMPONENT OVERVIEW

TRIMMING PLANT MATERIAL

CLEANING & MAINTENANCE

CLEANING & MAINTENANCE - DISASSEMBLE

CLEANING & MAINTENANCE - RE-ASSEMBLE

KIEF FILTER SCREEN UPGRADE

TRIMMER SAFETY

TROUBLESHOOTING

FREQUENTLY ASKED QUESTIONS

RETURN/REFUND POLICY

ADDITIONAL ASSISTANCE

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15

15

6cprosolutions.com1 855 535 0558

SIDE DRIVE

INSTALL SIDE DRIVE

1. Install Side Drive on trimmer using 2 locking pins.

2. Ensure wheel is clean and fully engaged on Tumbler.

CONNECT POWER CORDS

1. Connect the DBT Model 4 power cord to a 15 amp 120 VAC circuit. Do not connect and

disconnect the power cord with wet hands. Do not operate in the rain.

STARTING THE MACHINE

1. Rotate and pull the red Emergency STOP button outward.

2. Press the green START Button.

3. Turn the TIMER dial clockwise until it is aligned with the desired trimming duration,

or turn TIMER dial counter-clockwise for continuous trimming.

4. Turn the TUMBLER SPEED dial clockwise to set the desired speed, start o at the

lowest setting and increase as required.

STOPPING THE MACHINE

NOTICE: In an emergency, hit the red EMERGENCY STOP button.

1. At any other time, Turn TUMBLER SPEED dial counter-clockwise to align with ZERO.

2. Turn the TIMER dial counter-clockwise to align with ZERO.

3. Press in the Emergency STOP button.

DISCONNECT POWER CORDS

1. Disconnect the trimmer’s power cord.

NOTICE: The DBT Model 4 draws a max of 5 amps.

NOTICE: Be sure to hold the plug when disconnecting the power cord from

the electrical outlet. Do not disconnect by pulling on the power cord.

CONTROLS AND COMPONENTS

BEFORE OPERATION

Read and understand this manual. Educate yourself on the location and operation of the controls. Familiarize yourself with the trimmer and how

it works before you begin using it. Know how to quickly shut o the machine in case of an emergency.

Your safety is your responsibility.

PRE-OPERATION CHECK

For your safety, and to maximize the service life of your equipment, it is very important to take a few moments before you operate the trimmer to

check its condition before each use. If you happen to come accross any issues, be sure to take care of them before you operate the trimmer.

Improperly maintaining this trimmer, or failing to correct a problem before operation, could cause a malfunction which could cause you to be

seriously injured. Always perform a pre-operation inspection before each use, and correct any problem.

Before beginning your pre-operation checks, be sure the trimmer is on a level surface, the MOTOR SWITCH is in the OFF position, and all power

cords are unplugged.

CHECK THE GENERAL CONDITION OF THE TRIMMER

Clean the Tumbler, Blade Sheet, and tension system. Look for signs of damage.

Check each control for proper operation.

Check parts for wear. Replace if necessary.

Check that all nuts, bolts, and clamps are tightened appropriately.

NOTICE: Keep all shields, Trim Trays and covers in place while operating the trimmer.

BEFORE YOU START

7

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

SPRING

PLUNGER

TRIM

TRAY

TENSION

KNOB

TUMBLER

LID

SIDE DRIVE:

- SPEED

CONTROL

BOX

- MOTOR

STAND

TRIM

TRAY

TUMBLER

LID

TUMBLER

BLADE

SHEET

BRUSH

TOP

COVER

TRAY

STOP

TIGHTENING

ROD

COMPONENT OVERVIEW

8cprosolutions.com1 855 535 0558

LOAD

Remove clear Tumbler Lid from front of

Tumbler. Hold drum and pull out Plunger

and pivot drum into a upward facing posi-

tion, replace Plunger. Load dried, prepped,

untrimmed plant material into the Tumbler.

For best eciency, ll Tumbler 40-60% full

and run batches of similar material.

RUN

Re-apply clear Tumbler Lid. Pull out Plunger

and pivot Drum into a horizontal position.

Tighten Blade Sheet as required. Turn ma-

chine ON and allow to run for 1-15 minutes.

Check material every 2-5 minutes. For a

closer trim, continue running the DBT Model

4 until desired trim is accomplished.

EMPTY

Once desired trim is accomplished, remove

Trim Tray & Tumbler Lid, position separate

container (not included) to capture

processed material, pull out Plunger and

pivot drum to a downward facing position.

Processed material will be deposited in

container when correctly positioned.

TRIMMING PLANT MATERIAL

IMPORTANT NOTE:

TRIM TRAY SERVES AS A COLLECTION MECHANISM AND AS A SAFETY GUARD. MACHINE SHOULD NOT BE RUN

WITHOUT TRIM TRAY IN PLACE AND TABS ORIENTED IN THE VERTICAL POSITION.

SERVICING YOUR TRIMMER

Proper maintenance is essential for safe, economical, and trouble free operation.

Other service tasks that are more dicult, or require special tools, are best handled by professionals and are normally performed by a Centurion Pro technician or other qualied mechanic.

The maintenance schedule applies to normal operating conditions. If you operate your trimmer under severe conditions, such as sustained high load or high temperature operation, or use

it in unusually wet or dusty conditions, consult your servicing dealer for recommendations applicable to your individual needs and use.

Remember that an authorized Centurion Pro servicing dealer knows your trimmer best and is fully equipped to maintain and repair it. To ensure the best quality and reliability, use only new,

Centurion Pro parts or their equivalents for repair and replacement.

NOTICE: Improper maintenance, or failure to correct a problem before operation, can cause a malfunction which can cause serious injury

or death. Always follow the inspection and maintenance recommendations and schedules in this owner’s manual.

IMPORTANT NOTE:

SIDE DRIVE IS NOT WATERPROOF.

DO NOT GET WET.

Empty Trim Tray:

Lift the Tray Stop on the front of the machine to release the Trim Tray. Slide Trim Tray out of slots, empty tray and replace.

9

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

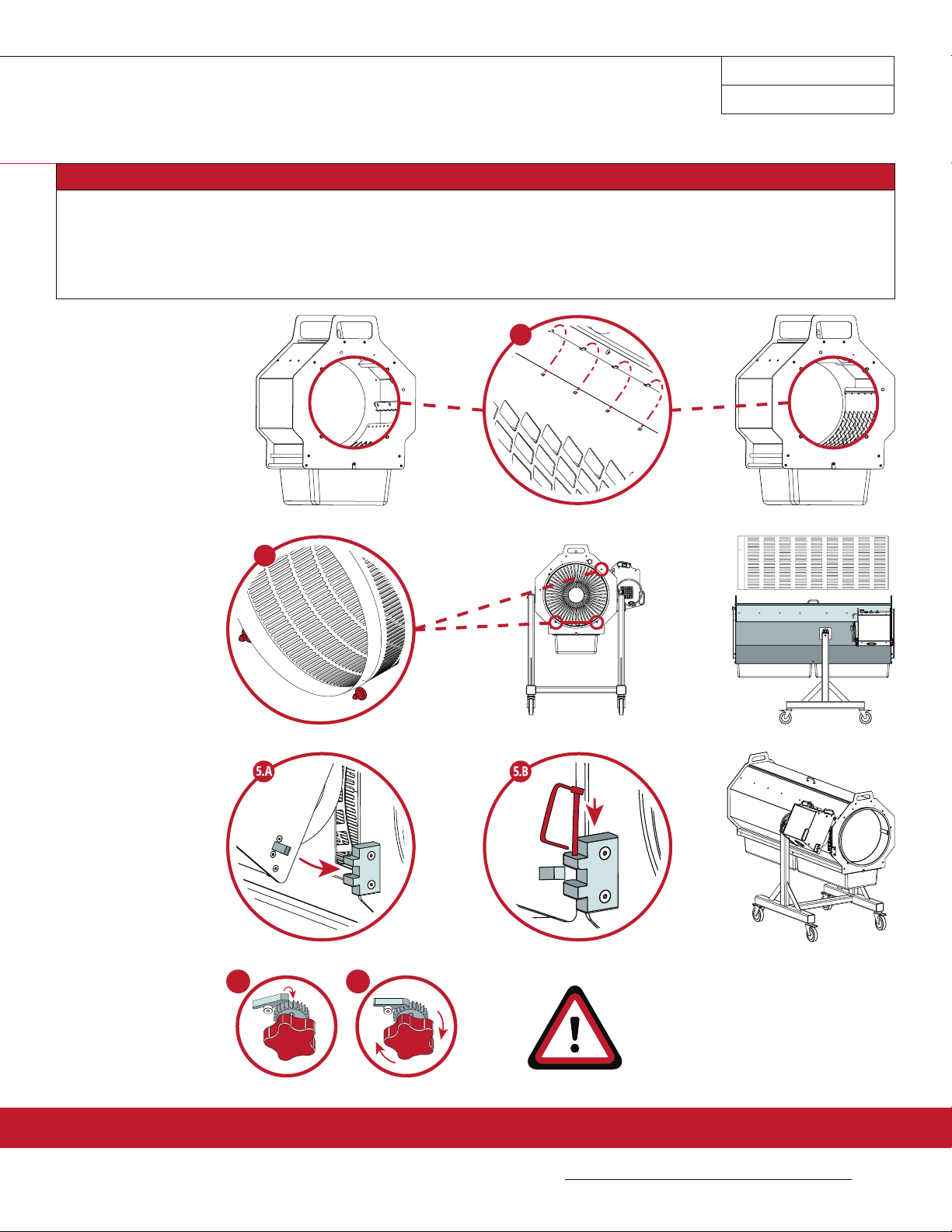

CLEANING & MAINTENANCE

PRESSURE WASHING THE DBT MODEL 4

WARNING:

PINCH POINT HAZARD - WEAR GLOVES WHEN REMOVING BRUSH.

ALWAYS WEAR PERSONAL PROTECTIVE EQUIPMENT WHEN CLEANING MACHINE.

STEP 2:

CLEAN

ELECTROPLISH

TUMBLER

Clean the length of

the tumbler of all

debris using hot

pressurized water.

NOTICE: Side Drive is NOT waterproof DO NOT GET WET. If you choose to

use a pressure washer take care not to damage the trimmer’s n-

ish by holding the nozzle excessively close to the machine. Avoid

spraying the bearings, located at the ends of the brush. These

components are not intended to be waterproof and water dam-

age is excluded from warranty coverage.

- Clean with pressure-washer at up to 1500 psi.

- Hot water, fan spray setting.

- Run for 15 mins after washing to allow components to dry.

STEP 1:

CLEAN

BRUSH

Simply pull on brush

to remove. Clean the

length of the brush of

all debris using hot

pressurized water.

CLEANING

INTERVAL ITEM

Before each use

Check that Blade Sheet is snug, and in contact with Tumbler and is tightened appropriately

Check that machine is free of excessive debris.

Ensure that machine is clean and the Tumbler can be rotated without power under manual force.

During use Although not required, application of a food grade lubricant to Tumbler and Blade Sheet can help reduce resin build up.

After each use For best performance and longevity, clean trimmer after every use or if plant material is visibly aecting the trim quality or speed of the trimmer.

Every 10 hours

of operation

To maximize Blade Sheet life, rotate orientation of blade sheet every 10 hours or when visible signs of wear are identied. Although not required, this will extend the life of

the Blade Sheet.

Remove Tumbler and Blade sheet and cover with a thick coat of cooking oil (olive, vegetable, etc.). Let sit for 3-12 hours. Using warm/hot water, concentrated dish soap and a non-metallic dish

scrubber, clean the Tumbler and other machine components by hand. Alternatively you can pressure wash with hot water, at up to 1500 psi on fan spray setting. After pressure washing, run

machine for 15 minute to allow components to dry.

Read full CLEANING AND MAINTENANCE instructions before cleaning.

When to Clean:

Depending on the material being processed and the frequency of use, the slots of the Tumbler may need to be cleaned after each use or periodically.

Indications that machine requires cleaning

• Reduced trim quality

• Visible build-up of material in the Tumbler slots which obscure the sharp edge of the slots

• Visible evidence of material on Blade Sheet

• Excessive noise (machine should run quietly so that you may converse normally when it is running)

The DB T Model 4's are precision machines. It is essential that they be operated and maintained with this in mind. It's important to inspect the machine at initial start-up and after each use

to ensure that no damage or plant material build-up has occurred and that the tumbler spins freely.

In addition, it is highly recommended to clean the machine after every day of use. This ensures that the Blade Sheet and Tumbler are kept lubricated and that resin does not build-up and

aect performance. This is especially important if the machine has been stored for an extended period of time.

REMOVING OBSTRUCTIONS

If the rotating Tumbler becomes restricted or clogged:

Stop the motor and Make sure that all rotating parts have come to a complete stop. Disconnect the trimmer’s power cord. Use a wooden stick to clear the obstruction.

4.

A

4.B

6

.B

5

.

A

6

.

A

3.A

3.A

10 cprosolutions.com1 855 535 0558

CLEANING & MAINTENANCE

DISASSEMBLE

STEP 1:

SHUT OFF MOTOR. UN-

PLUG POWER CORDS.

STEP 4:

RELEASE TENSION ON

THE BLADE SHEET:

A. Turn the tension adjustment

knob clockwise slightly to re-

lease tension on the ratchet.

B. While turning the tension ad-

justment as described above

ip the pawl o of the ratchet

so it is no longer in contact.

c. Release the tension knob; the

Blade Sheet will now hang

freely within the trimmer.

STEP 5:

REMOVE TUMBLER:

A. To remove the Tumbler, Turn

motor o, unplug power

cords, and put the machine

in a horizontal position. With

2 people, lift the Tumbler o

of the rollers.

B. Slide the Tumbler gently from

the machine and set it on a

non-abrasive surface.

(Tip: If the Tumbler does not

come out easily check that

the Blade Sheet has been re-

leased as described in step 4)

STEP 6:

REMOVE BLADE SHEET:

A. Reach inside the machine

and remove the Blade Sheet

by gently lifting the Blade

Sheet o of the metal tabs

which hold it in place.

B. Gently remove the sheet

from the machine and place

it on a non-abrasive surface.

STEP 2:

REMOVE BRUSH:

A. PUT ON GLOVES and, pull

brush rmly to release from

snap clips.

STEP 3:

REMOVE SIDE DRIVE:

A. Release side drive by remov-

ing the 2 locking pins.

BLADE SHEET WILL

BECOME VISIBLY

LOOSENED AROUD

THE TUMBLER.

2

.

A

3.A

6.

A

6.

B

11

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

CLEANING & MAINTENANCE

MONTHS OF WORK CAN BE RUINED IN A FEW HOURS AT THE END SO PLEASE BE PATIENT AND TAKE YOUR TIME WITH THE HARVESTING AND CURING PROCESS.

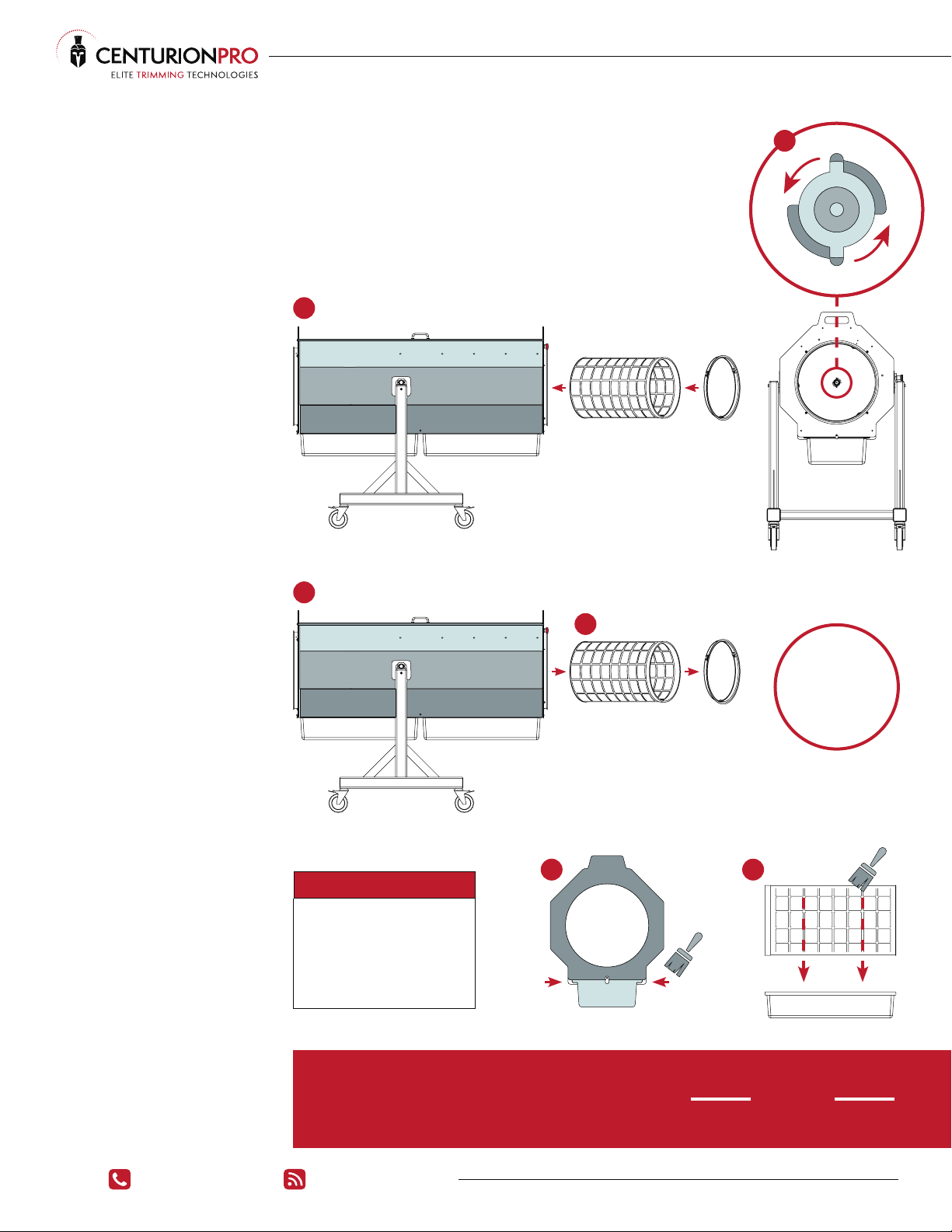

STEP 1:

SHUT OFF MOTOR.

UNPLUG POWER CORDS.

STEP 2:

INSTALL BLADE SHEET:

A. Reach inside the machine

and install the Blade Sheet by

gently placing the sheet on the

metal tabs until all holes are

resting evenly on metal tabs

on both sides of the machine.

STEP 6:

RE-TENSION

BLADE SHEET:

A. Flip the pawl so it is in contact

with the ratchet and prevents

the ratchet from moving in a

counter clockwise direction.

B. Turn tension adjustment knob

clockwise slightly until you en-

counter minor resistance and

the Blade Sheet has come in

full contact with the Tumbler.

STEP 3:

INSTALL THE TUMBLER:

A. With motor o, power cord

unplugged, and the machine

in a horizontal position, slide

the tumbler gently into the

machine until the Rollers are in

the grooves of the Tumbler.

STEP 4:

INSTALL BRUSH:

A. Place Brush on the snap clips

and rmly press into place.

STEP 1:

SOAK WITH

COOKING OIL

STEP 2:

USING WARM/

HOT WATER

A. Cover entire tumbler and

blade sheet with a thick coat

of cooking oil (olive, vegeta-

ble, etc). Let it sit for 3-12hrs.

A. Using warm/hot water, concen-

trated dish soap and a non-me-

tallic dish scrubber, clean the

tumbler and other machine

components by hand.

NOTICE: For best results use hot water whenever possible.

Be careful when selecting the degreaser that it will

not damage the painted or anodized components

of the trimmer. Always follow the operating in-

structions provided with the pressure washer.

STEP 5:

INSTALL SIDE DRIVE:

A. Hook Side Drive on the Trim-

mer and rmly press until

locking latch holes line up.

B. Insert locking pins to secure

Side Drive. Make sure Side

Drive wheel is fully engaged

to Tumbler.

IMPORTANT NOTE:

SIDE DRIVE IS NOT WATER-

PROOF. DO NOT GET WET.

REASSEMBLE

BEFORE RE-ASSEMBLY

4

4

7.

A

6

7.

B

7.

C

12 cprosolutions.com1 855 535 0558

STEP 3:

REMOVE BLADE SHEET:

STEP 2:

REMOVE TUMBLER:

STEP 1:

LOOSEN BLADE SHEET:

Refer to DISASSEMBLE instructions on (pg 11).

Refer to DISASSEMBLE instructions on (pg 11).

STEP 7:

REMOVE KIEF FILTER SCREEN:

STEP 5:

FILL FILTER SCREEN:

STEP 6:

RUNNING MACHINE:

Rotate the Trimmer into a horizontal position and

turn machine ON. Run materials for up to 10 minutes.

NOTE: If you wish to separate the differ-

ent Kief qualities, run for 5 min-

utes, remove first batch of Kief.

Then run for another 5 minutes.

With Kief Filter Screen in place and machine in a

vertical position, take your Kief and ll Filter Screen

1/2 up to 3/4 of the way full, then insert Tumbler Lid.

NOTE: Overfilling will lower quality and

processing speed.

Refer to DISASSEMBLE instructions on (pg 11).

A. Carefully remove Kief Filter Screen.

B. Brush excess kief o the inside ledges which

hold Trim Tray in place.

C. Carefully remove Trim Tray and brush Kief re-

maining on lter, into the Trim Tray.

NOTE: If you wish to separate the differ-

ent Kief qualities, run for 5 min-

utes, remove first batch of Kief.

Then run for another 5 minutes.

KIEF FILTER SCREEN UPGRADE

PREPARATION

NOTICE: Make sure all motors are o and power cords are unplugged before you begin.

- Before setting up your Kief Filter Screen Upgrade with your trimmer, be sure to read and understand entire manual.

- Refer to CLEANING & MAINTENANCE (pg 10 & 11) for DISASSEMBLE & REASSEMBLE instructions.

STEP 4:

INSERT FILTER SCREEN:

With motor o, power cord unplugged, and machine

in a vertical position, slide Filter Screen gently into

machine. Rotate Tumbler counter-clockwise to lock.

NOTE: Failure to keep hooks on Tighten-

ing Rod, away from Filter Screen

can result in damage.

IDEAL RATIOS FOR DRY ICE KIEF FILTERING

NOTICE: - Dry ice must be in pellet form or nely crushed.

- Large chunks of Dry Ice will damage the lter screen.

- Allow product t get realy cold. Approx. 5-10 minutes.

TRIM

DRY ICE

TRIM

DRY ICE

70%

30%

80%

20%

ALWAYS HAVE

TRIMMER IN A

HORIZONTAL POSITION

WHEN RUNNING

CLEANING

HAND CLEAN WIH

SOAP AND HOT WATER

WHEN YOU NOTICE

OUTPUT DIMINISHING

13

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

SAFETY

TRIMMER SAFETY

IMPORTANT SAFETY INFORMATION

Some of the most important safety precautions follow. However, we cannot warn you of every conceivable hazard that can arise in performing maintenance. Only you can decide whether

or not you should perform a given task. Failure to properly follow maintenance instructions and precautions can cause you to be seriously hurt or killed. Always follow the procedures

and precautions in this owner’s manual. Centurion Pro trimmers are designed to trim excess plant material from a variety of herbal material. Other uses could result in injury to the

operator or damage to the trimmer and other property. Injuries and property damage from trimmers can be prevented by following all instructions in this manual and on the trimmer.

The most common hazards are discussed below, along with the best way to protect yourself and others.

Safety Precautions

Make sure all motors are o and power cords are unplugged before you begin any maintenance or repairs.

Read the instructions before you begin, and make sure you have the tools and skills required.

AVOID ROTATING TUMBLER

The DBT Model 4 Tumbler can cause serious injury, cuts and even amputate ngers or hands. Keep hands, arms, and body away from the Tumbler whenever the Tumbler is in motion. Keep hair,

clothing, and jewelry away from the Tumbler. If you need to work around the trimmer to clear or clean plant material for any reason, always shut o the electric motor and disconnect the trimmer’s

power cord from the AC outlet. Use a wooden stick to remove any obstruction or debris. Never put your hand into the Tumbler while the machine is running; serious personal injury could result.

AVOID BLADE SHEET

The DBT Model 4’s Blade Sheet can cause serious cuts and even amputate ngers and hands. Keep Trim Trays and Tumbler Lids in place at all times while machine is operating. If you

need to work around the trimmer to clear or clean plant material for any reason, always shut o the electric motors and disconnect the trimmer’s power cord from the AC outlet.

CLEAR OPERATION AREA

Before operating the trimmer, carefully inspect the surrounding area and remove all hazards that could cause you to trip, slip, or fall into the trimmer. Anything which can be grabbed by the

rotating Tumbler is a potential hazard to you and others. Look for hazards and remove them from the work area. Tie back loose clothing and long, loose hair. Remove any and all jewelry.

KEEP GUARDS AND SHIELDS IN PLACE

Guards, Shields, Trim Trays and Tumbler Lids are designed to protect you from touching moving components. For your safety and the safety of others, keep all shields in place when the

trimmer is running.

TURN MOTOR OFF WHEN NOT OPERATING THE TRIMMER

If you need to leave or step away from the trimmer for any reason, always make sure to turn the motor o.

OPERATE ON FLAT SURFACE

Do not operate on slopes. To avoid overturning, only operate the trimmer on at surfaces. Control the trimmer carefully when transporting it across uneven ground or slopes. Do not push

the trimmer down or across steep slopes: the trimmer could overturn, causing damage to the machine or injury to the operator and/or bystanders.

OPERATOR RESPONSIBILITY

Know how to stop the trimmer quickly in case of emergency. Understand the use of all trimmer controls. Never permit anyone to operate the trimmer without proper instruction. Do not

let children operate the trimmer.

SAFE OPERATING PRECAUTIONS

- Before operating the trimmer for the rst time, please review both the BEFORE YOU START section and the TRIMMER SAFETY section.

- Even if you have operated other trimmers, to take time to become familiar with how the Centurion Pro works.

- Never operate Centurion Pro machines while under the inuence of drugs, alcohol or prescriptions, including over-the-counter cold/u/allergy medications.

- Protective clothing and eye and/or hearing protection should be worn during operation.

- For your safety, do not operate while wearing loose tting clothing, jewelry, etc..

- Rotating machinery parts can entangle loose clothing, long hair or dangling jewelry resulting in serious injury or death.

- Long hair should be secured in a manner that keeps it away from mechanical parts.

14 cprosolutions.com1 855 535 0558

MY SIDE DRIVE IS HOT.

1) Your machine may be overworking due to a voltage drop in your power supply. This can happen if you’re using an extension cord that is too long or undersized. You can

only use an extension cord with a maximum length of 25ft.

2) Use a voltage tester to test your electrical current to ensure you have the correct voltage. We recommend having a certied electrician come in and make sure

your power supply is consistent.

3) Having a motor on for an extended period can be the reason for overheating. Allow the motor to cool down by turning the machine o for an hour, every 5 hours of use.

THE CIRCUIT BREAKER KEEPS TRIPPING.

1) This is caused by a cord that is too long or undersized. Your cord must be no more than 25ft long and the same gauge of thickness as the main cord.

2) Also, ensure the machine is not sharing a circuit with other devices and the correct size breaker is present. Circuit sharing can signicantly decrease the power

being supplied to the devices therefore causing the breaker to trip.

3) Test your electrical current to make sure it is producing consistent power. We recommend having a certied electrician set up the proper power supply. This

will ensure your power source is supplying the correct electricity. If you have not done this, have a certied electrician come and test your electrical current to

ensure it complies with the electrical requirements.

MY TUMBLER IS NOT SPINNING.

1) If its not spinning, check for obstructions between Tumbler and Blade Sheet.

2) Ensure that the rollers are properly placed on grooved Tumbler and/or the Side Drive is engaged on Tumbler.

THE PRODUCT IS NOT COMING OUT TRIMMED.

1) Tumbler and/or Blade Sheet are excessively dirty. Clean Tumbler and Blade Sheet.

2) Make sure that the Blade Sheet is tightened onto the umbler.

3) Check plant to make sure that moisture content is between 8-10% and that the leaves are snappy and dry, not bendy and pliable.

MACHINE MAKES A LOUD SCRAPING OR CLICKING SOUND.

1) Tumbler and/or Blade Dheet are excessively dirty. Clean Tumbler and Blade Sheet.

2) Tumbler and/or Blade Sheet are Damaged and need to be replaced.

ELECTRIC MOTORS WILL NOT START OR HAVE LOW POWER

1) No electric power from the outlet. Plug trimmer into a functional electrical outlet.

2) Outlet is overloaded. Check that breaker is not overloaded and has not tripped. If tripped, switch plug to a dierent circuit.

3) Extension cord is faulty. Check extension cord is rated appropriately for the distance and current. Do NOT use a longer cord unless the wire size is larger.

Undersized extension cords may cause an under-voltage, over-current condition which could damage or destroy the drive motor and void the motor warranty.

4) Overcurrent circuit has been exceeded. Determine cause of excessive circuit resistance which may include: overloaded outlet, faulty extension cord, bad outlet,

underrated generator, excessively dirty machine, incorrectly tensioned Blade Sheet or obstruction between Tumbler and another part of machine. Once source

of resistance has been identied and resolved, reset circuit by pressing small button on control panel for 3 seconds then operate machine normally.

TUMBLER DOES NOT ROTATE UNDER MANUAL FORCE

1) Tumbler and Blade sheet are excessively dirty. Clean Tumbler and Blade Sheet; excessive plant material builts up on these surfaces and causes excess friction.

2) Tension on Blade Sheet is too tight. Reduce tension on Blade Sheet by releasing the pawl and rotating the tension knob in a counter clockwise direction until

the Tumbler can easily be rotated under manual force and the Blade Sheet is in contact with the Tumbler.

TROUBLESHOOTING

15

OWNERS MANUAL

MODEL 4 DBT

For more information or to watch our DIY video tutorials visit cprosolutions.com

FREQUENTLY ASKED QUESTIONS

You are about to enjoy the experience of CenturionPro Solution’s automated trimming machine. For critical information on assembly, cleaning, care, maintenance and

how to operate your machine correctly, please review this manual and check out our video tutorials, which are posted on our website for your ease and convenience.

Go to www.cprosolutions.com/video-tutorials for our video tutorials.

ADDITIONAL ASSISTANCE

These tutorials provide how-to assistance on the following aspects of machine maintenance:

• Straightening the Tumbler/Drum • Complete Unit Assembly • Trimmer Cleaning and Maintenance

• Replacing The Motor • Blade Sheet Removal and Cleaning • DBT Harvest Workow

**If for some reason you can’t nd an answer to your question online or in your manual, please do not hesitate to contact us.

RETURN/REFUND POLICY

Once the machinery/parts are opened and/or used they are no longer eligible for refund or exchange. Customers can only return if written notice of return has been provided to CenturionPro Solutions within 7

days of receiving their machine and the machine or any component of which have not been used. There will be a 20% restocking fee and the customer will be responsible for all shipping costs. Returns must be

packaged same as it arrived and CenturionPro is not liable for any shipping damage incurred on return. If damage occurs in transit on return, CenturionPro will refuse the return and customer will need to process

a claim with their shipping provider. Any missing or damaged items must be reported to CenturionPro within 14 business days of receiving the shipment.

HOW EASY IS IT TO CLEAN?

Please see the detailed cleaning instructions throughout this manual. Remove Tumbler and Blade

Sheet and cover with a thick coat of cooking oil (olive, vegetable, etc.). Let sit for 3-12 hours. Using warm/hot

water, concentrated dish soap and a non-metallic dish scrubber, clean the Tumbler and other machine

components by hand. Alternatively you can pressure wash with hot water, at up to 1500 psi on fan

spray setting. After pressure washing, run machine for 15 minute to allow components to dry.

We recommend to clean your after every day of use, but it depends on your strain. We know the

importance of down time during a harvest so we wanted to make this processas easy as possible.

ARE YOUR MACHINES BUILT TO AN INDUSTRIAL STANDARD?

We do not compromise quality for cost savings. All CenturionPro Solutions machines are composed

of the highest quality materials available in North America and each machine is put through a

comprehensive quality control inspection. We only use brand name components in the build out of

our machines which enables us to have the comfort in giving you a 3 year trimmer warranty. With

proper maintenance these machines will last you well over a decade.

HOW MUCH PRODUCT SHOULD BE IN THE TUMBLER AT ONE TIME?

The Tumbler should be 40-60% full when trimming.

WHAT IS THE MAINTENANCE LIKE?

We have several video tutorials on our website with how to fully service your machine. These step

by step DIY videos make it very easy to do everything necessary to maintain your machine. All parts

can be ordered through any hydroponic store nationwide.

WHAT IS THE OPTIMAL ROOM TEMPERATURE TO TRIM?

Use your CenturtionPro machine in 50-60 °F (10- 15 °C) room to get the best performance. Cooler

temperatures prevent excessive sticking to machine components.

WHY IS MY PRODUCT STICKING TO THE INSIDE OF THE TUMBLER?

If you nd that product is sticking to the inside of the Tumbler, rst clean the Tumbler. When you

reassemble it, make sure the top brush bristles are poking through 1/4" into the Tumbler.

This manual suits for next models

3

Table of contents

Other CenturionPro Trimmer manuals

CenturionPro

CenturionPro GC1 User manual

CenturionPro

CenturionPro Original User manual

CenturionPro

CenturionPro THE MINI User manual

CenturionPro

CenturionPro 3.0 User manual

CenturionPro

CenturionPro Original User manual

CenturionPro

CenturionPro The Gladiator User manual

CenturionPro

CenturionPro XL Series User manual