CenturionPro XL Series User manual

OWNERS MANUAL

XL TRIMMERS

2cprosolutions.com1 855 535 0558

HEMP &CANNABIS HARVESTING SOLUTIONS

GENERAL

• Do not move, disassemble, clean or inspect the trimmer while the power is still

connected to the machine.

• Replacement parts are specic to The XL Trimmers and must be purchased

from an authorized dealer only. Substituting factory parts with non-approved

third-party replacements may result in damage to the machine or bodily harm.

• Keep all individuals a safe distance from the work area. Do not operate the

machine around children.

• Do not remove safety labels. Replace any and all labels if they become

damaged or obscured.

CONNECTION

• As with home appliances, The XL Trimmers must be used in connection with a

properly grounded receptacle.

• Never plug in or power up your trimming machine if the protective shrouds

are removed.

• Do not use extension cords over 8m (25ft) in length to power the XL Trimmers.

The XL Trimmers are high-speed trimming systems, requiring that specic safety precautions are practiced during operation to reduce the risk of personal injury.

Improper use of The XL Trimmers, or any CenturionPro product, may cause serious or fatal injury. Please ensure you read the operations manual and warning notes

before using the XL Trimmers.

IMPORTANT SAFETY INFORMATION

CENTURIONPRO SOLUTIONS:

XL INDUSTRIAL TRIMMING SYSTEM

OPERATION

• The initial set up will show assembly instructions to unpack and set-up your machine.

• Your bed bar blades have been factory set to cut perfectly. Please do not adjust your

blades until it is time to clean the machine. Also, please watch the video tutorial

located on our website on how to adjust the blades before attempting.

• Safety glasses should be worn at all times while operating The XL Trimmers.

• Do not operate any trimming machine while tired or under the inuence of

medication, drugs or alcohol.

• Do not put anything other than plant material into the tumbler. Doing so may cause

damage to the tumbler, the machine or result in bodily harm.

• Operate the trimmer in a well ventilated area in order to prevent overheating.

MAINTENANCE

• Never leave an XL Trimmer system running unattended.

• Never conduct maintenance or cleaning while the machine is plugged in.

• Do not modify or adapt any part of the trimmer or its accessories. Doing so may

cause irreversible damage to the machine or result in bodily harm.

DO NOT LEND OUT OR RENT YOUR XL TRIMMER WITHOUT THIS OPERATING MANUAL.

A FIRST TIME USER SHOULD OBTAIN PROPER INSTRUCTION PRIOR TO USE.

3

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

TOOL REQUIREMENTS

AMOUNT SIZE TOOL ITEM

1 x #2 PHILLIPS SCREWDRIVER

1 x 3/32" T-Handle Allen Wrench

1 x 5/32" T-Handle Allen Wrench

1 x 1/8" T-Handle Allen Wrench

1 x 3/16" T-Handle Allen Wrench

1 x 3/8" Wrench

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION

TABLE OF CONTENTS

COMPONENT OVERVIEW

CONTROL PANEL OVERVIEW

MACHINE ASSEMBLY

LEAF BLOWER + COLLECTOR BAG ASSEMBLY

COVER ASSEMBLY

MEDICAL GRADE CONVEYOR SYSTEMS

RAIL JACK SYSTEM

HOPPER ASSEMBLY - MEDICAL GRADE

CLEANING & MAINTENANCE

LEAF COLLECTOR CLEANING

MACHINE MAINTENANCE

TRIM BOTH WET & DRY

TROUBLESHOOTING

TRIPLE BAG KIEF COLLECTION SYSTEM

FREQUENTLY ASKED QUESTIONS

ADDITIONAL ASSISTANCE

SPECIFICATIONS

WARRANTY

2

3

4

6

8

9

10

11

11

12

13

14

15

15

16

18

19

19

20

21

4cprosolutions.com1 855 535 0558

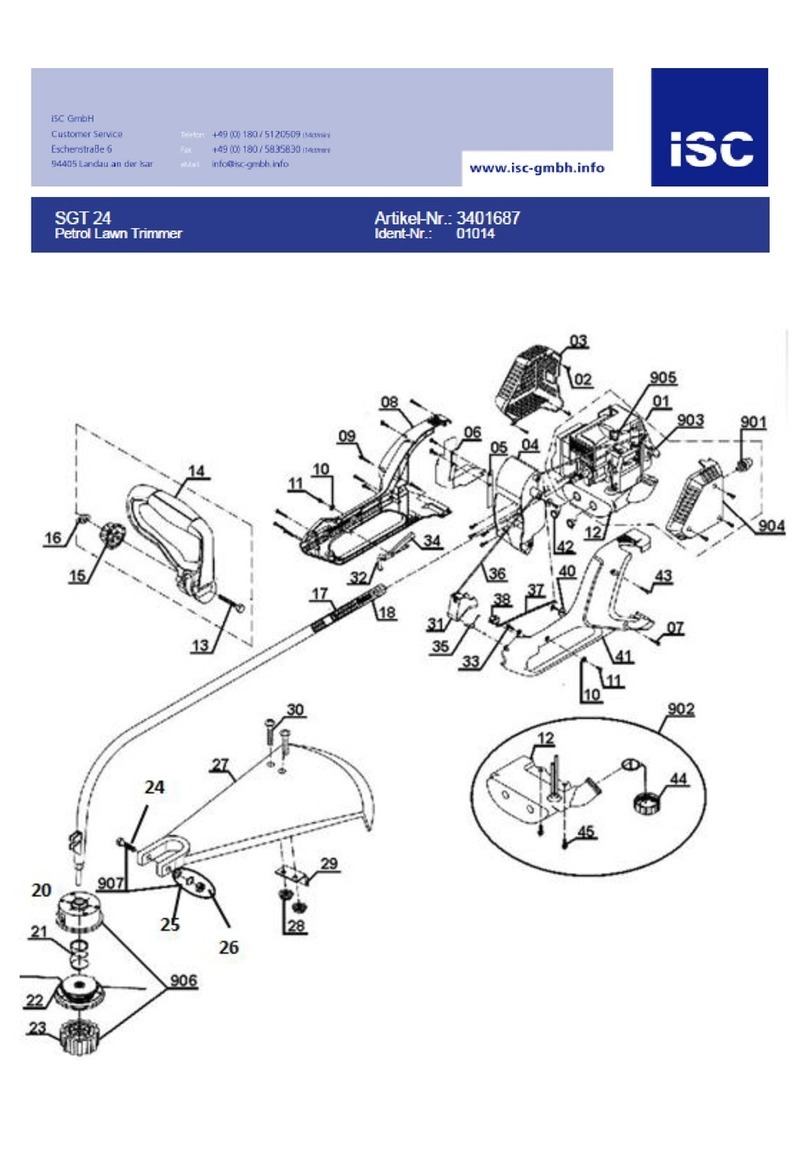

HEMP &CANNABIS HARVESTING SOLUTIONS COMPONENT OVERVIEW

TUMBLER O-RING

UPPER FRAME

CUTTING REELS

TRIM & KIEF

COLLECTION/SEPERATION BAGS LEAF COLLECTOR BLOWER

Requires Cleaning

See Pg. 13

Requires Cleaning

See Pg. 14

Requires Cleaning

See Pg. 14

OUTFEED CONVEYOR CONTROL PANEL DUAL-PURPOSE

HYBRID TUMBLER (X10)

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

5

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

COMPONENT OVERVIEW

BRUSH

COVER

BEARING COVER

LOWER FRAMECONNECTOR CLAMPS

Requires Cleaning

See Pg. 13

INFEED CONVEYOR

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

GMP COMPLIANT/

FOOD GRADE HOPPER

XL TRIMMERS COME STANDARD

WITH A FOOD GRADE HOPPER

Requires Installation:

See Pg. 12

6cprosolutions.com1 855 535 0558

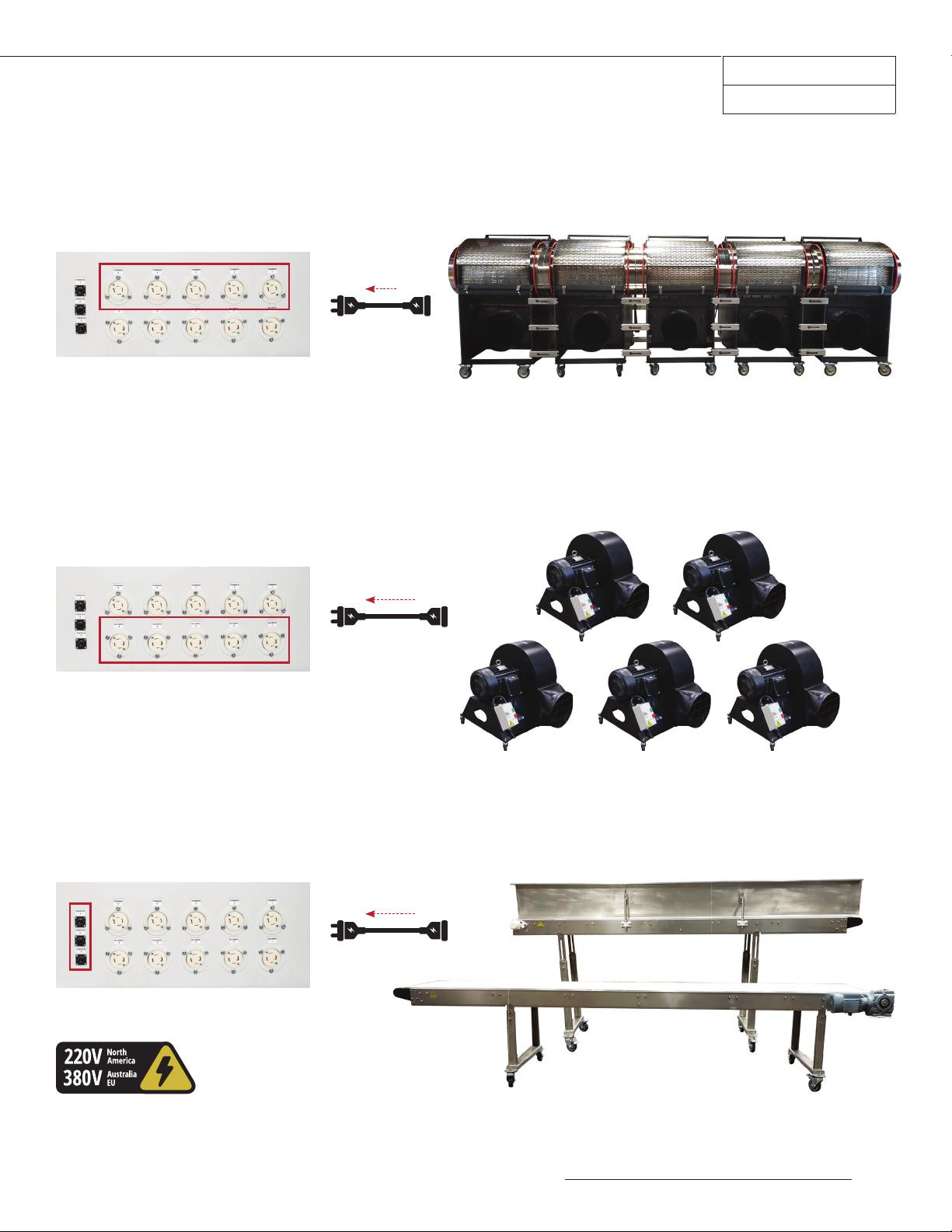

HEMP &CANNABIS HARVESTING SOLUTIONS CONTROL PANEL OVERVIEW

INFEED AND QUALITY CONTROL

CONVEYORS "ON" SWITCHES

LEAF BLOWERS SUCTION SYSTEM

"ON" SWITCHES

LEAF BLOWERS SUCTION SYSTEM

"OFF" SWITCHES

XL TRIMMER SYSTEM

"ON" SWITCH

"EMERGENCY OFF" SWITCH

INFEED AND QUALITY CONTROL

CONVEYORS "OFF" SWITCHES

FEMALE RECEPTICAL SOCKETS

XL TRIMMER SYSTEM

"OFF" SWITCH

CONTROL PANEL:

FRONT

CONTROL CONSOLE

CONTROL PANEL:

BACK

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

7

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

CONTROL PANEL OVERVIEW

CONNECT:

TRIMMERS x 5

CONNECT:

BLOWERS x 5

CONNECT:

CONVEYORS x 3

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

8cprosolutions.com1 855 535 0558

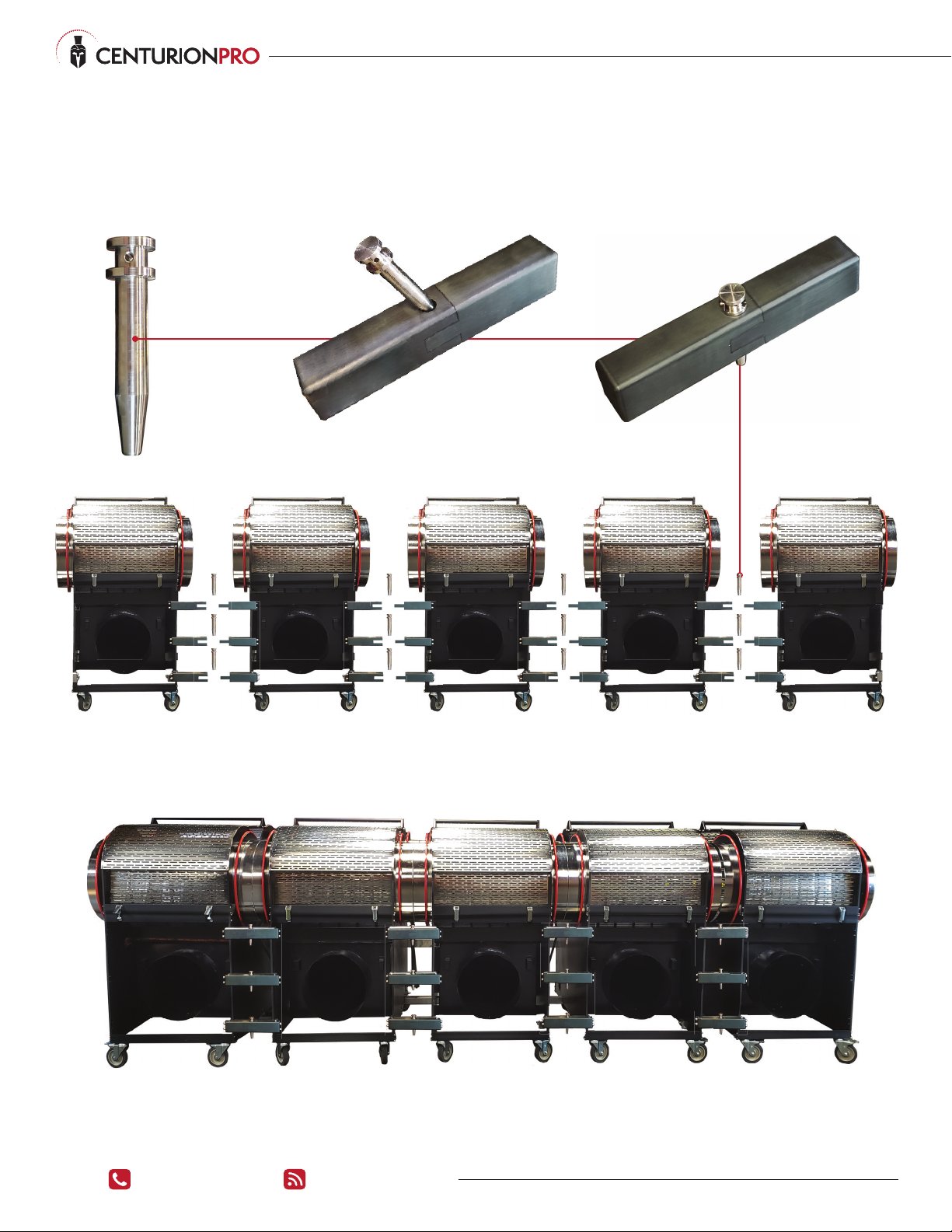

HEMP &CANNABIS HARVESTING SOLUTIONS MACHINE ASSEMBLY

STEP 1:

ATTACH INDIVIDUAL TRIMMERS x 5

- Use quick release pin system to connect all 5 trimmer units together

XL TRIMMER SYSTEM SEPARATED

XL TRIMMER SYSTEM CONNECTED

OR

QUICK RELEASE PIN LINE UP

HOLES OF THE

CONNECTOR

PLATES

PLACE PIN IN HOLE TO

SECURE TRIMMERS

TOGETHER

PULL PIN TO SEPARATE

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

OUTSIDE BAG

SECOND BAG

INSIDE BAG

ZIPPERS

16" 16"

16"

9

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

LEAF BLOWER + COLLECTOR BAG ASSEMBLY

STEP 3:

INSTALL DUCT TUBES TO

TRIMMER EXHAUST x 5

STEP 4:

INSTALL DUCT TUBES TO

LEAF BLOWERS x 5

Note: Use 16" hose clamps to

secure tubes.

Note: Use 16" hose clamps to

secure tubes.

LEAF

COLLECTOR

STEP 6:

ALIGN LEAF COLLECTOR SYSTEM IN THE SAME

DIRECTION FOR OPTIMAL SUCTION PERFORMANCE.

STEP 5:

ATTACH BAG SYSTEM

TO LEAF COLLECTOR

- Secure with 16" hose clamp

- Requires cleaning (pg. 14)

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

10 cprosolutions.com1 855 535 0558

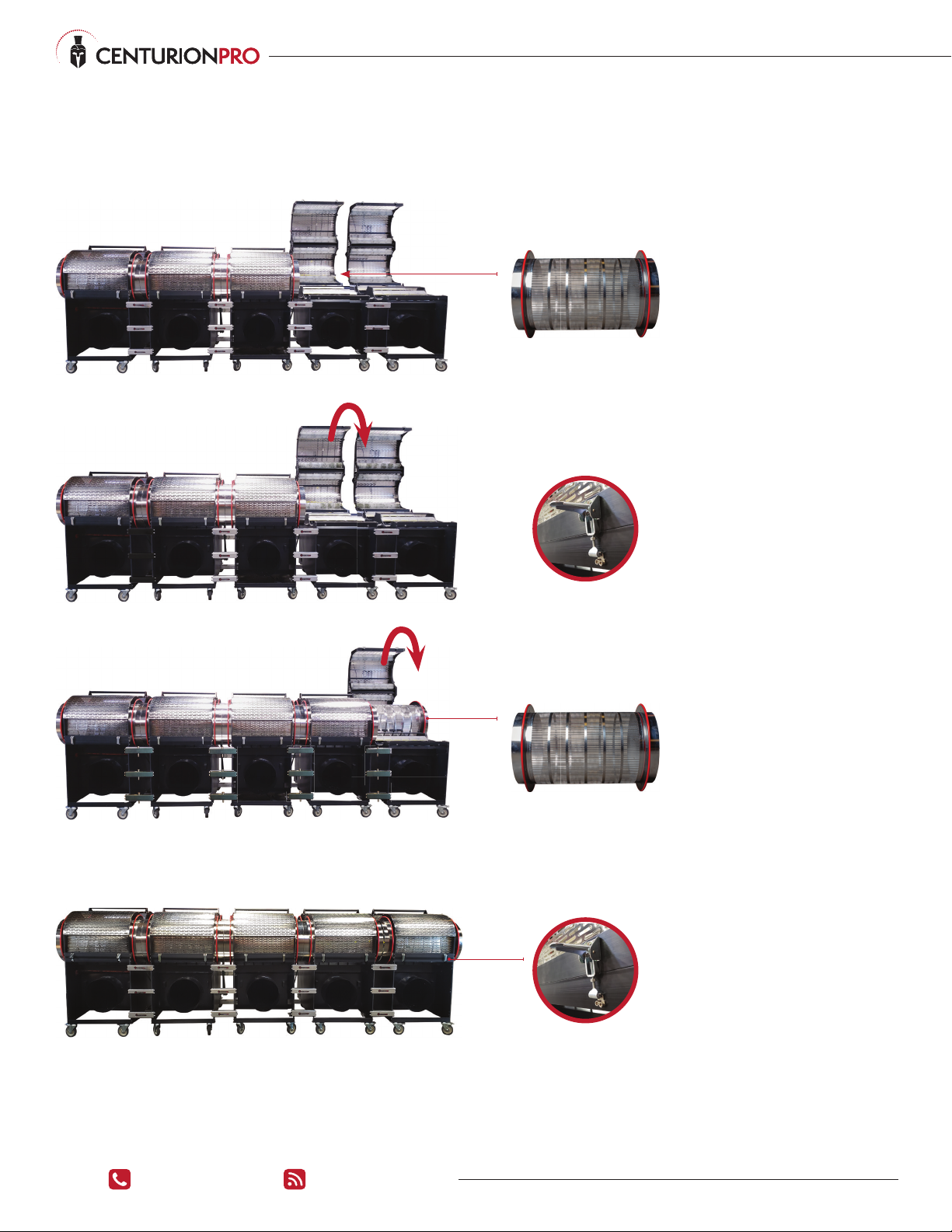

HEMP &CANNABIS HARVESTING SOLUTIONS COVER ASSEMBLY

STEP 1:

ALIGN TUMBLER TO PULLEY

GROOVES AND ENSURE THE

TUMBLERS ARE END TO END.

STEP 2:

CLOSE UPPER FRAME COWL

DOOR AND SECURE WITH

FRAME LATCHES.

STEP 3:

ALIGN TUMBLER TO PULLEY

GROOVES AND ENSURE THE

TUMBLERS ARE END TO END.

STEP 4:

CLOSE UPPER FRAME COWL

DOOR AND SECURE WITH

FRAME LATCHES.

XL DUAL-PURPOSE

HYBRID TUMBLER

XL DUAL-PURPOSE

HYBRID TUMBLER

INDUSTRIAL LATCH CLOSURES

INDUSTRIAL LATCH CLOSURES

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

11

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

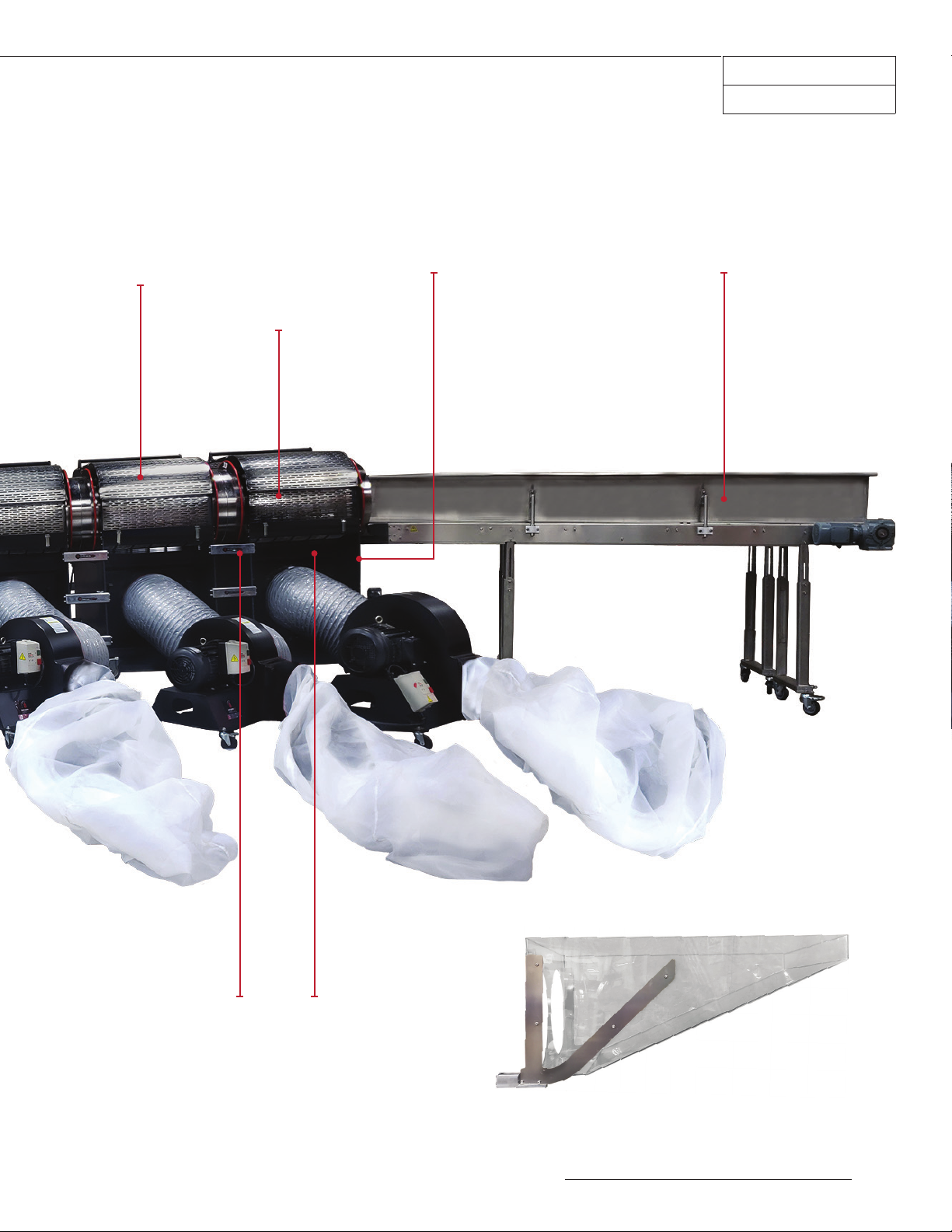

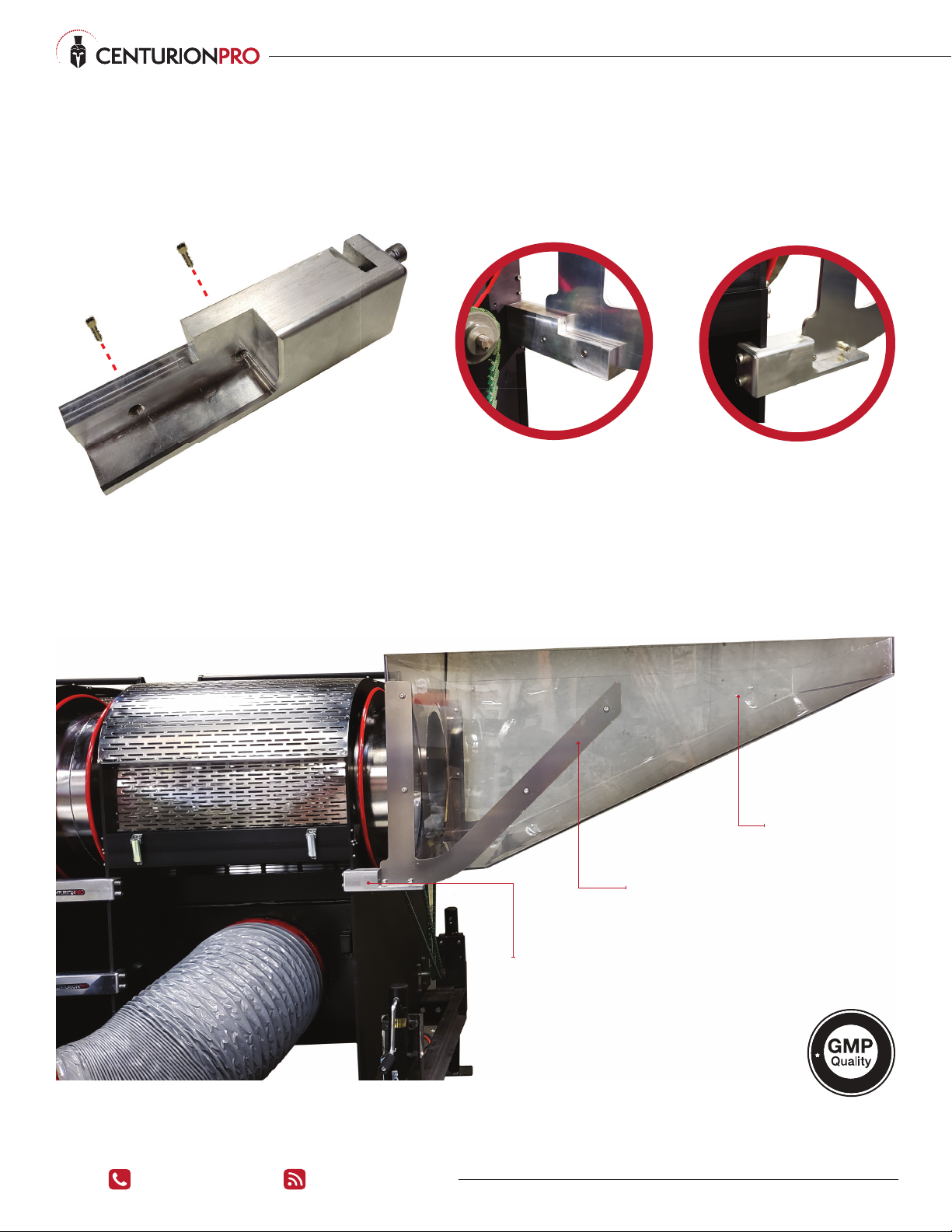

MEDICAL GRADE CONVEYOR SYSTEMS

RAIL JACK SYSTEM

INFEED CONVEYOR:

FULL CUSTOM SPEED CONTROL SYSTEM QUALITY CONTROL CONVEYOR:

FULL CUSTOM SPEED CONTROL SYSTEM

LIFTING JACK

STEEL RAIL SYSTEM

STOPPING

BRACKETS

STEP 1:

SLIDE XL TRIMMER ONTO

STEEL RAIL SYSTEM

STEP 2:

LOCK XL TRIMMER INTO PLACE

ONTO STEEL RAIL SYSTEM

- Adjust height of trimmer using jack stands for

optimal performance and ow of product.

- Once desired angle has been set, bolt on 2 Stopping Brackets

at the end of the rail to secure the XL Trimmer in place.

- Secure with 1/2" round - 1" long bolt

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

12 cprosolutions.com1 855 535 0558

HEMP &CANNABIS HARVESTING SOLUTIONS

STEP 1:

ATTACH TWO BRACKETS TO TRIMMER

Install using 8 bolts

(2 sets of bolts for each side)

Install using 4 x (1/4" round x 1" long) size bolts

- 2 bolts attach to Trimmer Frame

- 2 bolts attach to Hopper Frame Arms

STEP 2:

ATTACH HOPPER TO ATTACHED BRACKETS

Attach using 4 bolts and 4 washers

(2 sets of bolts and washers on each side)

INSIDE

HOPPER BRACKET

HOPPER BINDING

MOUNT (x2) OUTSIDE

HOPPER BRACKET

HOPPER

BRACKET ARMS

HOPPER

BINDING MOUNT

GMP COMPLIANT/FOOD

GRADE HOPPER

G

o

o

d

M

a

n

u

f

a

c

t

u

r

i

n

g

P

r

a

c

t

i

c

e

C

o

m

p

l

i

a

n

t

HOPPER ASSEMBLY - MEDICAL GRADE

Install using 4 x (1/4" round x 1" long) size bolts

- 2 bolts attach to Trimmer Frame

- 2 bolts attach to Hopper Frame Arms

Install using 6 x (1/4" round x 1" long) size bolts

- 2 bolts attaches to Hopper Binding Mount

- 4 bolts attach to Hopper

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

AVOID

WATER

ON THE

MOTOR

13

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

CLEANING & MAINTENANCE

BLADE REMOVAL

CLEANING THE XL TRIMMER

For optimal performance and life, the components must be cleaned every 3 to 4 hours.

For optimal performance and life, the BLADE and the MAGNET BAR must be removed and cleaned every few hours of operation.

INSTALLATION IS REVERSE ORDER OF REMOVAL

IMPORTANT NOTE:

- Clean by spraying hot pressurized water: 1500 - 2000 psi

- Run the XL Trimmer empty of material for 15 mins after washing to allow components to dry

STEP 1:

UNLOCK BLADE

STEP 1:

CLEAN

BRUSH

STEP 2:

UNPIN BLADE STEP 3:

BLADE & MAGNET REMOVAL

STEP 3:

CLEAN CUTTING

REEL & SHROUD

STEP 2:

CLEAN

ELECTROPLISH

TUMBLER

STEP 4:

BLADE & MAGNET CLEANING

- Remove 3/32" bolt

- Loosen the surrounding set screws ONLY

- Pivot the pin up from the blade - Carefully slide blade o magnets

- Carefully Remove bed bar blade

Clean the length of the

cutting reel and shroud

of all debris using hot

pressurized water.

Clean the length of the

tumbler of all debris using

hot pressurized water.

Clean the length of the

brush of all debris using

hot pressurized water.

- Clean blade and magnet bar with a utility knife.

IMPORTANT NOTE:

YOUR BED BAR BLADE HAS BEEN FACTORY SET TO CUT PERFECTLY. PLEASE DO NOT ALTER THE SETTINGS OF YOUR MACHINE. YOU

MIGHT NOTICE SLIGHT CONTACT BETWEEN YOUR ROTATING CUTTING REEL AND THE FLAT BED BAR BLADE - THIS IS NORMAL.

Note:

Images may not re ect exact product - Based on XL 10.0 prototype images.

14 cprosolutions.com1 855 535 0558

HEMP &CANNABIS HARVESTING SOLUTIONS

LEAF COLLECTOR CLEANING

INSTRUCTIONS:

Clean with pressure-washing at 1500 - 2000 PSI, Hot

Water, Fan Spray Setting. Run LEAF COLLECTOR for 15

minutes after washing, allowing components to dry.

FOR OPTIMAL PERFORMANCE AND LIFE, THE

LEAF COLLECTOR COMPONENTS MUST BE

CLEANED EVERY 30 DAYS OF USE.

AVOID WATER CONTACT ON BEARINGS

AND MOTOR.

STEP 1:

REMOVE COVER & IMPELLER

FROM LEAF COLLECTOR

STEP 3:

CLEAN LEAF

COLLECTOR BAGS

STEP 2:

PRESSURE WASH IMPELLER &

INTERIOR OF LEAF COLLECTOR

• Remove 8 screws from the side panel to

uncover the leaf collector

• Remove the 13mm bolt & washer

located in the middle of the fan blades

• When removing the blower impeller,

use a pulling tool only.

• Spray the impeller blades with your

pressure washer using hot water

• Tip the leaf collector up so that the

opening is in a drain position

• Spray the entire inside of the leaf

collector. Avoid spraying directly onto

the bearing

• To clean the outside of the unit, wipe the

leaf collector down with some isopropyl

alcohol to remove dirt and residue

AVOID SPRAYING

DIRECTLY ONTO

THE BEARING

ONLY USE PULLING TOOL

WHEN REMOVING THE BLOWER

IMPELLER FOR CLEANING.

CLEAN BLOWER EVERY 30-40

DAYS OF USE.

• Unzip all three bags to

empty contents

• Turn leaf collector bags

inside-out seperately and

pressure wash each bag

• Allow bags to dry

13mm

bolt & washer

Tilt the leaf

collector to drain

from the opening

Remove

8 screws

Black Mesh Bag White Filter Bag Outer Polyester Bag

Turn inside-out

to pressure wash

and let dry.

**INSTALLATION IS REVERSE ORDER OF REMOVAL

15

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

DUAL-

PURPOSE

HYBRID

TUMBLER

The XL Trimmers are precision machines. It is essential that they be operated and maintained with this in mind. The machine has been adjusted and tested by the manufacturer prior to shipping to ensure

optimal performance. However, it is important to inspect the machine at initial start-up and after each use to ensure that no damage or plant material build-up has occurred and that the blades spin freely.

In addition, it is highly recommended to clean the machine at the end of every use. This ensures that the blades are kept lubricated and that resin does not build-up and a ect performance. This is

especially important if the machine has been stored for an extended period of time.

If optional Quantanium coating is chosen, the machine will not require any lubricants or sprays. The application of which will only damage or alter the nal product and will not assist with the cutting

process. In fact, it may hinder it. Cold water is recommended to spray on blades during harvest.

MACHINE MAINTENANCE

• Begin by hanging the entire plant, leaving the leaf on. Starting with 30% humidity at 60-65 degrees Fahrenheit for 24 hours, raising the humidity to 50-60% for another ve to six days.

• Next, carefully cut all your owers o the main stocks of the plant, leaving only owers and leaves in tact. Then, depending on the density of the owers, it should be ready to run through the machine.

• The buds should be about 80-90% dry, which allow the fan leaf and sugar leaf to remain somewhat PLIABLE/BENDY, in a soft and exible state. If the larger leaf is too dry and brittle (which makes

it more di cult for the machine to pull this sti er leaf through the slots of the drum, preventing a clean, sharp cut) raise the humidity up to 75% for about half a day to a full day. This, remarkably,

softens up the unwanted leaf while returning almost no additional moisture to the main body of the buds.

THIS METHOD WILL ALLOW VIRTUALLY NO ADDITIONAL

MOISTURE BACK TO THE INNER BUD/FLOWER. THE

MOISTURE WILL ONLY SOFTEN UP THE OUTER LEAVES.

THE LEAVES MUST BE SOFT AND

PLIABLE FOR THE DRY TRIMMER TO

BE EFFECTIVE.

NOTE 1:CRITICAL: NOTE 2:

IT IS CRITICAL FOR THE UNWANTED LEAVES TO BE SOFT AND BENDY FOR THIS MACHINE TO

PREFORM A CLEAN PERFECT CUT. WE ALSO RECOMMEND USING A HUMIDIFIER OR A WATER

BOTTLE WITH A MISTING NOZZLE TO RE-INTRODUCE A SMALL AMOUNT OF MOISTURE TO THE

UNWANTED LEAVES BEFORE RUNNING THE FLOWERS THROUGH THE MACHINE.

TRIM BOTH WET + DRY

All CenturionPro trimming machines are specially designed to trim both wet and

dry material better than any other machine on the market. Our Dual-Purpose

Hybrid Tumbler has been extensively tested to outperform both the traditional wet

tumbler when trimming wet and the traditional dry tumbler when trimming dry.

This CenturionPro innovation allows you to switch between wet and dry material

with just a few small adjustments to your trimming system. This is a major

bene t because you can purchase one machine and still have the capability to

trim wet or dry fl owers.

See our dry trimming tips below for more details.

TRIMMING DRY? HERE ARE SOME IMPORTANT TIPS!

CENTURIONPRO

DUAL-PURPOSE HYBRID TUMBLER

After running the buds through the machine the chances are they are ready to bag up! All that might be necessary is a quick test after the bag has been sealed by opening it back up to air them out a

bit to achieve the perfect moisture content (curing process). You may prefer to run the machine with the plastic cover o , and diverter almost open (this varies depending on the density of the strain).

Please note the machine operates best when the tumbler is 40-60% full. A huge bonus to the DRY trimming method is that the machine will require almost no periodic cleaning, as the tumblers and

blades will not gum up and therefore not reduce performance. The main advantage of DRY trimming is said to be better preservation of all the strong natural aromas and avours after the harvesting

process is complete.

MONTHS OF WORK CAN BE RUINED IN A FEW HOURS AT THE END SO PLEASE BE PATIENT AND TAKE YOUR TIME WITH THE HARVESTING AND CURING PROCESS.

DESIGNED FOR BOTH WET + DRY TRIMMING

16 cprosolutions.com1 855 535 0558

HEMP &CANNABIS HARVESTING SOLUTIONS

TROUBLESHOOTING

MY PRODUCT IS STUCK IN THE MIDDLE OF MY TUMBLER AND WILL NOT COME OUT THE OTHER END.

1) The tumbler should always be 40%-60% full. You should be feeding the tumbler every 30-60 seconds; this will ensure that new product entering the machine will help push out

product that is trimmed. This constant ow of product will also help with your processing capacity. Infeed Conveyors will help with creating a constant ow of product.

2) You can also increase the downward slope of the machine. To do this, use the Rail Jack System instructions on pg.11. Before turning the machine ensure that the

machine is level and sturdy.

3) Try opening the Diverter fully and/or removing the outer bag on the trim collection system. This will increase the air ow and decrease the suction, allowing product to pass through quicker.

MY LEAF COLLECTOR IS NOT TURNING ON.

1) Ensure the correct voltage is being supplied as per your manual and never use an extension cord longer than 25 ft. Using an extension longer than 25 ft long will cause a

drop in power being supplied to the leaf collector. This can cause the motor to compensate for the lost power, therefore over heat and eventually burn out.

2) Test your electrical current to make sure it is producing power. We recommend having a certied electrician set up the proper power supply as noted on pg. 20. This will

ensure your power source is supplying the correct electricity. If you have not done this, have a certied electrician come and test your electrical current.

3) If you have tried all of the above, then your leaf collector’s capacitors or electrical box may need to be replaced. Ensure that you have a certied electrician install the parts

correctly. Also have them double check your power supply. If your power supply is inconsistent, the same problems will occur in the future.

MY TUMBLER IS SPINNING SLOWER THAN USUAL OR IS NOT SPINNING AT ALL.

1) You will need to take a link (or two) out of the belt. Use a pair of needle nose pliers to help you with this. When putting your tightened belt back on your

machine it might be a little dicult. Use the video tutorial “Removing and Replacing the Belt” on our website to help you with this. Once the belt is tightened

properly, the tumbler speed will resume back to normal.

2) Ensure that the tumbler is placed correctly in the grooves and there is no lubricant on the Tumbler O Rings (red o-rings on both sides of the tumbler). This will

cause the tumbler to slip in one spot rather than make a full rotation.

3) Ensure your Cam Follower's O Rings are in tact. You should NEVER run your machine without these. Cam Followers help guide the tumbler, without these your

tumbler and/or machine can incur damage.

THE LEAF COLLECTOR SUCTION SEEMS WEAK.

1) Ensure the correct voltage is being supplied as per your manual and never use an extension cord longer than 25 ft. Using an extension cord longer than 25 ft long will

cause a drop in power being supplied to the leaf collector. This can cause the motor to compensate for the lost power, therefore over heat and eventually burn out.

2) Test your electrical current to make sure it is producing power. We recommend having a certied electrician set up the proper power supply as noted on pg. 20. This will

ensure your power source is supplying the correct electricity. If you have not done this, have a certied electrician come and test your electrical current.

3) Ensure the leaf collector and surrounding parts are clean. Also ensure nothing is blocking the inlet or the outlet of the leaf collector. Often buildup of product around the

openings of the blower can cause weak suction. Be sure to clean the Kief Collection System, Impeller and the inside of the blower. Refer to pg. 14 for cleaning instructions.

THE PRODUCT IS NOT COMING OUT TRIMMED.

1) First, ensure that your machine is clean. Clean the Bed Bar Blade (at blade), top and underneath every 3-4 hours of use. The Reel Blade (rotary blade) should be

cleaned every 6-8 hours of use. Think of the blades as a pair of scissors, if the blades are not clean the machine will not be able to do its job.

2) Secondly, ensure that the Bed Bar Blade is set close to the Reel Blade. The space between the two blades should be the same thickness as a single sheet of newspaper –

essentially, they should be skimming. Please refer to the video tutorial “Adjusting the Blade” on our website on how to set the Bed Bar Blade accurately. Again, think of the

blades as a pair of scissors, if the blades are too far away from each other they will not trim your product.

3) Lastly, ensure the suction from the Leaf Collector is working correctly. Make sure there are no air-leaks. Keep in mind that long extension cords result in a decrease in

performance of the machine and its components.

17

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

MY MACHINE MOTOR IS HOT

1) Your machine may be overworking due to a voltage drop in your power supply. This can happen if you’re using an extension cord that is too long or undersized. You can

only use an extension cord with a maximum length of 25ft.

2) Use a voltage tester to test your electrical current to ensure you have the correct voltage. We recommend having a certied electrician to come in and make sure

your power supply is consistent.

3) Having a motor on for an extended period can be the reason for overheating. Allow the motor to cool down by turning the machine o for an hour, every 5 hours of use.

MY LEAF COLLECTOR IS MAKING A LOUD BANGING NOISE

1) Ensure your blower is clean of debris and build up. Build up inside the blower and on the impeller can cause contact with the housing of the blower.

2) If cleaning the build up in your blower does not stop the noise, there may be a bend in your impeller. As such, you will need to purchase a new impeller to

replace the one in your leaf collector. To remove the impeller use ONLY a pulling tool. Refer to pg. 14 for instructions on how to properly remove the impeller.

THE CIRCUIT BREAKER KEEPS TRIPPING.

1) This is caused by a cord that is too long or undersized. Your cord must be no more than 25ft long and the same gauge of thickness as the main cord.

2) Also, ensure the machine is not sharing a circuit with other devices and the correct size breaker is present. Circuit sharing can signicantly decrease the power

being supplied to the devices therefore causing the breaker to trip.

3) Test your electrical current to make sure it is producing consistent power. We recommend having a certied electrician set up the proper power supply as

noted on pg. 15. This will ensure your power source is supplying the correct electricity. If you have not done this, have a certied electrician come and test your

electrical current to ensure it complies with the electrical requirements on pg. 20.

THERE IS A HIGH PITCH SCREECHING NOISE COMING FROM MY MACHINE.

1) Determine if the noise is coming from your reel bearings or brush assembly. Check your reel bearings to ensure they are greased suciently, Take a look at the video

tutorial “Packing the Bearings” on our website to help you with this. If the noise persists after you grease your bearings you will need to purchase and replace them. If the

noise is coming from your brush assembly, you will need to purchase and replace the brush bearings.

2) If the noise is coming from your leaf collector, you will need to replace the bearings in your leaf collector. Please contact our tech support for more details on this.

3) It is very important to ensure that after cleaning your machine, you run it for 10-15 mins to ensure there is no residual water around the bearings.

THERE IS A HIGH-SPEED TICKING SOUND COMING FROM THE BLADES.

1) The ticking sounds might be the bed bar blade and reel blade making slight contact. If the machine is producing a louder than usual ticking/banging sound, then turn o

the machine and inspect the blades. Ensure your blades are properly adjusted by following the video tutorial “Adjusting the Bed Bar Blade” on our website.

2) A n on the tumbler might be slightly protruding therefore causing slight contact with the bed bar blade. This will cause a ticking sound for every rotation the

tumbler does. Watch the video tutorial on our website called “Straightening the Drum”. Also ensure the blade is adjusted properly.

MY TUMBLER IS HOPPING AND/OR WOBBLING.

1) All tumbles are hand rolled and welded. None of our tumblers are cut from a perfectly cylindrical pipe, therefore the tumbler might appear as it is slightly

wobbling while the machine is on.

2) You might notice a slight hop to your tumbler every rotation. This is from the Red Tumbler O Ring. This should not aect the functioning of your machine.

However, if you notice the hop getting worse, you will need to replace this part.

THE BAGS ARE EASY TO WASH WITH A PRESSURE WASHER

USING COLD WATER. THE BAGS CAN ALSO BE PUT THROUGH

THE WASHING MACHINE, BUT IT IS RECOMMENDED TO BE

RUN THROUGH ON A COLD DELICATE CYCLE ONLY.

18 cprosolutions.com1 855 535 0558

HEMP &CANNABIS HARVESTING SOLUTIONS

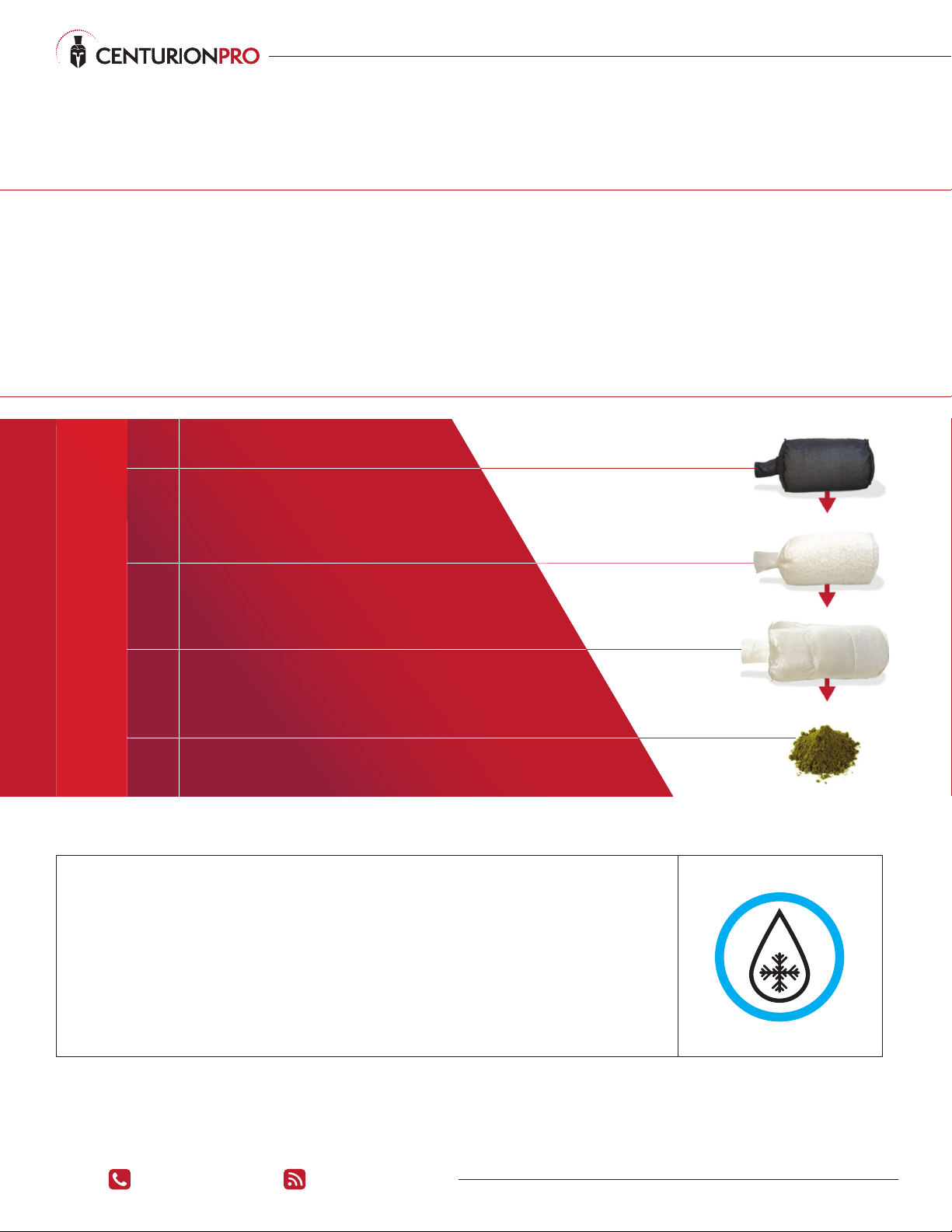

Kief is becoming wildly popular due to the rise of extractions. Unfortunately, machines that require sprays can contaminate and destroy your

Kief, making it virtually useless. Thankfully, CenturionPro offers an optional non-stick Quantanium coating on the tumblers. This means no

spray is needed so your Kief remains 100% pure and usable. To further benefit growers, we developed a new triple-bag filtration system. This

system will assist with Kief collection and separating it from your trim. This allows you to safely and easily collect the precious trichomes for

further processing and profits. With your machine, you will see that you have a black mesh bag, a white filter bag, and an outer polyester bag.

The black bag goes inside the white filter bag, which then goes inside the polyester bag.

THE GREEN LEAFY TRIM WILL COLLECT

IN THE NEW INNER BLACK BAG.

STEP

1

STEP

2

STEP

3

STEP

4

ONLY THE KIEF MAKES IT THROUGH THE BLACK

BAG AND COLLECTS IN THE WHITE FILTER BAG.

OUTER POLYESTER BAG CATCHES ANY KIEF THAT

MAY PASS THROUGH THE WHITE FILTER BAG.

TURN OFF THE MACHINE AND REMOVE THE INNER

BLACK MESH BAG AND THEN EXTRACT KIEF. ENJOY!

TRIPLE-BAG KIEF COLLECTION SYSTEM

HOW IT WORKS

19

OWNERS MANUAL

XL TRIMMERS

For more information or to watch our DIY video tutorials visit cprosolutions.com

HOW EASY IS IT TO CLEAN?

Our machines can be taken apart and cleaned within 15 minutes. Please see the detailed cleaning

instructions throughout this manual. Our Quantanium coating is similar to a Teon pan you would have

at home which is even easier to clean. Just submerge in warm water, let soak and then wipe with a

soft cloth. We recommend to clean every 3-4 hours of use, but it depends on your strain. We know the

importance of down time during a harvest so we wanted to make this process extremely quick and easy

WHAT IS THE MAINTENANCE LIKE?

We have several video tutorials on our website with how to fully service your machine. These step by

step DIY videos make it very easy to do everything necessary to maintain your machine. All parts can be

ordered through any hydroponic store nationwide.

DO YOUR MACHINES TRIM WET OR DRY?

All CenturionPro trimming machines are specially designed to trim both wet and dry material better than any

other machine on the market. Our Dual-Purpose Hybrid Tumbler has been extensively tested to outperform

both the traditional wet tumbler when trimming wet and the traditional dry tumbler when trimming dry.

This CenturionPro innovation allows you to switch between wet and dry material with just a few small

adjustments to your trimming system. This is a major benet because you can purchase one machine

and still have the capability to trim wet or dry owers.

FREQUENTLY ASKED QUESTIONS

ARE YOUR MACHINES BUILT TO AN INDUSTRIAL STANDARD?

We do not compromise quality for cost savings. All CenturionPro Solutions machines are composed

of the highest quality materials available in North America and each machine is put through a

comprehensive quality control inspection. We only use brand name components in the build out of our

machines which enables us to have the comfort in giving you a 10 year trimmer warranty. With proper

maintenance these machines will last you well over a decade.

WHAT IS THE OPTIMAL ROOM TEMPERATURE TO TRIM?

Use your CenturtionPro machine in 50-60 °F (10- 15 °C) room to get the best performance. Cooler

temperatures prevent excessive sticking to machine components.

MY MACHINE IS NOT WORKING LIKE IT DID WHEN IT WAS NEW, WHY?

Make sure to fully clean the machine and blades. If the machine is clean, the blade is adjusted properly

and the leaf collector has full suction, then your machine should trim exactly like it was new.

WHY IS MY PRODUCT STICKING TO THE INSIDE OF THE TUMBLER?

If you nd that product is sticking to the inside of the tumbler, rst clean the tumbler. When you

reassemble it, make sure the top brush bristles are poking through 1/4" into the tumbler.

HOW MUCH PRODUCT SHOULD BE IN THE TUMBLER AT ONE TIME?

The tumbler should be 40-60% full when trimming.

WE ARE OPEN MONDAY THROUGH FRIDAY FROM 9AM TO 5PM PST - PH: 1-855-535-0558

FILLING OUT THE “CONTACT US” FORM ON THE WEBSITE, IS ANOTHER SURE WAY TO GET IN TOUCH.

You are about to enjoy the experience of CenturionPro Solution’s automated trimming machine. For critical information on assembly, cleaning, care, maintenance and

how to operate your machine correctly, please review this manual and check out our video tutorials, which are posted on our website for your ease and convenience.

Go to www.cprosolutions.com/video-tutorials for our video tutorials.

These tutorials provide how-to assistance on the following aspects of machine maintenance:

• Straightening the Tumbler/Drum • Complete Unit Assembly • Sharpening The Blade

• Skirt Assembly • Replacing the Bearings • Cleaning The Blower

• Removing and Replacing The Belt • Manually Bucking Your Product • Adjusting The Blade

• Replacing The Motor • Trimmer Cleaning and Maintenance • Packing The Bearings

• Blade Removal and Cleaning • Replacing The Tumbler/Drum Ring • Replacing The Pulleys

**If for some reason you can’t nd an answer to your question online or in your manual, please do not hesitate to contact us.

ADDITIONAL ASSISTANCE

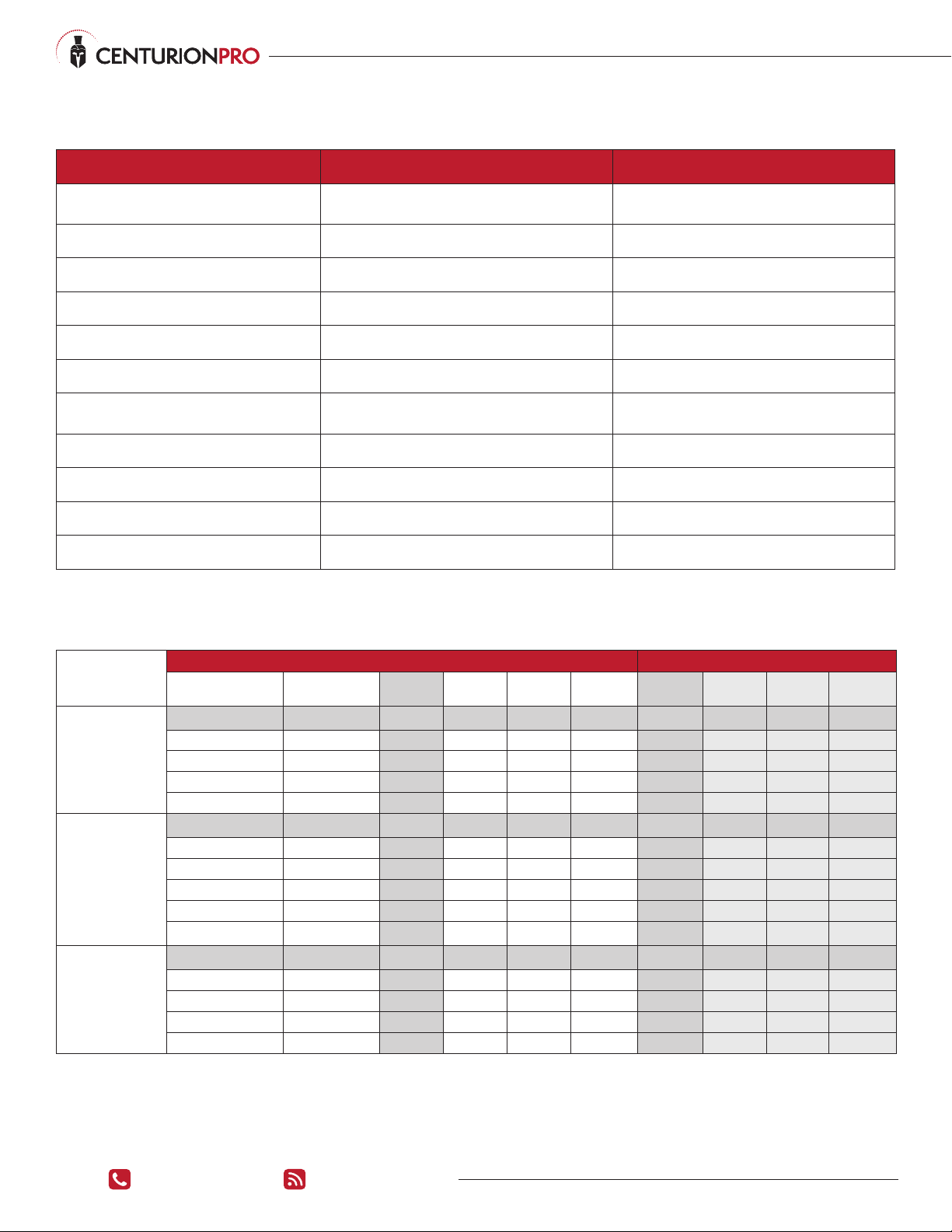

XL TRIMMERS SPECIFICATIONS

ELECTRICAL POWER SUPPLY SET-UP

XL 5.0 XL 5.0 SE XL 10.0

5 x DUAL-PURPOSE HYBRID

304 STAINLESS STEEL TUMBLERS

5 x DUAL-PURPOSE HYBRID

304 STAINLESS STEEL TUMBLERS

10 x DUAL-PURPOSE HYBRID

304 STAINLESS STEEL TUMBLERS

10 x 11-BLADE (26″) CUTTING REELS 15 x 11-BLADE (26″) CUTTING REELS 20 x 11-BLADE (26″) CUTTING REELS

420,000 CUTS PER MINUTE 630,000 CUTS PER MINUTE 840,000 CUTS PER MINUTE

5 x 6HP LEAF COLLECTORS 5 x 8HP LEAF COLLECTORS 5 x 8HP LEAF COLLECTORS

20″ TUMBLER DIAMETER 20″ TUMBLER DIAMETER 20″ TUMBLER DIAMETER

38.9 CUBIC FEET OF TUMBLER VOLUME 38.9 CUBIC FEET OF TUMBLER VOLUME 77.8 CUBIC FEET OF TUMBLER VOLUME

MAIN POWER REQUIREMENT AVAILABLE AS 60HZ 220V

3-PHASE 150 AMP OR 50HZ 380V 3-PHASE 100 AMP

MAIN POWER REQUIREMENT AVAILABLE AS 60HZ 220V

3-PHASE 150 AMP OR 50HZ 380V 3-PHASE 100 AMP

MAIN POWER REQUIREMENT AVAILABLE AS 60HZ 220V

3-PHASE 150 AMP OR 50HZ 380V 3-PHASE 100 AMP

UP TO 1500 LBS/HR WET THROUGHPUT UP TO 2250 LBS/HR WET THROUGHPUT UP TO 3000 LBS/HR WET THROUGHPUT

UP TO 300 LBS/HR DRY THROUGHPUT UP TO 450 LBS/HR DRY THROUGHPUT UP TO 600 LBS/HR DRY THROUGHPUT

5-YEAR TRIMMER WARRANTY 5-YEAR TRIMMER WARRANTY 5-YEAR TRIMMER WARRANTY

2-YEAR LEAF COLLECTOR WARRANTY 2-YEAR LEAF COLLECTOR WARRANTY 2-YEAR LEAF COLLECTOR WARRANTY

NORTH AMERICA (60 HZ) EUROPE (50 HZ)

COMPONENTS MOTOR QUANTITY VOLTS AMPS HP PHASE VOLTS AMPS HP PHASE

XL 5.0

Main Power 220V 150A −3PH 380V 100A −3PH

Infeed Conveyor 1220V 1.6A 1/2HP 3PH 380V 1A 1/2HP 3PH

Tumbler/Blade Motor 5220V 3A 1HP 3PH 380V 1.6A 1HP 3PH

Outfeed Conveyor 1220V 3A 3/4HP 3PH 380V 1.9A 3/4HP 3PH

Leaf Collectors 5220V 18A 6HP 3PH 380V 8A 6HP 3PH

XL 5.0 SE

Main Power 220V 150A −3PH 380V 100A −3PH

Infeed Conveyor 1220V 1.6A 1/2HP 3PH 380V 1A 1/2HP 3PH

Tumbler/Blade Motor 5220V 3A 1HP 3PH 380V 1.6A 1HP 3PH

3rd Blade Motor 5220V 1.4A 1/4HP 3PH 380V 1A 1/4HP 3PH

Outfeed Conveyor 1220V 3A 3/4HP 3PH 380V 1.9A 3/4HP 3PH

Leaf Collectors 5220V 21A 8HP 3PH 380V 11A 8HP 3PH

XL 10.0

Main Power 220V 150A −3PH 380V 100A −3PH

Infeed Conveyor 2220V 1.6A 1/2HP 3PH 380V 1A 1/2HP 3PH

Tumbler/Blade Motor 5220V 3A 1HP 3PH 380V 1.6A 1HP 3PH

Outfeed Conveyor 1220V 3A 3/4HP 3PH 380V 1.9A 3/4HP 3PH

Leaf Collectors 5220V 21A 8HP 3PH 380V 11A 8HP 3PH

TEST YOUR ELECTRICAL CURRENT TO MAKE SURE IT IS PRODUCING POWER. WE RECOMMEND HAVING A CERTIFIED ELECTRICIAN SET UP THE

PROPER POWER SUPPLY. THIS WILL ENSURE YOUR POWER SOURCE IS SUPPLYING THE CORRECT ELECTRICITY. IF YOU HAVE NOT DONE THIS,

HAVE A CERTIFIED ELECTRICIAN COME AND TEST YOUR ELECTRICAL CURRENT.

20 cprosolutions.com1 855 535 0558

HEMP &CANNABIS HARVESTING SOLUTIONS

This manual suits for next models

3

Table of contents

Other CenturionPro Trimmer manuals

CenturionPro

CenturionPro GC1 User manual

CenturionPro

CenturionPro Original User manual

CenturionPro

CenturionPro DBT 4 User manual

CenturionPro

CenturionPro THE MINI User manual

CenturionPro

CenturionPro 3.0 User manual

CenturionPro

CenturionPro The Gladiator User manual

CenturionPro

CenturionPro Original User manual

Popular Trimmer manuals by other brands

Zenoah

Zenoah EXZ2610DL owner's manual

Gardena

Gardena EasyCut 40/18V P4A Operator's manual

Flymo

Flymo Power-Trim PN 248722 Operator's manual

Dolmar

Dolmar HEDGE HT-345 Owner's and safety manual

American Gardener

American Gardener ReadyHedger RH18 instruction manual

EINHELL

EINHELL GE-EH 6056 Original operating instructions