CLINTON INDUSTRIES 189 User manual

ML189-3A

CLINTON'S

MODEL 189

UNDERBED TRIMMER

FOR

SINGER 591

SERVICE

MANUAL

40-0152-01

ML1889-25B

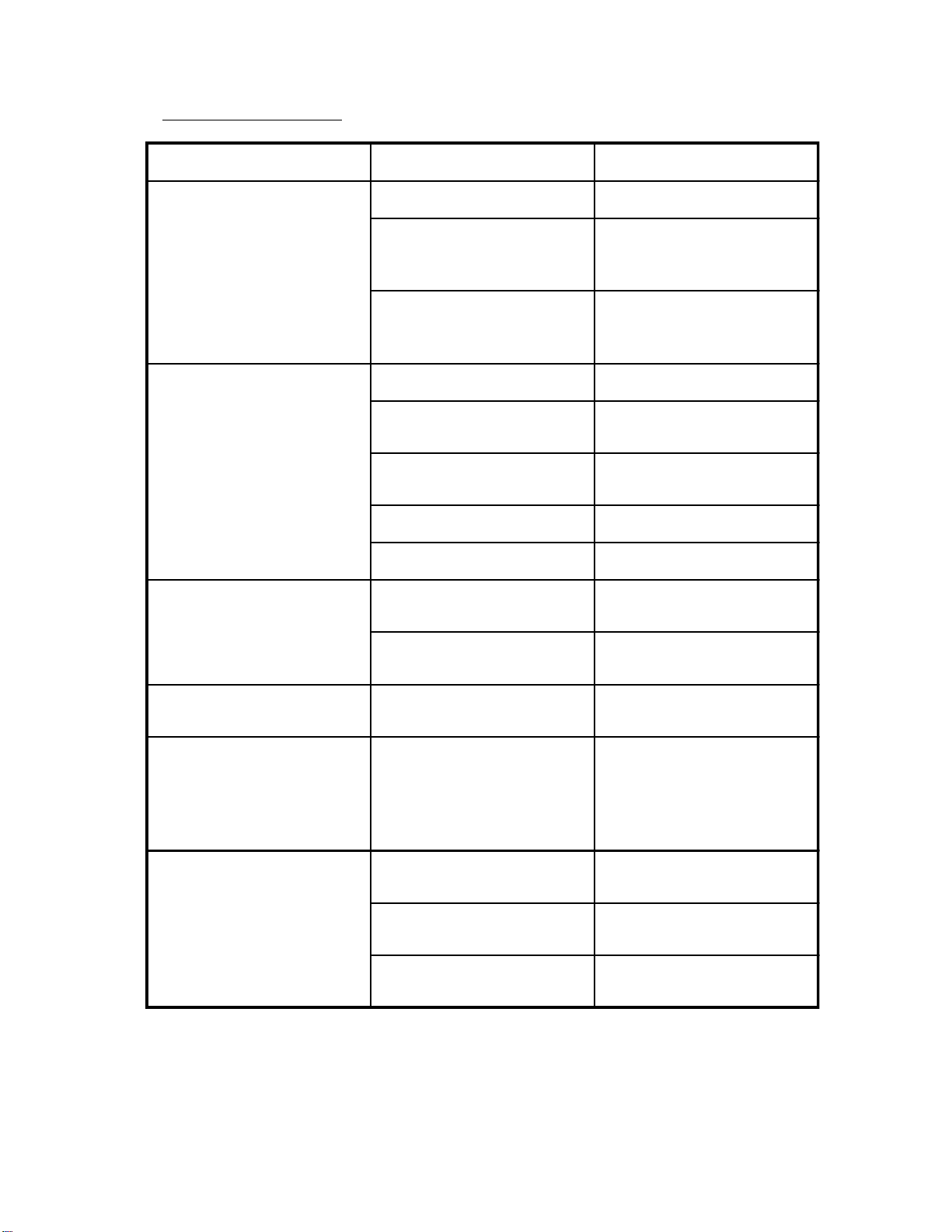

TABLE OF CONTENTS

THREAD TRIMMER SECTION

SECTION I - GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

A.

B.

C.

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIMMER COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . .

1

1

1

SECTION II - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SECTION III - AIR CIRCUIT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

A.

B.

C.

NEEDLE COOLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIM VALVE AND PILOT VALVE . . . . . . . . . . . . . . . . . . .

FOOTLIFT, FOLDER OPENER & THREAD BLOWER . .

2

2

3

SECTION IV - ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

A.

B.

C.

D.

TRIMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THREAD PULLOFF CYCLE TIME . . . . . . . . . . . . . . . . . .

TRIM CYLINDER SPEED . . . . . . . . . . . . . . . . . . . . . . . . .

NEEDLE THREAD BLOWER BLAST TIME . . . . . . . . .

3

4

4

4

SECTION V - TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION VI - PARTS DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

ML1889-26

I. GENERAL INFORMATION

A. INTRODUCTION

The air Operated Underbed Trimmer contains a trimming system that cuts both the

needle and bobbin threads simultaneously. A movable and a stationary blade, mounted

on the throat plate are used in combination to pick up and cut the threads.

Solid state electronics are used to sense the position of the needle and to trigger the

trimming mechanism at the proper time as well as to control footlifting and backtacking

operations.

B. APPLICATION

The underbed Trimmer/Positioner enables the operator to automatically control the

position of the needle in or out of the work, thereby eliminating the need for hand position-

ing. In addition, the top and bottom threads are automatically cut beneath the throat

plate after positioning. This eliminates the need for hand trimming.

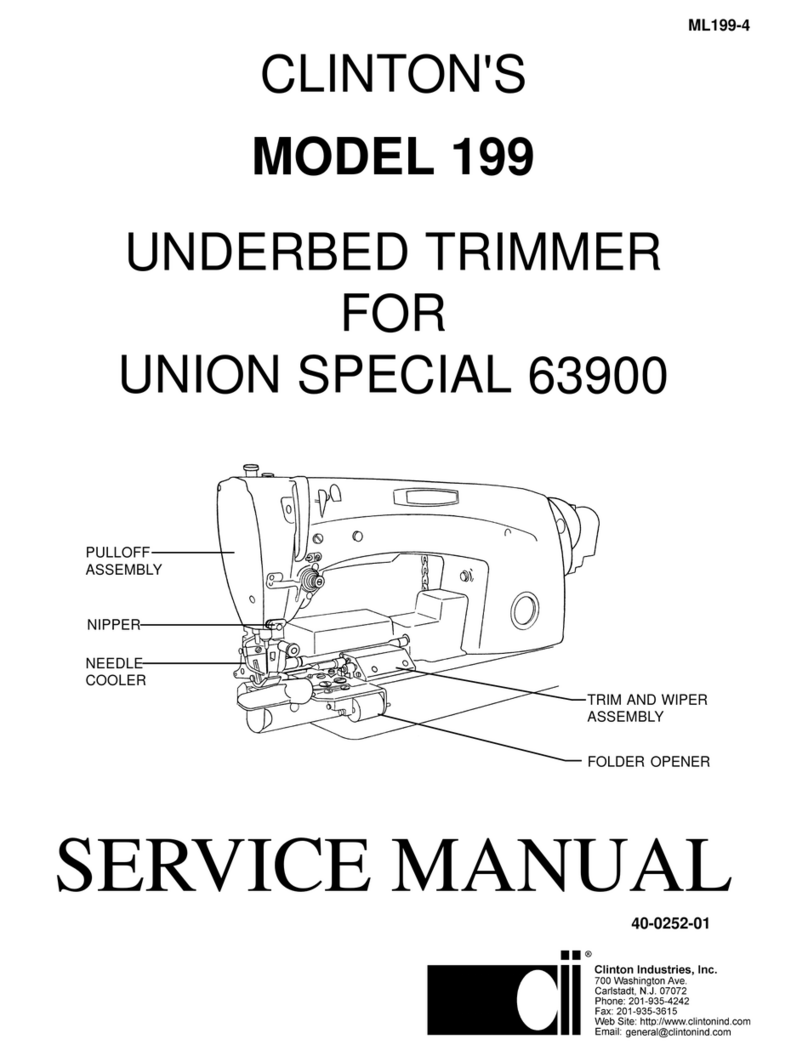

C. TRIMMER COMPONENTS

The trimmer components, which can be either pre-installed on the sewing machine head

and factory tested, or field installed, include:

1. Standard Components

a. Thread Cutter Assembly

b. TensionReleaseAssembly

c. Needle Thread Pulloff Assembly

d. Needle Thread Blower and Needle Cooler Assembly

e. Foot Lifter

f. FolderOpener

g. Solenoid Air Valve Control Unit

- 1 -

ML1889-27

II. INSTALLATION

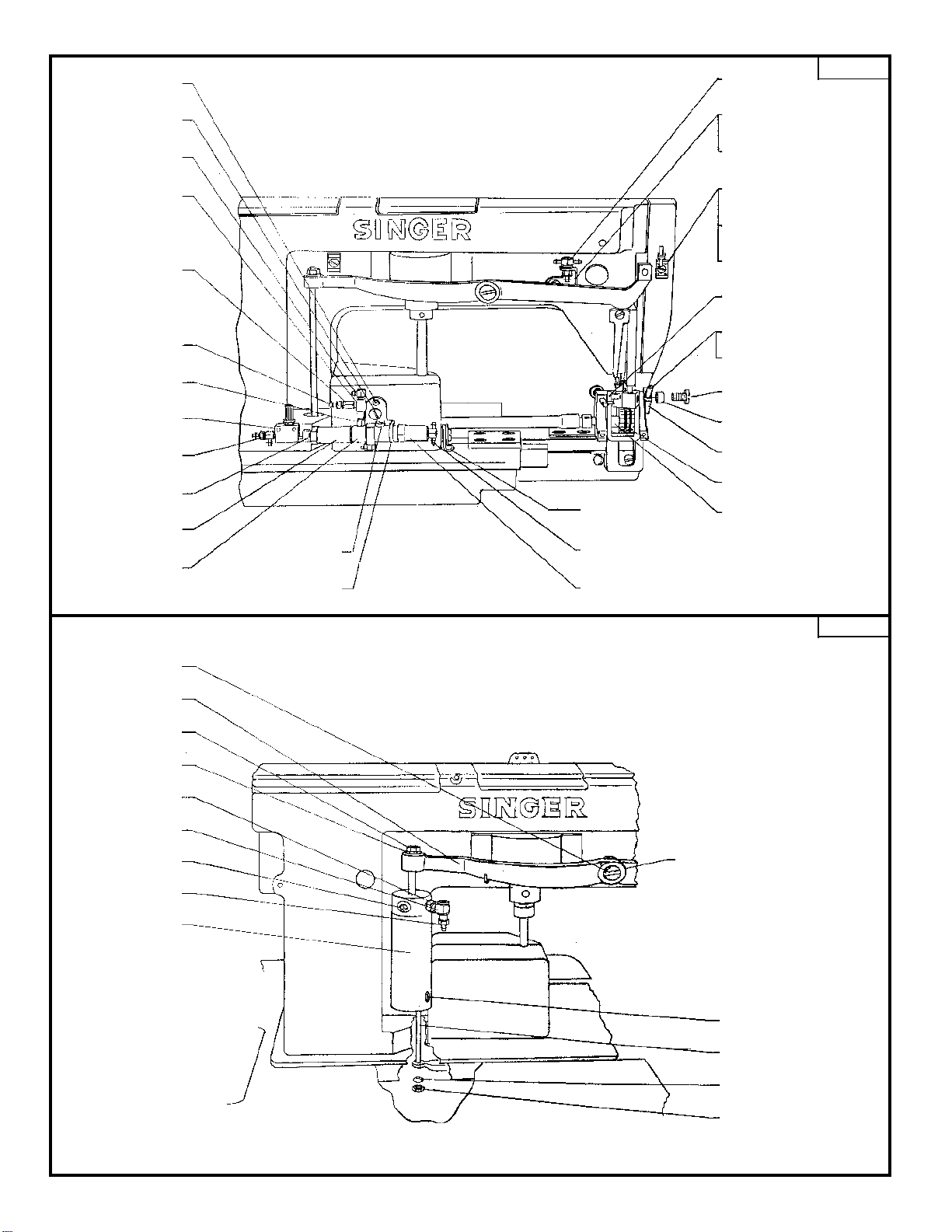

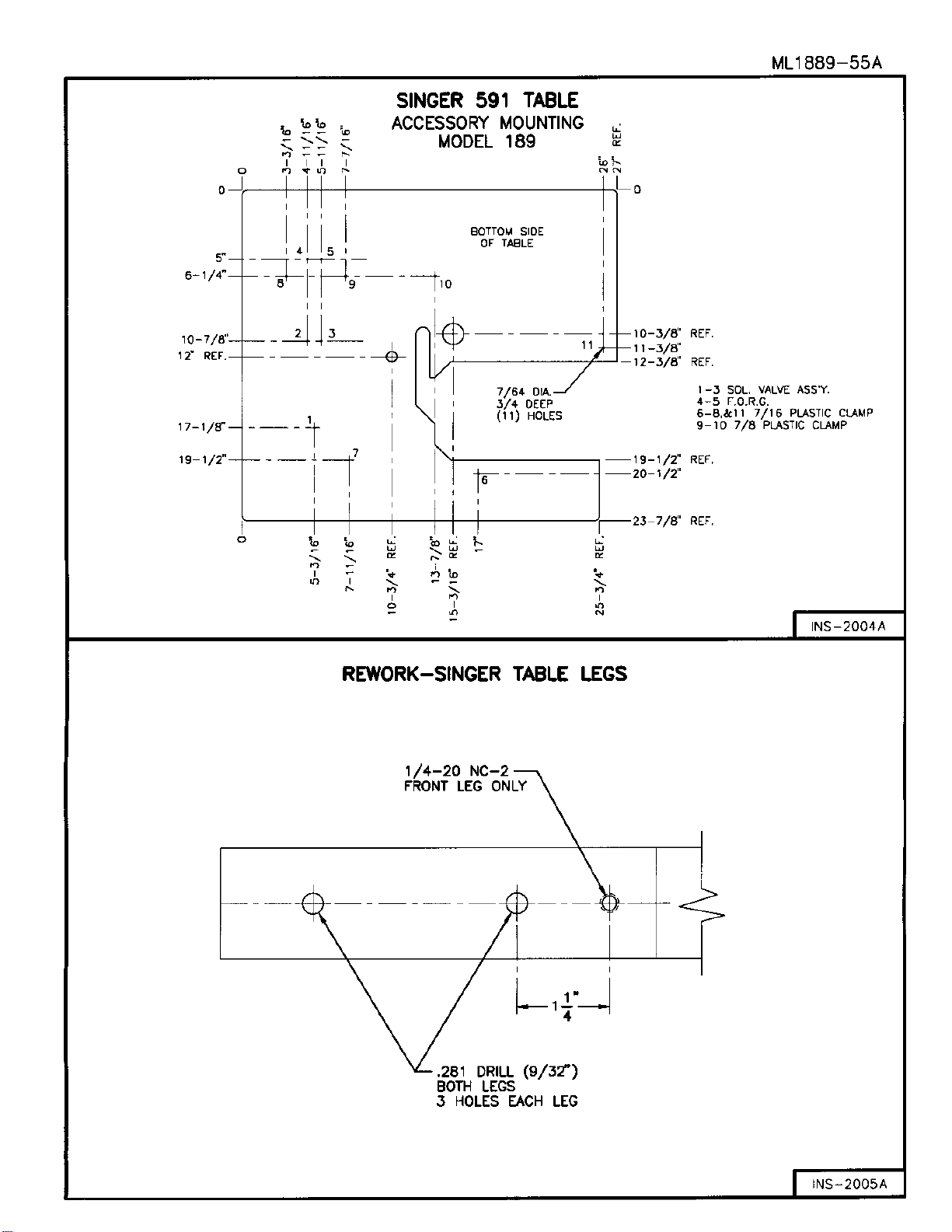

A. Install the solenoid air valve assembly under the table as shown in drawing INS-1954.

B. The treadle air valve is used in place of the treadle rods for the needle cooler. Refer to

speed control installation on page 7.

C. The folder opener air valve is installed as shown in (INS-1955). This should be placed in

a position convenient to the operators right knee.

D. Set the machine head in the table and install the "V" belt.

E. Connect all electrical cables tot he control box.

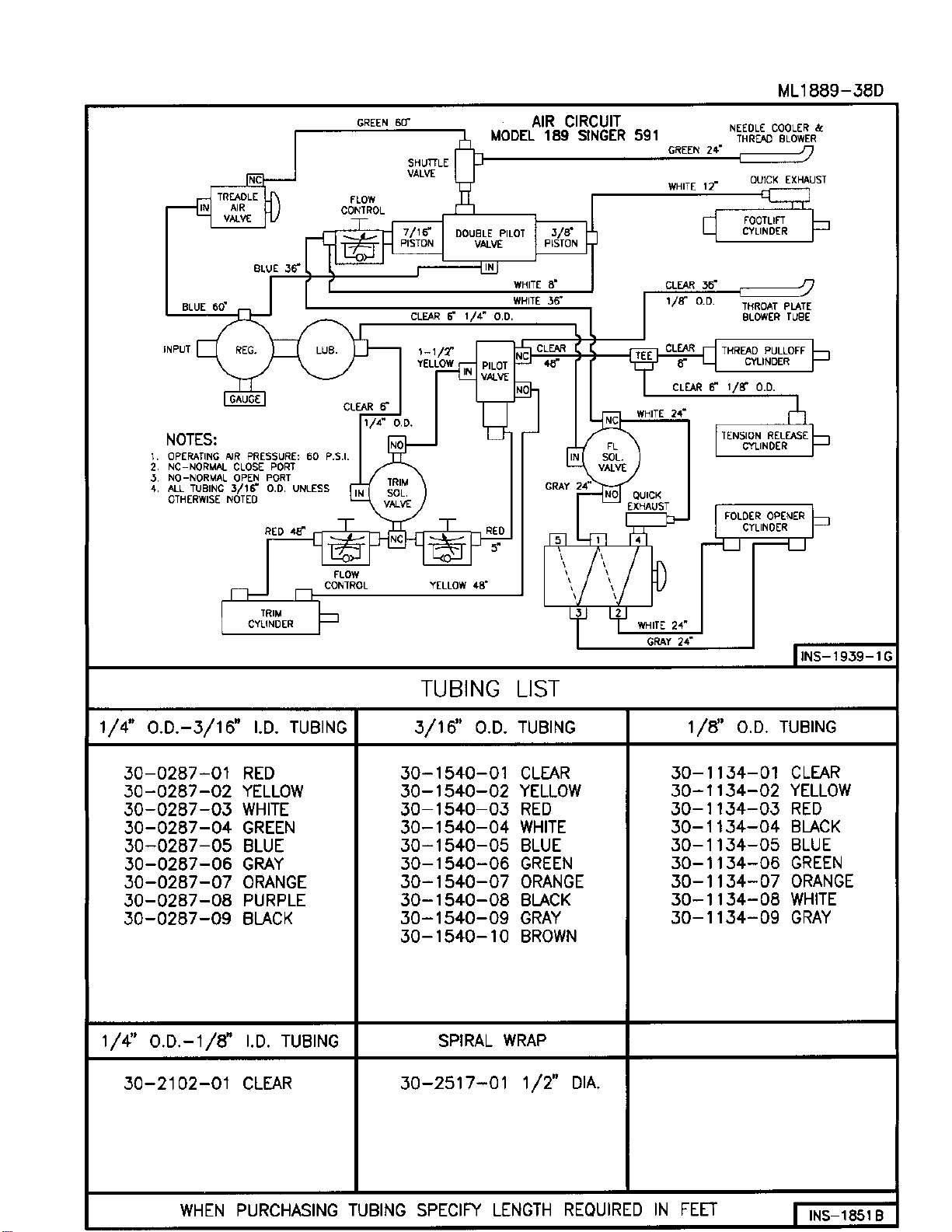

F. Connect all air lines as shown in circuit diagram drawing INS-1939-1.

Note: Do not connect the air supply at this time.

G. Thread the machine and sew on material being used for the operation.

H. When heeling the treadle observe the 6 o'clock positioning of the thread across the hook.

If it is not between 5 and 6 o'clock readjust as described under synchronizer timing page

11.

I. Connect the air supply then sew and operate the trimmer. Refer to section III for air

circuit operations and section IV for adjustments.

III. AIR CIRCUIT OPERATION

A. NEEDLE COOLER

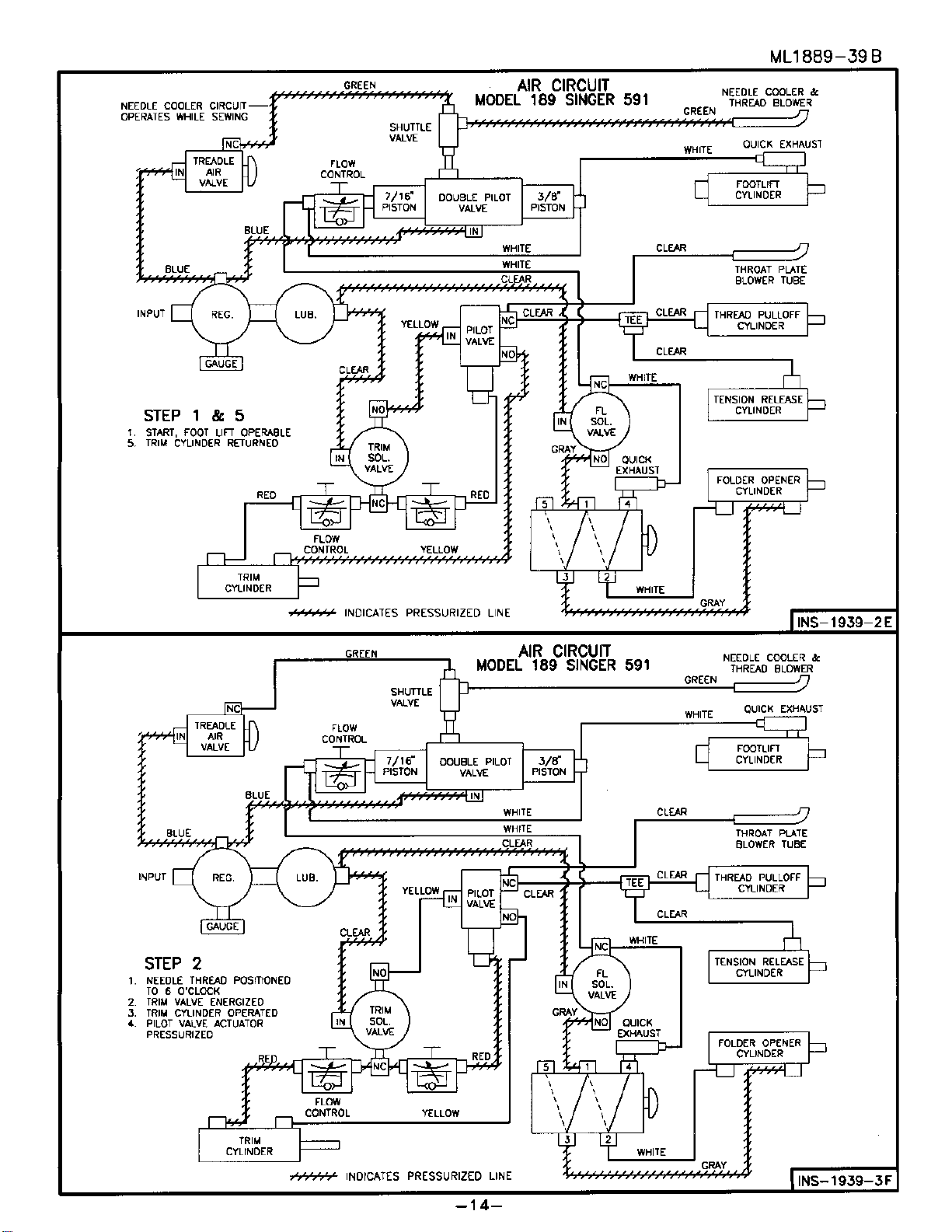

Air is distributed throughout the circuit as shown in INS-1939-2. When the treadle is

pushed forward for sewing the treadle valve is opened and air flows to the needle cooler

tube.

B. TRIM VALVE AND PILOT VALVE

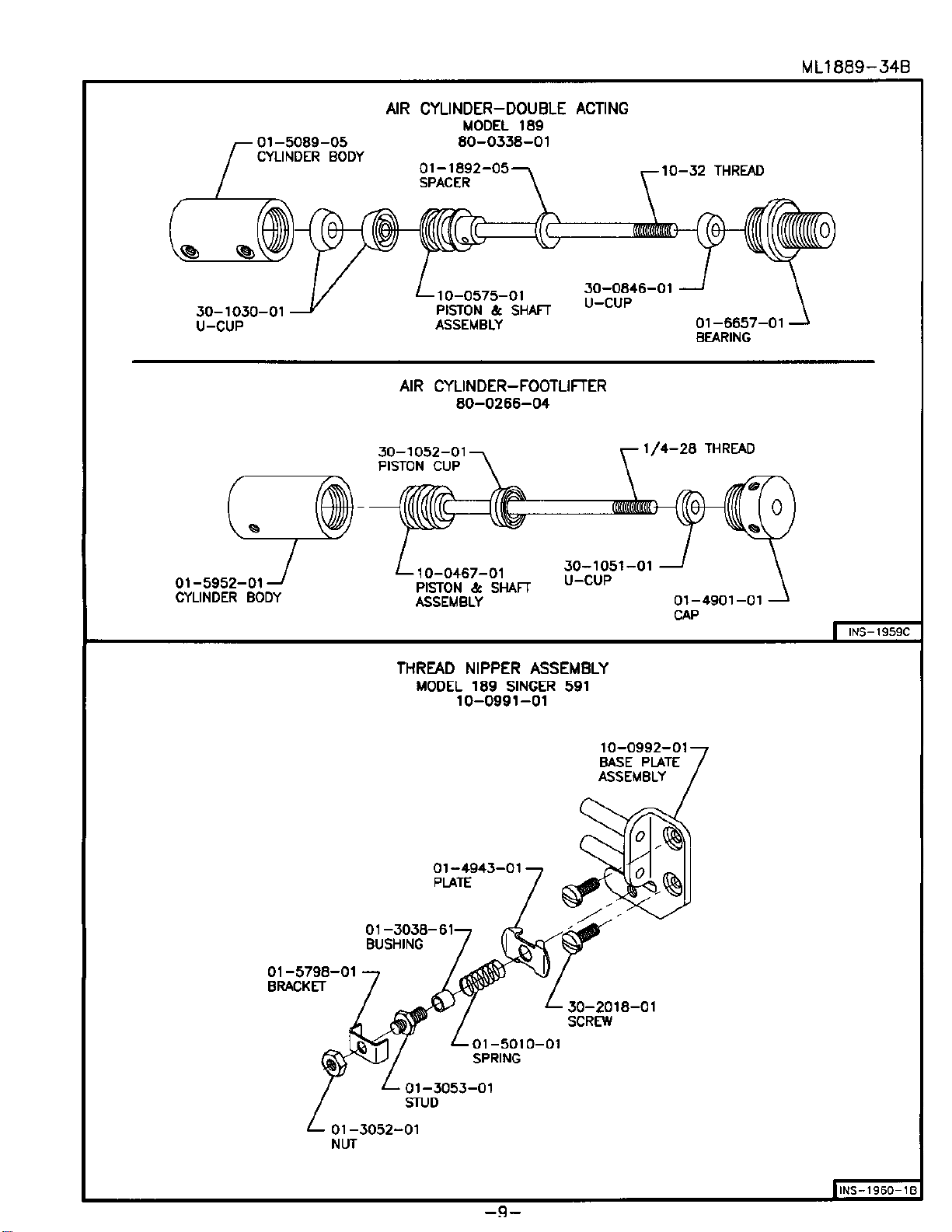

At the end of the sewing operation the brake is applied and the needle positioner is

activated. The needle positioner will stop with the needle thread across the hook in the 6

o'clock position. The trim solenoid valve will energize. (See INS-1939-3). The trim

cylinder operates. The pilot valve actuator is pressurized shifting the pilot valve. There is

no air flow through the pilot valve since there is no pressure at the input.

- 2 -

ML1889-28

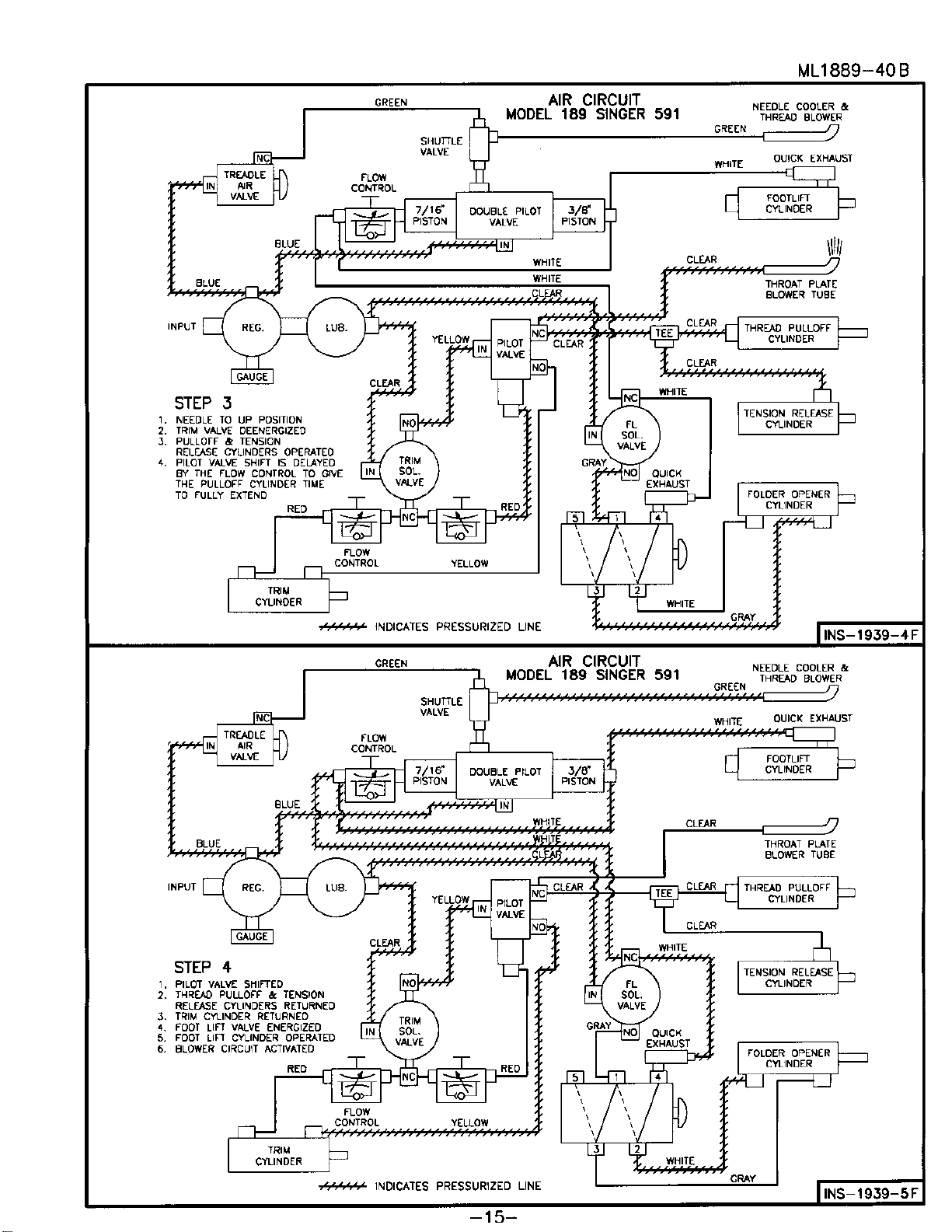

The needle is raised to the up position and the trim valve is deenergized.

(See INS-1933-4). The flow control in the pilot valve actuator circuit leaks the air slowly

from the actuator keeping the valve shifted. Air is applied to the IN port through the NC

port, now open, to the thread pulloff cylinder, tension release cylinder and throat plate

blower tube.

The pilot valve returns (INS-1939-5). Air is applied to the trim cylinder to return the

blade. The rate or speed of return is controlled by the flow control which controls the air

exhausting from the trim cylinder. This control is used to minimize bobbin spin.

C. FOOTLIFT, FOLDER OPENER andTHREAD BLOWER

While the treadle brake is still applied the foot lift solenoid valve will energize

(see INS-1939-5). Air is applied to the foot lift cylinder and the folder opener. The folder

can be operated independent of the footlifter at any time in the cycle with a knee oper

ated air valve.

At the same time air is applied to the double pilot valve actuators. One actuator has a

larger piston than the other. The larger piston will have more force than the smaller one

at the same pressure. The air flow to the larger piston is restricted by the flow to the

larger piston is restricted by the flow control When air is first applied the smaller piston

will shift the valve and open the port to the shuttle valve. Air will flow to the needle

thread blower. Pressure is slowly increasing in the larger piston until it overcomes the

other and shuts off the air supply to the blower.

IV. ADJUSTMENTS

A. TRIMMER

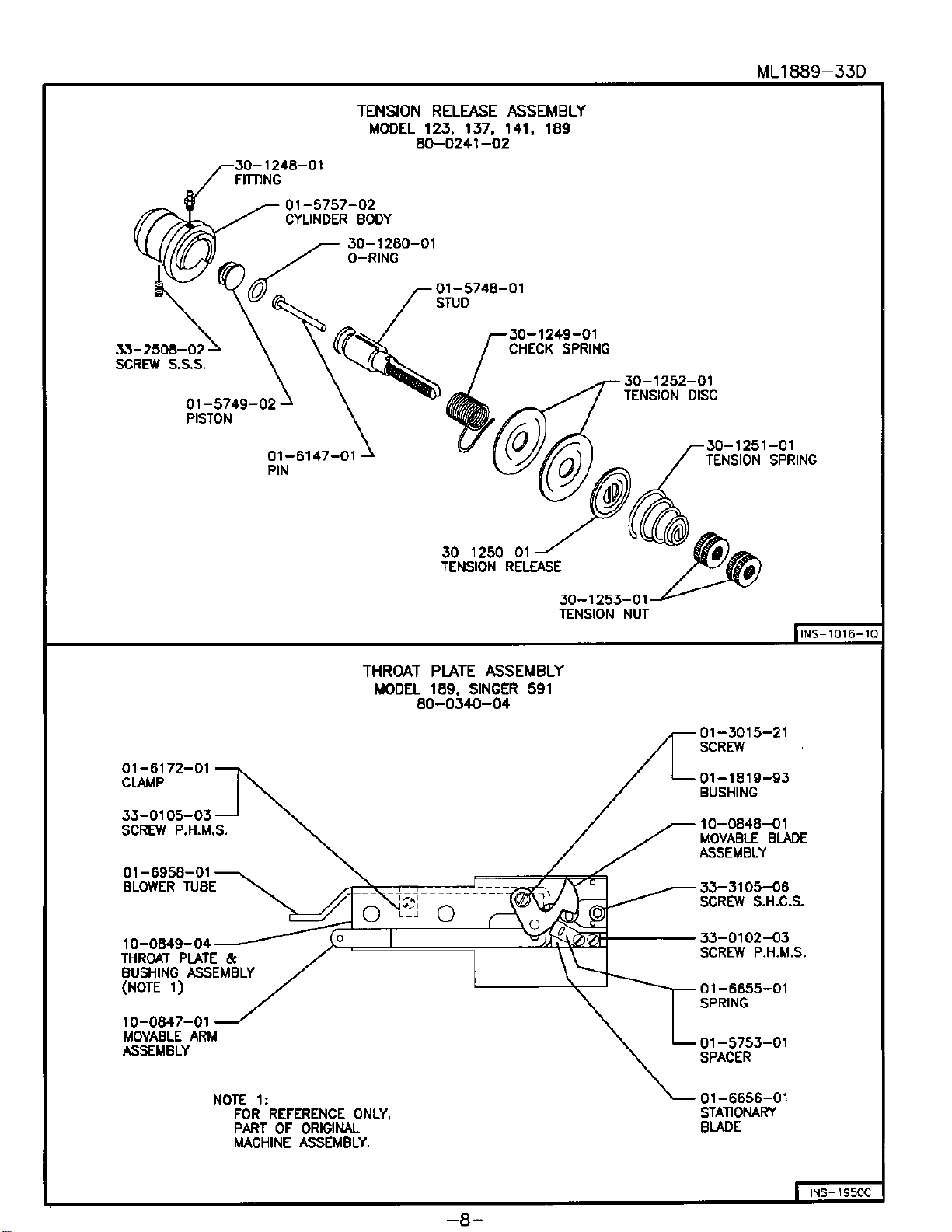

1. Cutter Assembly

In the cut position the cutting edge of the movable blade should pass the cutting

edge of the stationary blade about 1/16". If adjustment is required loosen the lock

nuts on the cylinder shaft and adjust as required.

The pickup position on the movable blade is controlled by the stroke length of the

cylinder and proper positioning of the cutting edge as above.

2. Thread Pulloff and Tension Release

No adjustment is required for the Thread Pulloff and Tension Release assemblies for

trimmer operations. If check spring adjustment is required for stitch formation,

remove the assembly from the machine, loosen the stud lockscrew, adjust spring

tension, tighten lockscrew and replace assembly.

- 3 -

ML1889-29

B. THREAD PULLOFF CYCLE TIME

The flow control in this circuit determines the time these cylinders have to complete

their stroke. Too much time will show a noticeable hesitation before return of the pulloff

cylinder. If the time is short the cylinder will not complete its stroke. Turning is (cw) will

increase time, turning out (ccw) will decrease time.

C. TRIM CYLINDER SPEED

Turning the flow control needle in (cw) will slow down the cylinder and reduce spin.

Turning out (ccw) will increase cylinder speed. If cylinder speed is too slow the presser

foot will rise before the thread is cut and the operator could start removing the garment

too soon. If this happens the cylinder speed should be increased and some mechanical

device such as star springs used in conjunction with the flow control to reduce spin.

D. NEEDLE THREAD BLOWER BLAST TIME

The duration of this blast is controlled by the flow control mounted to the larger actuator.

Turning in (cw) increases time turning out (ccw) decreases time. About one second is

enough to give the operator time to remove the garment and blow the thread above the

foot. Should the operator be delayed in removing the garment the thread will remain

under the foot. If the foot is lowered and again raised the above sequence will repeat.

- 4 -

- 5 -

PROBLEM CAUSES CORRECTIVE ACTION

Needle thread not cut.

Bobbin thread is cut

Defective PC Board Replace board

Movable blade missed

needle loop Check synchronizer timing

to see that trimmer is fired

at correct time

Binds in trimmer linkage Locate and remove bind. A

light bind would slow it

enough to miss needle loop

Both threads not cut not

picked up

Defective movable blade Replace

Water in air lines Check filter. Remove water

from air lines

Defective solenoid air valve

or air cylinder Repair or replace

Defective PC board Replace board

Binds in trimmer linkage Locate and remove bind

Both threads picked up, not

cut

Defective movable or

stationary blade Replace

Stroke misadjusted failing

to reach cutting position Readjust

Needle thread cut short Pulloff cylinder improperly

adjusted Readjust

Long tail left on top side at

start of sewing Blower not operating

causing thread to be

trapped under presser foot.

Operator not removing

garment fast enough

Check blower circuit qand

flow control adjustment. If

blower time is short

readjust flow control to

increase

Bobbin thread is cut short

Bobbin tension too tight Loosen bobbin tension as

much as possible

Bobbin thread slipped out of

hook on case Run Bobbin thread through

hook

Bobbin case without hook

being used Replace with correct bobbin

case

ML1889-30A

V. TROUBLE SHOOTING

ML1889-31C

INS-1940E

INS-1944F

FOLDER ASSEMBLY

MODEL 189

SINGER 591

80-0384-01

01-3066-01

SCREW

01-3286-01

BUSHING

FOLDER ASS'Y

SEE NOTE

30-1936-01

AIR CYLINDER

33-1508-01

HEXNUT

33-0706-24

SCREW-FIL.H.M.S.

33-1806-01

INTERNAL TOOTH WASHER

30-1783-01

ELBOW

01-6939-01

FACE PLATE

10-0991-01

THREAD NIPPER

ASSEMBLY

30-1729-01

AIR FITTING

80-0338-01

AIR CYLINDER

01-3061-11

SCREWF.H.M.S.

01-6947-01

BRACKET

33-1628-02

HEXNUT

THREAD PULLOFF AND CUTTER DRIVE ASSEMBLY

MODEL 189

SINGER 591

80-0382 -01

80-0383-01

01-6940-01

BLOCK

33-3105-05

SCREWS.H.C.S.

33-1805-01

LOCKWASHER

30-0463-01

RETAINING

RING

01-3800-01

PIN

01-6941-01

ROD

30-1164-01

NUT

01-6942-01

BLOCK

01-6944-01

NUT

30-0813-01

O-RING

01-6945-01

ESNA NUT

30-0920-01

AIRCYLINDER

30-1729-01

AIRFITTING

01-6943-01

ROD

30-0618-01

NUT

01-4907-01

LINK

NOTE: ALL PARTS NOT IDENTIFIED ARE SUPPLIED BY SINGER. SEE SINGER PARTS MANUAL.

33-1710-01

FLAT WASHER

33-1506-01

HEXNUT

ML1889-32D

30-1124-01

PLUG

01-6953-01

BRACKET

30-0139-01

CLAMP

30-1800-01

TEE

30-1258-01

PILOTACTUATOR

33-0105-04

SCREW-

P.H.M.S.

EXISTING

SCREW

30-1783-01

ELBOW

30-1615-01

VALVE

30-1648-01

COUPLING

30-1729-01

TUBEFITTING

30-1749-01

COUPLING

30-0819-01

FLOWCONTROL

30-1896-01

TEE

30-1104-01

REDUCER

30-1754-01

PILOTACTUATOR

30-1935-01

VALVE

FOOTLIFTER ASSEMBLY - MANIFOLD ASSEMBLY

MODEL189

80-0180-87

SINGER 591V

33-2210-03

SCREW-S.S.S.

01-6818-01

ROD

545873- SWIVEL SINGER PART

(SEENOTE)

30-0618-01

ELASTICSTOPNUT

NOTE:

REMOVETHECONNECTING ROD SWIVEL

FROMTHELIFTER ARM ANDTRANSFER IT

TOTHELOWER BELL CRANK. RETAIN THE

SWIVEL WITH 30-0618-01 ELASTIC STOP

NUT.

REMOVESPACER FROM UNDERTHE HEAD

OFTHE PIVOTSTUD AND PLACE IT

BETWEENTHE LIFTER ARMAND THE

MACHINE. THIS WILL SPACE THE ARM 1/8"

FURTHERFROMTHEMACHINE. IF

ADDITIONALCLEARANCE IS NECESSARY,

USE01-4379-01 SPACER AS REQUIRED.

C'BORELIFTERARM EQUALTOTHE

SPACERS USED. EACH SPACER IS

.082 THICK.

PIVOTSTUD

LIFTERARM

33-1616-02

JAMHEX NUT

01-6817-01

NUT

30-1104-01

REDUCER

30-1615-01

QUICKEXHAUST

30-1299-01

PIPEPLUG

30-1729-01

FITTING

80-0266-04

AIRCYLINDER

NEEDLE THREAD BLOWER AND PRESSER FOOT ROLLER ASSEMBLY

MODEL189

80-0386-01

80-0413-01

SINGER 591

30-2125-01

BULKHEADTEE

01-6971-01

BRACKET

33-0106-04

SCREW-P.H.M.S.

30-1940-01

TIEANCHOR

30-1382-01

CABLETIE

33-0106-03

SCREW-P.H.M.S.

01-6956-01

SHANK

01-6955-01

TUBE

30-2024-01

TUBELOCK SCREW

30-1559-02

SCREW

01-1829-21

BUSHING

01-6954-01

BLOCK

01-7557-01

DRIVEROLLER

01-2221-02

SPACER

INS-1953C

INS-2016D

SPIRAL WRAP INSTALLATION

MODEL 189

UNION SPECIAL 63900

ML1889-58B

30-2517-01

SPIRAL WRAP

(1/2" DIA.)

ML-000-5B

30-1160-01

BONNET

30-1108-01

FILTER ELEMENT

5 MICRON 30-1561-01

BOWL

30-1085-01

BOWL

30-1610-01

LUBRICATOR

REPAIR KIT

(CONTAINS ITEMS

18,20,22)

30-2788-01

FILTER/REG.

REPAIR KIT

(CONTAINS ITEMS

3,4,5,6,7,8,10,14,16)

INS-2100-2A INS-2100-1B

FILTER, REGULATOR, AND LUBRICATOR

30-2347-01

FILTER/REGULATOR

OPERATION

AIRENTERS THE INTEGRALFILTER/REGULATORUNITAND IS DIRECTEDDOWNWARD

THROUGH A SET OF LOUVERS (10) TOIMPART A WHIRLING ACTION. THIS CENTRI-

FUGALACTION CAUSES LIQUIDPARTICLESTOBE SEPARATED FROMTHE AIRSTREAM

ANDSETTLE TOTHE BOTTOM OF THEBOWL. ACCUMULATEDLIQUID ISDRAINED

MANUALLY (15).

AIRTHENPASSES THROUGHTHE SINTEREDBRONZEFILTERELEMENT (11)WHERE

SMALLERSIZE FOREIGN PARTICLES AREREMOVED.

THECLEAN AIR PASSES THROUGHTHE VALVE (5,6,7,8) OF THE REGULATOR AND IS

CONTROLLEDTOAPRESSURE,DETERMINED BY THEADJUSTMENTOF THE REGULATOR.

PRESSUREIS INCREASEDBY ROTATINGTHE KNOB CLOCKWISE, OR DECREASED BY

ROTATINGTHEKNOBCOUNTERCLOCKWISE.

CAUTION: THIS MINIATURE INTEGRAL FILTER/REGULATOR SHOULD NOT BE USED IN

APPLICATIONS WHICH MAY EXCEED 250 PSIG. DURING MAINTENANCE PERIODS,

INSPECT AND CLEAN EACH PART CAREFULLY, USING ONLY CLEAR, WARM

WATER OR KEROSENE. DO NOT USE SOLVENTS AS THE POLYCARBONATE BOWL

MAY BE DAMAGED.

MAINTENANCE:

REGULATORSECTION: DISASSEMBLETHE REGULATORSECTIONAS FOLLOWS: TURNOFF

AIRSUPPLY. TURNTHEADJUSTING KNOB COUNTERCLOCKWISETORELIEVE COMPRESSION

ONTHEREGULATINGSPRING (2). UNSCREWTHE BONNET (1),REMOVE THE REGULATING

SPRING (2), AND PISTON ASSEMBLY (4). UNSCREW THE VALVE SEAT (5) WITH A 3/8"

SOCKETAND REMOVE THE VALVEASSEMBLY (7) AND VALVE SPRING (8).

CLEANAND INSPECT EACH PART FOR WEAR ORDAMAGE. REPLACE IF NECESSARY.

CAUTION: WHEN REASSEMBLING, VALVE SEAT (5) SHOULD NOT BE TIGHTENED TO MORE

THAN 4 TO 6 INCH POUND TORQUE. BONNET ASSEMBLY (1) SHOULD BE

TIGHTENED 50 TO 60 INCH POUNDS TORQUE.

MANUALDRAIN FILTERSECTION: TOSERVICETHE FILTER SECTIONSHUT OFTHE AIR

PRESSURE. UNSCREWBOWL ASSEMBLY (14) ANDREMOVE "O" RING (9) UNSCREW STUD (13)

ANDFROM THESTUD REMOVEFILTERELEMENT (11),LOUVER (10)AND GASKETS (12).

THEFILTERELEMENT SHOULD BE CLEANED PERIODICALLY WITH KEROSENE AND BLOWN

OUTWITH COMPRESSED AIR.

AFTERCLEANING, INSPECTEACH PARTCAREFULLY,REPLACE ANYDAMAGED PARTS. WHEN

REASSEMBLING,TIGHTENSTUD (13)TO5 TO 10 INCHPOUNDS TORQUE.

LUBRICATOR

CAUTION: THIS UNIT HAS A POLYCARBONATE BOWL.

1. BESURE ITIS NOTMOUNTED WHERETEMPERATURESOF 125 FOR MORE WILL BE

NEARIT, OR ON A LINE WHERE AIRPRESSURE EXCEEDS 150PSI.

2. BEWAREOF CONDITIONS,FUMES AND FLUIDSTHAT WILLHARM THETRANSPARENT

BOWL.

3. TOCLEAN BOWL, RINSE OR WIPE WITH APETROLEUM SOLVENT ONLY,SUCHAS

KEROSENE,ORHOUSEHOLDDISHWASHERDETERGENT.

4. DO NOT USENEAR, ORCLEAN WITHSUCH MATERIALSAS ACETONE,ALCOHOL,

BENZENE,DIOXANE,ETHEL ACETATE, LACQUERTHINNER, TOLUENE,CHLORIDE,

CARBONTETRACHLORIDE, ALKALIES, AMINES,ESTERS, KETONESAND AROMATIC

HYDROCARBONS.

5. DO NOT INSTALL ON A COMPRESSED AIR LINE WHERE THECOMPRESSOR ISLUBRI-

CATED WITH,OR THE AIR CONTAINS,A SYNTHETIC,FIRE-RESISTANT LUBRICANT.

IMPORTANT: INSTALLATIONS INSTRUCTIONS FOR LUBRICATORS.

WHERE AND HOW TO INSTALL:

1. INSTALL AS CLOSE AS FEASIBLE TOEQUIPMENT TOBE LUBRICATEDWITH AIR

FLOWINGIN AND OUT PORTS SOMARKED.

2. TOFILLTHE LUBRICATOR,TURNOFF AIR PRESSURE, REMOVE BOWL AND FILL.

3. POURIN ONLYCLEAN OIL. SAE10 OR LIGHTER USUALLY IS BEST, NEVER USE

ONEOF THEFOLLOWING OILS: CELLULUBE #150 AND #220, KANO KROIL,

KEYSTONEPENETRATINGOIL #2 ORPYDRAUL AC.

4. AS SOON AS AIR PRESSURE REBUILDSINSIDE THEBOWL, OIL WILL DRIP THROUGH

THESIGHT GAUGE. CONTROL THERATEOF OIL ENTERINGTHE AIR STREAMBY

TURNINGTHE ADJUSTMENT SCREW DOWN TOGIVE LESS OIL AND UPTO GIVE MORE

OIL. THISIS AUNIQUE LUBRICATOR. YOUADJUSTTHIS TYPE SO THAT WHILE

THESMALLEST AMOUNT OFAIR IS FLOWINGTHROUGH IT YOUGET THEDESIRED

AMOUNTOF OIL FOR THATFLOW. THEMORETHE AIRFLOW INCREASES,THE MORE

OILYOU WILLNEED AND THE MORE YOU WILL GET AUTOMATICALLY.

HOWTOMAINTAIN:

1. PERIODICALLY CLEAN ADJUSTING SCREW NEEDLE VALVE AND SEAT BY SWISHING A

CLEANERAND BLOWING OFF WITH AIR.

2. DRAIN OFF ANYCONTAMINANTSOR WATERIF THEY SETTLEIN THEBOTTOM OF

THEBOWL.

30-2797-01

Table of contents

Other CLINTON INDUSTRIES Trimmer manuals