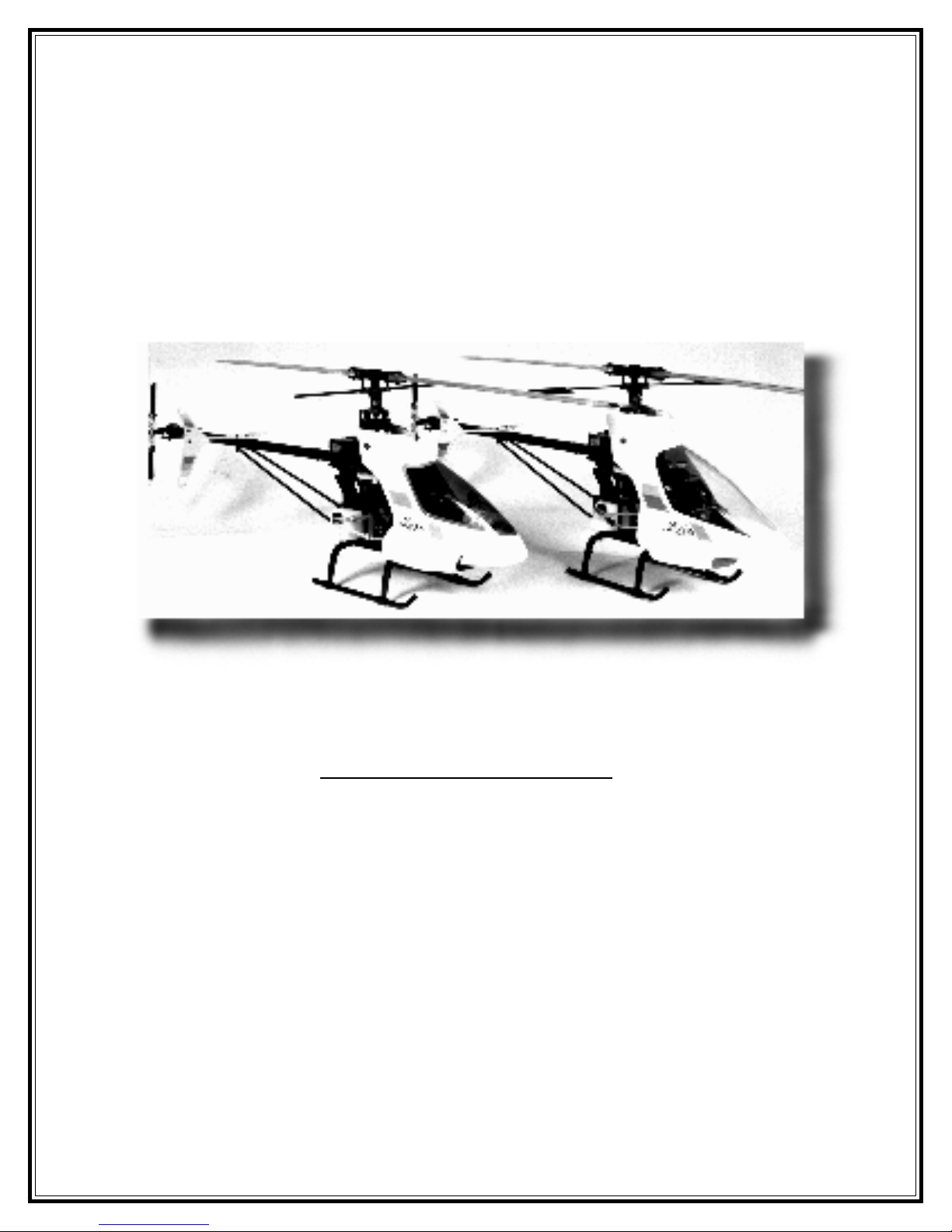

CENTURY PRODUCTS Pro Master User manual

Pro

Pro M

Master & Ninja Pro

aster & Ninja Pro

Instruction Manual

Instruction Manual

SPECIFICATION

* MAIN ROTOR DIAMETER 49.10 in.

* TAIL ROTOR DIAMETER 9.37 in.

* OVERALL LENGTH 44.90 in.

* HEIGHT 15.23 in.

* GEAR RATIO 9.6 : 1 : 5.5

* ENGINE 32 ~ 46

* WEIGHT 5.8 LB

CENTURY HELICOPTER PRODUCTS

9 / 1995

Building Instructions for Ninja Pro

Building Instructions for Ninja Pro

Helicopter Kit

Helicopter Kit

Congratulations you have just purchased the finest 30-46 size RC helicopter model on the market. The Ninja

Pro and Pro Master series of helicopters feature cutting edge design along with state of the art materials used

throughout. Modern composite G-10 is used for the side frames for strength and to minimize vibration.An all

metal swashplate, metal washout and metal main rotor head are used to give precise control and handling

characteristics.Your Ninja Pro has been carefully researched and developed to give the highest performance

level achievable with present technology. We are constantly reevaluating our line of kits as technology ad-

vances in order to give you the highest degree of performance at all times. The instruction manual is divided

into twenty sections.. The parts bags have also been separated into eleven different numbered bags. The bags

should be opened in their numbered sequence with the exception of bag # eight as this is the hardware bag

and will be used in all steps.

Explanation:

* This instruction is written for 4 types of Ninja series, Ninja Pro 30,

Ninja Pro 46, Ninja Pro 30 Master and Ninja Pro 46 Master.

* Use locktite at the point where this mark is shown.

* Use oil at the point where this mark is shown.

* Special attention at the point where this mark is shown caution !

OPERATE YOUR NINJA PRO HELICOPTER SAFELY

Your new Ninja Pro helicopter is state of the are using proven design techniques and the best materials

available. This is done for two reasons, first to give you the highest quality helicopter available and second,

to insure it’s SAFE operation. It is imperative that the instructions be followed carefully during construction.

This will insure that your Ninja Pro is properly assembled and safe to operate. We are not responsible for

any damages or injuries caused by improper building, careless flying practices or the use of non-

factory parts.We can not stress the importance of using ONLY factory replacement parts for your Ninja Pro.

Every part in your Ninja Pro Kit has been thoroughly tested and made from the best materials.After market

parts may substandard and will compromise the safety of yourself and others at flying field. While flying,

always do so away from any obstacles. This includes trees, power lines, animals, people...... in the other

words, ANYTHING that can be hit if your model should go out of control. It is strongly recommended that

you NEVER go flying alone, a second person can warn you if anything comes into your flying area.

22

22

2

EDED

EDED

ED

33

33

3

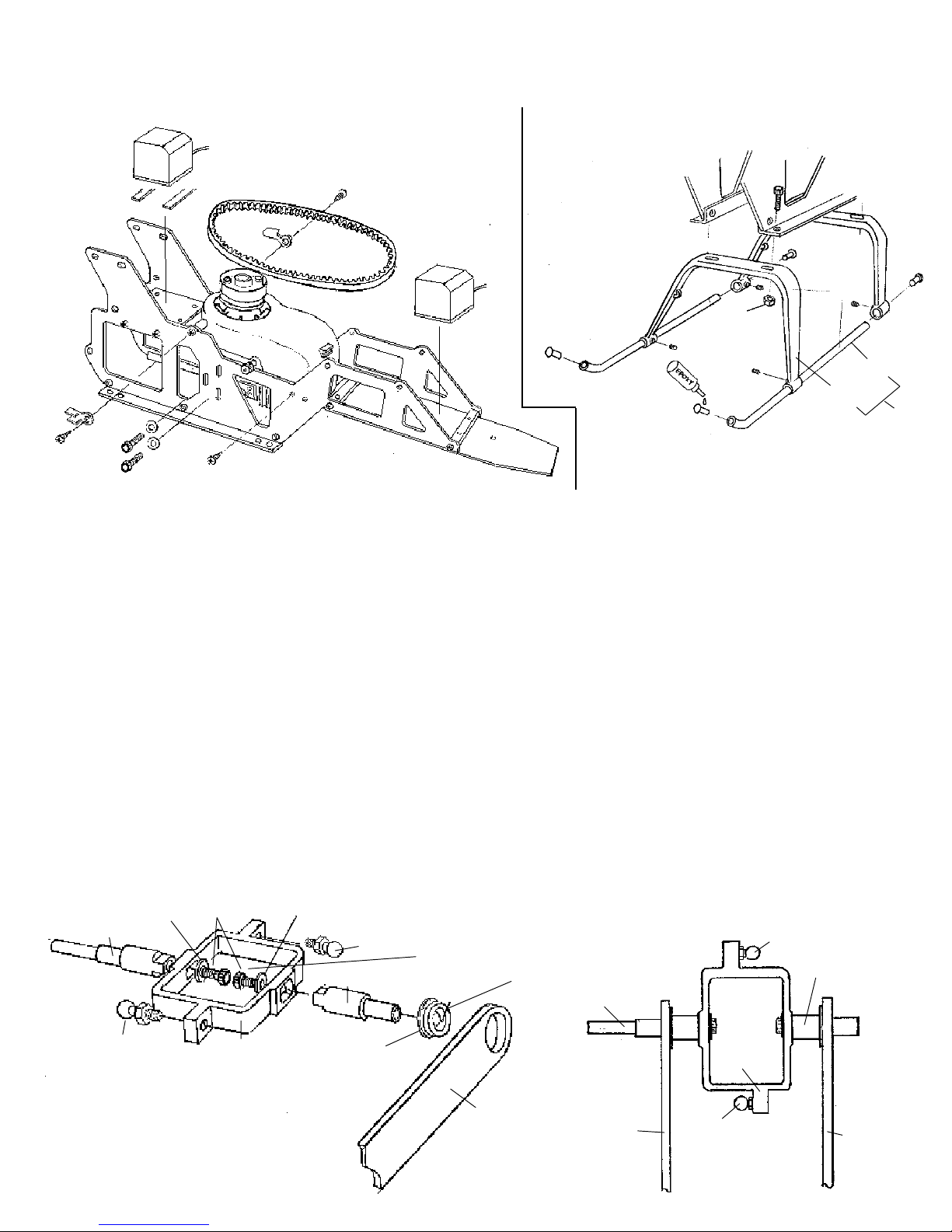

Step 1 Lower side FrameAssembly

1. Attach the 90 degree aluminum angle support (2002-079 Bag #1) to the “inside” of the lower side frame. See

drawing below. Do this for the left and the right side. Each bracket is held on with three M3x8 cap head bolts and

Locknuts.

2.Attach two plastic battery tray mounts (2002-055 Bag #4) between the two lower side frames using four M3x8 self-

tapping screws. Install the battery tray plate (2002-113 Bag #1) using four M3x8 self-tapping screws. Please note that

there has been a change in the servo tray length. The mounts must be located at the very front and rear of the available

locations. Double check to make sure that the hole provided for the front cannot mount is on the proper side of the

battery tray.

3.Attach the two gyro plate cross members (2002-055) between the side frames using four M3x8 self-tapping screws.

Add gyro plate (2002-119 Bag #1) on top of the cross members with four M3x6 countersink screws.An optional gyro

location would be on the battery tray.This should only be considered if a center of gravity change is deemed necessary.

44

44

4

M3X10

103

147

149

151

099

M3X12

M3X10

147 MASTER

302

103 M3X10

097

096

101

M3X12

46 CUT THIS

AWAY

057

115

057

M3X8 Self

Tapping

M3X8 Self

Tapping

M3X6

098

101

bent here to fit

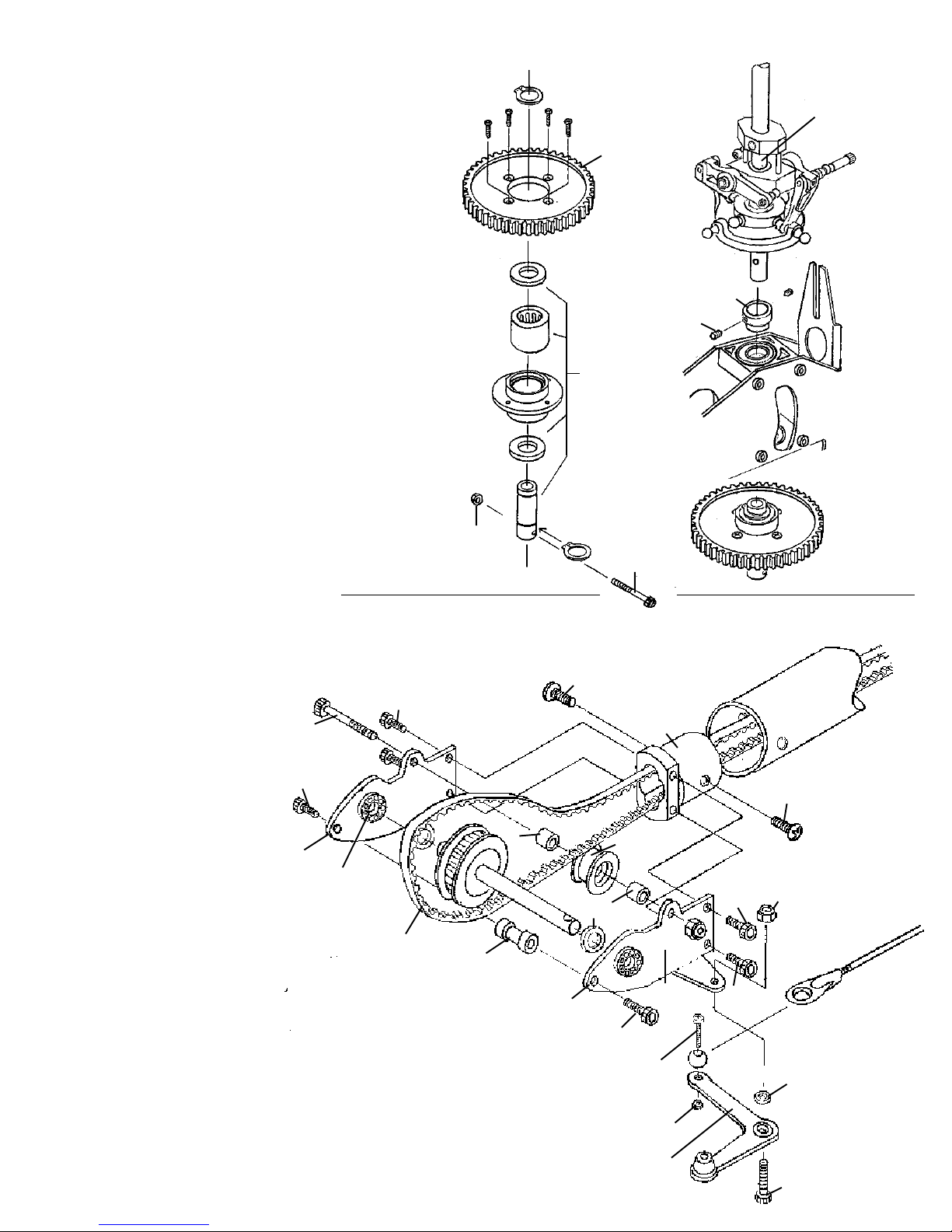

Step 2 Engine/Clutch Assembly

Slide the cooling fan (2002-115 Bag #1 for 30-size and 2002-097 Bag #2 for 46-size) onto the engine crankshaft. Then

slide the starter pulley (2002-149 Bag #4) on top of the fan. Add the engine nut and tighten it, but do not use any

Locktite. Install the centrifugal clutch (2002-147 Bag #4) to the pulley with two M3x10 bolts. Put the ball bearing

(2002-103 Bag #4) in the center of the clutch.

For 30-size engine: Install the engine to the engine mount (2002-099 bag #2) using four M3x12 bolts. Take the engine

assembly and slide it into the side frames from the top side. Use four M3x10 bolts and four washers to secure the

engine mount to the side frames. Do not tighten the four bolts completely. The position will be adjusted later. Drop

the fan shroud over the fan and between the lower frames. Use two M3x8 Philip head self-tapping screws to secure the

starter belt retaining clips (2002-057 bag #8) and the fan shroud to the side frames. The front end of the fan shroud is

secured by a M3x8 Philip head screw on each side of the frames. Now, hang the engine starting belt (2002-109 Bag

#4) around the fan shroud and secure in the starter belt retaining clips. It may be necessary to slightly squeeze the clips

in order to get a tight enough grip on the belt.

For 46-size engine: Install the engine to the engine mount (2002-101 Bag #2) using four M3x12 bolts. Take the

engine assembly and slide it into the side frames from the top side. Use six M3x12 bolts and six washers to secure the

engine mount to the side frames. Do not tighten the four bolts completely. The position will be adjusted later. The fan

shroud for the 46-size engine is different from the 30-size. The 46-size shroud (2002-107 bag #2) comes in two pieces.

Screw the two pieces together using two M3x8 Philip self-tapping screws. Add the fan bracket (2002-098 Bag #2 )

between the rear of the fan shroud and the engine mount and adjust the fan to proper height. The bottom of the fan

should be flush with the bottom of the shroud. Add the two starting belt retainer clips (2002-057 Bag #8) on the fan

shroud using two M3x8 Phillips screws and two washers. Now hang the engine starting belt (2002-109 Bag #4)

around the fan shroud and secure the belt in the clips.

The Pro Master has the addition of a top start system. This system is assembled and installed as a complete unit.! Do

not use anyABC engine for shaft start system. Start by sanding the inside of the clutch bell (2002-303 BAG #4M) with

220 grit sandpaper to aid the bond when installing the clutch lining. Thoroughly clean with solvent. Trim the liner so

it fits snugly in the bell. Remove and reinstall using JB weld epoxy or slow CA to hold the liner in place. Press the

4x9x4 ball bearing (2002-103 BAG #4M) into the inside of the clutch bell. Lightly grease the start shaft (2002-306

BAG #4M) and insert into the clutch bell from the bottom. Take the double bearing block (2002-307 BAG #4M) and

slip over the pinion shaft. It is advisable to use a little Locktite on the pinion shaft where it makes contact with the ball

bearing. Clean off the end of the start shaft and slide the one way start adapter (2002-304 Bag #4M) in place. Install the

set-screws that hold the adapter in place. Take note that one of the set-screws must seat on the flat on the start shaft and

Locktite must be used. 55

55

5

Step 3 Installing the Rate Gyro

Use two layers of 1/8 inch thick double-sided foam tape to install the electronic rate gyro to the gyro mounting plate.

The double sided tape can be found at your local hobby shop or at hardware stores. Use the same procedure if you

intend to mount the gyro on the battery tray.

Step 4 Landing Gear

Attach the two landing gear struts (2002-067 Bag #1) onto the lower frames using four M3x16 bolts 3mm Lock-nuts

and washers. Slide the landing skids into the landing gear struts. Install four M3x6 set screws to the struts to prevent

the skids from moving. It is advisable to pre-thread the struts by running a M3x8 screw into them before installing the

skids.

Step 5 Collective and Cyclic Control

Now put the lower side frame assembly aside. We will start on the upper side frame assembly now.

Fit the elevator axle (2002-153 and 2002-155 Bag #3) to the elevator lever (2002-069 Bag #3). Use a M3x5 bolt and

a small washer to hold each axle; use a drop of Locktite on the M3x5 bolt. Use two steel ball end (2002-229 Bag #3)

and locktite to hold the steel balls in place. Install a plastic bushing (2002-072 Bag #3) onto each of the two collective

pitch levers (2002-071 Bag #3). The 2002-072 bushings can be replaced by optional ball bearings 2002-070. The

plastic bushing flange must rest against the face of the pitch lever. If not, it will be necessary to slightly bevel the edge

of the hole in the lever. Please note that all the plastic bushings should rotate freely on their mating shafts. If not than

the bushings should be reamed out slightly until they do. This can easily be done by rolling some 400 grit wet or dry

sandpaper and working it in and then out of the bushing until the proper fit is achieved.

109

M3X8 S/T M3X16

M3NUT

3X6 SET

SCREW

3X6 SET

SCREW

068

066

067

M3X10(30)M3X10(30)

M3X10(30)M3X10(30)

M3X10(30)

M3X12(46)M3X12(46)

M3X12(46)M3X12(46)

M3X12(46)

M3X8 S/TM3X8 S/T

M3X8 S/TM3X8 S/T

M3X8 S/T

M3X8 S/T

105

155

069

072

(070 BALL

BEARING

OPTION)

229

071

229

WASHER(S)

M3X5

WASHER(S)

153

071 071

229

229

155

153

069

66

66

6

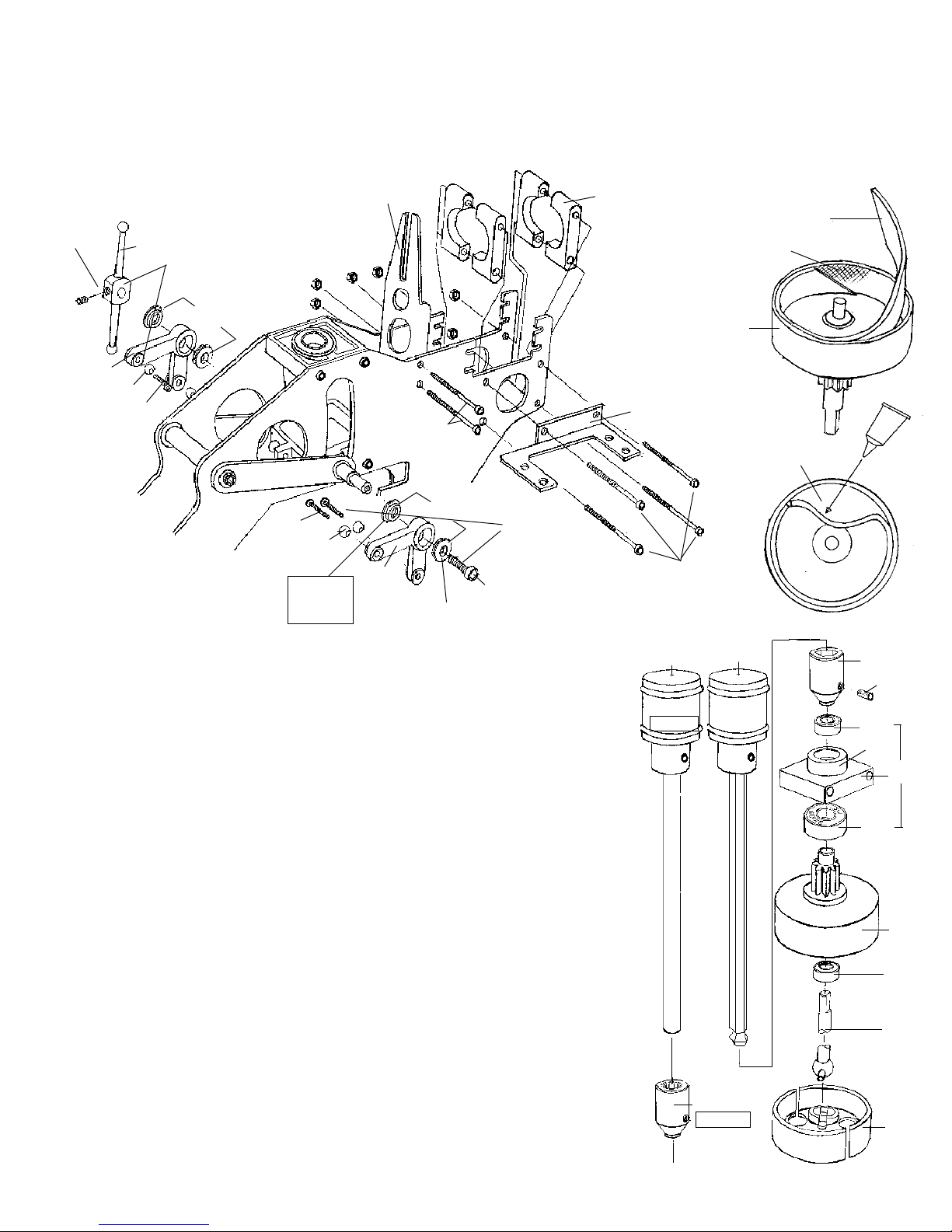

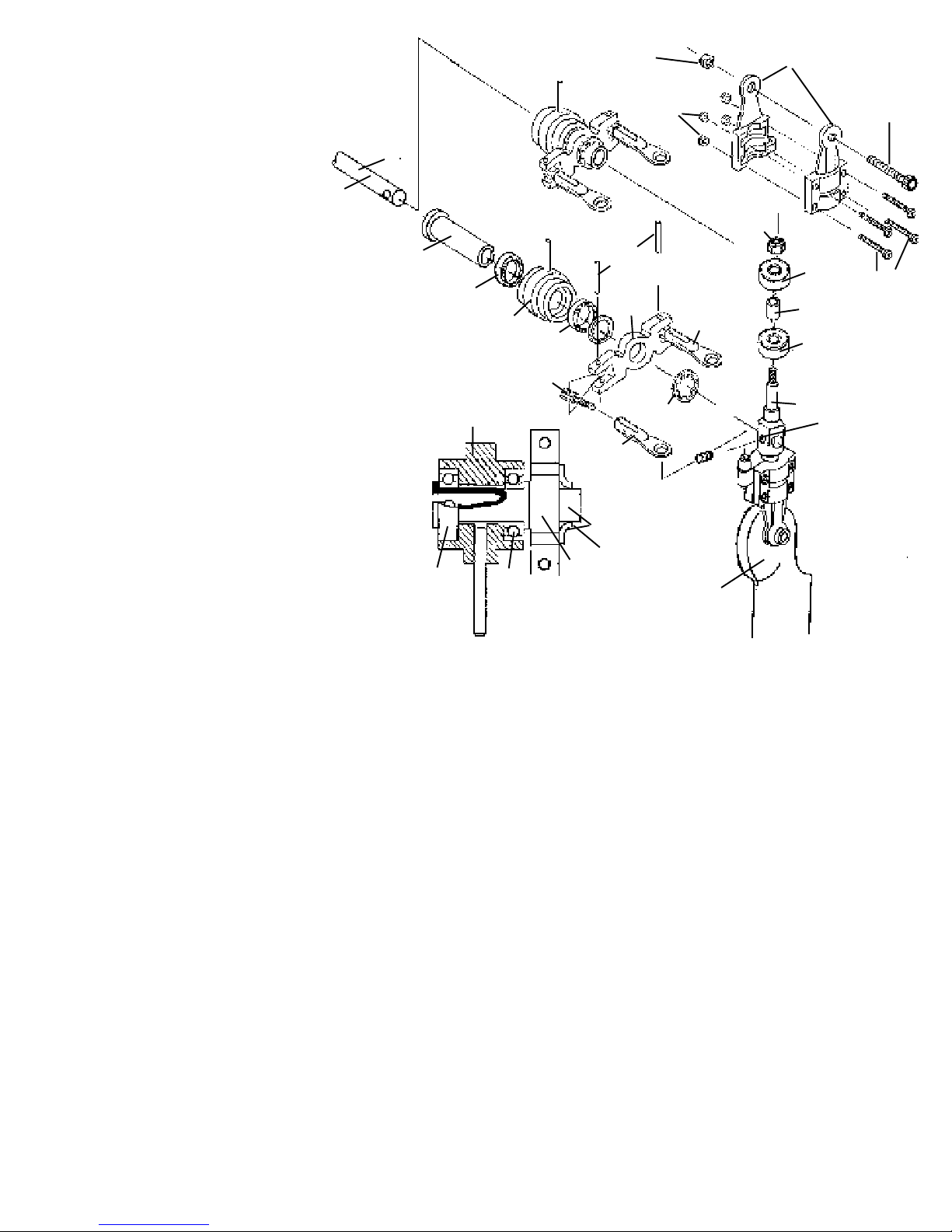

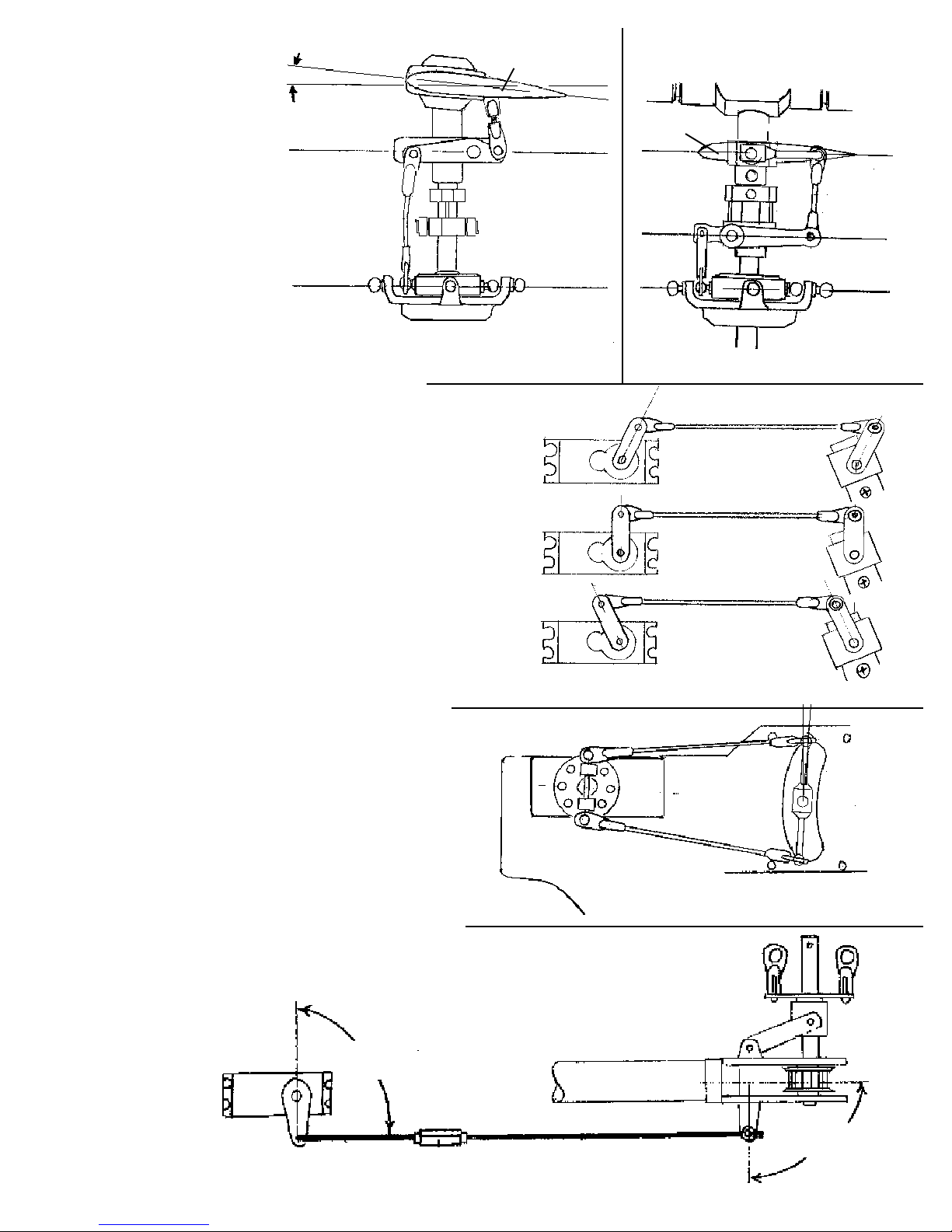

Step 6 Upper Main FramesAssembly

Fit the elevator control lever set and collective control axle (2002-157 Bag #3)between the top left and top right side

frames (2002-117 Bag #1). Press a plastic flanged bearing (2002-059 Bag #3) for the collective control lever axle into

inside of each side frame.The shorter elevator axle should be on the left side of the helicopter. Install two main bearing

blocks (2002-083 Bag #4 or Bag #4M) onto the top side frames using four M3x35 bolts and four 3 mm nuts. The top

bearing block should have the ball bearing facing up. The bottom bearing block should have the ball bearing facing

downward. After insert the collective control lever axle into the flanged bearing. Add the collective lever (2002-071

Bag #3) to the collective axle. The lever needs to slide onto the elevator axle (2002-153 and 2002-155 Bag #3) with

the flange bearing facing toward the elevator lever. Please see the drawing.

The 2002-059 bushings can be replaced by optional ball bearings (2002-061). Please note once again that these

bushings or ball bearings must move freely and with minimal freeplay in order for your helicopter to operate properly.

It is imperative that the retaining screws be set at the proper tension. Too tight will bind the bearing and too loose will

create unwanted freeplay. Fit the plastic tail boom holders (2002-085 Bag #4 or Bag #4M) in-between the upper side

frames. Also add the tail rotor servo mount plate (2002-073) outside the left side frame. The tail boom holders and

servo mount are held by four M3x35 bolts and four nuts. Do not tighten the four nuts and bolts completely. They will

tightened later, after the tail boom is installed.

Take the Y- shaped push-pull collective lever and install the 5mm control balls (2002-239 Bag #8) using M2x10

screws and 2mm nuts. Now add the lever (2002-075 Bag #1) on top of the right side aluminum arm (2002-071 Bag

#3). Use a M3x8 bolt and washer to secure theY-shaped lever at the collective axle, and a M3x6 bolt to secure theY-

shaped lever to the 2002-071 arm. Install two M3x6 flanged plastic bushings (2002-160 Bag #3) The 2002-160 bush-

ings can be replace by optional ball bearing 2002-022 on each 90 degree bell crank (2002-159 Bag #3). Install two

steel balls onto each bell crank using two M2x8 bolts, take care not to have any excess bolt protruding the opposite

side of the bell cranks. There are two 90 degree bell cranks, do this for both left and right side bell cranks. Slide a 90

degree bell crank onto the left side elevator axle (2002-155 Bag #3) Use a M3x10 bolt and Locktite to retain the bell

crank onto the elevator control axle. Do not overtighten this M3x10 bolt; the bell crank should be able to pivot freely,

but there should not be any free play.

125

125

083

083

157

155

153

M3X8 WASHER(S)

M3X8

WASHER(S)

M3X35

071

071

117

117 WASHER(S)

M3X8

071

117

059

061 (OPTION

BALL BEARING)

059

059

2X10

075

M2 NUT

M2 NUT

M3X6

M3X8

WASHER(S)

239

239

071

77

77

7

Now, install a similar 90 degree bell crank to the right side. Install the steel elevator bell crank (2002-161 Bag #3) on

the right side elevator axle (2002-153 Bag #3). We suggest that you file a flat on the elevator axle where the set screw

makes contact. Put a 3x3mm set screw in the steel bell crank. Do not tighten the set screw very tightly yet, because the

exact angle will be adjusted later. When permanently tightened be sure to use a drop of locktite on the elevator bell

crank. Fit the swashplate anti rotation bracket (2002-077 Bag #3) between the upper side frames. Fit two M3x35 bolts

through the frames and the bracket. Secure them with two M3 nuts. Do not overtighten as this will only distort the

frames.

Clutch Bell Assembly

Roughen the inner surface of the clutch bell (2002-127 Bag #4 or #4M) with #220

grit sand paper. Then, clean off the debris. Trial fit the clutch lining (2002-129

Bag #4 or #4M) to the clutch bell, make sure it fits snugly. Once you are

satisfied, then remove the lining and permanently glue it back in using JB weld

Epoxy, or slow CA glue. Fit the clutch bearing (2002-131 Bag #4 or 4M) and

block (2002-081 Bag #4 or #4M) in-between the upper side frames. The ball

bearing should face downward. Use two M3x35 bolts to secure the bearing block

in place. Insert the clutch bell in the clutch bearing. It is recommended to apply

a little locktite to the pinion shaft where it inserts into the bearing.

The Pro Master has the addition of a top start system. This system is assembled

and installed as a complete unit. Start by sanding the inside of the clutch bell

(2002-303 Bag #4M) with 220 grit sandpaper to aid the bond when installing the

clutch lining. Thoroughly clean with solvent. Trim the liner so it fits snugly in the

bell. Remove and reinstall using JB weld epoxy or slow CA to hold the liner in

place. Press the 4x9x4 ball bearing (2002-103 Bag #4M) into the inside of the

clutch bell. Lightly grease the start shaft (2002-306 Bag #4M) and insert into the

clutch bell from the bottom. Take the double bearing block with ball bearing

(2002-307 bag #4M) and slip over the pinion shaft. It is advisable to use a little

Locktite on the pinion shaft where it makes contact with the ball bearing. Clean

off the end of the start shaft and slide the adapter (2002-304 Bag #4M) in place.

Install the set screws that hold the adapter in place. Take note that one of the set

screws must seat on the flat on the start shaft and Locktite must be used. Slide the

assembly into place and secure the bearing block to the frames with two M3x35

screws and nuts. Take note that the heads of these bolts must be on the same side

as theY shaped collective bell crank.

085077

M3 NUT

M3

NUT

M3X35

M3X35

073

M3X10

WASHER(S)

022 BALLBALL

BALLBALL

BALL

BEARINGBEARING

BEARINGBEARING

BEARING

OPTIONOPTION

OPTIONOPTION

OPTION

239

2X8

161

M3X6

SET SCREWSET SCREW

SET SCREWSET SCREW

SET SCREW

159

160

160

159

2X8

239

304

OPTION

309

305

OPTIONOPTION

OPTIONOPTION

OPTION

3X6 SET

308

103

301

131

307

303

103

306

302

129

127

ROUGHEN INNER

SURFACE

JB WELD EPOXY

OR SLOW CA GLUE

JB

88

88

8

Step 7 Tail Rotor Drive

Insert the steel pinion shaft (2002-087 Bag #4 or #4M) into two bearing blocks (2002-081 Bag #4 or #4M). The ball

bearings should face upward for both bearing blocks. Carefully smear a small amount of slow CA glue around bearing

(2002-131 Bag #4 or 4M) before pushing bearing into bearing block (2002-081 Bag #4 or #4M). Add the plastic

pulley (2002-133 Bag #4 or #4M) onto the pinion shaft. Insert a M3x8 bolt and a washer on top of the plastic pulley.

Now fit this pulley assembly in-between the upper side frames. Use three M3x35 bolts and three locknuts to secure it

to the frames. Fit a 40 mm long 3 mm stud (2002-094 Bag #3) into the rear hole of the bottom bearing block. Add a

threaded spacer (2002-091 Bag #3) on each side of the 3 mm stud. Leave this assembly slightly loose so you can adjust

the gear mesh later.

M3x35

WASHER(S)

131

081

127

M3 NUT

M3x35

WASHER(S)

M3 NUT

303

306

307

3X6 SET

308

WASHER(S)

M3X8

133

131

081

131

087

094

081 094

091

091

M3 NUTS

M3X35

M3X35

M3X35

133

PRO MASTERPRO MASTER

PRO MASTERPRO MASTER

PRO MASTER

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

NINJA PRONINJA PRO

NINJA PRONINJA PRO

NINJA PRO

CLUTCHCLUTCH

CLUTCHCLUTCH

CLUTCH

99

99

9

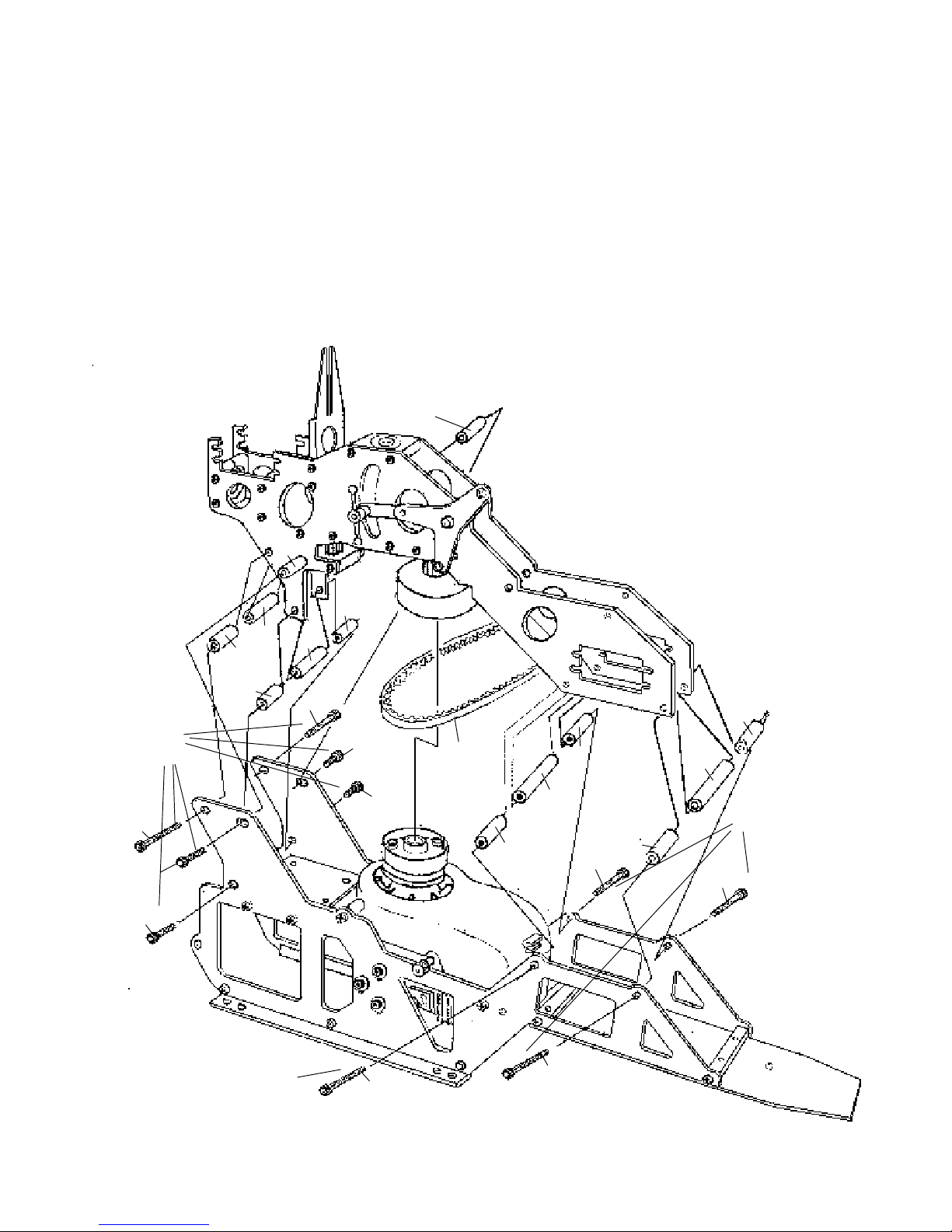

Step 8 Mating The Upper and Lower Main Frames

Find the four 26 mm long threaded aluminum spacers (2002-093 Bag #3). Fit them in-between the upper side frames

in the locations shown in the drawing.

Mate the upper frame assembly onto the lower frame assembly. Fit the clutch bell onto the clutch first. Add eight 14

mm long aluminum spacers (2002-089 Bag #3) in-between the upper and lower side frames. See drawing for their

locations. Use eight M3x25 bolts to go through these eight spacers. Then add two M3x8 bolts to the two spacers that

are on the pulley bearing block. Use blue Locktite on these bolts.

NinjaPro don’t forget the engine starting belt (2002-109 Bag #4) Or if building a Pro Master don’t forget to grease the

uniball at the base of the start shaft.

093

089

091

089

093

089 093

089

093

089

093

089

089

109

M3X25 M3X25

M3X25

M3X25

M3X25

M3X25

M3X25

M3X25

M3X8

M3X8

1010

1010

10

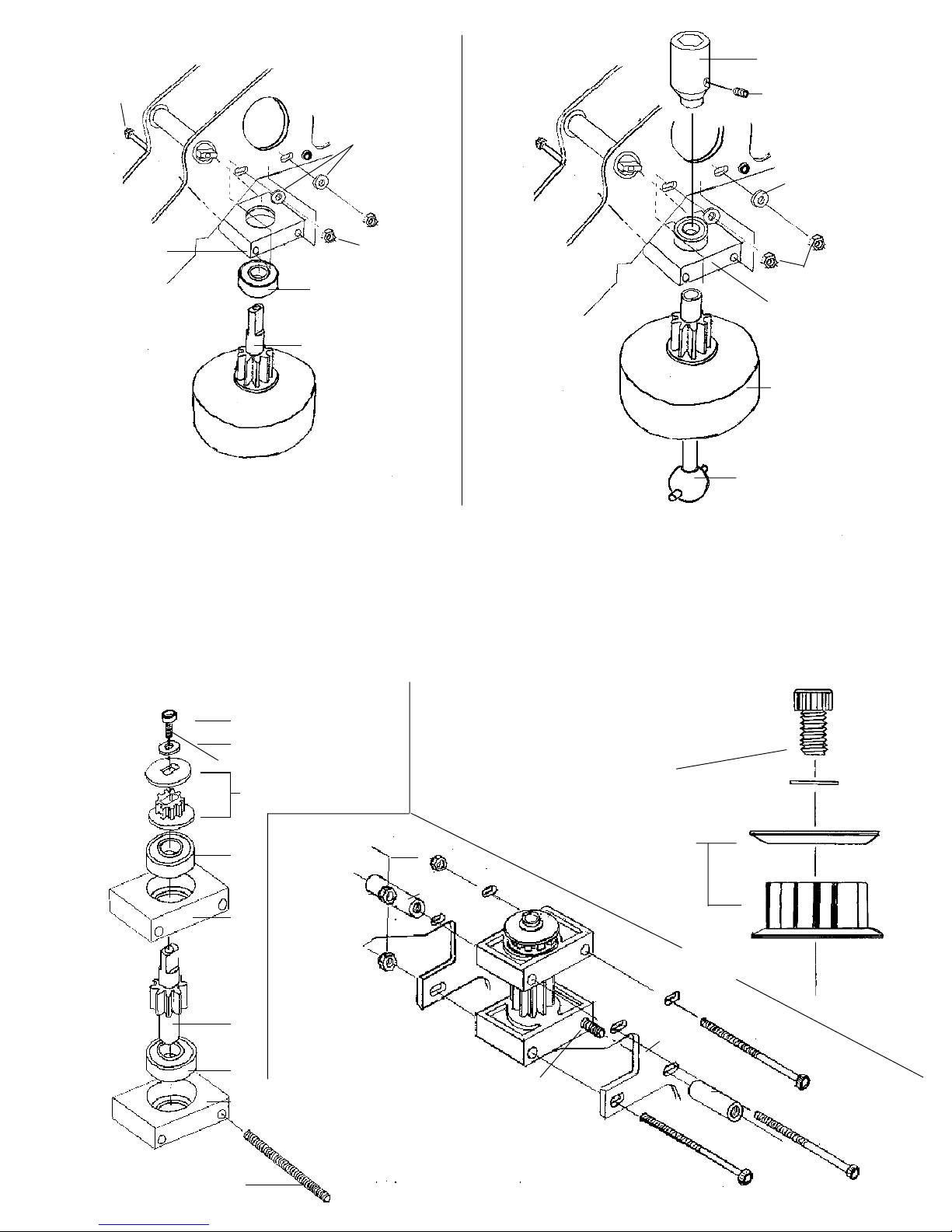

Step 9 Main Rotor Head

Insert the metal center hub (2002-003 Bag #5) into the metal center yoke (2002-001 Bag #5). Add a M3x8 bolt on

each side of the yoke. Use blue Locktite on the two bolts. (2002-001, 2002-003) Smear some Vaseline on the two

rubber dampers (2002-011 Bag #5). Then insert one damper on each side of the yoke. Slide the feathering spindle

(2002-005 Bag #5) through the rubber damper and the yoke.

Find the two blade grips (2002-007 Bag #5) note that the four main blade bearings (2002-008 Bag #5) are pre-

installed in the blade grip. Add the metal pitch control arm (2002-009 Bag #5) onto the blade grip using a single M3x6

bolt. Add the steel pitch control ball stud (2002-231 Bag#1) to the pitch control arm (2002-009 Bag #5). Use Locktite

on the pitch are and pivot control ball.

Slide the completed blade grip onto the feathering spindle (2002-005 Bag #5). Insert a M3.5x12 bolt and a washer

through the blade grip to secure the hub to the spindle. Use Locktite on this bolt !Do not over tighten as this will only

mushroom the shaft and make bearing removal difficult.

Slide the seesaw (2002-017 Bag #5) onto the center hub. Fit two flanged plastic bearings (2002-160 Bag #3) or the

flanged ball bearings (2002-022 OP) if you are building a Ninja pro master , into the center hole of the seesaw. Secure

the seesaw to the hub by using a M3x6 bolt through each flanged bearing. Tighten the two M3x8 bolts sufficiently to

remove all free play, but the seesaw should still be able to move smoothly ! Use Locktite on the bolts. On this and the

following steps it cannot be stressed enough the importance of the seesaw and mixing arms pivoting freely without

excessive play. The use of Locktite is mandatory during these steps.

Fit two flanged plastic bearings (2002-160) or non-flanged ball bearings (2002-022A Bag #4M) if building a Pro

Master onto each mixing arm (2002-019 Bag #5). Add the two mixing arms (2002-019) onto the seesaw. Use a

M3x10 bolt with Locktite to secure the mixing arm to the seesaw. Tighten the M3x10 bolts sufficiently to remove all

free play, but the arms should still be able to move smoothly. Fit steel ball (2002-239) onto mixing arm (2002-019) use

M2x8 screw with nut and Locktite.

Insert two plastic flanged bearing (2002-160) or (2002-022A) if building a Pro Master on the seesaw. Slide the flybar

(2002-015 Bag #10) through the flanged bearings and the seesaw ! Use a ruler to check to make sure equal length

sticks out on either side of the seesaw. Add a flybar control arm (2002-013 Bag #5) on either side of the seesaw. Coat

the threads of each M3x6 set screw with Locktite, then fit a set screw inside each control arm. Make sure both arms are

level ! Insert a 3mm locknut into the underside of each control paddle (2002-253 Bag #5) Then screw the paddles

onto the flybar. Wick some thin CA glue into the paddle hole after threading it onto the flybar ! Make sure the two

paddles are at same distance from the control arm and are level with the control arms. This is an extremely important

step you can follow the picture to cut a flybar jig template. Check the flybar balance by letting the seesaw pivot on its

bushings. Add tape to the light paddle until balance is achieved.

M3x8

M3x8

003

011

005

005 231

007A

008

007 008

009

043

001

3.5X12

WASHER(S)

M3 NUT

M3X25

M3X6

CN2135 HEAD BUTTON (PURPLE)OPTION

CN2136 HEAD BUTTON (GOLD)OPTION

CN2122 CARBON

STIFFENER FOR

FLY BARS

(OPTION)

M3 NUT

1111

1111

11

121

021

023

023

025

032

031

229

229

229

226 226

160

160

022A

230

230 022A

PRO MASTER

4X4 SET4X4 SET

4X4 SET4X4 SET

4X4 SET

SCREWSCREW

SCREWSCREW

SCREW

M3X10 M2X12M2X12

M2X12M2X12

M2X12

239

M2 NUTM2 NUT

M2 NUTM2 NUT

M2 NUT

M3X3M3X3

M3X3M3X3

M3X3

SETSET

SETSET

SET

M3X16

013

013

160

230

015

253

019

160

160

M3x6 160

M3X10

230

017

230 M3X3

239

M2

NUT

MASTER

USE 022

HERE

M2X8

MASTER

USE 022A

HERE

CN2029A

FLY BAR

WEIGHTS

(OPTION)

CUT A FLY BAR JIG TEMPLATE

SOME THIN

CA GLUE MAKE SURE

PADDLES & ARM

ARE LEVEL

The Pro Master has all of these plastic bearings replaced with ball bearings. The installation is the same except that

some small micro washers 3x4.5x0.5T are used in-between the ball bearing and the part it mates against.

Step 10 Washout and Swashplate

Find the metal washout mixing base (2002-021 Bag #6) and the two metal washout arms (2002-023 Bag #6). Insert a

plastic flanged bearing (2002-160) Or 2002-160 ball bearing if building a Pro Master onto either side of the washout

arm. Attach the washout arm to the mixing base with a M3x10 bolt. Tighten the M3x10 bolts sufficiently to remove

all free play, but the arms should still be able to move smoothly.

Put a plastic radius link (2002-025 Bag #5)

on each washout arm. Slide a 2 mm pin through

the radius link and the washout arm to

secure them. Insert a 3 mm set screw

in the washout arm. This set screw is

used to secure the pin. Add a metal

spacer and steel ball and a M2x10

bolt on each washout arm. Secure the

M2x10 bolt with a 2 mm nut

(2002-239 Bag #8).

Fit three short threaded steel balls

(2002-229 Bag #3) onto three outside

arms on the swashplate ! Use Locktite

on all these threaded balls. Be careful

not to scratch or overtighten the balls.

They are easily damaged during

installation. For the swashplate

antirotation arm (2002-032 Bag #6)

fit a M3x16 bolt with the plastic sleeve,

a brass spacer, and special threaded

steel ball and another brass spacer;

see drawing ! Use Locktite on the bolt.

Fit four long threaded steel balls

(2002-226 Bag #5) onto the four holes

on the inside swashplate ring. See

drawing below. Use Locktite on all

these threaded balls. 1212

1212

12

Step 11 Main Gear and Main Shaft

Slide the aluminum main shaft stopper (2002-123 Bag #6)

onto the main shaft from the bottom. Hold the plastic

main gear (2002-135 Bag #6) underneath the main rotor

shaft bearing block. Slide the main rotor shaft (2002-121

Bag #6) from the top through the bearing blocks and into

the main gear. Install a M3x20 bolt through the main

gear auto rotation hub and through the main shaft and

secure with a 3mm Lock-nut. Note that the end of the

shaft with the most distance between the hole and the

end is the top end of the shaft. Insert two 3x3 mm set

screws into the mast stopper (2002-123) and tighten

them. Make sure the main shaft has nofreeplay up or

down.

Slide the swashplate and the washout assembly onto

the main rotor shaft. Snap the two radius links

(2002-025 Bag #6) onto the inner swashplate

long steel balls (2002-226) 180 degrees from one

another. Add the washout retaining block (gold part

with two steel pins) with the pins pointing downward.

Temporarily use a 4x4mm set screw to secure this part

to the main shaft. Then, add the main rotor head on the

shaft. Insert a M3x20 bolt and locknut through the

main rotor hub and shaft, and tighten it.

Step 12 Tail Rotor System

Tail Rotor Gearbox

Install the right side plate (2002-185 Bag #7)

onto the gearbox housing (2002-187 Bag #7)

with two M3x6 bolts.

Fit the tail rotor drive

shaft (2002-193 Bag #7)

and a thin (2002-187 Bag #7)

spacer to the right tail plate.

Now fit the tail rotor drive

belt through the hole in

the tail rotor gearbox

housing (2002-187),

then loop the tail rotor

drive belt (timing belt)

(2002-183 Bag #4 or 4M)

around the tail pulley (2002-193).

Add the left side tail plate to the tail

gearbox housing using two M3x6 bolts.

Fit guide pulley (2002-189 Bag #7) and two

thick (2002-187 Bag #7) spacers between the

side plates. Use a M3x25 bolt through the side

plates and through the guide pulley to hold it in

place ! It is extremely important to use Locktite

to all screws that thread into a tapped hole in this step.

135

136

M3X20

M3 NUT

123

3X3

SET

187

187

187

M3X25

M3X6

M3X6

187

197

185

189

M3X6

M3X6

183

M3X6 M3

NUT

187

185

185

M3X10

191

M2 NUT

M2x10 230

M4X6

M4X10

1313

1313

13

Tail Rotor Blade Grip

Sliding Tail Rotor Pitch Control Mechanism

Slide a ball bearing (2002-209 Bag #7) onto the

tail hub (2002-199 Bag #7) followed by a

spacer (2002-211 Bag #7) then

another bearing. Secure the

bearings and spacer to the

hub with a small washer

and a 3mm lock-nut. Repeat

for the next side. Fit the tail blade

grips (2002-207 Bag #7) to the bearings

with four M2x10 screws and nuts !Note

that one of the grip halves has a nub for the

pivot ball to be mounted to the grip. Repeat for the

next side. Attach a pivot ball on each assembly with

a M2x10 screw and nut.

Install a ball bearing (2002-204 Bag #7) on either

side of the tail pitch plate housing

(2002-205 Bag #7). Insert the tail

pitch plate inner sleeve (2002-203

Bag #7) into the tail pitch plate

housing. Note that the pivot pin is

offset and the brass slider must be

inserted into the side with less distance

between the pin and housing edge. .

Attach the tail pitch plate (2002-201 Bag #7)

to the brass tail pitch slider. Press the locking

ring onto the brass pitch slider to hold the pitch

control plate in place. It is advisable to add some

JB Weld epoxy to the locking ring for some added security.Add two small plastic ball links (2002-235 Bag #8) on the

tail pitch control plate. Secure them with (2002-202Bag#7) special screw and pin, slide the entire assembly onto the

tail rotor shaft. Attach the tail pitch lever (2002-191 Bag #7) to the tail rotor gear box with a M3x10 bolt two micro

shims (2002-230 Bag #5) and a lock nut.The steel pin on the tail rotor control housing (2002-205 Bag #7) fits into the

steel ball pressed into the end of the bell crank.

Fit the tail rotor hub (2002-199 Bag #7)) with the tail grip onto the tail rotor shaft (2002-193 Bag #7). Put two 3x3mm

set screws in the tail rotor hub, and use them to secure the hub to the shaft. Use Locktite on these set screws.

Fit the tail rotor blades to the blade holders with a 3mm washer on each side of the blade. Secure each blade with a

M3x16 bold and a 3mm nut.

NOTE: make sure the tail blades are facing the proper direction

Step 13 Tail Fins

Put the two half pieces of plastic fin mount (2002-085 Bag #4 or 4M)) on the tail boom (2002-173 Bag #10). Put the

horizontal fin (2002-175 Bag #1)) on top of them Insert two M3x35 bolts through the fin and the plastic mounts. Add

the two tail boom support rods (2002-179 Bag #10) under the plastic mount (2002-085 Bag #4 or 4M). Use two M3

lock nuts to secure all of them, but do not tighten them completely, yet. We will tighten them later.

Slide three tail pushrod guides (2002-171 Bag #4 or 4M) onto the tail boom: two are in front of the horizontal fin, and

one is behind the horizontal fin.

Fit the two plastic mounts (2002-085 Bag #4 or 4M) for the vertical fin (2002-177 Bag #1) on the tail boom. Add the

vertical fin. Insert two M3x35 bolts through the fin and the plastic mounts. Secure them with two 3 mm locknuts.

193

203

204

204

205

203

235

235

201

202

202

203

205

204

204

228

M3X3

SET

M3

NUT

M3X16

M2 NUT

M2X10

207

209

209

211

199

M3

NUT

201

JB WELD

HERE

1414

1414

14

Step 13 Tail Fins

Step 14 Mating Tail Boom to the Main Frames

Feed the tail drive belt (2002-183 Bag #4) through the tail boom starting with the end with two holes. A piece of wire

with a hook bent into it works well for pulling the belt through. Fit the tail boom (2002-173 BAG #10) into the upper

side frames. Loop the drive belt onto the front pulley. The belt should have a 90 degree turn inside the tail boom !

Check to make sure when the main rotor is turning in the clockwise direction (viewed from the top), the tail rotor

should turn counter-clockwise when viewed from the right hand side. Adjust the belt tension by pulling on the tail

boom. Do not over tighten the belt, it should not be too loose so the belt slips. Slowly, tighten the four M3x35 bolts

that hold the tail boom.

Attach the front of the tail boom support rods to the lower main frames. Use two M3x8 bolts and a 57mm threaded

cross member (2002-095 Bag #3) to secure the front of the tail boom support rods to the frames. Mount the aft end of

the boom-struts to the horizontal fin mounts, making sure the horizontal fin is level tighten the two M3x35 bolts

holding the horizontal fin and fin clamp together.

Step 15 Fuel Tank

Assemble the fuel tank (2002-063 Bag #9) carefully according

to the drawing shown below. Use caution while bending the

brass tubing. Do not use any pliers as this will kink the

tubing use your hand and make a smooth flowing bend

to avoid kinking. Add one strip of double sided foam

tape to the top surface of the tank so it will make

contact with the gyro plate mount. Slide the tank

into the side frames from the right hand side.

The fuel line should come out of the right

hand side of the helicopter.

M3x35

175

085

085

085

085

179

177

171

171

223

M3X35

173

M3 NUT

171

M3 NUT

RIGHT !

WRONG !

(TOO TIGHT)

179

063

095

M3X10

Double sided

foam tape

215

173

171

From muffler

pressure fitting

To engine carbure-

tor

1515

1515

15

Step 16 Main Rotor Blades

The rotor blades that are included in your Ninja Pro kit come

pre-finished and require no building. They however

should be checked for balance before use. If you have

a balancer follow the instructions that came with

the balancer. Next attach the blades to the rotor

head. Balance the Rotor head and blades on two

drinking glasses suspending the whole unit by the

flybar. The heavy side will hang lower than the light

side. Add self-adhesive tape on the light blade on a

location that will result in the proper CG shift. Add

the tape until the rotor head hangs horizontally.

Step 17 Radio Installation

All five servos are mounted with the screws that came with your radio system with the exception of the aft two

screws that hold the elevator servo. These two are replaced by two M3x8 self tapping screws. They are screwed

trough the cutouts in the frame and into the plastic servo mounting plates (2002-169 BAG #3) located with the

plastic parts tree. Mount the five servos as illustrated in the instructions.

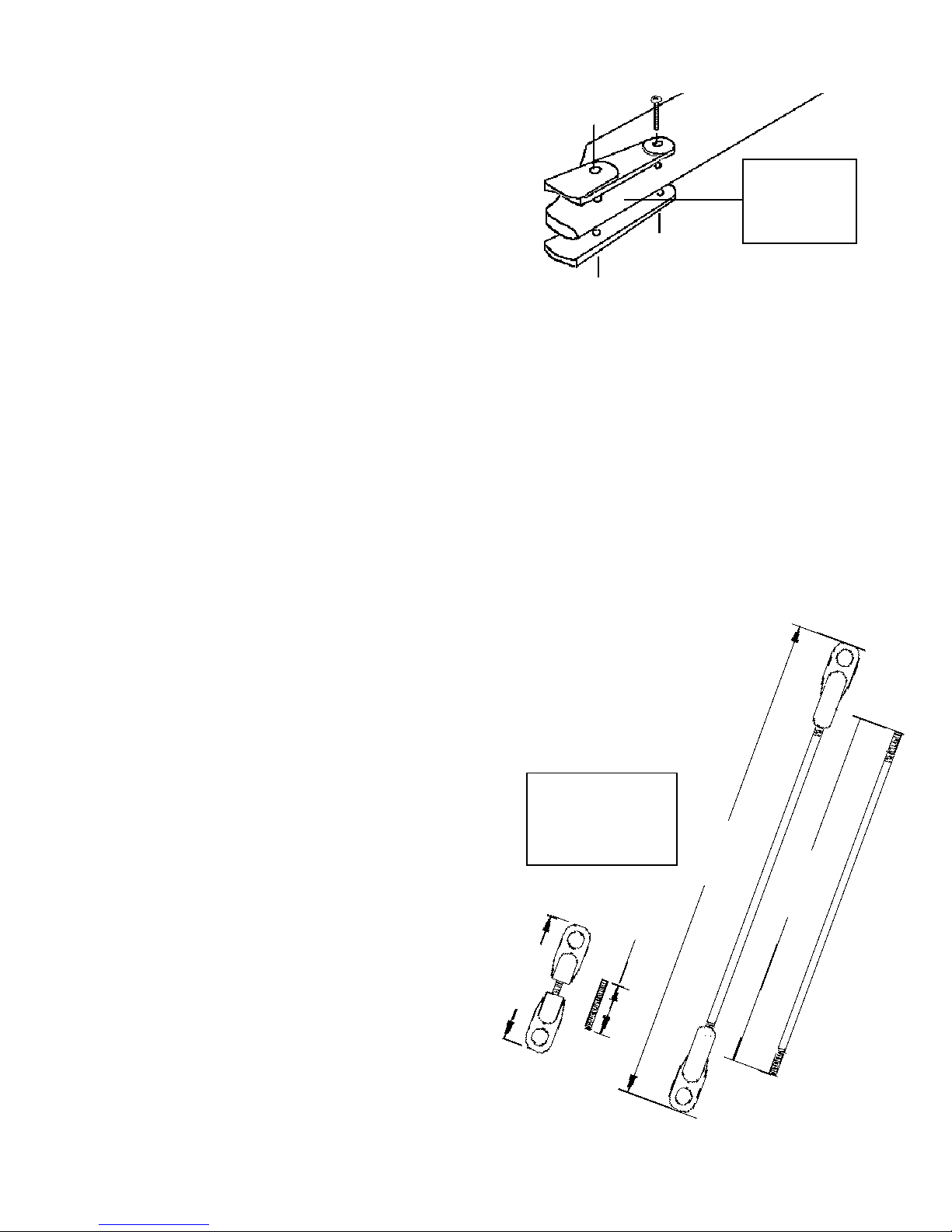

Step 18 Making Up the Control Push rods

Make up all the control push rods according to the specified length shown in the drawing. Please note that these

dimensions are from end to end of the plastic rod-end and are only guidelines.You will have to fine adjust them

according to your particular servos.

#2002-213 ELEVATOR: Total 91 mm for JR servos ( 2 )

(Use 68mm rod,see FIG #7 ) Total 92 mm for Futaba servos (2)

#2002-217 COLLECTIVE: Total 117 mm for JR servos (2)

(Use 80mm rod,see FIG #2) Total 118 mm for Futaba servos (2)

#2002-215 ROLL(AILERON): Total131 mm for JR servos (2)

(Use 100mm rod,see FIG #1 Total 132 mm for Futaba servos (2)

& FIG #3 Slightly bent 10 degree)

#2002-221 SWASHPLATE: Total 69mm (4)

(Use 40mm rod, seeFIG #3A & FIG#3B)

#2002-221 PITCH ( long ): Total 66mm ( 2 )

(Use 40 mm rod, see FIG #4 )

#2002-225 PITCH ( short ): Total 36mm ( 2 )

(Use10mm rod, see FIG #4 )

#2002-219 FLYBAR: Total 47mm (2 )

(Use 25mm rod See FIG #5)

#2002-221 THROTTLE: Total 80 mm (1 )

(Use 40 mm rod, see FIG #6)

# 2002-215 / 223 RUDDER: Total 618mm (1 )

(Use 100 & 476 mm rod, see FIG #8)

EXSAMPLE:

2002-217

TOTAL 117mm(JR)

USE 80mm ROD

SEE FIG.# 2 117MM

80MM

CUT THIS

WHITE SHRINK

COVER OFF

THEN USE THIN

CA GLUE HERE

1616

1616

16

Use this pitch gauge

1. Cut a 1:1 pitch gauge

2. Put the gauge into the blade holder of the rotor head.

3. Makesure the flybar parallel to the tail boom.

4. Referring to the table bellow, set the flybar to each pitch

gauge line, and read the pitch.

5. Adjust your transmitter referring to the data of next page.

Use this flybar jig template

1. Cut two 1:1 template.

2. Referring step 9 main rotor head to

setup.

CUT A FLY BAR JIG TEMPLATE

Add tape on the

lighter blade

Accuratech main blade balancer

with C.G checker (Option) # CN2052

can help you to find out the position

of C.G and balance a pair of the main

rotor blade.

1717

1717

17

213

213

165

163

229

233 166

ELEVATOR

SERVO

ELEVATORELEVATOR

ELEVATORELEVATOR

ELEVATOR

LINKAGELINKAGE

LINKAGELINKAGE

LINKAGE

COLLECTIVE LINKAGECOLLECTIVE LINKAGE

COLLECTIVE LINKAGECOLLECTIVE LINKAGE

COLLECTIVE LINKAGE

217

217

169

215

215

111

053

051

169

215

ROLL(AILERON)ROLL(AILERON)

ROLL(AILERON)ROLL(AILERON)

ROLL(AILERON)

THROTTLE(ENGINE)THROTTLE(ENGINE)

THROTTLE(ENGINE)THROTTLE(ENGINE)

THROTTLE(ENGINE)

221

RUDDER LINKAGERUDDER LINKAGE

RUDDER LINKAGERUDDER LINKAGE

RUDDER LINKAGE

215 170 223

169

1818

1818

18

FIG.1FIG.1

FIG.1FIG.1

FIG.1

FIG.1FIG.1

FIG.1FIG.1

FIG.1

215

FIG.2FIG.2

FIG.2FIG.2

FIG.2

16-18mm

221 221

FIG.3BFIG.3B

FIG.3BFIG.3B

FIG.3B

217

217

FIG.2FIG.2

FIG.2FIG.2

FIG.2

FIG.3AFIG.3A

FIG.3AFIG.3A

FIG.3A

221

221

217

217

213

213

215

80

100

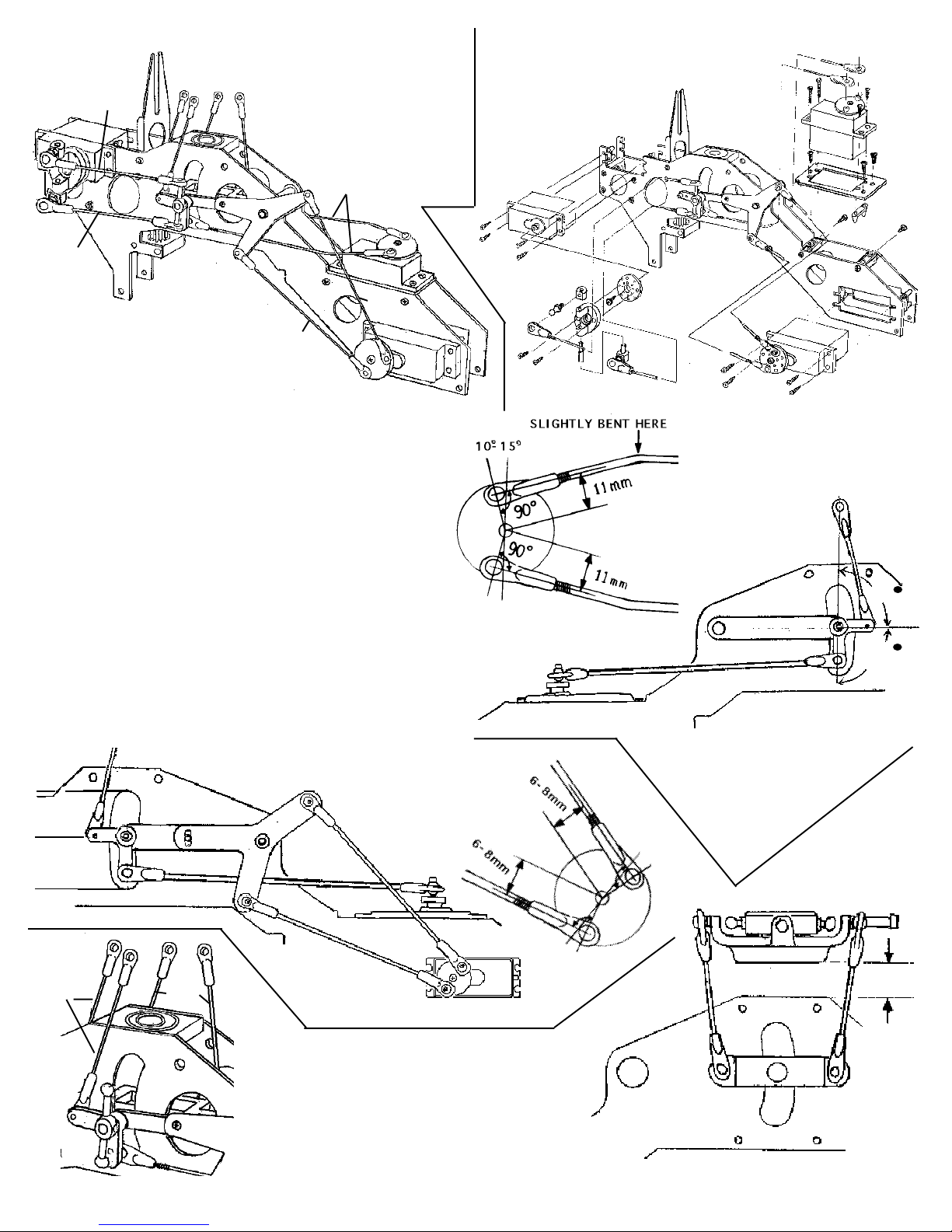

Step 19 Setup

All of the push rods now need to be fine adjusted to

the proper length. First adjust the roll push rods

(2002-215 Bag #8) so that the top edge of the bell

cranks are 80 degrees with the roll servo in the

neutral position( Figure1 ). Now adjust the

collective rods (2002-217 Bag #8) so that the

pitch arms are in the center of the slot within

the main frame at collective half stick. When

installing the control balls on the collective servo

space the balls 6mm-8mm from the center of the

servo wheel if using a standard radio. If using a

computer radio space the balls 8mm from the

center of the output wheel. This will insure that

you don't have too much collective travel.( FIGURE 2 ).

With this done four swashplate rods

( 2002-221Bag#8) so that the swashplate

will be16-18mm above the upper

bearing block ( Figure 3A/3B ).

1919

1919

19

Adjust the pitch control rod

(2002-221 & 2002-225) as

needed to achieve 4-5

degrees pitch ! ( Figure 4 )

you need slightly bend

#2002-221 to clear mixing

arm too. Now using the high

and low pitch trimmers on

your transmitter set the low

pitch to -1 degree and the

high to +8 degrees !

(see your radio instruction

manual). Adjust the flybar

control rods (2002-219 Bag #8)

so that at half collective stick the

washout control arms will be level ( Figure 5 ).

Now lets move on to the throttle.Adjust the throttle rod

(2002-221 ) and the servo arm so that at full low throttle

and trim the carburetor will be completely closed,You

can using throttle trim to set up idle speed.

At half stick the carburetor should be open exactly 50%

and at full stick the carburetor will be open to 100%.

If you do not get to 100% open than your servo arm

is too short and must be lengthened ( Figure 6 ).

Adjust the elevator lever so that it is 3 degrees

forward with the swashplate level ( Figure 7 ).

The two elevator push rods ( 2002-213 Bag #8)

must be the same length with the servo in the

neutral position.

The last item that needs to be adjusted is the rudder

pushrod. With the servo output arm set at 90 degrees

to the servo, adjust

the pushrod so that

the tail pitch lever

is 90 degrees to the

tail boom

( Figure 8 ).

221

225

4-5

FIG.4FIG.4

FIG.4FIG.4

FIG.4

253

219

043

FIG.5FIG.5

FIG.5FIG.5

FIG.5

FIG.8FIG.8

FIG.8FIG.8

FIG.8

90

90

223

170

215

213

213

FIG.7FIG.7

FIG.7FIG.7

FIG.7

221

221

221

50% (HOVER SPEED)

0% (LOW SPEED)

100% (FULL POWER)

FIG.6FIG.6

FIG.6FIG.6

FIG.6

2020

2020

20

This manual suits for next models

1

Table of contents

Popular Toy manuals by other brands

Eduard

Eduard Yak-130 Assembly instructions

AquaCraft

AquaCraft Gunslinger P-27 instruction manual

Carl Goldberg Products

Carl Goldberg Products EXTRA 300 instruction manual

TechOne Hobby

TechOne Hobby FPV Kraftei 650 EPO user manual

Fisher-Price

Fisher-Price DYM82 quick start guide

Evenflo

Evenflo ExerSaucer instructions