Contents

1General ..................................................................................................................................3

1.1 Comfort......................................................................................................................................................3

1.2 Installation .................................................................................................................................................3

1.3 Long-term security.....................................................................................................................................3

1.4 CE-marking................................................................................................................................................3

1.5 Information about the document................................................................................................................3

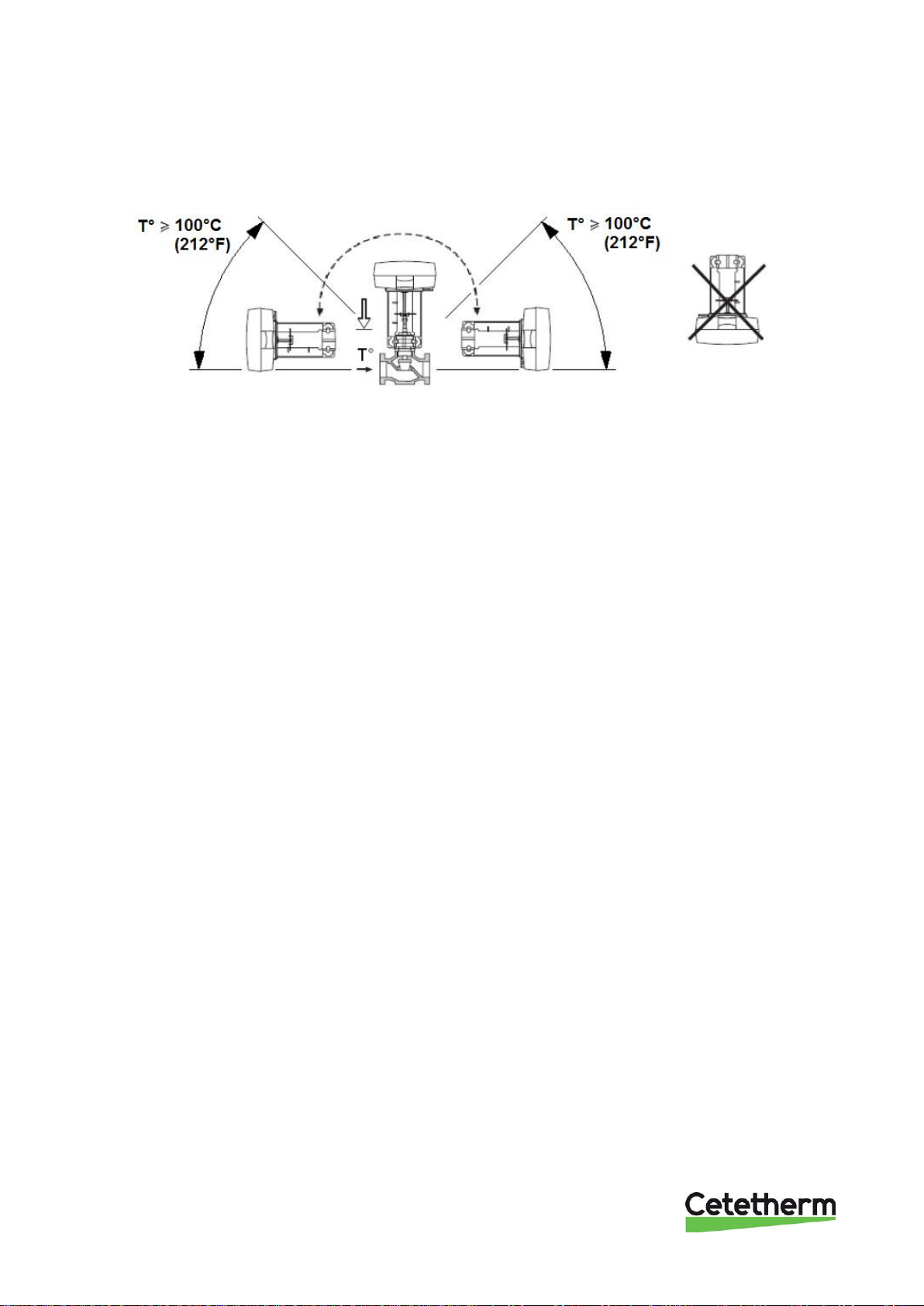

1.6 General warnings ......................................................................................................................................4

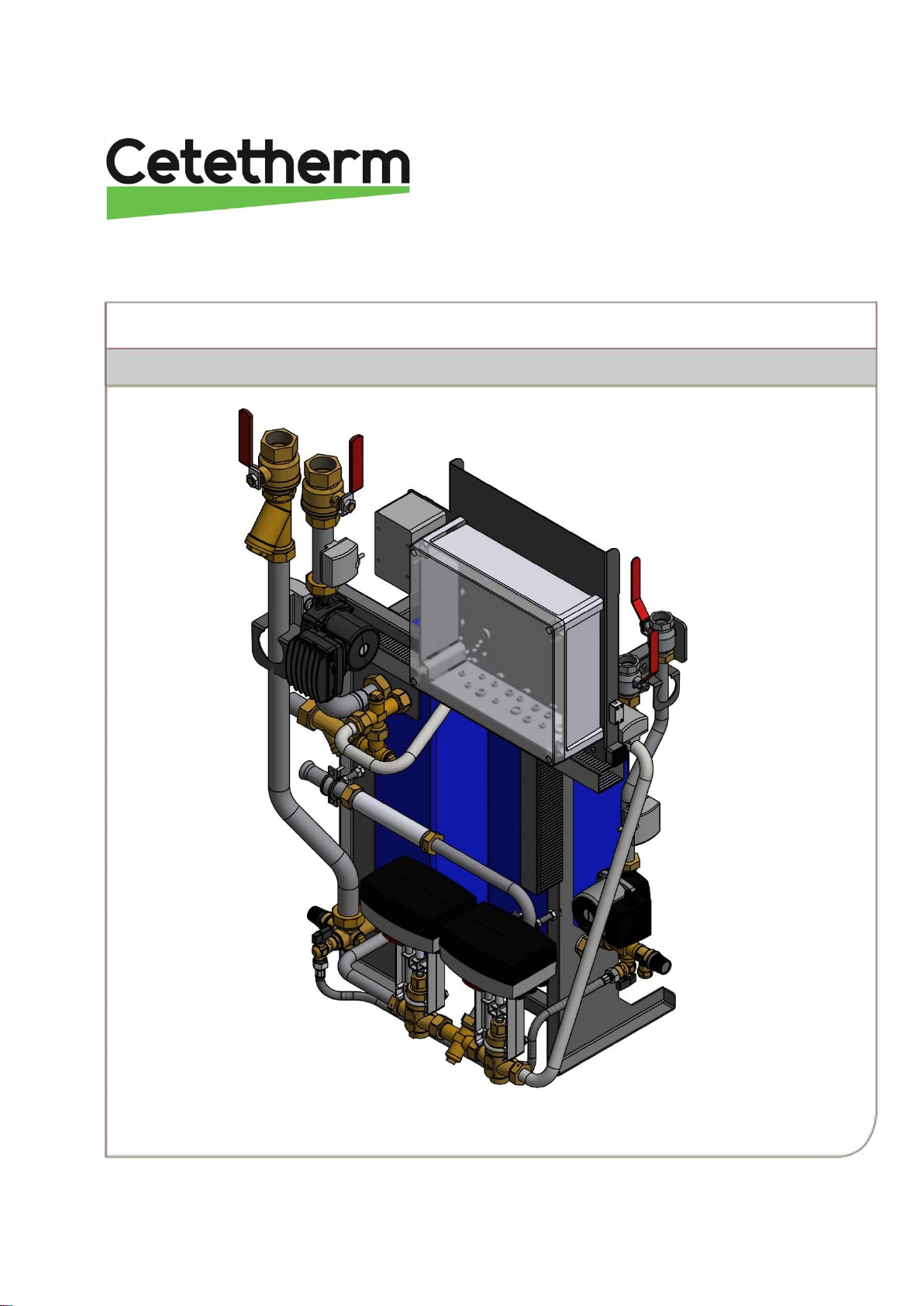

1.7 Product overview Midi Wall .......................................................................................................................5

2Operating instructions..........................................................................................................6

2.1 Operation...................................................................................................................................................6

2.2 Safety equipment/inspection.....................................................................................................................6

3Installation.............................................................................................................................7

3.1 Unpacking..................................................................................................................................................7

3.2 Preparation................................................................................................................................................7

3.3 Mounting....................................................................................................................................................7

3.4 Mounting the options.................................................................................................................................8

3.5 Adjustments and settings for start up........................................................................................................8

3.6 Dismantlement...........................................................................................................................................8

3.7 Commissioning advice ..............................................................................................................................8

3.8 Connection overview.................................................................................................................................9

3.9 Measure sketch Midi Wall IQHeat.......................................................................................................... 10

4Control center IQHeat.........................................................................................................11

4.1 Password and login................................................................................................................................ 12

4.1.1 Log in................................................................................................................................................. 13

4.2 Time functions setting of time and date ................................................................................................. 13

4.2.1 Reading date and time...................................................................................................................... 13

4.2.2 Setting date and time ........................................................................................................................ 13

5Troubleshooting..................................................................................................................14

5.1 Fault indication for IQHeat...................................................................................................................... 14

6Electrical installation..........................................................................................................15

6.1 General................................................................................................................................................... 15

6.2 Connection to internet ............................................................................................................................ 15

6.3 Installation of outdoor temperature sensor............................................................................................. 15

6.4 Electrical circuit diagram ........................................................................................................................ 16

7Schematic diagram, main components.............................................................................17

7.1 Option 3-point HB metering.................................................................................................................... 17

8Pump settings and capacity...............................................................................................18

8.1 General................................................................................................................................................... 18

8.2 DHWC pump Grundfos UPSO 15-55, capacity...................................................................................... 18

8.3 Heating circuit pump Grundfos UPMXL 25-125 180 Auto (GFJOC), settings and capacity.................. 19

8.3.1 Changing pump curve setting ........................................................................................................... 20

8.4 Heating circuit pump Grundfos Magna3 25-100, capacity..................................................................... 21

9Service instructions............................................................................................................22

9.1 Tap water, service instructions............................................................................................................... 22

9.1.1 Tap water too cold............................................................................................................................. 22

9.1.2 Tap water too warm........................................................................................................................... 22

9.1.3 Hot water temperature unstable........................................................................................................ 22

9.1.4 Nosie in the DHWC system............................................................................................................... 23

9.2 Heating system, service instruction........................................................................................................ 23

9.2.1 Heating system temperature too high or too low .............................................................................. 23

9.2.2 No heating......................................................................................................................................... 23

9.2.3 Noise in the radiator system.............................................................................................................. 24

9.2.4 Heating temperature unstable........................................................................................................... 24

9.2.5 Heating system often needs topping up............................................................................................ 24