Cetetherm Mini UK

Installation, service and operating instruction

3

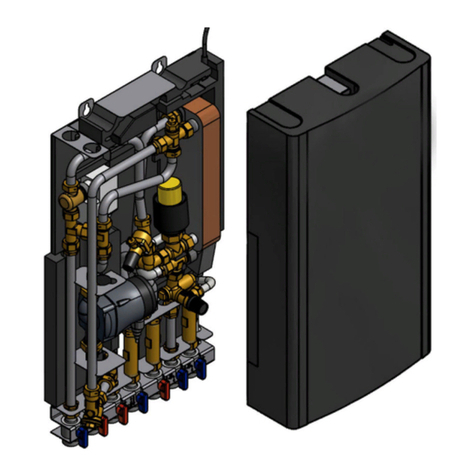

Contents

1General information................................................................................................................ 5

Comfort......................................................................................................................................................5

Installation .................................................................................................................................................5

Long-term security.....................................................................................................................................5

CE-marking................................................................................................................................................5

Information about the document ...............................................................................................................5

General warnings ......................................................................................................................................6

2Operating instructions ........................................................................................................... 7

General operation......................................................................................................................................7

Safety equipment/inspection .....................................................................................................................7

3Product overview and flowchart ........................................................................................... 8

4Installation............................................................................................................................... 9

Unpacking..................................................................................................................................................9

Preparation................................................................................................................................................9

Mounting the HIU ......................................................................................................................................9

Filling up the system................................................................................................................................10

Filling up the tap water circuit.............................................................................................................10

Filling up and bleeding the heating circuit ...............................................................................................10

Connect to heating network ...............................................................................................................10

Commissioning advice Mini UK...............................................................................................................11

Connect the pump..............................................................................................................................11

Adjust the hot water temperature.......................................................................................................11

Set the heating temperature...............................................................................................................11

General adjustments and settings...........................................................................................................11

Dismantlement.........................................................................................................................................11

5Pump settings and pump performance .............................................................................. 12

Performance view....................................................................................................................................12

Operation status.................................................................................................................................12

Alarm status .......................................................................................................................................12

Setting view .............................................................................................................................................13

Toggling the settings of UPM3 ................................................................................................................13

Key lock function .....................................................................................................................................13

Pump curve proportional pressure mode 2, PP2 ....................................................................................14

Fault finding pump...................................................................................................................................15

6Service instructions ............................................................................................................. 16

Tap water service instructions.................................................................................................................16

Tap water temperature too low ..........................................................................................................16

Tap water temperature too high.........................................................................................................17

Hot water temperature unstable or too low ........................................................................................17

Heating system service instructions........................................................................................................17

Heating system temperature too high or too low ...............................................................................17

Heating temperature unstable............................................................................................................18

No heating ..........................................................................................................................................18

Disturbing noise from the circulation pump or the radiator system....................................................19

Heating system often needs topping up.............................................................................................19

7Service actions for the installer .......................................................................................... 20

Check the function of the actuator and valve for hot water.....................................................................20

Check the function of the actuator and valve for heating........................................................................21

Check the volume take-up and pressure equalizing of the expansion vessel ........................................21

8Maintenance and repairs...................................................................................................... 22

Cleaning the heating media filter.............................................................................................................22

Cleaning the heating circuit filter .............................................................................................................23

Change pump components or the complete pump .................................................................................24

Change the hot water actuator and heat exchanger...............................................................................25

Change the hot water valve.....................................................................................................................25