Contents

1General information..............................................................................................................3

1.1 Comfort......................................................................................................................................................3

1.2 Installation .................................................................................................................................................3

1.3 Long-term security.....................................................................................................................................3

1.4 CE-marking................................................................................................................................................3

1.5 Information about the document................................................................................................................3

1.6 General warnings ......................................................................................................................................4

2Operating instructions..........................................................................................................5

2.1 Operation...................................................................................................................................................5

2.2 Safety equipment/inspection .....................................................................................................................5

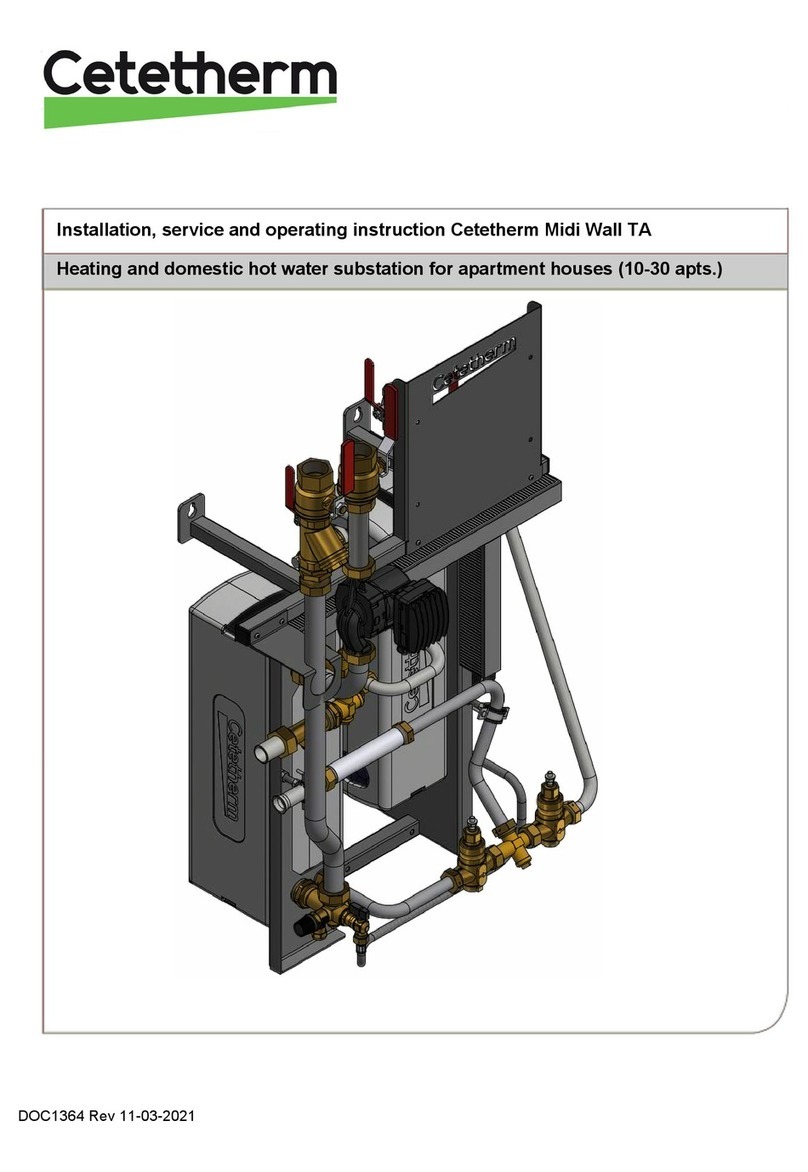

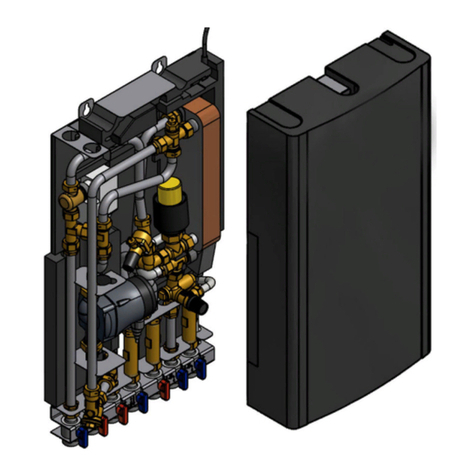

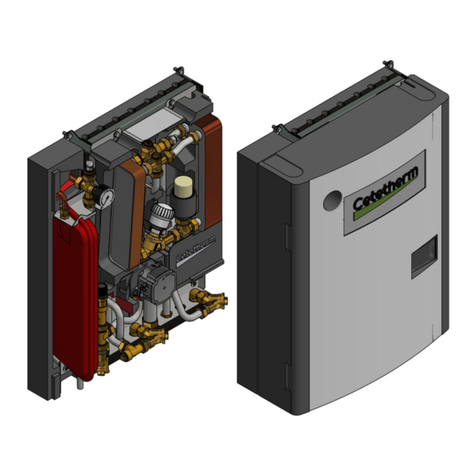

3Product overview..................................................................................................................6

4Installation.............................................................................................................................7

4.1 Unpacking..................................................................................................................................................7

4.2 Preparation................................................................................................................................................7

4.3 Mounting....................................................................................................................................................7

4.4 Mounting options.......................................................................................................................................8

4.5 Adjustments and settings ..........................................................................................................................8

4.6 Dismantlement...........................................................................................................................................8

4.7 Commissioning advice ..............................................................................................................................8

5Measure sketch Mini Plus ....................................................................................................9

6Control panel with room thermostat CM737 .....................................................................10

6.1 General................................................................................................................................................... 10

7Installing and start up the control panel ...........................................................................11

7.1 Using the control panel as a room thermostat ....................................................................................... 11

7.2 Installing the outdoor temperature sensor.............................................................................................. 13

7.3 Starting up and component control of control panel............................................................................... 13

7.4 Configure the control panel after installation.......................................................................................... 13

7.5 Setting the day........................................................................................................................................ 14

7.6 Setting the time....................................................................................................................................... 14

8Operating the room thermostat CM737.............................................................................15

8.1 Choosing the operating mode................................................................................................................ 15

8.2 Temperature Enquiry with the Info-button (7) ........................................................................................ 15

8.3 Holiday function...................................................................................................................................... 16

8.4 OTC heating curve ................................................................................................................................. 16

8.5 Parallel adjustment of heating curve...................................................................................................... 16

8.6 Operating mode Auto ............................................................................................................................. 17

8.6.1 The Built-in Heating Program............................................................................................................ 17

8.6.2 Reviewing the Heating Program ....................................................................................................... 17

8.6.3 Temperature Override....................................................................................................................... 17

8.6.4 Disabling/enabling time periods ........................................................................................................ 17

8.6.5 Modifying the heating program.......................................................................................................... 18

9Activation of installer parameters......................................................................................19

9.1 Entering the installer set-up mode ......................................................................................................... 19

9.2 Category 1 parameters: Control panel settings...................................................................................... 20

9.3 Category 2 parameters: ECO-functions................................................................................................. 20

9.4 Category 3 parameters: Setting and displaying sensor values.............................................................. 21

9.5 Category 4 parameters: Heating actuator settings................................................................................. 21

9.6 Category 5: Fault History........................................................................................................................ 21

10 Troubleshooting the control panel....................................................................................22

10.1 Fault codes on the control panel............................................................................................................ 23

11 Electrical circuit diagram ...................................................................................................24

12 Schematic diagram, main components.............................................................................25

13 Pump settings and pump performance.............................................................................26

13.1 General................................................................................................................................................... 26