CFS 1200 User manual

• !

• " #$ %

•&' (

)#*

• #* +

• "#* ,

) $

• * -

•. */"'$

•"'$

•. *

•0 $/'' !

•1 '0$$ %

•'2*$' +

•$$3$'$ ,

•"4 $ -

•5$" 62

•4"

•. 7'$ !

!) 8 "

• +

•74$/$$$

o' !+

o2 !-

o$$9 !6

o: %

o. $: %

o$/1 '*$' %%

o$;'$;'$ %(

•. * %+

!"#$$

%

&

!!!'

$!$

'#

$$'$$"$' '*5#

"' "<

(!)$

('

*

! #

+

*,,

-.

$/*0.12

.-3.0

.-..201(4

5 )!

*

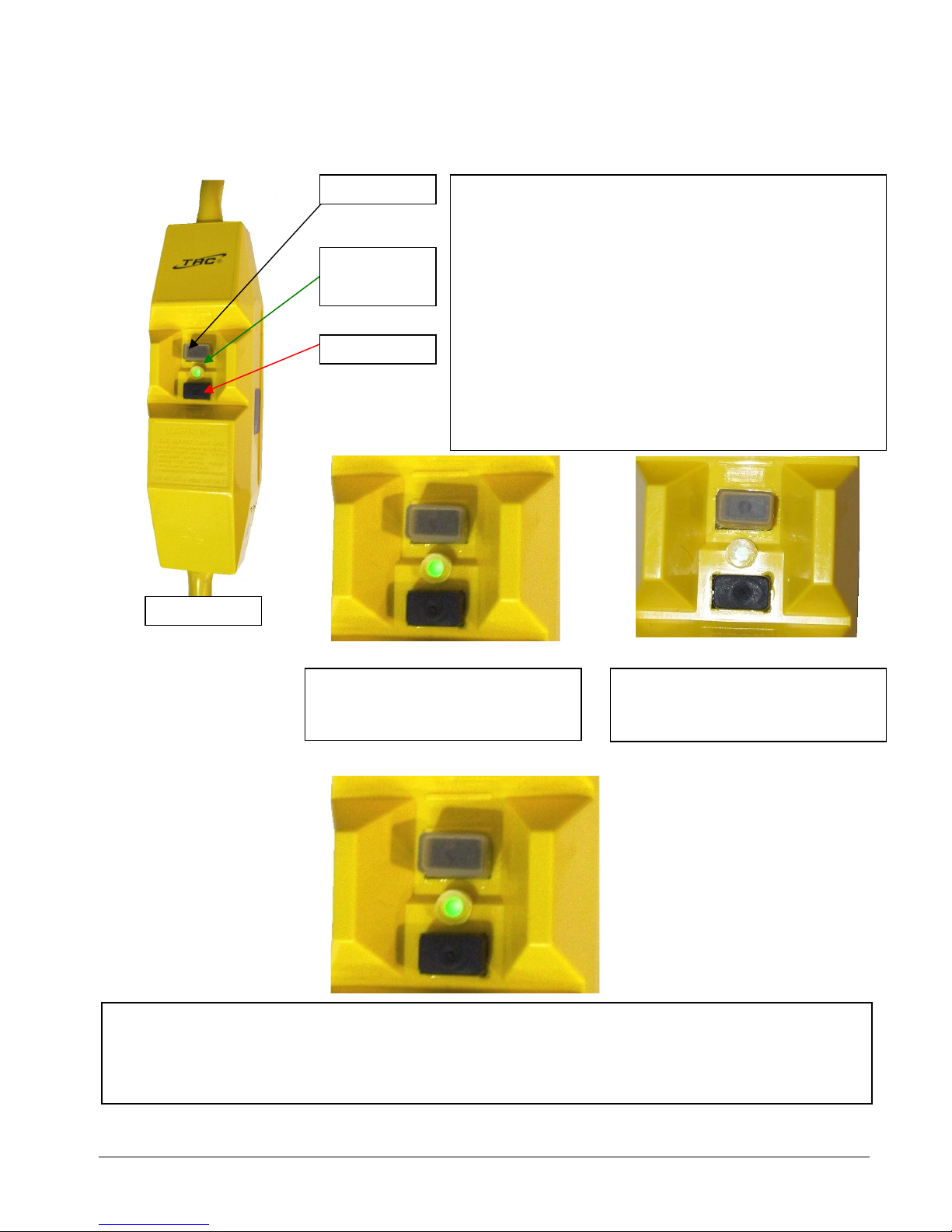

0 "$$=

0")!->

")->

. ")628>

. ")%5$<

: *)

9 ?*: *)

') '2 !(+'4"280

2$@<'

1 '$) 4A'5(<,>'@$ "

4$/"$@$$

'2') 1-2'

=''$<%@='''""+#<

474) @-<+'48<-'#

@6<!''=B%<!'8(<. $'C

&'

0 "$$=

1 '0 $) (DE28>4"28> ##/> ##

%D=28>4"> ##$

0*22

'74@0,

00 $) (D=8%>74"8%>'8#'&: $

*$'4" "'4)

A) %##$# " "'

. *0$) (D=!8->4"8%>#'&: /

#'"$#

'2*$')

'20$) (D=!8%>4"'/#'"$#$

4$) @(D= 48'/#'$

) :*7

'':

8&'

. ) . 6

E20# ) . %

E2,/) .

::/. ) 9(%

::0) 9(

::E2,) .

28>1 '0 $2)B(D@28> ##$C 0!-

> ###28>1 0 $) 0 %+

28> ###28>1 0$) 0%

>0$ 1) 0,+

28>0 $ 1) 0,%

00$8%>E(D482F: $ 0 ,67

8%>F: ) 0

8%>'F: ) 0

'20 $) 0+(

9 '$#0*2)

A) 7

GH"$' "$ <'$5

: "$:# $" :<

•977G7979G990<

•)$

#*

•6! #

•78G$4"

BC $* "$:# $" :<

•8$!!

•8!

•5#$!

•8! 9!

•8#

•5$:!!

•(!

•/! :!

•!! 7!;

7!; .(7

<<!!

=>?

. 9H"$' "'$5 #' $4""'*

'"';:;"$$" '$<

•I#4"$' "4 $$$'$$

@$$'

! @=-AA?5 @$

!

•5' !$ @

@!$$$

$!@

!

o@

• !

• ! $ $

8 * '

!

•8! 0A

•:$$!!B

•8!(!'

•*7!8*7$ $

!C#*7

•6*

!

•D E5 8

!E5G$#''#'52

?#'8'$#'? '$<

JJJG$ ''$$ *$#"$4"$"$&'<JJJ

•D!!

•D $$!(!!

'!

•6#!%

•8!!!8

!,

•% $$ #7!!!

!

"#

A4#"#"$&

$$$#*###' #"= <

G79

< $)

!.B95!!;!

&;!!'

'! +

•;=?!'

•;=? .(7

(7

(!

$ !

7!!!=:95?5<<

$

•5<<$!7

!

•5 $

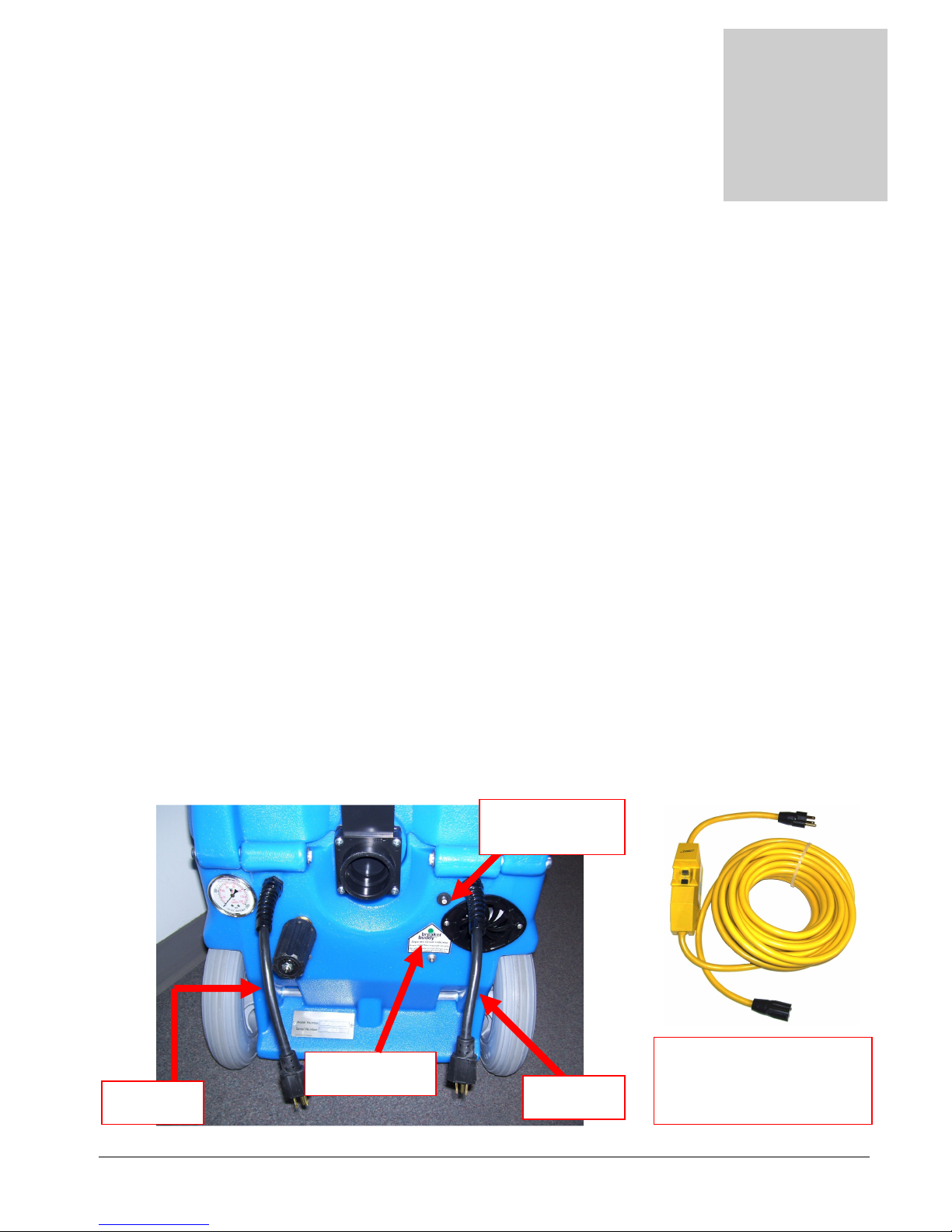

Cord #1

Breaker Buddy

Power Cord – NM4407

50’ – 12 gauge GFCI

protected with M-F Plugs

PUMP CIRCUIT

BREAKER

Cord #2

"$:# $" :; " :"4 $#4

' $5# "$)

$ #$*<

95

% 95 !

$:CC<$

C 95B

•5 :CC

$

:CC !

•

5 :CC

!C $

:CC</F

95,/F

:CC</

95,/

:CC<6/F

9

5,

C<6/F

795:CC</F

/F!

<. */"'=@)

•7!!

!"4

' = %°

°°

°<

•'!

!$!

$ &#

•7! ! !

79GG. 9. 0G00 H$"":

$"4 ' "35<#"4?$4)"'

4 "$"$""'##<#;$ ;##"';#":<

9"'*4'"'?"4*<

<. */"'7@2)

• $

=G*!H7?

"')

•:

•7'

•5$!$! >+=

'1I0@!?

•!'!.1+

!!$I!

•##$"4$4" "'$$;$'*?" "'#"$$"

$:<

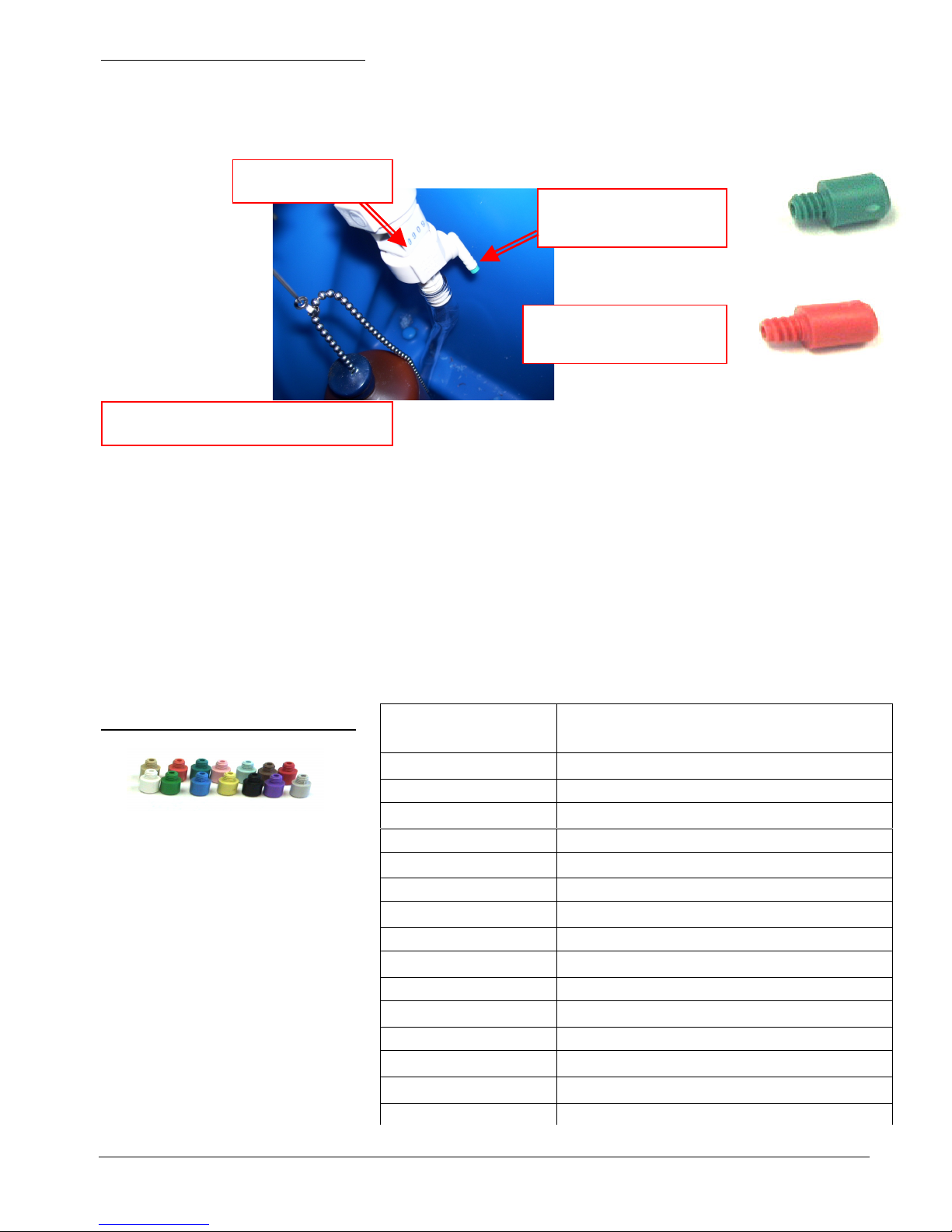

Proportioning Valve

Chemical Feed Hose

Float Hanger

Float

Pour the appropriate amount of hot water

into

the

solution t

ank

Add appropriate amount of chemical to the

hot

water in

the

solution tank

04"")

•:

•6!

•!

AB'7C0$!

+03+: !

•#+'I!$

!>.+

• !!=?!

•!$' #

B$

•*'

")

Metering Tip Kit – PDE001

Turquoise Tip

Dilution 256 - 1

Red Tip

Dilution 85 - 1

57

/,/:

*C5(,85,65/F:(C

/JI9(,=:(5/?

(F -=03+?

/:(F9C 0=-+?

G9FG <(B(+)C

75FD 3.=3+?

,59*<,6C =>+?

<:/% F =0+?

:C8 .=>.+?

% *5C 3.=3-+?

9:CCF =10+?

<,6C .=.+?

"C,,/% -3.=-0+?

<,(D .=1+?

76:7,C >.=.+?

9:(" .=+?

F/57 1.=>+?

Proportioning Valve

. *)

•/+

o(% *!='

?

o!$!

•*! #0°

•=;(4K(4? !

3$"4?"$:)

•!

•()

•

o !!

o !

•

•!

"4?'$5""""

'4 "#$'<

5!$

!$ $

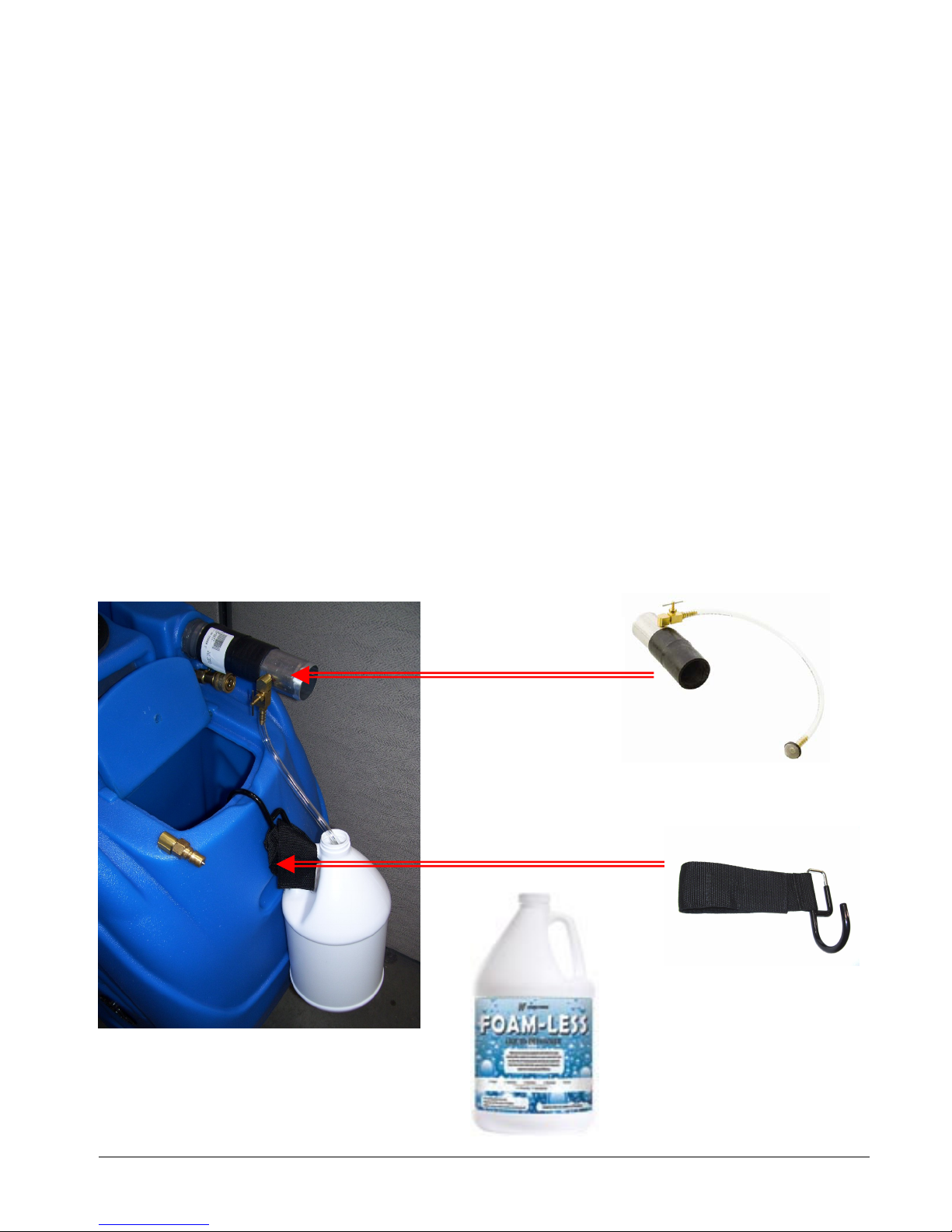

Connect the Auto-Fill Water Supply Hose to Solution Inlet

(Male quick connect on the front of the machine.)

3/8” id X 25’ with F Quick Connect & F Garden Hose Fitting

Chain

Float Valve

Float Bottle

Connect the Auto-Fill Water Supply Hose to a

faucet and turn on the water

Chemical

Feed Hose

Float Hanger

Solution Pump

Float Switch

!< #0 $)

='

?'%

$!/F

%<'"0"2$$')

/!$

+

•!

• 7!!

!!

•,(

•($5$

!

5$!!$

=!?$$I

5 !$ *

7:5CE(,EC

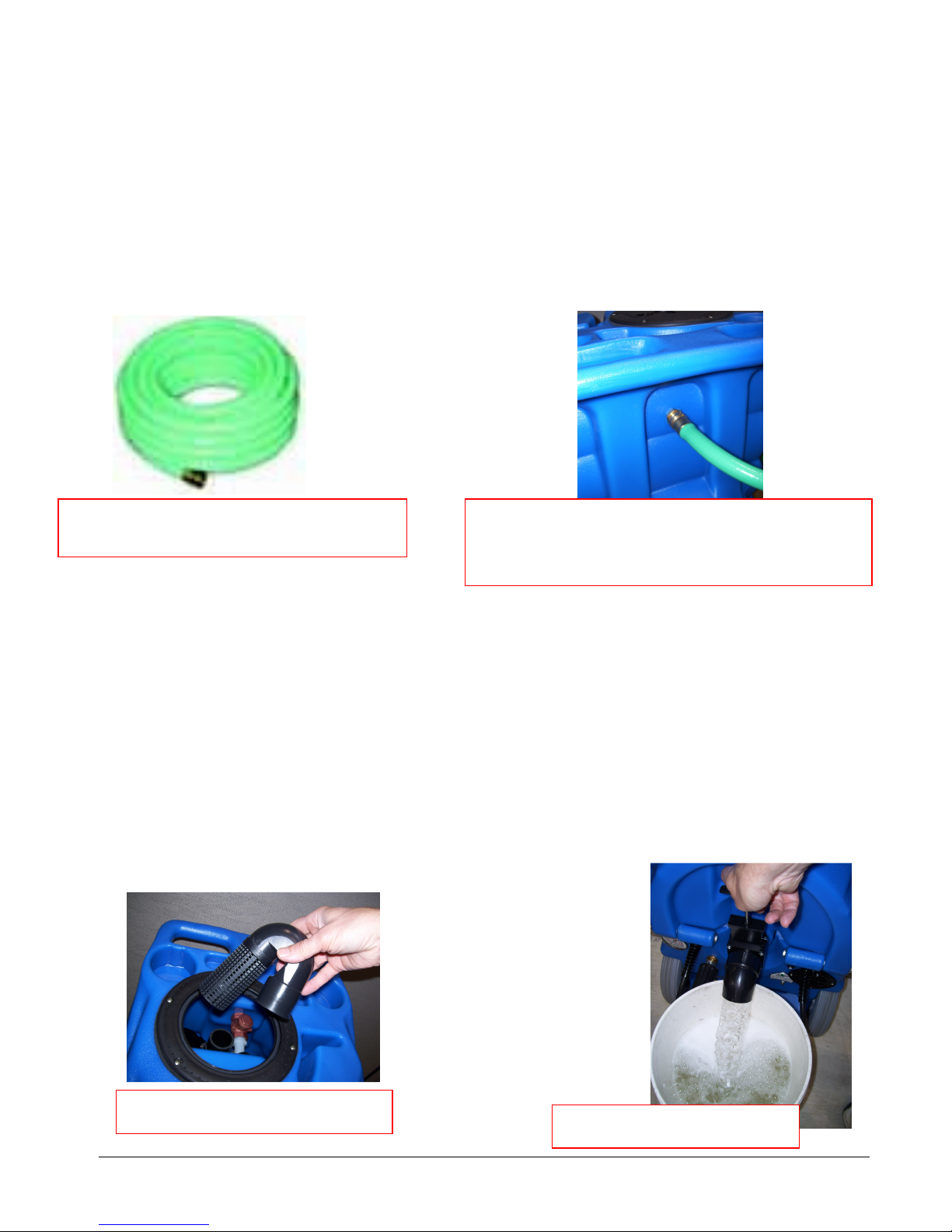

Connect the male end of the HP Solution Hose

Assembly to the female solution outlet fitting on

the machine. Connect the female end to the

cleaning tool.

HP Solution Hose Assembly – AH79AD

1/4” ID X 25’ with 1/4” M-F Quick Connects

(< #1 '0$$)

+

(0B+

*

(*

- (.BE*+H.B

!IH

% $ !/F%

! $!

!/F

Hydro-Filter – AC11

Vacuum Hose

1-1/2” x 25’ with 2” cuff & 1-1/2” cuff

Short Vacuum Hose

1-1/2” x 4’ with 2” cuffs

CFS M1200 Vacuum Hoses & Hydro Filter Connections

'74)

( ! #!!5

! $!!8!

!!

! ! $

8!!!6**=F?

)'!'

8!$ !

•

•6

•F/,(</:LB

•D!

8!!!

!!!%

'!=-?7!

5

!!

% !#

**

(*2.

/(

8/% FC:

/(

,C

*039,

,'

8

+< #'20 $)

.B-I0H

•:

•

•7!

•

G$#'?#'52 ?*: :#'8'$

#'? '$<

% $!!/F

•74$'$4 "$$'2"$$ "$5

<

5!$ %

$ !!

!!!

% +

•5!

•8

o!!

o!

•! !

5!$

Pump-out Hose – AH65

3/4” id X 50’ with M-F Garden Hose Fittings

Connect the Female Garden Hose Fitting end of the

Pump-out Hose to the outlet fitting on the back of the

recovery tank. Place the other end of the pump-out

hose in a sanitary drain.

Float Shutoff Assembly – NM5037

8

:

,<$$3$')

% $!!!

. ""$$*"4$*"$$5?"

<. ""$5$*"4I<

•$ =

!?

•$ =!?

•)'+

o

o

o:)

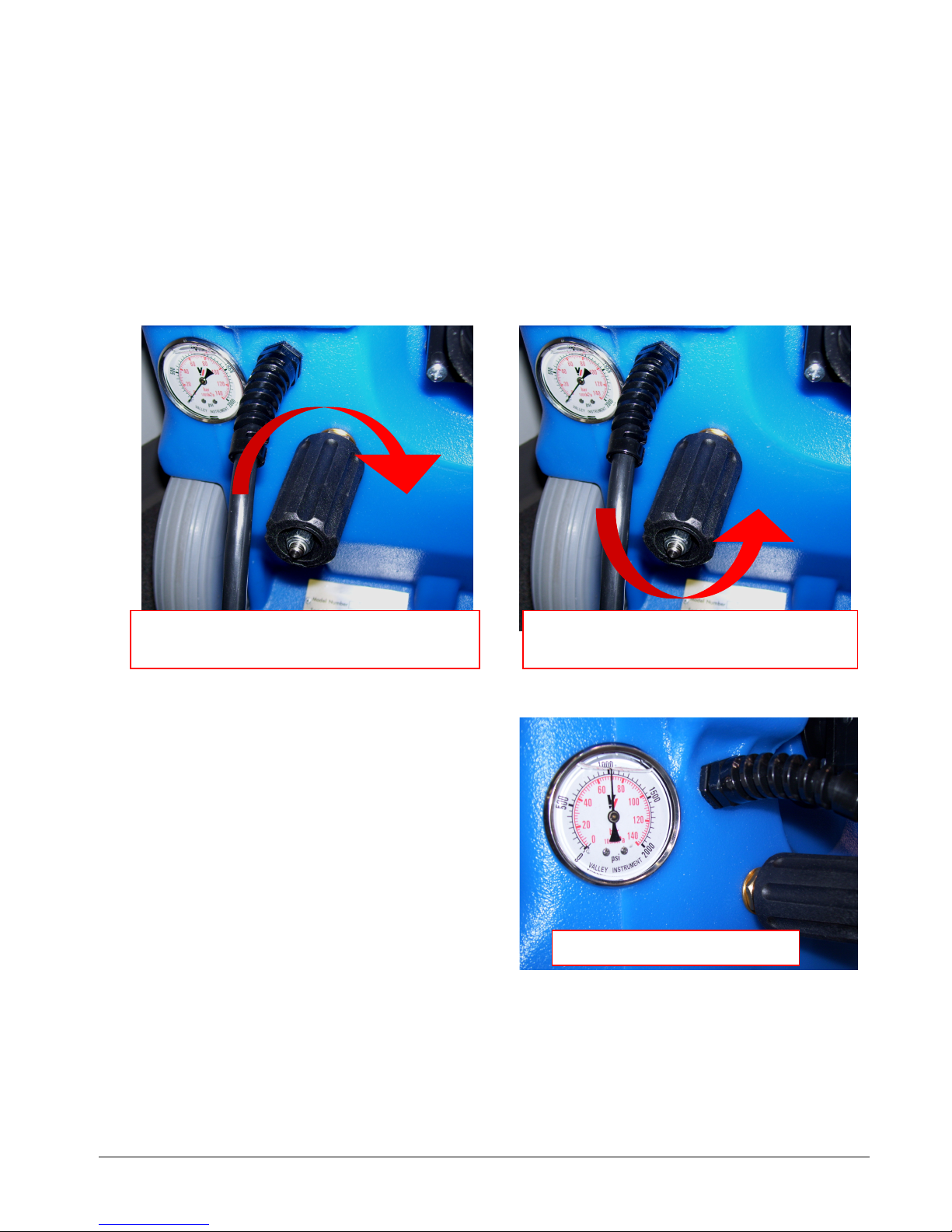

o

To increase the solution pressure, turn the

regulator knob clockwise.

To decrease the solution pressure, turn the

regulator knob counter-clockwise.

#&

!$

!!

+

•)!!!!

•,)!!!

#

!

#+

•!)(% 2!+0

•!4+

5)

$

Pressure gauge

!

"4 $)

•5$! ) !!

!$!#!

•% $!

•5!!$

!!

8!'

•87

•8*

: =((?

•8

•5!$

#!

•5!@$

•5!!+

o!!GH!

o!$

o:!!

o!

•8!

•:

:

•8!

8

•:

#$$

Troubleshooting –

CFS M1200

Problem Cause Solution

Machine not Building circuit breaker tripped. Reset breakers or move cords to other outlets

turning on - Power Cord GFCI tripped Reset GFCI

No power Faulty power cord or GFC1 Replace cord (NM4407)

Faulty switches or internal wiring Check wiring & test switches - Repair as needed *

Building circuit breaker tripped. Reset breakers or move cords to other outlets

Solution Power Cord GFCI tripped Reset GFCI

Pump Faulty power cord or GFC1 Replace cord (NM4407)

not running Water Level too low Raise solution tank water level to engage float switch

Float Switch stuck or defective Free float switch or replace as needed

Faulty switches or internal wiring Check wiring & test switches - Repair as needed *

Float Relay Defective Replace Relay

Pump motor breaker tripped Push in reset button on pump motor

Pump motor faulty Replace pump motor (PT059)

Pump seized - trips breaker

Repair or replace pump head & bearing (PT058) - Check

motor and/or replace complete pump & motor assy. (AP48)

Jets too large for pressure desired

Check jets size & flow rates use smaller jets or lower

pressure

Jets worn allowing too much flow Replace jets

Low Solution Solution inlet filter plugged Clean or replace filter

Pressure or Hose from solution tank restricted Repair or replace hose

Pulsation Pump intake hose / fittings leaking Repair or replace hose. Tighten clamps or replace fittings

Pressure regulator sticking Lube o-rings on regulator shaft

Pressure regulator faulty Repair or replace pressure regulator (PT019A or PT019)

Filter screen or jets plugged on

tool Clean out filter or jets

Solution tank empty Add water to tank - Check & repair auto fill assembly

Pump not primed Perform pump priming procedure

Pump faulty Repair or replace pump (PT059 or AP48)

Pressure Gauge faulty Replace gauge (PT063)

Tool valve faulty Repair or replace valve

Quick connects or hoses restricted

Clean out or replace quick connects and/or hoses

Can't connect Pressure in lines Release pressure

solution hose Quick connects faulty Replace quick connects (100008, 100007)

to machine Wrong style/size quick connects Replace quick connects to match connects on machine

*

To reduce the risk of fire electrical shock or injury, repairs to wiring should only be performed by

experienced service technicians.

If you are not experienced in checking electrical wiring contact your nearest authorized service

center to perform tests and repairs to wiring and switches.

$%

Problem Cause Solution

Pump-out Building circuit breaker tripped. Reset breakers or move cords to other outlets

not working Power Cord GFCI tripped Reset GFCI

Faulty power cord or GFC1 Replace cord (NM4407)

Faulty switches or internal wiring

Check wiring & test switches - Repair as needed *

(NM5008)

Pump-out pump faulty Replace pump-out pump (NM5053)

Pump-out pump clogged

Clean pump-out - Keep recovery tank clean - Use Hydro-

Filter

Outlet check valve stuck Clean or replace check valve

Discharge hose restricted Un-kink, clean out or replace hose

Float switch stuck Clean switch make sure float slides up & down easily

Float switch faulty Replace float switch (NM5054)

Vacuum Building circuit breaker tripped. Reset breakers or move cords to other outlets

Motor Power Cord GFCI tripped Reset GFCI

not running Faulty power cord or GFC1 Replace cord (NM4407)

Faulty switches or internal wiring Check wiring & test switches - Repair as needed *

Vacuum motor faulty Replace vacuum motor (AV010, AV14)

Loss of Vacuum motor faulty Replace vacuum motor (AV010, AV14)

Vacuum Vacuum motor gasket damaged Replace gasket (PA010)

Recovery tank lid gasket damaged

Replace gasket (NM5059)

Drain valve open Close valve

Drain valve leaking Repair or replace drain valve (PEA11)

Vacuum motor hoses loose /

leaking Reconnect or replace vacuum motor hoses

Vacuum hose or tool clogged Clean out vacuum hoses and tool

Vacuum hoses or cuffs leaking Replace vacuum hoses, cuffs & connectors as needed

Recovery tank full Drain tank

Float shutoff filter clogged Clean float shutoff filter

Ball stuck in float shutoff Repair or replace float shutoff (NM5037)

Pump-out Check Valve stuck open

Clean out or replace check valve (NM5052)

Recovery tank damaged Replace recovery tank

Chemical not Solution tank not filling Check & repair auto fill assembly

feeding Chemical hose restricted Un-kink, shorten, clean out or replace hose

Filter screen plugged Clean or replace filter (PDE100-11P)

Low Incoming Water Pressure

Set chemical bottle on top of machine – Shorten Chemical

hose – Find other water source.

Wrong size metering tip Change metering tip

Chemical proportioner faulty Replace chemical proportioner (PDE61-22-3)

Check valve in filter faulty Replace filter (PDE100-11P)

Tool won't Jets clogged Clean out or replace jets

spray - low or Inline filter clogged Clean out or replace filter

uneven spray Jets worn Replace jets

Jets not aligned properly Re-align jets

Tool valve faulty Repair or replace valve

Quick connects or hoses restricted

Clean out or replace quick connects and/or hoses

*

To reduce the risk of fire electrical shock or injury, repairs to wiring should only be performed by

experienced service technicians.

If you are not experienced in checking electrical wiring contact your nearest authorized service

center to perform tests and repairs to wiring and switches.

Popular Floor Machine manuals by other brands

HAKO

HAKO Sweepmaster P1500 RH instruction manual

Pacific

Pacific 535401 Parts & operating manual

SPE

SPE DFG400 Series operating manual

Truvox

Truvox Orbis ECO 200 user manual

Nilfisk-Advance

Nilfisk-Advance AquaRide 56314009 Instructions for use

Nilfisk-Advance

Nilfisk-Advance Advance ConvertaMAX 28 Instructions for use

NSS

NSS CHAMP 3329 RB Operation manual

Numatic

Numatic CRO 8055 troubleshooting guide

Tennant

Tennant castex falcon 2800 WF2800 Operator and parts manual

Windsor

Windsor CLP12 Operator instructions

Kärcher

Kärcher BDS 43/180 C manual

Kent Euroclean

Kent Euroclean SelectGloss 21PH Operator's manual and parts list