CH Hanson PALMGREN 9661616 Instructions for use

Operating Instructions & Parts Manual EN

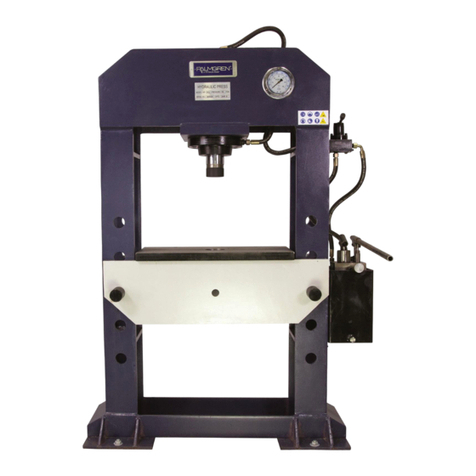

50 Ton Electric

Hydraulic Press

Model 9661616

9643571.01

PLEASE READ AND SAVE

THESE INSTRUCTIONS.

READ CAREFULLY

BEFORE ATTEMPTING

TO ASSEMBLE, INSTALL,

OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED.

PROTECT YOURSELF AND

OTHERS BY OBSERVING ALL

SAFETY INFORMATION. FAILURE

TO COMPLY WITH INSTRUCTIONS

COULD RESULT IN PERSONAL

INJURY AND/OR PROPERTY

DAMAGE! RETAIN INSTRUCTIONS

FOR FUTURE REFERENCE.

PLEASE REFER TO BACK COVER

FOR INFORMATION REGARDING

PALMGREN’S WARRANTY

AND OTHER IMPORTANT

INFORMATION.

Model #: ___________________

Serial #: ___________________

Purch. Date: _______________

© 2019 Palmgren / a C.H. Hanson Brand

All Rights Reserved

3

GETTING STARTED SAFETY / SPECIFICATIONS ASSEMBLY / INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE / REPAIR

GETTING STARTED

Save this manual

You will need this manual for the safety warnings and precau-

tions, assembly instructions, operating and maintenance

procedures, parts lists and diagrams. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover.

Keep this manual and invoice in a safe and dry place for future

reference.

Structural requirements

Make sure all supporting structures and load attaching

devices are strong enough to hold your intended loads.

If in doubt, consult a qualified structural engineer.

Electrical Requirements

• Requires 230V at 60 Hz, with a standard deviation of 10%

• A plug, rated for 230V, 13A, and 2.2 KW, is required to be

wired. Ensure the ground wire(yellow+green) is correctly

wired to the ground of the plug. It does not matter which side

of the plug the two black wires are wired to.

Tools needed

Standard professional mechanic’s hand tool set (i.e. hammer,

screwdrivers, wrenches, socket wrenches, pliers, etc.).

UNPACKING

When unpacking, check to make sure all parts listed below are

included. If any parts are missing or broken, please contact your

local retailer.

IMPORTANT: Many unpainted steel surfaces have been

coated with a protectant. To ensure proper fit and operation,

remove the coating. Coating can be easily removed with mild

solvents, such as mineral spirits, and a soft cloth. Avoid getting

solution on paint or any of the rubber/plastic parts. Solvents may

deteriorate these finishes. Use soap and water on paint, plastic

or rubber components. After cleaning, cover all exposed surfaces

with a light coating of oil.

Never use highly volatile solvents. Avoid

getting cleaning solution on paint as it

may tend to deteriorate these finishes. Use soap and water

on painted components.

Package Contents:

Pipe holders 2

Frame with cylinder 1

Hydraulic pump assembly 1

Replacement rubber o-rings

and hardware

1

Ram cap 1

Manual 1

Unpack

Remove all the over packing materials, but leave unit

attached to its pallet. Do not discard packing materials

until after the machine has been inspected for damage and

completeness. Locate loose parts and set aside.

Inspect

After unpacking the unit, carefully inspect for any

damage that may have occurred during transit. Check

for loose, missing or damaged parts. Shipping damage

claims must be filed with the carrier.

All tools should be visually inspected before use, in addition to

regular periodic maintenance inspections.

MAINTENANCE / REPAIR TROUBLESHOOTING OPERATION ASSEMBLY / INSTALLATION SAFETY / SPECIFICATIONS GETTING STARTED

4

SAFETY RULES

Completely read and understand this

owner’s manual before assembly or tool

operation. Read and understand the warnings shown on the

machine and in this manual. Failure to comply with all of

these warnings may cause serious injury or death.

PROPOSITION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm.

Some Examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry

products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and work with approved

safety equipment. Always wear an OSHA/NIOSH approved,

properly fitting face mask or respirator when using such tools.

Always follow proper operating

procedures as defined in this manual

even if you are familiar with the use of this or similar tools.

Remember that being careless for even a fraction of a

second can result in severe personal injury.

PREPARING FOR YOUR JOB

• Wear proper apparel. Do not wear loose clothing, neckties,

rings, bracelets or other jewelry which may get caught up in

moving parts of machine. Do NOT wear gloves.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lenses.

They are not safety glasses. Use guards and eye shields.

• Wear face mask or dust mask if operation is dusty.

• Wear ANSI approved ear protection for extended operation.

• Some coolants used for machining contain chemicals that

may be hazardous to your health if not used properly. Read

and understand all information on the coolant container and

protect yourself accordingly.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

• Focus your attention completely on your work. Looking

around, careless actions and other distractions can result in

serious injury.

Preparing the work area for your job

• Do not use this machine in dangerous environments. Do not

use it in damp or wet locations. Do not expose it to rain.

• Keep the work area clean. Cluttered work areas and work

benches invite accidents. Keep the area around the machine

clean of scrap metal, oil and grease.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

• Provide adequate space around the hydraulic press and light

the area properly with non-glare, overhead lighting.

• Make certain the hydraulic press is securely anchored before

use.

Maintaining your tool

• Failure to follow the guidelines in this manual can result in

serious injury.

• Disconnect the tool completely from its power supply before

performing any service, maintenance, repair or adjustments.

• Follow OSHA lock-out, tag-out procedures to prevent

accidental machine starts.

• Consult this manual for the proper use, specific maintenance,

and adjustment procedures.

• Keep tool lubricated and clean for safest operation.

• Read and understand warnings posted on the machine and

in this manual. Replace the warning labels if they become

obscured or removed. Failure to comply with all of these

warnings can result in serious injury.

• Before turning on the machine, check for damaged parts.

Check for alignment of moving parts, binding, breakage,

mounting issues and any other conditions that may affect

the tools operation. Replace any guard or damaged part that

does not function properly before using the tool.

• Before cleaning, turn off the machine and disconnect it from

its power source. Use compressed air or a suitable brush to

clear chips or debris — do not use your hands.

Know how to use your tool

The operation of any tool can result in

foreign objects being thrown into the

eyes, which can result in severe eye damage. Always wear

safety goggles complying with United States ANSI Z87.1.

before commencing power tool operation.

Think safety! Safety is a combination of operator

common sense and alertness at all times when tool

is being used.

• The Model 9661616 Hydraulic Press is designed and

intended for use by properly trained operators. You must

be familiar with the proper and safe operation of a hydraulic

press. Obtain proper training and knowledge before operating

this machine.

5

GETTING STARTED SAFETY / SPECIFICATIONS ASSEMBLY / INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE / REPAIR

• Do not use the Model 9661616 Hydraulic Press for any use

other than its intended application. Improper use of this

tool revokes and voids any real or implied warranty. The

manufacturer is not responsible for any injury that may result

from improper use of the machine.

• Do not force an attachment to do a job it was not intended or

designed for.

• Never stand on the machine or work in an awkward position.

Maintain your balance. Never lean against the machine, over

reach or use excessive force when working. You could tip or

fall into the machine causing serious injury.

• Know your tool. Learn the tool’s operation, application and

specific limitations. Never force the machine to do a task it

was designed for.

• Use recommended accessories. Understand and obey all

safety instructions supplied with accessories. The use of

improper accessories may cause risk of injury to persons.

• Always use guards and eyeshields.

SPECIFICATIONS

Model 9661616 50 Ton Electric Hydraulic Press

Capacity (tons) 50

Stroke travel (inch) 8.7

Ram diameter (inch) 1.5 (or 2.25 with ram cap)

Table Size (inch) 16x20 with 4” dia. hole

Max distance ram to table (inch) 27

Head movement No

Dimension (inch) 35x14x62

Weight (lbs) 705

RPM 3450

Volts 230

Amps 13

KW/HP 2.2/3

Phase 1

Operating temperature °F (°C) 50-122 (10-50)

ASSEMBLY/INSTALLATION

Power source

• The motor on this machine is designed for operation on

the voltage and frequency specified. Normal loads will be

handled safely on voltages not more than 10% above or

below specified voltage.

• Running the unit on voltages which are not within the range

may cause overheating and motor burn-out. Heavy loads

require that the voltage at the motor terminals be no less than

the voltage specified.

Electrical connections

Make sure unit is turned off and

disconnected from power before

performing service or maintenance actions on the machine.

This machine must be grounded. To avoid

electrocution or fire, any repairs to

electrical system should be done only by a qualified

electrician, using genuine replacement parts.

Electrical safety

• This machine must be grounded in accordance with the

National Electrical Code and local codes and ordinances. Any

electrical work must be handled by a professional, qualified

electrician. To help prevent and protect the user from shock,

this machine must be properly grounded.

• Confirm that power supply matches power requirements of

the machine before any electrical connection is made to the

machine. Before connecting the machine to a power source,

ensure that the switch is in the off position.

Lifting and setting up your machine

Make certain that slings, cables, chains,

forklifts or other load suspending gear or

machines used to move this unit are properly rated to

handle the weight. The machine is extremely heavy.

The machine must be properly secured

and anchored before use. Make sure that

it is supported equally on all four corners. Failure to comply

may result in the machine twisting and causing binds in the

working table.

1. The machine arrives assembled and ready to us except

that it requires proper electrical wiring to be installed. Have

an authorized electrician prepare an electrical box near the

machine’s installation location.

2. Remove any crating or overpacking materials which may be

covering the machine. Leave the machine attached to the

pallet.

TROUBLESHOOTING OPERATION ASSEMBLY / INSTALLATION SAFETY / SPECIFICATIONS GETTING STARTED

6

MAINTENANCE / REPAIR

NOTE: The Model 9661616 Hydraulic Press weighs 507 lbs. Be

certain any machine or devices used to lift the press are

capable of handling this weight. If manually lifting, ensure

that enough people are performing the lift.

3. Ensure sufficient space is available for the press. See

Machine Dimensions.

4. Remove all accessory items from the pallet or shipping

carton. Compare these items with the listed on page 3.

5. Remove all the nuts and/or bolts securing the machine to the

pallet.

6. Center an overhead crane or other suitable overhead lifting

device and sling arrangement over the frame.

7. Carefully lift the machine off the pallet. Lift the machine no

higher than necessary to clear the surface on which it is to

be installed and pull the pallet out of the way. DO NOT get

your hands or feet underneath the machine when removing

the pallet.

8. Place the machine into its final location where it will be

anchored to the table top. Anchor bolts of sufficient size and

length must be fastened to the table top according to the

footprint of the press.

9. While it is not recommended, the machine may be mounted

to a wooden floor. The floor must be sturdy and properly

braced to ensure a solid foundation for safety and machine

accuracy.

10. When the machine is over its anchor location, level the

machine using shims under the corners needing them. A

highly accurate spirit or digital level should used for leveling.

Leveling should be done on the table top since it is the

reference standard for both side-to-side and front-to-back

leveling. It is very important that the machine be properly

leveled for accurate performance.

Note: The diagrams to the right show the reasonable

approximate dimensions of the machine and its parts. When

determining a final location for your machine ensure there is

enough clearance for both the operator and for technicians

who will service the machine. Also, consider any larger

workpieces that would extend beyond the machine’s table

and require extra space.

11. Have an authorized electrician connect the machine to the

power source installed in step 1. If required, install a plug

the machine’s electrical cable if it is to be plugged in and not

hard-wired.

Note: The direction of the motor will be shown as a large red

arrow on the motor.

Machine dimensions

62”

35”

14”

Lubrication

Do not operate this machine before

lubrication and ensuring proper oil level.

Failure to comply may damage the machine.

Fill the pump with 32# or 46# hydraulic oil as shown by the fill

indications.

7

GETTING STARTED SAFETY / SPECIFICATIONS ASSEMBLY / INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE / REPAIR

OPERATION

Always wear safety glasses complying

with U.S. ANSI Z87.1 before beginning any

power tool operation.

Do not operate this machine before

properly lubricating the machine. Failure

to lubricate the machine before using can cause damage to

the machine.

If the temperature exceeds the maximum

operating temperature (see ) wait until

cool.

Do not use the press with no load and when

the piston rod is on the up dead position.

NOTE: The machine is adjusted to produce proper pressure at

the factory.

Using the press

1. Ensure that the piece to be pressed is centered on the table

with respect to the piston.

Pieces to be pressed must have a

compact, solid structure and must not be

subject to crumbling or other structural damage potential.

And do not activate the press with no load.

2. Before starting the pump, ensure the direction valve handle

is set to the center position.

3. Turn the motor on by pressing the “ON” button as shown

below. Pressing the “OFF” button will shut the motor off.

On/O

Switch

Direction

Control

Lever

4. The piston is controlled by a direction control lever (with a

red ball handle) shown above. The lever has 3 states:

• Left : Up

• Middle: Stop

• Right: Down

When using the press beware of any part

that could be ejected out the front, by the

force applied.

Adjusting the table height

1. Unload the table of all extra items.

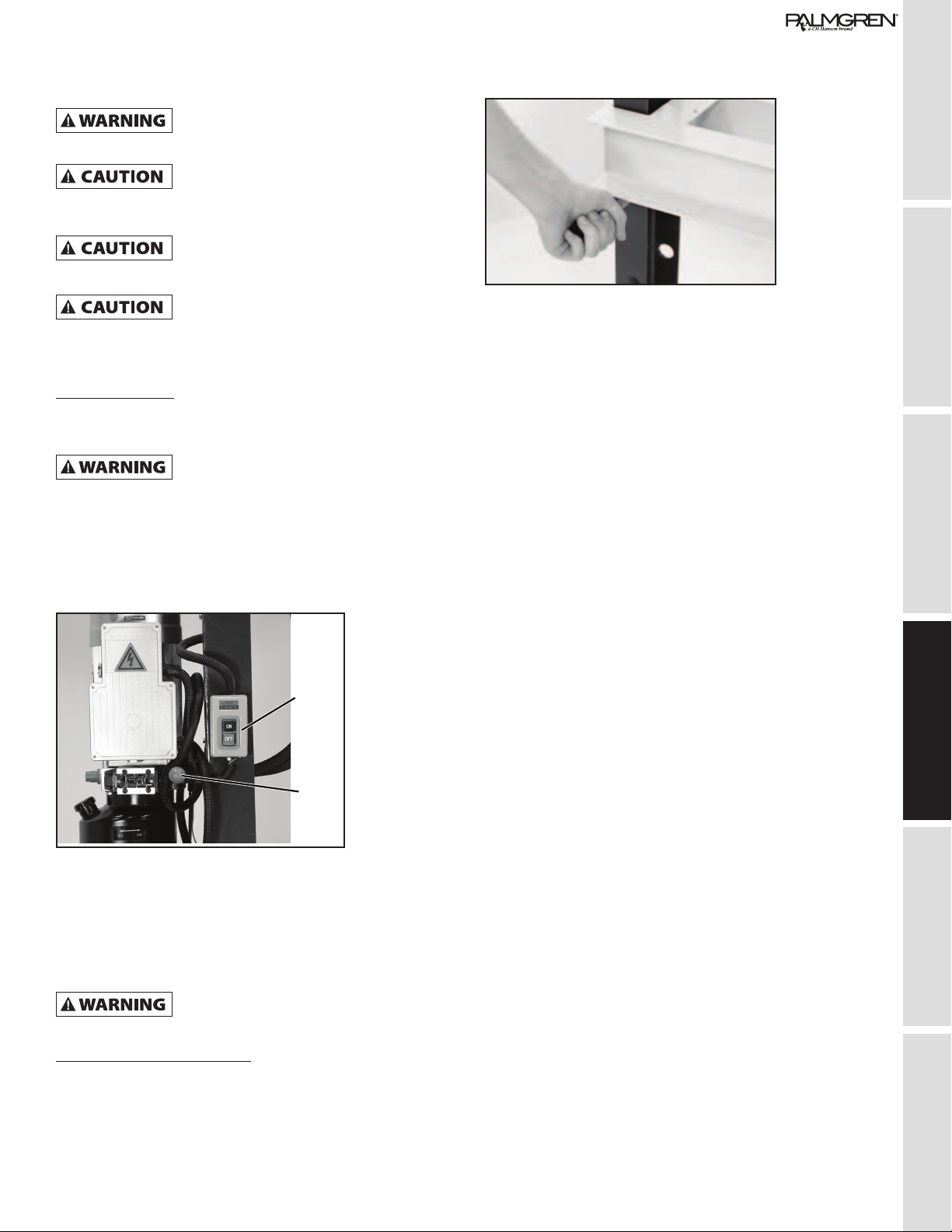

2. Lift the table support beam on one side. We recommend

asking for assistance in holding the beam, although it is

possible to do so only by oneself.

3. Extract the support pin as shown below.

4. Insert the pin into the next adjacent hole, either above or

below the original hole. Make sure to insert the pin all the

way through both the front and back of the hydraulic press

frame.

5. Then ease the support beam back onto the pin. When done

this way, only one person is required.

6. Repeat all previous steps for the opposite side.

7. Repeat until the desired height achieved.

MAINTENANCE / REPAIR TROUBLESHOOTING OPERATION ASSEMBLY / INSTALLATION SAFETY / SPECIFICATIONS GETTING STARTED

8

TROUBLESHOOTING GUIDE

Symptom Possible Cause(s) Corrective Action

Ram does not move • Low oil condition

• Not enough pressure

• Fill oil

• Check motor

Ram does not press Cylinder valve not closed Close cylinder valve

Motor does not run Power disconnected Check on/off switch and circuit breaker

9

GETTING STARTED SAFETY / SPECIFICATIONS ASSEMBLY / INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE / REPAIR

MAINTENANCE/REPAIR

Before any maintenance is performed, ensure all pressure has

been released.

Daily

• General visual inspection-check for any visible damage or

missing parts

• Check that all labels are clearly visible- must be legible as

well

• Check for any leaks in the hydraulic units

• Check the up/down lever is in the stop (middle) position when

not in use

Weekly

• Check oil level

• General cleaning

Monthly

• Check wear on the hydraulic piston and station

• Check tightness of the bolts

Half Year

• Refill with #32 or #46 Hydraulic oil every 6 months. After

refilling, have the piston move up and down to remove the air

from the inside the cylinder.

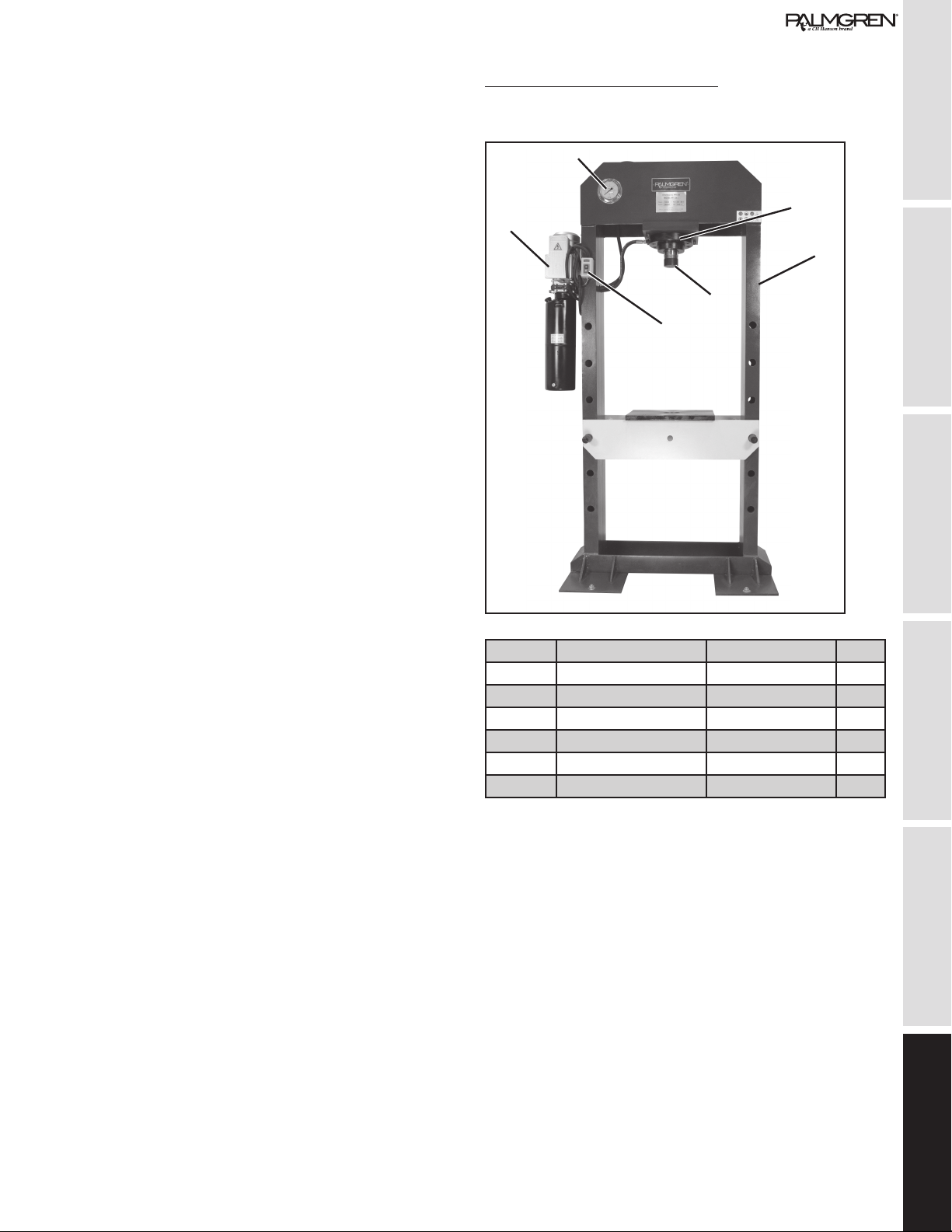

The machine’s functional parts

To properly operate the Model 9661616 Hydraulic Press, you

must familiarize yourself with all of the machine’s controls.

1

2

4

5

3

6

Item No. Description Part No. Qty

1 Cylinder 9643620.01 1

2 Framework NA 1

3 Motor 9643574.01 1

4 Hydraulic Gauge 9643622.01 1

5 On/Off Switch 9643576.01 1

6 Ram Cap 9643621.01 1

MAINTENANCE / REPAIR TROUBLESHOOTING OPERATION ASSEMBLY / INSTALLATION SAFETY / SPECIFICATIONS GETTING STARTED

10

MAINTENANCE/REPAIR -

CROSS SECTION OF PISTON

Item No. Description Qty Item No. Description Qty

1 Oil Vat 1 7 Pressurize Ring 1

2 Stopcock 1 8 Pressurize Ring 1

3 Piston Ring 1 9 Pressurize Ring 1

4 Pressurize Ring 1 10 Vat Cover 1

5 Piston Shaft 1 11 Pressurize Ring 1

6 Pressurize Ring 1 12 Flange 1

ELECTRICAL SCHEMATIC

GETTING STARTED SAFETY / SPECIFICATIONS ASSEMBLY / INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE / REPAIR

11

HYDRAULIC SCHEMATIC

PALMGREN WARRANTY

C.H. Hanson / Palmgren warrants their products to be free of defects in material or

workmanship. This warranty does not cover defects due directly or indirectly to misuse,

abuse, normal wear and tear, failure to properly maintain the product, heated, ground or

otherwise altered, or used for a purpose other than that for which is was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives,

jaws), damage to tools arising from alteration, abuse or use other than their intended

purpose, packing and freight. The duration of this warranty is expressly limited to the terms

noted below beginning from the date of delivery to the original user.

The Palmgren branded items carry the following warranties on parts:

All vises, clamps, positioning tables, tombstones, jack screws and vise

accessories - LIFETIME.

All bench grinders, drill presses, tapping machines, band saws, lathes, milling

machines, arbor presses, abrasive finishing machines and work stands - 3

YEARS.

The obligation of C.H. Hanson / Palmgren is limited solely to the repair or replacement, at

our option, at its factory or authorized repair agent of any part that should prove inoperable.

Purchaser must lubricate and maintain the product under normal operating conditions at

all times. Prior to operation become familiar with product and the included materials, i.e.

warnings, cautions and manuals.

Failure to follow these instructions will void the warranty.

This warranty is the purchaser’s exclusive remedy against C.H. Hanson for any inoperable

parts in its product. Under no circumstances is C.H. Hanson liable for any direct, indirect,

incidental , special or consequential damages including loss of profits in any way elated to

the use or inability to use our products. This warranty gives you specific legal rights which

may vary from state to state.

Palmgren - a C.H. Hanson Company

2000 N. Aurora Rd., Naperville, IL

60563

U.S.A.

or call 1-800-827-3398

Table of contents

Other CH Hanson Power Tools manuals