CH Hanson Norse 9680202 Instructions for use

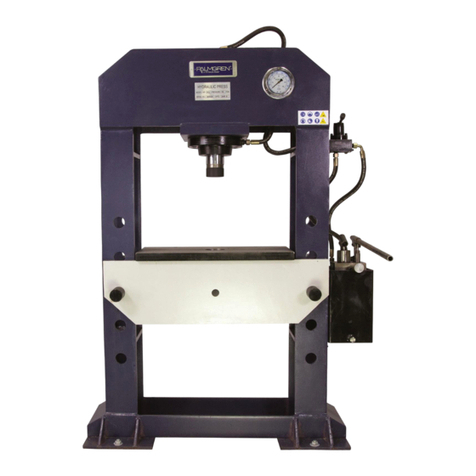

8˝ Drill Press

Operating Instructions & Parts Manual

9640915.01 0318

Model 9680202

9680202_oipm_En011_9640915.01 03/21/18 Page 1

2

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9680202

Please read and save hese ins ruc ions. Read carefully before a emp ing o assemble, ins all,

opera e or main ain he produc described.

Pro ec yourself and o hers by observing all safe y informa ion. Failure o comply wi h ins ruc ions

could resul in personal injury and/or proper y damage! re ain ins ruc ions for fu ure reference.

Model #: ________________________

Serial #: _________________________

Purchase Da e: ___________________

9680202_oipm_En011_9640915.01 03/21/18 Page 2

GE ING S AR ED

Save his Manual

You will need the manual for the safety warnings and pre cautions,

assembly instructions, operating and maintenance procedures,

parts list and diagram. Keep your invoice with this manual. Write

the invoice number on the inside of the front cover. Keep this

Manual and invoice in a safe and dry place for future reference.

Structural Requirements

Ensure all supporting structures and load attaching devices are

strong enough to hold the intended loads. If in doubt, consult a

qualified structural engineer.

Electrical Requirements

The power supply to the 8” Bench Model Drill Press needs to be

120 volts, single phase, 60 Hz. The standard allowable voltage

variation is plus or minus 10%.

ools Needed:

Standard mechanic’s hand tool set (i.e. hammer, screwdrivers,

adjustable wrenches, etc.).

UNPACKING

When unpacking, check to make sure all parts listed below are

included. If any parts are missing or broken, please contact your

local retailer.

IMPOR AN : Many unpainted steel surfaces, such as the column

and table top, have been coated with a protectant. To ensure

proper fit and operation, remove coating. Coating can be easily

removed with mild solvents, such as mineral spirits, and a soft

cloth. Avoid getting solution on paint or any of the rubber/ plastic

parts. Solvents may deteriorate these finishes. Use soap and water

on paint, plastic or rubber components. After cleaning, cover all

exposed surfaces with a light coating of oil. Paste wax is

recommended for table top.

Never use highly vola ile solven s.

Nonflammable solven s are recommended

o avoid possible fire hazard.

Contents:

• Head assembly/motor (1)

• Base (1)

• Column (1)

• Table assembly (1)

• Handles (3)

• Chuck/chuck key (1)

• Table lock handle (1)

• 3mm hex-wrench (1)

• 4mm hex-wrench (1)

• Operating Instructions & Parts Manual (1)

Unpack

Open carton and carefully remove the top Styrofoam section,

containing the base, table assembly, chuck box, and hardware bag.

Then remove the head assembly and column from the lower

Styrofoam section. Do not discard packing materials until after the

machine has been inspected for damage and completeness.

Locate loose parts and set aside.

Inspect

After unpacking the unit, carefully inspect for any damage that may

have occurred during transit. Check for loose, missing, or damaged

parts. Shipping damage claims must be filed with the carrier. All

tools should be visually inspected before use, in addition to regular

periodic maintenance inspections. Be sure that the voltage labeled

on the unit matches your power supply.

SAFE Y RULES

For you own safe y, read all of he

ins ruc ions and precau ions before

opera ing he ool.

PROPOSI ION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm. Some Examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry

products

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

When using he ool, basic safe y

precau ions should always be followed o

reduce he risk of personal injury and damage o equipmen .

Read All Instructions Before Using his ool!

• Dress properly. Do not wear loose clothing or jewelry as they

can be caught in moving parts. Protective, electrically non -

conductive clothes and non-skid footwear are recommended

when working. Wear restrictive hair covering to contain long hair

• Use eye and ear protection. Always wear ANSI approved

impact safety goggles.

• Stay alert. Watch what you are doing, use common sense. Do

not operate any tool when you are tired.

• Guard against electrical shock. Prevent body contact with

grounded surface such as pipes, radiators, ranges and

refrigerator enclosure.

• Do not operate tool if under the influence of alcohol or drugs.

Read warning labels on prescriptions to determine if your

judgement or reflexes will be impaired. If there is any doubt, do

not operate the tool.

3

NOR E Operating Manual & Parts List 9680202

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9680202_oipm_En011_9640915.01 03/21/18 Page 3

SAFE Y RULES CON INUED

Prepare Work Area for Job

• Keep work area clean. Cluttered areas invite injuries.

• Observe work area conditions. Do not use machines or power

tools in damp or wet locations. Do not expose to rain.

• Keep work areas well lighted. Do not use electrically powered

tools in the presence of flammable gases or liquids.

• Keep children away. Children must never be allowed in the

work area. Do not let them handle machines, tools or extension

cords.

• Use proper size and type extension cord.

• If an extension cord is required, it must be of proper size and

type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or

cause electrical damage to the tool. If you are using the tool

outdoors, use an extension cord rated for outdoor use

(signified by “WA” on the jacket).

ool Should Be Maintained

• Store idle equipment. When not in use, tools must be stored in

a dry location to inhibit rust. Always lock up tools and keep out

of reach of children.

• Maintain tools with care. Keep tools sharp and clean for better

and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if

damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry and free from oil and

grease at all times.

• Disconnect power. Unplug too when not in use.

• Replacement parts and accessories. When servicing, use only

identical replacement parts. Use of any other parts will void the

warranty. Only use accessories intended for use with this tool.

Approved accessories are available from your local retailer.

• Maintenance. For your safety, service and maintenance should

be performed by a qualified technician.

Know How to Use ool

• Do not force tool. It will do the job better and more safely at the

rate for which it was intended. Do not use inappropriate

attachments in an attempt to exceed the tool capacity.

• Use the right tool for the job. Do not attempt to force a small

tool or attachment to do the work of a large industrial tool.

There are certain applications for which this tool was designed.

Do not modify this tool and do not use this tool for a purpose

for which it was not intended.

• Do not overreach. Keep proper footing and balance at all times.

Do not reach over or across machines while in operation.

• Remove adjusting keys and wrenches. Check that keys and

adjusting wrenches are removed from the tool or machine work

surface before plugging it in.

• Avoid unintentional starting. Be sure the switch is in the OFF

position when not in use and before plugging in.

• Check for damaged parts. Before using any tool, any part that

appears damaged should be carefully checked to determine

that it will operate properly and perform its intended function.

Check for alignment and binding of moving parts; any broken

parts or mounting pieces should be properly repaired or

replaced by a qualified technician. Do not use the tool if any

switch does not turn ON and OFF properly.

The warnings, cau ions and ins ruc ions

discussed in his ins ruc ion manual

canno cover all possible condi ions and si ua ions ha may

occur. I mus be unders ood by he opera or ha common

sense and cau ion are fac ors which canno be buil in o

his produc , bu mus be supplied by he opera or.

SPECIFICA IONS*

Chuck size 1/2˝

Spindle taper T33

Spindle travel 2˝

Spindle axis to column surface distance 4˝

Spindle to base surface distance 111⁄2˝

Spindle to table surface max distance 81⁄4˝

Spindle speeds 5

Spindle RPM 750 – 3200

Table dimensions 61⁄2˝ x 61⁄2˝

Table rotation around column 360°

Base size (L x W) 103⁄4˝ x 7˝

Overall dimension (L x W x H) 17˝ x 8˝ x 23˝

Net weight 35 lbs.

Motor 120V, 2.3A, 300W, 1/3 HP, 60 Hz

Motor RPM 1725

Column diameter 1-13/16” or 46mm

*NOTE: Spindle measurements are from the bare spindle without

the chuck.

4

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9680202

9680202_oipm_En011_9640915.01 03/21/18 Page 4

ASSEMBLY

ools Needed for Entire Assembly

• Adjustable wrench

• Hammer with block of wood or rubber hammer

• Screwdriver

Base to Column

1. Place the base on a stable surface (either on a sturdy table or

the floor)

2. Set the column on the base, making sure to line up the three

holes in both the base and column.

3. Insert a bolt, first with a lock washer then a flat washer, into

each hole.

4. Tighten with a wrench.

able to Column

1. Slide the table’s sleeve onto the column and set at desired

height.

2. Make sure to line up and center the table to the base, below.

3. Use the handle to tighten and lock in position.

Drill Press Head to Column

1. Carefully place the head on the column, and ensure the head

is seated properly on the column.

2. Align the drill spindle with the table and base.

3. Using the provided Allen wrenches, tighten the set screws on

the side of the drill head, until the drill head can no longer

swivel on the column.

Install the Drill Chuck

1. Using a clean cloth, inspect and clean the spindle and tapered

hole of the chuck. Remove all grease, coatings and particles.

2. Ensure the chuck jaws are fully retracted.

3. Fit the chuck onto the spindle by placing a piece of wood under

the chuck and tapping the wood with a hammer, or use a

rubber hammer instead of the wood and normal hammer.

Do no direc ly hi he chuck wi h a

normal hammer.

Mount the Drill Press

If needed, the drill press can be mounted to a stand or work bench

with heavy duty fasteners, using the slots on the base.

INS ALLA ION

All elec rical connec ions mus be

performed by a qualified elec rician.

Power Source

The motor is designed for operation on the voltage and frequency

specified. Normal loads will be handled on voltages not more than

10% above or below the specified voltage.

Running the unit on voltages which are not within the range may

cause overheating and motor burn-out. Heavy loads require that

the voltage at motor terminals be no less than the voltage specified.

Grounding Instructions

Improper connec ion of equipmen

grounding conduc or can resul in he risk

of elec rical shock. Equipmen should be grounded while

use o pro ec opera or from elec rical shock.

Check with qualified electrician if grounding instructions are not

understood or if in doubt as to whether the tool is properly

grounded.

Extension Cords

• Your tool has a three-prong plug; therefore, you must use a

three-prong extension cord. Only use rounded jacket extension

cords listed by the UL.

• Improper use of extension cords may cause inefficient

operation of your tool which can result in overheating. Be sure

your extensions cord is rated to allow sufficient current flow to

the motor. If you are using the tool outdoors, use an extension

cord rated for outdoor use (signified by “WA” on the jacket).

• Avoid body contact with the grounded surfaces such as pipes

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded. If operating the

power tool in damp locations is unavoidable, a Ground Fault

Circuit Interrupter must be used to supply the power to your

tool. Electrician’s rubber gloves and footwear will further

enhance your personal safety.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tool or

pull the plug from an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase risk of electric shock.

• The use of an extension cord will cause some drop in voltage

and loss of power.

• Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

• Use only 3-wire extension cords, having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way,

replace it immediately.

• For wire size, lengths up to 25 ft. have an A.W.G of 16. 25 ft. to

100 ft. have an A.W.G. of 14 NOTE: Using extension cords

over 100 ft. are not recommended.

5

NOR E Operating Manual & Parts List 9680202

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9680202_oipm_En011_9640915.01 03/21/18 Page 5

OPERA ION

Starting and Stopping the Drill

Be sure drill bi is no in con ac wi h

workpiece when s ar ing he mo or. S ar

he mo or and allow bi o come up o full speed before

drilling.

1. The ON/OFF switch is located on the front of the head casting.

2. To turn drill ON, ensure the plastic key is inserted into the

switch and flip the switch to the up position.

3. To turn drill OFF, push the switch to the down position.

The drill can be locked from authorized use by locking the switch:

To lock turn the switch to the OFF position, disconnect the drill from

the power source, and remove the key from the switch.

NOTE: Should the key be removed from the switch at the ON

position, the switch can be turned off but cannot be turned on

again.

To replace key, slide key into the slot on switch until it snaps in.

Speed Adjustments

Ensure drill press is urned off and is

disconnec ed from power source before

adjus ing speeds.

1. To change the spindle speed, unlatch the plastic casing on the

head, and loosen the bolts attaching the motor to the head, if

needed.

2. Push the motor towards the rest of the head, and use the

locking knob on the same side as the drill quill handles, to lock

the motor in position. This will loosen the belt and permit

relocation to the desired pulley groove for desired spindle

speed.

3. After belt is repositioned, push motor back to original position

and tighten the motor lock knob.

4. Check belt for proper tension and make any final adjustments.

A belt is properly tensioned when light pressure applied to

midpoint of the belt produces about ½˝ deflection.

able Adjustments

1. To adjust the height, loosen the handle on the back of the

sleeve, and slide along the column to desired height, and re-

tighten the handle.

2. To tilt the work table, loosen the table bolt/nut on the underside

of the table and tilt to desired angle up to 45° and retighten.

3. To obtain more distance between chuck and the table, the

work table can be rotated to the back of the column using the

steps from number 1 of this list. This permits drilling larger

objects

4. Clamp the table securely after all adjustments have been

made.

Depth Stop Adjustment

To decrease the drilling depth,

loosen the hex nuts on the opposite

side of the head from the 3 quill

feed handles. Using the depth

measure, set the bottom of the hex

nuts to the desired depth.

Mount Drill Bit

Ensure drill

press is urn -

ed off and is dis con nec ed from

power source before moun ing

drill bi .

1. Place drill bit in jaws of chuck.

2. Using the chuck key, tighten using all 3 positions on chuck

body and remove key.

3. Use only the self-ejecting chuck key provided with this drill

press, or a duplicate. Use of any other key might allow start

with the key still in the chuck. An airborne key could strike the

operator and cause injury.

MAIN ENANCE

Turn swi ch off and remove power plug

from wall ou le before main aining or

lubrica ing your drill press.

Replace worn drive belt when needed.

Lubrication

The ball bearings are lubricated at the factory and need no further

lubrication. Using 20 wt. non-detergent oil, periodically lubricate the

splines (grooves) in the spindle and the rack (teeth on the quill) as

follows:

1. Lower quill assembly all the way down.

2. Apply lubricant around the inside of the hole in the spindle

pulley

3. Apply lubricant to rack (teeth) on quill, while fully extended.

4. Apply lubricant to rack and pinion gear on column and table

assembly.

5. Frequently blow out any dust that may accumulate inside the

motor. If the power cord is worn, cut, or damaged in any way,

have it replaced immediately. For motor lubrication, follow

instructions on motor plate.

6

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9680202

9680202_oipm_En011_9640915.01 03/21/18 Page 6

7

NOR E Operating Manual & Parts List 9680202

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

ROUBLESHOO ING GUIDE

Symptom Possible Cause(s) Corrective Action

Noisy operation

Bit burns or smokes

Excessive drill run out or wobble

Drill bit binds in work piece

1. Incorrect belt tension

2. Dry spindle

3. Loose spindle

4. Loose motor pulley

1. Incorrect speed

2. Chips not coming out of hole

3. Dull bit

4. Feeding too slow

5. Bit not lubricated

6. Bit running backwards

1. Bent bit

2. Bit not properly installed in chuck

3. Chuck not installed properly

4. Worn spindle bearings

1. Workpiece pinching bit or excessive

feed pressure

2. Improper belt tension

3. Workpiece not supported or clamped

properly

1. Adjust tension

2. Lubricate spindle (see Maintenance, page 6)

3. Tighten pulley nut

4. Tighten set screw in pulley

1. Change speed

2. Retract bit frequently to clear chips

3. Sharpen or replace bit

4. Feed faster; enough to allow drill bit to cut

5. Lubricate bit

6. Check motor rotation to be sure it is clockwise

facing shaft end

1. Replace bit

2. Install bit properly

3. Install chuck properly

4. Replace bearings

1. Support or clamp work, decrease feed pressure

2. Adjust belt tension

3. Support or clamp workpiece securely

9680202_oipm_En011_9640915.01 03/21/18 Page 7

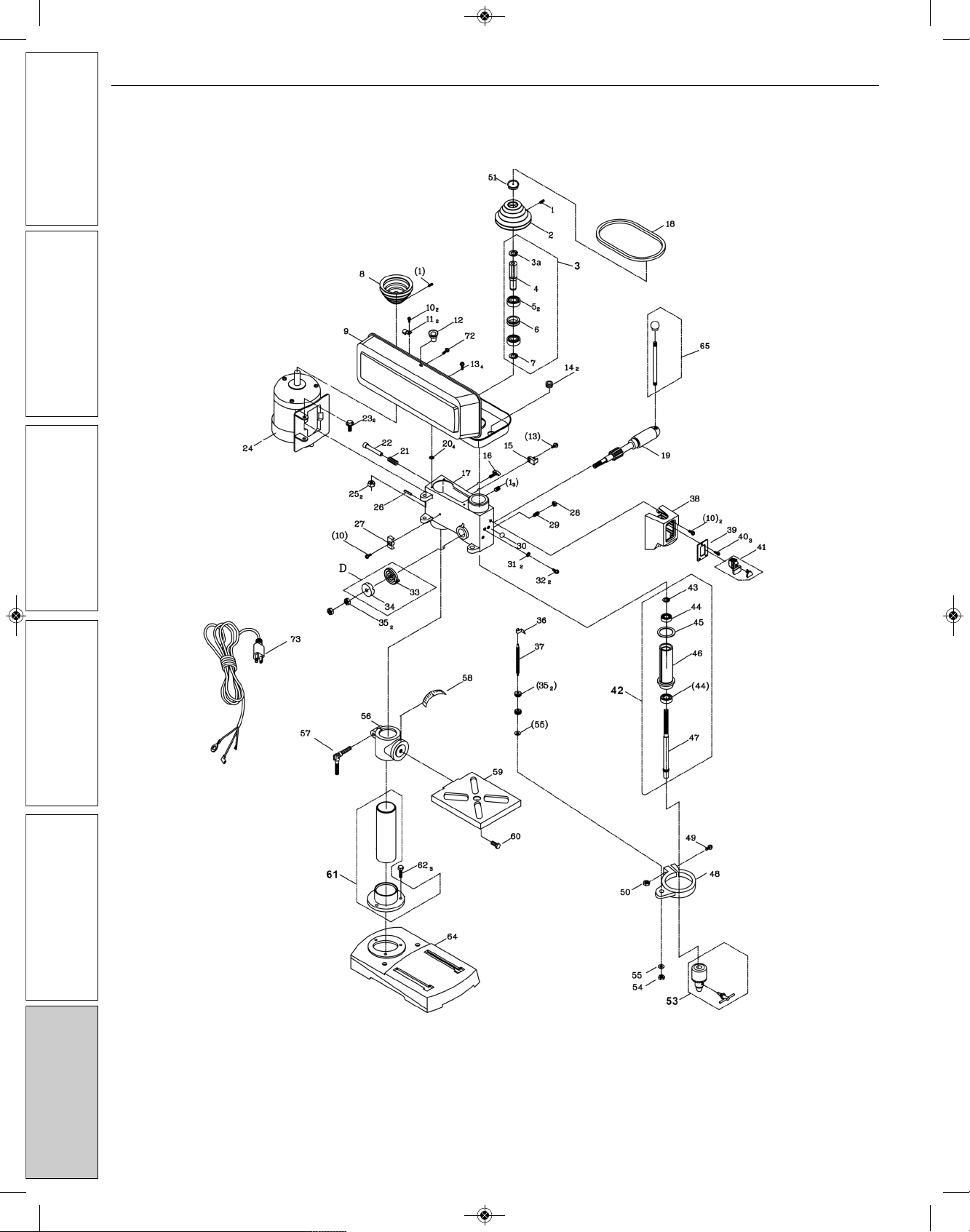

REPAIR PAR S ILLUS RA ION FOR 9680202 8˝ DRILL PRESS

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9680202

8

Replacement Parts Illustration for 8˝ Drill Press

9680202_oipm_En011_9640915.01 03/21/18 Page 8

NOR E Operating Manual & Parts List 9680202

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9

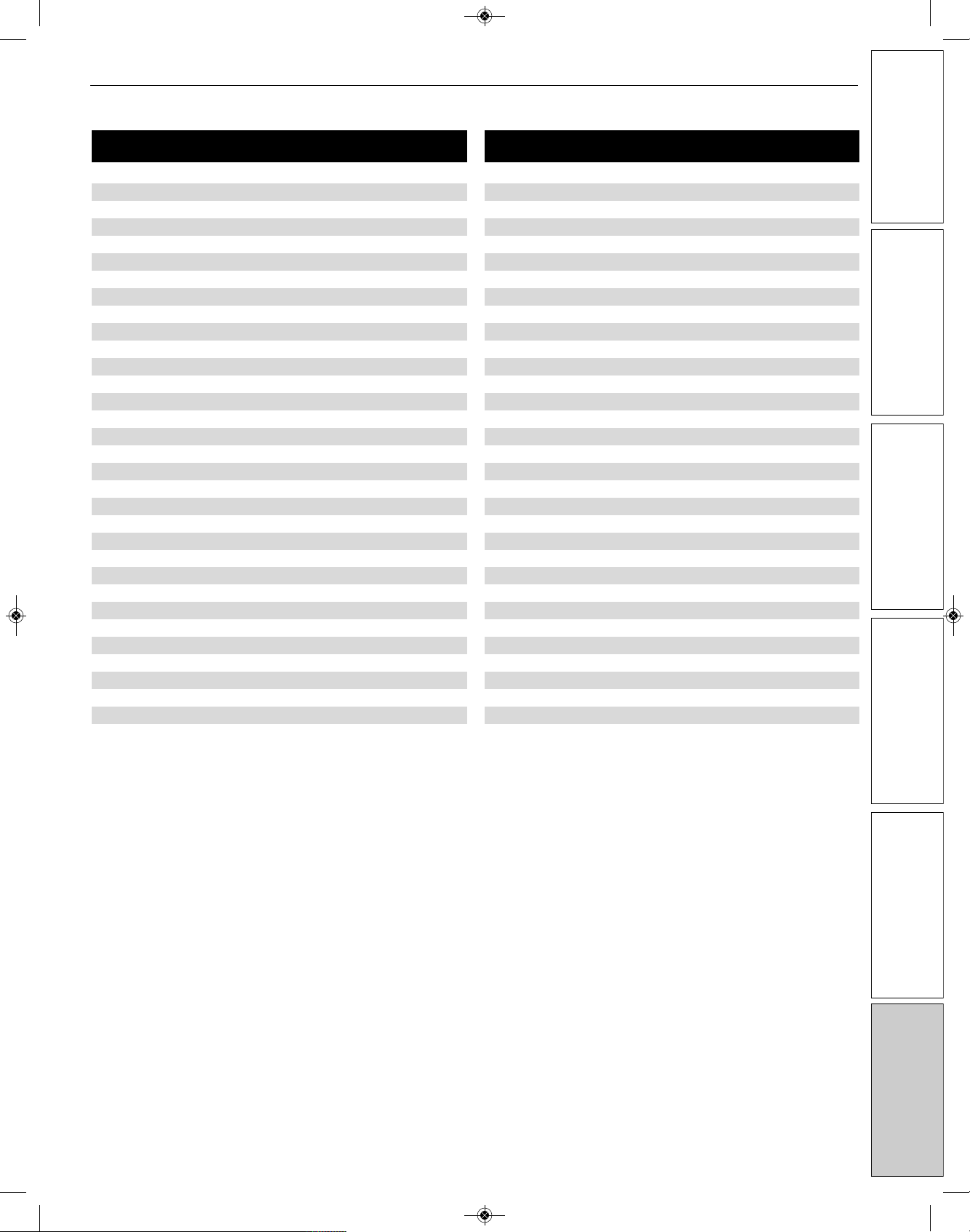

REPAIR PAR S LIS FOR 9680202 8˝ DRILL PRESS

1 Hex screw 8 x 8mm *5

2 Spindle pulley 9639232.01 1

3 Upper spindle assy. (3a thru 7) 9639233.01 1

4 Pulley Insert NA 1

5 Ball bearing 6203RZ NA 2

6 Ring NA 1

7 Retaining ring NA 1

8 Motor pulley 9639212.01 1

9 Pulley cover 9639220.01 1

10 Philips screw 5 x 12mm *5

11 Washer 5mm *2

12 Pulley cover knob 9639236.01 1

13 Phillips screw 6 x12mm *5

14 Rubber bushing *2

15 Key holder 9642740.01 1

16 Lock knob 8 x 16mm 9639210.01 1

17 Head NA 1

18 V-Belt K690 9639213.01 1

19 Pinion shaft 9639208.01 1

20 Flat washer M6 *4

21 Compression spring 9639216.01 1

22 Motor stop 9639215.01 1

23 Hex screw 8 x 25mm *2

24 Motor 9639211.01 1

25 Nut 8mm *2

26 Spring pin 4 x 18mm 9639217.01 1

27 Block 9639235.01 1

28 Hex nut 8mm *1

29 Quill screw 8 x 14mm 9639609.01 1

30 Grounding label NA 1

31 Lock washer 5mm *2

32 Philips screw 5 x 8mm *2

34 Spring cap cover assembly 9639227.01 1

35 Hex nut 10mm *4

36 Pointer 9639250.01 1

37 Stop rod 10 x 1.5mm 9639249.01 1

38 Switch box 9639238.01 1

39 Switch plate 9639239.01 1

40 Philips screw ST4.2 x 10 *3

41 Switch 9608066.01 1

42 Lower spindle assembly (43 thru 47) 9639241.01 1

43 Nut NA 1

44 Ball Bearing 6201RZ NA 2

45 Rubber washer NA 1

46 Quill NA 1

47 Spindle shaft NA 1

48 Set ring 9639248.01 1

49 Philips screw 5 x 20mm *1

50 Hex nut 5mm *1

51 Seal 9639229.01 1

53 Chuck & key 9639240.01 1

54 Hex nut 6mm *1

55 Flat washer 6mm *2

56 Table support 9639245.01 1

57 Lock handle 9639247.01 1

58 Scale 9639246.01 1

59 Table 9639244.01 1

60 Hex bolt 12 x 25mm *1

61 Column & collar assembly 9639206.01 1

62 Hex bolt 8 x 25mm *3

64 Base 9639205.01 1

65 Feed handle assembly 9639207.01 3

70 Capacitor 16μF 250V 9640914.01 1

73 Power cable 9639218.01 1

∆ Operating Instructions & Parts Manual 9640915.01 1

Ref. Part

No. Description Number: Qty.

Ref. Part

No. Description Number: Qty.

(∆) Not shown.

(*) Standard hardware item, available locally.

(NA) Not available as replacement part.

9680202_oipm_En011_9640915.01 03/21/18 Page 9

NO ES

10

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9680202

9680202_oipm_En011_9640915.01 03/21/18 Page 10

11

NO ES

NOR E Operating Manual & Parts List 9680202

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9680202_oipm_En011_9640915.01 03/21/18 Page 11

NOR E by C.H. Hanson warrants their products to be free of defects in material or workmanship. This

warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure

to properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than

that for which it was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives, jaws), damage to

tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The

duration of this warranty is expressly limited to the terms noted below beginning from the date of

delivery to the original user.

The NOR E branded items carry the following warranties on parts:

All NOR E branded Tools and Accessories 1 YEAR

The obligation of NOR E by C.H. Hanson is limited solely to the repair or replacement, at our option, at its

factory or authorized repair agent of any part that should prove inoperable. Purchaser must lubricate and

maintain the product under normal operating conditions at all times. Prior to operation become familiar

with product and the included materials, i.e. warnings, cautions and manuals.

Failure to follow these instructions will void the warrant .

This warranty is the purchaser's exclusive remedy against C. H. Hanson for any inoperable parts in its

product. Under no circumstances is C. H. Hanson liable for any direct, indirect, incidental , special or

consequential damages including loss of profits in any way related to the use or inability to use our

products. This warranty gives you specific legal rights which may vary from state to state.

SERVICE & REPAIR

1. If a NOR E product requires a repair or warranty service DO NOT return the product to

the place of purchase.

2. All warranty related work must be evaluated and approved by NOR E.

3. Prior to returning any item the user must obtain factory approval and a valid RGA number.

4. For instructions and RGA number call toll free (800) 827-3398.

NORSE - a C.H. Hanson brand

2000 N. Aurora Rd., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

NOR E Operating Manual & Parts List 9680202

NORSE Warranty

9680202_oipm_En011_9640915.01 03/21/18 Page 12

Table of contents

Other CH Hanson Power Tools manuals

Popular Power Tools manuals by other brands

WorkPro

WorkPro W125063AU Original operating instructions

Central Pneumatic

Central Pneumatic 65902 Set up and operating instructions

Sherman + Reilly

Sherman + Reilly SRK15X Operation manual

Thermaltronics

Thermaltronics TMT-HA200 user manual

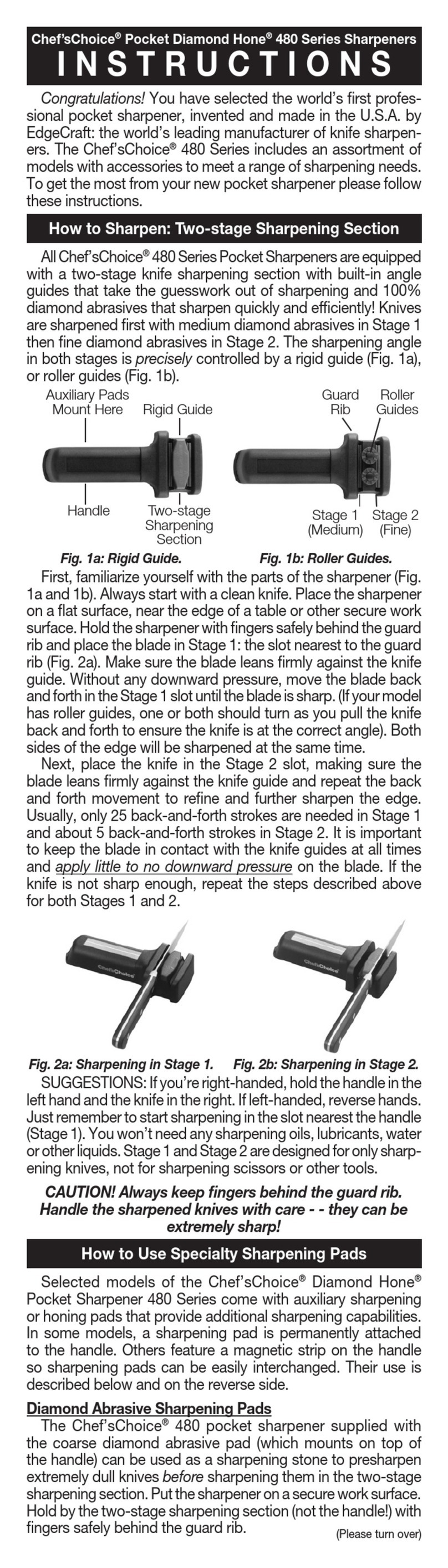

Chef's Choice

Chef's Choice Diamond Hone 480 Series instructions

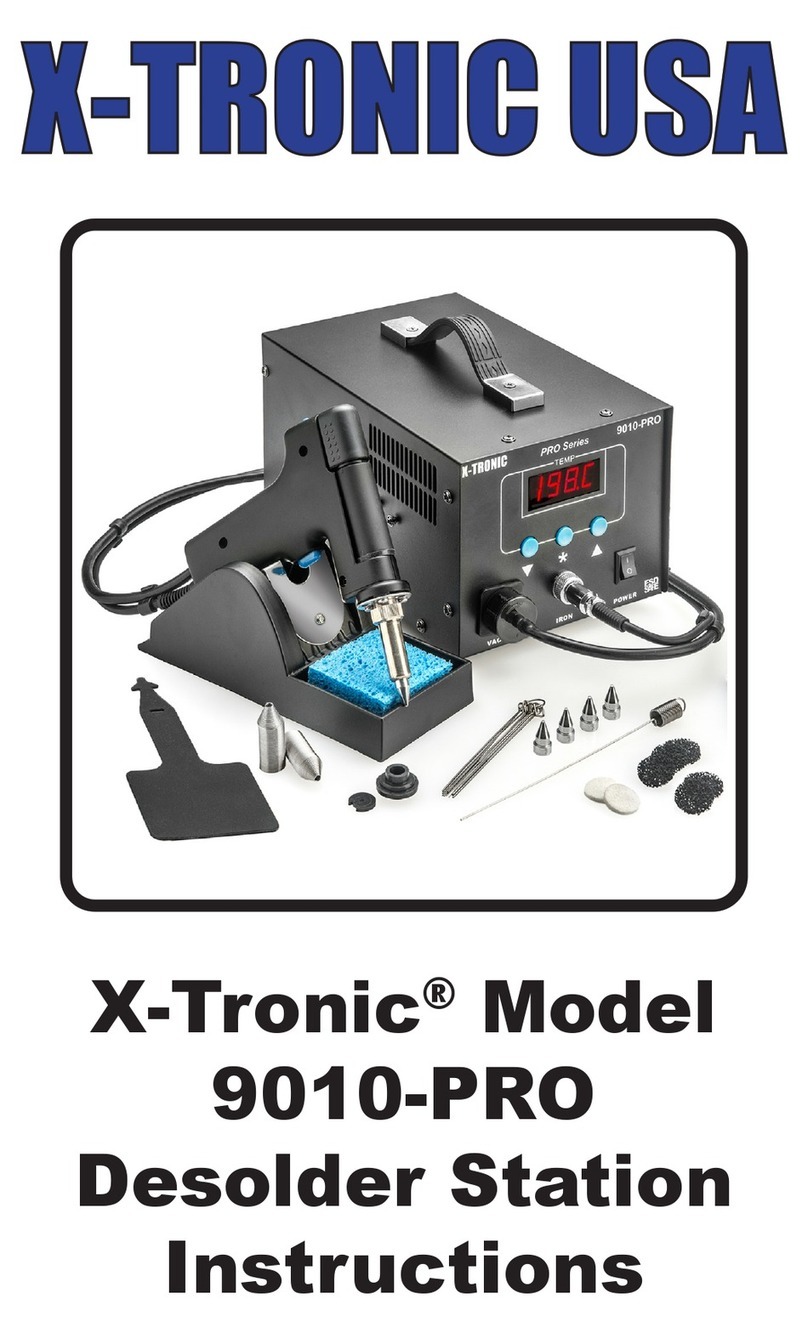

XTRONIC

XTRONIC 9010-PRO instructions