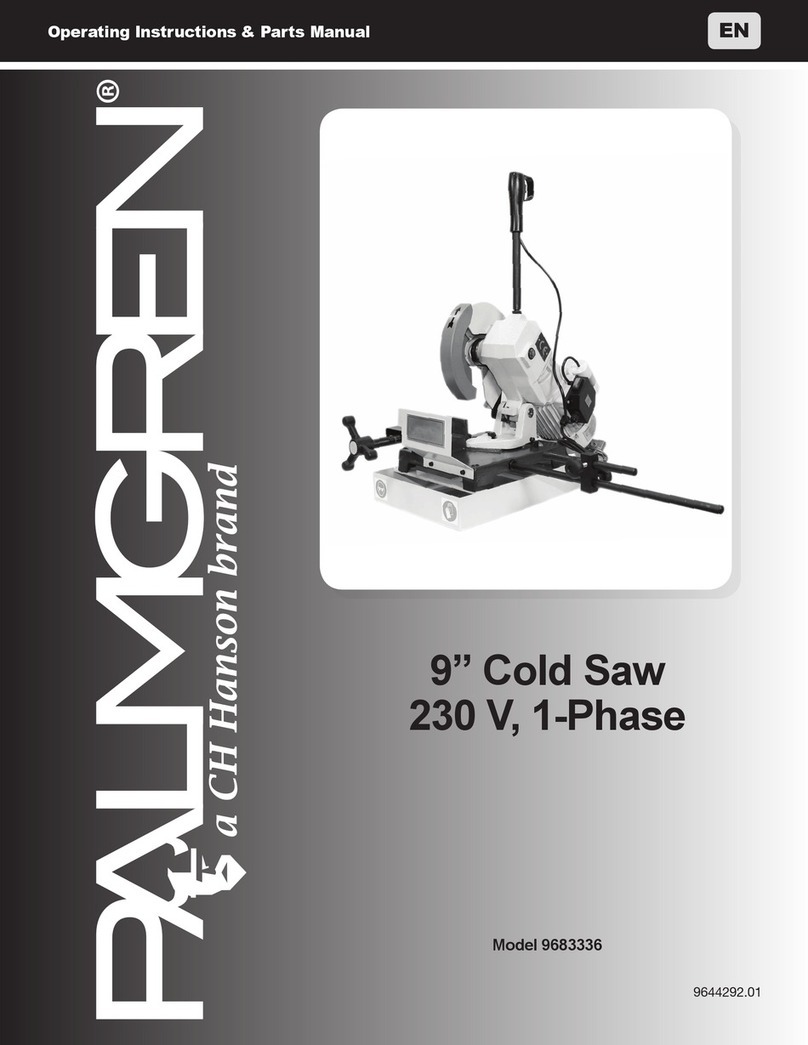

CH Hanson NORSE 9683113 User manual

Operating Manual & Parts List

9683113

15˝

7 Speed Metal/Wood Cutting

BAND SAW

Read carefully and follow all safety

rules and operating instructions before

first use of t is product.

9644206.01-0519

2

NORSE Operating Manual & Parts List 9683113

GETTING STARTED

DESCRIPTIO

The NORSE 15˝ Metal/Wood Cutting Band Saw is for cutting ferrous

and non-ferrous metals and also hard and soft woods. The band

saw features a unitized frame of welded steel construction and a

solid cast iron work surface to ensure durability. Table tilts 45° and

has a miter gauge and precision machined rip fence for performing

many different operations. Fifteen inch balanced cast iron wheels

with ball bearings and rubber treads accommodate blade widths

up to 3/4˝. A convenient tensioning and tracking mechanism

makes blade changing quick and easy. Rip fence and miter gauge

can be stored on the saw when not in use.

U PACKI G

Check for shipping damage. If damage has occurred, a claim must

be filed with carrier. Check for completeness. Immediately report

missing parts to dealer.

The band saw comes assembled as one unit. Additional parts which

need to be fastened to the saw should be located and accounted

for before assembling:

A Table Assembly

B Rip Fence with Knob

C Miter Gauge Assembly

D V-belt

E Metal Cutting Blade, 14 TPI

F Wood Cutting Blade, 6 TPI

G Dust Chute

ardware Bag (Part No. 24958.00) includes:

Trunnion Rod with Acorn Nut

I Knob with Internal Threads

J andle

K Front Trunnion

• 5/16˝ Flat Washer (3)

• 8-1.25 x 20mm Socket ead Bolt (2)

• 8mm Lock Washer (2)

• 8/10mm Open End Wrench (1)

• 12/14mm Open End Wrench (1)

• 2.5, 3mm and 5mm ex Wrench (1 each)

• 5-0.8 x 8mm Pan ead Screw (4).

IMPORTANT: Table is coated with a protectant. To ensure proper fit

and operation, remove coating. Coating is easily removed with mild

solvents, such as mineral spirits, and a soft cloth. Avoid getting solu-

tion on paint or any of the rubber or plastic parts. Solvents may de-

teriorate these finishes. Use soap and water on paint, plastic or

rubber components. After cleaning, cover all exposed surfaces with

a light coating of oil. Paste wax is recommended for table top.

WAR I G: Never use highly volatile solvents. Non flammable

solvents are recommended to avoid possible fire hazard.

SPECIFICATIONS

Depth of throat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 ¾˝

Maximum depth of cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ¼˝

Maximum depth of cut at 45° . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 ½˝

Table size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 × 15˝

Table tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10° left - 45° right

Wheel diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15˝

Blade length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113˝

Blade range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 – 114˝

Blade width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/16 to 3/4˝

Blade speeds . . . . . . . . . . . . . . . 45, 65, 90, 110, 155, 215 and 3,000 FPM

Overall dimensions (W × D × ) . . . . . . . . . . . . . . . . . . . . 25 × 27 × 71.5˝

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 lbs

Crate dimension (W × D × ) . . . . . . . . . . . . . . . . . . . . . . . . 23 × 23 × 78˝

Shipping weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346 lbs

Dust collection port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4˝

SAFETY RULES

WAR I G: For your own safety, read all of the instructions and

precautions before operating tool.

PROPOSITIO 65 WAR I G: Some dust created by using power

tools contain chemicals known to the state of California to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry

products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/ IOSH approved, properly fitting

face mask or respirator when using such tools.

WAR I G: Always follow proper operating procedures as

defined in this manual even if you are familiar with the use of this

or similar tools. Remember that being careless for even a fraction

of a second can result in severe personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves, neck-

ties, rings, bracelets or other jewelry which may get caught in

moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

OT safety glasses.

• Wear face mask or dust mask if operation is dusty.

I

K

F

E

D

G

BC

A

J

Figure 1 - Unpacking

3

NORSE Operating Manual & Parts List 9683113

SAFETY RULES (CONTINUED)

• Be alert and think clearly. Never operate power tools when tired,

intoxicated or when taking medications that cause drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite accidents.

• Do not use power tools in dangerous environments. Do not use

power tools in damp or wet locations. Do not expose power

tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool. Three-

prong plug should be plugged directly into properly grounded,

three-prong receptacle.

• Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof. Use

padlocks, master switches or remove switch keys to prevent any

unintentional use of power tools.

TOOL SHOULD BE MAI TAI ED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting proce-

dures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that ad-

justing tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their in-

tended function.

• Check for damaged parts. Check for alignment of moving parts,

binding, breakage, mounting and any other condition that may

affect a tool’s operation.

• Damaged parts should be properly repaired or replaced. Do not

perform makeshift repairs. (Use the parts list provided to order

replacement parts.)

K OW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment to do a

job for which it was not designed.

• Disconnect tool when changing the blade.

• Avoid accidental start-up. Make sure that the tool is in the OFF

position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from moving parts and cutting surfaces.

• Never leave tool running unattended. Turn the power off and do

not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

or if blade is unintentionally contacted.

• Know your tool. Learn the tool’s operation, application and spe-

cific limitations.

• Use recommended accessories. Use of improper accessories

may cause risk of injury to persons.

• andle workpiece correctly. Protect hands from possible injury.

• Turn the machine off if it jams. Blade jams when it digs too

deeply into the workpiece. (The motor force keeps it stuck in

workpiece). Do not remove jammed or cut off pieces until the

saw is turned off, unplugged and the blade has stopped.

WAR I G: The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in severe eye

damage. Always wear safety goggles complying with United States

ANSI Z87.1 before commencing power tool operation.

ASSEMBLY

Refer to Figures 2 and 6 – 11 (pages 4, 7 and 10 – 18).

CAUTIO : Do not attempt assembly if parts are missing. Use

operator’s manual to order replacement parts.

I STALL METAL CUTTI G BLADE

Refer to Figures 2, 8 and 9.

• Make sure blade teeth are pointing down towards table. Turn

blade inside out if necessary.

• Rotate handwheel (Figure 8, Ref. No. 23) counterclockwise to

move blade wheels towards each other.

• Loosen handle (Figure 9, Ref. No. 30). Rotate handwheel (Figure

9, Ref. No. 22) to lower upper blade guide assembly as low as

possible.

• Loosen three screws (Figure 9, Ref. No. 5). Remove blade guards

(Figure 9, Ref. Nos. 4 and 38).

• Slip blade over upper and lower blade wheels, and center blade

on blade wheels. Slide blade in between blade guides.

• Rotate handwheel clockwise to tension blade.

• Replace blade guards and secure in place by tightening screws.

Raise upper blade guide assembly.

• Position clutch handle (Figure 8, Ref. No. 62) to “Metal”. See Figure 2.

NOTE: The blade must be tensioned and tracked, and the blade

guides must be adjusted before operation of the saw. Refer to

“Tensioning Blade”, “Tracking Blade” and “Blade Guides” in the

OPERATION section, page 6.

I STALL WOOD CUTTI G BLADE

Refer to figures 2, 7, 8, 9 and 11 (pages 4, 10, 12, 14 and 18).

• The V-belt (Figure 11, Ref. No. 44) must be installed first when

using the saw to cut wood.

• Loosen knob (Figure 7, Ref. No. 14). Place V-belt on motor and

drive pulleys (Figure 8, Ref. Nos. 46 and 50).

• Tension V-belt by pushing down on motor mount plate and

tightening knob. Belt is properly tensioned when light pressure

applied to midpoint of the belt produces about 1/2˝ deflection.

• Make sure blade teeth are pointing down towards table. Turn

blade inside out if necessary.

• Rotate handwheel (Figure 8, Ref. No. 23) counterclockwise to

move blade wheels towards each other.

• Loosen handle (Figure 9, Ref. No. 30). Rotate handwheel (Figure

9, Ref. No. 22) to lower upper blade guide assembly as low as

possible.

• Loosen three screws (Figure 9, Ref. No. 5). Remove blade guards

(Figure 9, Ref. Nos. 4 and 38).

• Slip blade over upper and lower blade wheels, and center blade

on blade wheels. Slide blade in between blade guides.

• Replace blade guards and secure in place by tightening screws.

Raise upper blade guide assembly.

• Rotate handwheel clockwise to tension blade.

• Position clutch handle (Figure 8, Ref. No. 62) to “Wood”. See Figure 2,.

NOTE: The blade must be tensioned and tracked, and the blade

guides must be adjusted before operation of the saw. Refer to “Ten-

sioning Blade”, “Tracking Blade” and “Blade Guides” in the OPERA-

TION section, page 6.

4

NORSE Operating Manual & Parts List 9683113

ASSEMBLY (CONTINUED)

ATTACH DUST CHUTE

Refer to Figure 7, page 10.

• Position dust chute (Ref. No. 29) against saw frame. Secure in po-

sition using four pan head screws (Ref. No. 3).

ATTACH TABLE

Refer to Figure 10, page 16.

• Table (Ref. No. 1) is attached to frame with two cast iron trunnions.

• Remove table stud (Ref. No. 16).

• Finger tighten one socket head bolt with washer (Ref. Nos. 3 and

4) on left side of front trunnion (Ref. No. 2) into table.

• Bring table to frame by inserting back of blade into slot. Position

table with back trunnion (Ref. No. 5) on guide posts which are

welded to frame.

• Position front trunnion so it rides on guide post. Attach handle

with flat washer (Ref. Nos. 13 and 11) to secure back trunnion.

• Insert trunnion rod with acorn nut and flat washer (Ref. Nos. 10

and 11) through other guide post and attach the internally

threaded knob with flat washer (Ref. Nos. 12 and 11) to the trun-

nion rod.

• Mount second bolt with washer on front trunnion. Position

front trunnion flat against bottom of table and tighten inter-

nally threaded knob to secure.

• Tighten socket head bolts (Ref. No. 3) to secure trunnions to

table. Install table stud.

SET HORIZO TAL STOP

Refer to Figure 10, page 16.

• When table is attached to frame, a bolt (Ref. No. 14) is used for a

horizontal stop.

• Loosen trunnion knob and set table at 90° to blade using a

square.

• Secure position of table with knob.

• Adjust bolt to contact bottom edge of table.

• Lock bolt in position with hex nut (Ref. No. 15).

ATTACH RIP FE CE

Refer to Figure 10, page 16.

• Rip fence (Ref. No. 19) rides in the slot of table (Ref. No. 1).

• Slide rip fence into slot.

• old rip fence to table and fasten by threading knob (Ref. No.

20) into rip fence.

• Rip fence can be repositioned by loosening knob.

ALIG TABLE

Refer to Figure 10, page 16.

• The table must be aligned properly so that the blade is at a

right angle to the table and that the rip fence is aligned with

the blade.

• Lock the table in the horizontal position. Mount the rip fence on

the table. Slide the rip fence next to, but not touching, the

blade. Lock the rip fence.

• Check that the blade is aligned parallel with the rip fence. If the

blade and fence are not parallel, loosen handle and knob (Ref.

Nos. 12 and 13) on the trunnions (Ref. Nos. 2 and 5). Adjust the

table position so that the blade and rip fence are parallel. Se-

cure the table position by tightening handle and knob.

• After assembly, the table has to be aligned in order to have the

blade running through the center of the slot in the table insert.

• To move table sideways, loosen bolts (Ref. No. 3) on the trun-

nions (Ref. Nos. 2 and 5). Move table to left or right until blade

runs through the center of slot. Tighten bolts and make sure

that table stays in position while bolts are being tightened.

I STALL V-BELT (METAL CUTTI G)

Refer to Figures 6, 7 and 11 (pages 7, 10 and 18).

• Band saw uses a step-pulley drive system to provide a selection

of blade speeds for metal cutting.

• Loosen knob (Figure 7, Ref. No. 14). Place V-belt (Figure 11, Ref.

No. 44) on idler pulley and motor pulley (Figure 11, Ref. Nos. 38

and 40) with V-belt in desired location on pulleys. (See Figure 6,

Blade Speeds, page 7.)

• Do not over tighten V-belts. Excessive tension on V-belt will re-

duce life of belt. Belt is properly tensioned when light pressure

applied to midpoint of the belt produces about 1/2˝ deflection.

• Tension V-belt by pushing down on motor mount plate and

tightening hex head bolt and hex nut.

MOU T SAW TO FLOOR

• If saw is not properly positioned on a flat surface, it may

develop excessive vibration.

• Mount to a flat, level surface through holes on top of base.

INSTALLATION

Refer to Figures 3, 4 and 5, page 5.

MOTOR

The 115/230 Volt AC motor has the following specifications:

orsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115/230

Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14/7

ertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1725

POWER SOURCE

The motor is designed for operation on the voltage and frequency

specified. Normal loads will be handled safely on voltages not more

than 10% above or below the specified voltage.

Running the unit on voltages which are not within the range may

cause overheating and motor burn-out. eavy loads require that

the voltage at motor terminals be no less than the voltage speci-

fied. Power supply to the motor is controlled by a double pole lock-

ing rocker switch. Remove the key to prevent unauthorized use.

Wood

Metal

Figure 2 - Clutch Handle Position

5

NORSE Operating Manual & Parts List 9683113

INSTALLATION (CONTINUED)

GROU DI G I STRUCTIO S

WAR I G: Improper connection of equipment grounding

conductor can result in the risk of electrical shock. Equipment

should be grounded while in use to protect operator from

electrical shock.

Check with a qualified electrician if grounding instructions are not

understood or if in doubt as to whether the tool is properly

grounded.

This tool is equipped with an approved 3 conductor cord rated at

300V and a three prong grounding type plug for your protection

against shock hazards.

Grounding plug should be plugged directly into a properly in-

stalled and grounded 3- prong grounding-type receptacle, as

shown (Figure 3).

Do not remove or alter grounding prong in any manner. In the

event of a malfunction or breakdown, grounding provides a path of

least resistance for electrical shock.

WAR I G: Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

Plug must be plugged into matching outlet that is properly in-

stalled and grounded in accordance with all local codes and ordi-

nances. Do not modify plug provided. If it will not fit in outlet, have

proper outlet installed by a qualified electrician.

Inspect tool cords periodically, and if damaged, have them repaired

by an authorized service facility.

Green (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is neces-

sary, do not connect the green (or green and yellow) wire to a live

terminal.

Where a 2-prong wall receptacle is encountered, it must be re-

placed with a properly grounded 3-prong receptacle installed in

accordance with National Electric Code and local codes and

ordinances.

WAR I G: This work should be performed by a qualified

electrician.

A temporary 3-prong to 2-prong grounding adapter (see Figure 4)

is available for connecting plugs to a two pole outlet if it is properly

grounded.

Do not use a 3-prong to 2-prong grounding adapter unless permit-

ted by local and national codes and ordinances. (A 3-prong to 2-

prong grounding adapter is not permitted in Canada.) Where

permitted, the rigid green tab or terminal on the side of the

adapter must be securely connected to a permanent electrical

ground such as a properly grounded water pipe, a properly

grounded outlet box or a properly grounded wire system.

Many cover plate screws, water pipes and outlet boxes are not

properly grounded. To ensure proper ground, grounding means

must be tested by a qualified electrician.

ELECTRICAL CO ECTIO S

WAR I G: All electrical connections must be performed by a

qualified electrician. Make sure unit is off and disconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

• Band saw motor can be wired for 115 or 230 volts, single-phase

operations.

• See wiring diagram (Figure 5) for wiring instructions.

EXTE SIO CORDS

• The use of any extension cord will cause some drop in voltage

and loss of power.

• Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.) ex-

tension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way, re-

place it immediately.

EXTE SIO CORD LE GTH (120 VOLTS)

Wire Size A.W.G.

Up to 25 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

25-50 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

NOTE: Using extension cords over 50 ft. long is not recommended.

Figure 3 – 3-Prong receptacle.

Properly grounded outlet.

Grounding Prong

3-Prong Plug

Figure 4 – 2-Prong receptacle with adapter.

Grounding Lug

Adapter

3-Prong Plug 2-Prong Re-

ceptacle

Make sure this is con-

nected to a known

grounded receptacle.

Figure 5 - Wiring Diagram

Switch

Motor

L1

L1

L2

L2

Red

Red

#6

#6

#5

Circuit

Breaker

Yellow Black White

White #5Black Yellow

115 V

230 V

6

NORSE Operating Manual & Parts List 9683113

INSTALLATION (CONTINUED)

EXTE SIO CORD LE GTH (240 VOLTS)

Wire Size A.W.G.

Up to 50 ft.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

50-100 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

100-200 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

200-300 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

NOTE: Using extension cords over 300 ft. long is not recommended.

OPERATION

CAUTIO : Always observe the following safety precautions:

• Make sure that blade guides and thrust bearings are positioned

and adjusted correctly to prevent sideways and rearward move-

ment of the blade. Adjust upper guide to just clear workpiece.

• Check to make sure blade is tensioned and tracking properly.

Do not over tension the blade in order to prevent premature

blade wear and breakage. Avoid under tensioning to eliminate

back and forth, side to side blade movement as it cuts.

• Use proper blade and speed for the cutting operation.

• After turning saw on, allow blade to come to full speed before

attempting any cutting operation.

• Support workpiece properly and use a smooth steady feed to

guide work through the cut. Use push sticks or push blocks

when required.

• Keep hands away and out of line with moving parts.

• Always wear eye protection.

REMOVI G BLADE

Refer to Figures 8, 9 and 10 (pages 12, 14 and 16).

WAR I G: Disconnect band saw from power source when

changing or adjusting blades. Wear leather gloves when handling

band saw blades. Never wear gloves when operating saw.

• Loosen three screws (Figure 9, Ref. No. 5). Remove blade guards

(Figure 9, Ref. Nos. 4 and 38). Loosen handle (Figure 8, Ref. No.

30) and rotate handwheel (Figure 8, Ref. No. 23) to release blade

tension. Be careful; blade may spring from saw when tension is

released. Remove table stud (Figure 10, Ref. No. 16), take out the

released blade and replace with another blade.

I STALLI G BLADE

• Although many of the adjustments may not be altered when

blade is removed, every adjustment should be checked prior to

using a newly installed blade.

• Follow safety precautions every time saw is operated.

• Make sure blade teeth are pointing down towards table. Turn

blade inside out if necessary.

• Slip new blade into table slot and over upper and lower blade

wheels and center blade on blade wheels. Slide blade in be-

tween blade guides. Replace table stud. Replace blade guards

after blade guide adjustment.

• Tension and track blade as described in the following sections.

TE SIO I G BLADE

Refer to Figure 8, page 12.

• Tension blade by rotating handwheel (Ref. No. 23). Be sure blade

guides do not interfere with blade path.

• Tighten blade until it is properly tensioned.

• A properly tensioned blade will ring slightly when back of blade

is plucked (like a string on an instrument).

NOTE: Check tension of new blade. Additional tension may be re-

quired after a few minutes of operation.

TRACKI G BLADE

Refer to Figure 8, page 12.

• Track blade after it has been tensioned. A change in blade ten-

sion will affect wheel alignment.

• Proper tracking is achieved when drive and idler wheels are

aligned. Knob (Ref. No. 29) is used to tilt tracking bar (Ref. No. 13)

and align blade wheels.

• Loosen hex nuts (Ref. No. 30) which lock tracking knob (Ref. No.

29). Turn idler wheel (Ref. No. 7) by hand and observe how blade

rides on wheels.

• If blade rides away from cabinet, turn knob clockwise to tilt idler

wheel up.

• If blade rides into cabinet, turn tracking knob counterclockwise.

• When blade is tracking properly, lock position by holding knob

and tightening hex nuts (Ref. No. 30) against the cabinet.

ALIG ME T OF DRIVE WHEEL

Refer to Figure 11, page 18.

NOTE: Only attempt adjusting drive wheel alignment if blade

cannot be properly tracked with tracking adjustment alone.

• A blade under high tension may also pull drive wheel out of

alignment.

• Adjust alignment of drive wheel using hex head bolts (Ref. No. 9).

BLADE GUIDES

NOTE: Adjust blade guides only after blade has been properly

tensioned and tracked.

• Blade guides support blade at sides and rear of blade, and

prevent twisting or deflection.

• Blade guides should not touch blade when no workpiece is in

contact with blade. Adjust guides as described in following

sections.

UPPER BLADE GUIDES

Refer to Figure 9, page 14.

• Upper blade guides employ guide pins for side support and a

ball bearing on an adjusting pin at rear.

• Upper guide bracket (Ref. No. 13) should be positioned so guide

on either side of blade will support as much of blade width as

possible without interfering with the tooth set.

• Adjust bracket depth by loosening bolts (Ref. Nos. 9 and 12) and

sliding brackets into position. Secure position of upper guide

casting by tightening bolts.

• Loosen set screws (Ref. No. 15) and adjust guide pins (Ref. No.

14) to side of blade. Use a feeler gauge to check that guide pins

are .002˝ away from blade.

• Lock adjustment by tightening set screws.

• Adjust thrust bearing (Ref. No. 17) at rear of blade by loosening

set screw (Ref. No. 15).

• Position thrust bearing .002˝ away from back of blade.

• Secure position of thrust bearing by tightening set screw.

• Adjust the height of upper guide casting to clear the workpiece

by 1/4˝. Loosen knob (Ref. No. 30) and rotate height adjustment

knob (Ref. No. 22) until upper blade guide bracket clears work-

piece by 1/4˝. Tighten knob.

7

NORSE Operating Manual & Parts List 9683113

OPERATION (CONTINUED)

LOWER BLADE GUIDES

Refer to Figure 9, page 14.

• Lower blade guides employ two guide blocks for side support.

Lower guide bracket is spaced close to table surface to mini-

mize unsupported length of blade.

• Loosen screw (Ref. No. 5) and remove blade guard (Ref. No. 38).

• Loosen bolt (Ref. No. 19) to position lower guide bracket on

alignment block (Ref. No. 31). Adjust lower guide bracket so

guide blocks do not interfere with blade set. Loosen set screws

(Ref. No. 23) for guide blocks (Ref. Nos. 21 and 34) and adjust

guide blocks to .002˝ from each side of blade.

• Adjust thrust bearing (Ref. No. 36) at rear of blade by loosening

set screw (Ref. No. 23). Position thrust bearing .002˝ away from

back of blade. Secure position of thrust bearing by tightening

set screw.

• Replace blade guard and secure in position.

BLADE SELECTIO

• Blades vary depending on type of material, size of workpiece

and type of cut that is being performed.

• Characteristics which make blades different are width, thickness

and pitch.

BLADE WIDTH

• Width of blade describes distance from tip of a tooth to back of

blade.

• Width of blade will affect rigidity of blade. A wider blade will

wander less and produce a straighter cut.

• Width of blade also limits the smallest radius which can be cut.

A 1/4˝ wide blade can cut about a 1/2˝ radius.

BLADE THICHK ESS

• Blade thickness describes the distance between sides of blade.

A thicker blade has more rigidity and stronger teeth.

• A narrow thick blade would be used to cut curves while a wide

thin blade would be used to make long, straight cuts.

BLADE PITCH

• Pitch describes number of teeth per inch or tooth size. A blade

with more teeth per inch will produce a smoother cut.

• The type of material being cut determines number of teeth

which should be in contact with work.

• For soft metals, the proper blade has between 6 to 12 teeth per

inch.

• When cutting hard metals, where shocking is more detrimental,

use a blade with 12 to 24 teeth per inch.

• For softwoods, the proper blade has 4 to 8 teeth per inch.

• For hardwoods, the proper blade has 8 to 12 teeth per inch.

• There should always be at least three teeth in contact with cut

to avoid shocking blade.

• Blade shocking occurs when pitch is too large and blade tooth

encounters too much material. This can strip teeth from blade.

• Blade manufacturers are prepared to supply information about

blades for specific applications.

BLADE SPEED

Refer to Figure 6.

• The amount of force with which the blade cuts is determined by

speed.

• igh cutting speeds are used on soft materials where less force

is needed and a high rate of material removal is desired.

• Low cutting speeds are used on hard materials when more

force is required.

• To change blade speed, position V-belt in proper configuration

(see Figure 6). Reposition and tension V-belt as described in the

next section.

45 FPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel

65 FPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cast Iron

90 FPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tool Steel, Alloy Steel

110 FPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ard Brass, Bronze

155 FPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Soft Brass, Copper

215 FPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum

REPOSITIO I G V-BELT (METAL CUTTI G)

Refer to Figures 6, 7 and 11(pages 7, 10 and 18).

• Blade speed is determined by the position of the V-belt on the

idler and motor pulleys (Figure 11, Ref. Nos. 38 and 40). Blade

speed is changed by changing pulley position of V-belt.

• Be sure to disconnect saw from power and turn saw OFF before

attempting to change blade speed.

• To change blade speed loosen motor mount plate (Figure 7, Ref.

No. 9) by loosening knob (Figure 7, Ref. No. 14). Position V-belt

on motor and idler pulleys as required. See Figure 6, Blade

Speeds, for recommended pulley and belt settings.

• Tension V-belt by pushing down on motor mount plate and

tightening knob. Belt is properly tensioned when light pressure

applied to midpoint of the belt produces about 1/2˝ deflection.

Do not over tighten V-belt.

CHA GI G THE SAW OPERATIO FROM METAL TO

WOOD CUTTI G

Refer to Figures 2, 7, 8 and 11 (pages 4, 10, 12 and 18).

• Remove metal cutting blade. See “Removing Blade”, page 6.

• Remove shroud (Figure 11, Ref. No. 48).

• Loosen knob (Figure 7, Ref. No. 14). Remove V-belt from motor

and idler pulleys (Figure 11, Ref. Nos. 38 and 40).

• Place V-belt on motor and drive pulleys (Figure 8, Ref. Nos. 46

and 50).

• Tension V-belt by pushing down on motor mount plate and

tightening knob. Belt is properly tensioned when light pressure

applied to midpoint of the belt produces about 1/2˝ deflection.

• Change clutch handle from “metal” to “wood”. (Refer to Figure 2,

page 4).

• Replace shroud.

• Install wood cutting blade. See “Installing Blade”, page 6. Prop-

erly tension, track and adjust blade guides before operation.

LH

High Range

LH

Low Range

110 FPM 155 FPM 215 FPM

45 FPM 65 FPM 90 FPM

Figure 6 - Blade Speeds

8

NORSE Operating Manual & Parts List 9683113

OPERATION (CONTINUED)

CHA GI G THE SAW OPERATIO FROM WOOD TO

METAL CUTTI G

Refer to Figures 2, 7, 8 and 11 (pages 4, 10, 12 and 18).

• Remove wood cutting blade. See “Removing Blade”, page 6.

• Loosen knob (Figure 7, Ref. No. 14). Remove V-belt from motor

and drive pulleys (Figure 8, Ref. Nos. 46 and 50).

• Remove shroud (Figure 11, Ref. No. 48).

• Place V-belt on motor and idler pulleys (Figure 11, Ref. Nos. 38

and 40).

• Tension V-belt by pushing down on motor mount plate and

tightening knob. Belt is properly tensioned when light pressure

applied to midpoint of the belt produces about 1/2˝ deflection.

• Change clutch handle from “wood” to “metal”. (Refer to Figure 2,

page 4).

• Replace shroud.

• Install metal cutting blade. See “Installing Blade”, page 6. Prop-

erly tension, track and adjust blade guides before operation.

TYPE OF CUT

• Rip fence guides workpiece to produce straight cuts on longer

pieces.

• Contour cutting is done by guiding workpiece free-handed to

produce curved shapes.

• Beveled cutting can be done by tilting table and using proper

work guide method.

• Regardless of which work guiding method is used, a workpiece

which overhangs table by more than 7˝ should be properly sup-

ported by support stands. (See Recommended Accessories,

page 13.)

RIP FE CE OPERATIO

Refer to Figures 10 and 11 (pages 16 and 18).

• Rip fence can be used to guide boards with one square edge

past blade when table is aligned properly.

• Set rip fence to desired width of cut on inside of throat. Remem-

ber to include the thickness of material that will be removed by

blade.

• Use a square to measure from tip of a tooth to fence. Lock fence

securely with knob (Fig 10, Ref. No. 20).

• The portion of material between blade and fence is considered

the workpiece. Material on outside and behind cut is the scrap

material which is being cut off. Use the right hand to keep work

against fence.

• Do not push on scrap portion of the work. This could pinch or

bind blade.

• Avoid passing hands beyond the cut. Use push sticks or push

blocks to finish cuts and pass workpiece away from blade.

• A storage bracket (Fig. 11, Ref. No. 21) for rip fence is located on

the rear of saw.

CO TOUR SAWI G

• When contour sawing, use both hands to keep work-piece flat

against table and guided along desired path.

• Avoid positioning hands in line with blade. If hands slip they

could contact blade.

• Try to stand to front of the saw and use hands over the portion

of table which is to right of blade and before cut.

• Cut small corners by sawing around them. Saw to remove scrap

until desired shape is obtained.

BEVEL CUTTI G

Refer to Figure 10, page 16.

• Perform a bevel operation by tilting table. Loosen handle and

knob (Ref. Nos. 12 and 13) and tilt table to desired position.

• Use a square or protractor to set angle and lock table in posi-

tion with knob. Use caution when supporting work while bevel

cutting. Do not allow work to hang on blade.

MITER GAUGE

Refer to Figure 10, page 16.

• Use miter gauge for securing and holding workpiece at desired

angle to produce angled cuts. Use scale to adjust gauge to de-

sired angle.

• Never use miter gauge and rip fence at the same time. The

blade might bind in the workpiece. Operator could be injured

and/or workpiece could be damaged.

• A storage bracket (Ref. No. 39) for miter gauge is located on the

rear of saw.

BLADE CLEA I G BRUSH

Refer to Figure 8, page 12.

• Make sure that brush (Ref. No. 36) is in contact with blade to

properly remove foreign particles from drive wheel.

CHIP BLOWER

Refer to Figure 11, page 18.

Band saw is equipped with chip blower used to remove chips to

make contour cutting easier.

Adjust air nozzle (Ref. No. 45) so that pump air blows chips away

from blade and workpiece.

MAINTENANCE

WAR I G: Make certain that unit is disconnected from power

source before attempting to service or remove any component.

CLEA I G

• Keep machine and workshop clean. Do not allow sawdust to ac-

cumulate on band saw.

• Keep wheels clean. Debris on wheels will cause poor tracking

and blade slippage.

• Keep mechanisms and threaded or sliding surfaces clean and

free of foreign particles.

• Operate band saw with a dust collector to minimize clean up.

LUBRICATIO

• The shielded ball bearings are permanently lubricated and re-

quire no further lubrication.

• Small amounts of machine oil can be applied to belt tension

mechanisms and threaded or sliding surfaces.

• Occasionally apply a coat of paste wax to table top to keep it

slick and corrosion free.

KEEP BA D SAW I REPAIR

• If power cord is worn or cut in any way, have it replaced.

• Replace V-belt and blade when they are worn. Replace any

damaged or missing part.

• Use parts list to order parts.

TROUBLESHOOTING

9

NORSE Operating Manual & Parts List 9683113

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTIO

Excessive blade breakage

Premature blade dulling

Crooked cuts

Rough cuts

Blade is twisting or unusual wear on

side/back of blade

Teeth ripping from blade

Motor running too hot

Saw will not start

1. Material not secure on table

2. Incorrect speed or feed

3. Blade too coarse for material

4. Incorrect blade tension

5. Teeth in contact with work before sawing

6. Blade rubs on wheel flange

7. Misaligned guides

8. Blade too thick for wheel diameter

9. Cracking at weld

1. Blade too coarse

2. Excessive blade speed

3. Inadequate feed pressure

4. ard spots or scale in or on material

5. Work hardening of workpiece

6. Blade installed backwards

7. Insufficient blade tension

1. Work not square

2. Rate of feed too great

3. Blade guides not adjusted properly

4. Insufficient blade tension

5. Upper blade guide too far from workpiece

6. Dull blade

7. Incorrect speed

8. Blade guide assembly loose or blade thrust

bearing loose

1. Too much speed or feed

2. Blade too coarse

1. Cut is binding blade

2. Blade guides or bearing worn

3. Blade guides or bearings not adjusted

properly

4. Blade guide brackets loose

1. Teeth too coarse for work

2. Rate of feed too great

3. Vibrating workpiece

4. Teeth filling with material

1. Blade tension too great

2. Blade too coarse for work (typical when

cutting pipe)

3. Blade too fine for work (typical when

cutting slick or soft material)

4. Excessive dirt and chips

Loose electrical connections

1. Squarely place work on table

2. Check Blade Speed (Figure 6, page 7)

3. Use finer pitch blade

4. Tension blade properly; see “Operation”

5. Place blade in contact with work after saw is

started and has reached full speed

6. Adjust wheel alignment properly

7. Adjust blade guides properly

8. Use thinner blade

9. Replace blade

1. Use finer tooth blade

2. Try lower speed

3. Gently increase pressure

4. Reduce speed; increase rate of feed for scale and

change blades for hard spots

5. Increase rate of feed

6. Remove blade, twist inside out and reinstall blade

7. Tension blade properly; see “Operation”

1. Use rip fence; adjust tilt of table at 90° to blade

2. Reduce rate of feed

3. Move both guide blocks within .002˝ from blade

(use gauge)

4. Tension blade properly; see “Operation”

5. Adjust upper guide to just clear workpiece by 1/4˝

6. Replace blade

7. Check Blade Speed; see Figure 6, page 7 for

recommended speeds

8. Tighten blade thrust bearing within .002˝ behind

blade back

1. Reduce speed or feed

2. Replace with finer blade

1. Decrease feed pressure

2. Replace

3. Adjust blade guides; see “Operation”

4. Tighten properly

1. Use blade with finer teeth

2. Decrease feed rate

3. old workpiece firmly

4. Use blade with coarser teeth

1. Reduce tension on blade

2. Use blade with finer teeth

3. Use blade with coarser teeth

4. Clean thoroughly; vacuum motor and

speed change mechanism

ave qualified electrician check electrical connections

10

NORSE Operating Manual & Parts List 9683113

6

25

20

8

7

28

22

21

23

9

18

18

11

12

14

15

17

12

21

22

3

2

1

10

4

5

13

19

16

12

27

26

3

3

24

23

Figure 7 - Replacement Parts Illustration for Motor

11

NORSE Operating Manual & Parts List 9683113

1 Switch 9616080.00 1

2 Switch Plate 9603668.00 1

3 5-0.8 × 8mm Pan ead Screw 9600361.00 9

4 4mm Serrated Washer * 1

5 4-0.7mm ex Nut * 1

6 Line Cord 9618970.00 1

7 Motor Cord 9618971.00 1

8 Strain Relief 9602434.00 2

9 Motor Mount Plate 9608294.00 1

10 Slide Bracket 9608295.00 1

11 3/8-16 × 6 ½˝ Carriage Bolt 9618924.00 1

12 3/8˝ Flat Washer * 3

13 Spacer 9608297.00 1

14 Knob 9618953.00 1

15 Pivot Bracket 9608299.00 1

16 Clevis Pin 9608300.00 1

17 1/8 × 1˝ Cotter Pin 9600665.00 1

18 8-1.25 × 20mm ex ead Bolt * 4

19 8-1.25 × 20mm Carriage Bolt 9605188.00 4

20 Strain Relief 9601634.00 1

21 8mm Lock Washer * 8

22 8-1.25mm ex Nut * 8

23 3/16 × 3/16 × 1 ½˝ Key 9602813.00 2

24 Motor 9636033.00 1

25 4-0.7 × 15mm Pan ead Screw 9608685.00 1

26 Dust Chute 9624934.00 1

27 Cord Clamp 9603981.00 1

28 Circuit Breaker 9604287.00 1

∆ Capacitor 9622807.00 1

REPLACEMENT PARTS LIST FOR MOTOR

(∆) Not shown.

(N/A) Not available as repair part.

(*) Standard hardware item, available locally.

Ref.

o. Description Part umber: Qty.

12

NORSE Operating Manual & Parts List 9683113

Figure 8 – Replacement Parts Illustration for Front

18

19

6

5

4

3

6

6

5

4

7

9

9

2

8

6

8

24

26

26

26

31

30

57

10

10

25

25

26

36

27

27

34

43

44

45

45

49

50

51, 52

47

48

53

54

56

58

62

42

63

59

60

61

55

46

38

15

15

15

15

15

33

40

32

1

41

6

29

35

35

28

23

16

17

21

21

21

20

20

20

22

12

11

13 14

37

39

13

NORSE Operating Manual & Parts List 9683113

1 Frame N/A 1

2 Upper Cabinet Door 9624959.00 1

3 Lower Cabinet Door 9608303.09 1

4 Knob (External Threads) 9603663.00 2

5 Latch 9608304.00 2

6 6-1.0 × 6mm Set Screw 9600964.00 9

7 Idler Wheel 9624960.00 1

8 Rubber Tread 9608306.00 2

9 3BMI-40 Retaining Ring 9603838.00 2

10 6203ZZ Bearing 9601901.00 2

11 Idler Shaft 9606358.01 1

12 3AMI-17 Retaining Ring 9600341.00 1

13 Tracking Bar 9603605.01 1

14 8-1.25 × 25mm ex ead Bolt * 1

15 8mm Lock Washer * 12

16 Tracking Adjustment Bracket 9603608.00 1

17 Tension Bracket 9603606.00 1

18 Upper Cabinet Support 9603609.00 2

19 8-1.25 × 70mm ex ead Bolt * 2

20 8mm Flat Washer * 8

21 8-1.25mm ex Nut * 9

22 Threaded Shaft 9608601.00 1

23 andwheel 9605598.01 1

24 Tension Support 9603610.00 1

25 6-1.0 × 16mm ex ead Bolt * 8

26 6mm Flat Washer * 16

27 6-1.0mm ex Nut * 8

28 Tension Nut 9603607.00 1

29 Tracking Knob 9608307.00 1

30 5/16˝-18 ex Nut * 2

31 10-1.5mm Eye Bolt 9608308.00 1

32 10mm Flat Washer * 1

33 10-1.5mm ex Nut * 1

34 Drive Wheel 9624961.00 1

35 3BMI-42 Retaining Ring 9607904.00 2

36 Brush 9620071.00 1

37 Bracket 9603620.00 1

38 4.8-2.1 × 8mm Thread Forming Screw 9617741.00 2

39 5-0.8 × 15mm Pan ead Screw 9601090.00 1

40 5mm Flat Washer * 2

41 17mm Wavy Washer 9608439.00 1

42 8-1.25 × 8mm Set Screw 9600958.00 1

43 3AMI-20 Retaining Ring 9600256.00 1

44 8-1.25 × 30mm ex ead Bolt * 3

45 6004ZZ Bearing 9607061.00 2

46 Drive Pulley 9636034.00 1

47 Drive Clutch 9618927.00 1

48 8-1.25 × 20mm ex ead Bolt * 3

49 Movable Clutch 9618928.00 1

50 Motor Pulley 9636035.00 1

51 Metal Cutting Blade, 14 TPI 9624963.00 1

52 Wood Cutting Blade, 6 TPI 9624964.00 1

53 8-1.25 × 20mm Socket ead Bolt 9601822.00 4

54 Shift Bar 9618930.00 1

55 Stud 9618931.00 1

56 Pillow Block with Bushing 9616985.00 2

57 5/16˝ Flat Washer * 1

58 Collar 9616981.00 2

59 8-1.25 × 12mm Socket ead Bolt 9602681.00 3

60 1/2˝-12 × 1 3⁄16 Ball Plunger 9620073.00 1

61 Cam 9618934.00 1

62 Clutch andle 9618933.00 1

63 Knob 9618942.00 1

REPLACEMENT PARTS LIST FOR FRONT

Recommended Accessories

∆ Support Stand 9670141

∆ V-Roller Support Stand 9670181

(∆) Not shown.

(N/A) Not available as repair part.

(*) Standard hardware item, available locally.

Ref.

o. Description Part o. Qty.

Ref.

o. Description Part o. Qty.

14

NORSE Operating Manual & Parts List 9683113

23

10 12

37

30

23

22

24

12

31

10 21

19

34

36

35

23

23

10

33

26

38

10

5

20

29

28

27

25

32

4

5

6

11

2

3

10

9

10

12

13

15

14 10

12

14

16

39

17

18

41 42

40

15

1

8

7

23

Figure 9 – Replacement Parts Illustration for Blade Guides

15

NORSE Operating Manual & Parts List 9683113

1 Guide Bar 9624965.00 1

2 Rack 9636036.00 1

3 5-0.8 × 20mm Socket ead Bolt 9606045.00 3

4 Upper Blade Guide 9636037.00 1

5 Thread Forming Screw 9603619.01 3

6 5mm Flat Washer * 2

7 Guide Attaching Bracket 9608314.00 1

8 Guide Depth Bracket 9608607.00 1

9 6-1.0 × 25mm ex ead Bolt * 2

10 6mm Flat Washer * 14

11 6-1.0mm ex Nut * 2

12 6-1.0 × 16mm ex ead Bolt * 10

13 Upper Guide Bracket 9608316.00 1

14 Guide Pin 9608317.00 2

15 8-1.25 × 8mm Set Screw 9600958.00 2

16 Bearing Pin 9608318.00 1

17 6200ZZ Bearing 9607062.00 1

18 3CMI-10 E-Ring 9601434.00 1

19 6-1.0 × 12mm ex ead Bolt * 1

20 Guide Casting 9608319.00 1

21 Guide Block 9608298.00 1

22 andwheel 9624942.00 1

23 6-1.0 × 6mm Set Screw 9600964.00 6

24 andle 9607305.00 1

25 Pinion Shaft Assembly 9608322.00 1

26 3CMI-8 E-Ring 9608323.00 1

27 6-1.0 × 35mm Socket ead Bolt 9601097.00 1

28 Spring 9609564.00 1

29 Positioning Block 9608324.00 1

30 andle 9608352.00 1

31 Alignment Block 9606376.00 1

32 5/16-18 × 1 ¼˝ ex Low ead Bolt 9608325.15 1

33 Lower Guide Bracket 9608353.00 1

34 Guide Block 9608354.00 1

35 Bearing Pin 9608355.00 1

36 608ZZ Bearing 9603804.00 1

37 5/16˝ Flat Washer * 1

38 Lower Blade Guard 9620163.00 1

39 Air Nozzle 9636038.00 1

40 Clamp 9636039.00 1

41 8-1.25mm ex Nut * 1

42 8-1.25 × 20mm Set Screw * 1

REPLACEMENT PARTS LIST FOR BLADE GUIDES

(∆) Not shown.

(N/A) Not available as repair part.

(*) Standard hardware item, available locally.

Ref.

o. Description Part umber: Qty.

16

NORSE Operating Manual & Parts List 9683113

14

15

37

38

98

13

11 6

5

4

3

3

412

11

2

10

7

11

16

24

34 22 33

25

29

30

31

32

35

21

23

28

27

26

20

19

17

18

1

36

Figure 10 – Replacement Parts Illustration for Table

17

NORSE Operating Manual & Parts List 9683113

(∆) Not shown.

(N/A) Not available as repair part.

(*) Standard hardware item, available locally.

1 Table 9608326.09 1

2 Front Trunnion 9603660.09 1

3 8-1.25 × 20mm Socket ead Bolt 9601822.00 4

4 8mm Lock Washer * 4

5 Back Trunnion 9608327.09 1

6 Trunnion Scale 9608328.00 1

7 Rivet 9601286.00 3

8 Trunnion Indicator 9608329.00 1

9 5-0.8 × 8mm Pan ead Screw 9600361.00 1

10 Trunnion Rod with Acorn nut 9609574.00 1

11 5/16˝ Flat Washer * 3

12 Knob (Internal Threads) 9603659.00 1

13 andle 9608330.00 1

14 8-1.25 × 25mm ex ead Bolt * 1

15 8-1.25 ex Nut * 1

16 Table Stud 9608331.00 1

17 Table Insert 9600210.00 1

18 3 × 10mm Spring Pin 9606369.00 1

19 Rip Fence 9605351.09 1

20 Knob (External Threads) 9600010.00 1

21 Miter Gauge 9608251.00 1

22 Miter Gauge Bar 9608250.00 1

23 #10 Fiber Washer 9608049.00 1

24 Guide 9601093.00 1

25 Indexing Pin 9608256.00 1

26 Knob (Internal Threads) 9608252.00 1

27 #10-24 ex Nut * 3

28 #10-24 × 3/4˝ Pan ead Screw * 3

29 Indicator 9608253.00 1

30 Scale 9608254.00 1

31 #10 Flat Washer * 1

32 #10-24 × 1/4˝ Washer ead Screw 9601605.00 1

33 #10-24 × 1/2˝ Flat ead Screw 9605991.00 2

34 5-0.8 × 8mm Flat ead Screw 9601883.00 1

35 Threaded Pin 9608255.00 1

36 Miter Gauge Assembly (Key Nos. 21 - 35) 9608257.00 1

37 Bracket 9624943.00 1

38 6-1.0 × 12mm ex ead Bolt 9600960.00 2

REPLACEMENT PARTS LIST FOR TABLE

Ref.

o. Description Part umber: Qty.

18

NORSE Operating Manual & Parts List 9683113

Figure 11 – Replacement Parts Illustration for Gear Box

1

2

3

4

24

54

44

45

46 39

47 48

50

51

53

8

4

55

49

39

40

56

60

61

62 57 4

64 65

66

67

59

58 57

13

17

25

37

36

38

8

22

21

76

14

13

12

11

10 15

16

17

18 19

20

9

4

8

7

6

5

41 42 43

34 35

25

23

25

26 27

28 29

30 31 32 33 23

4

52

A

A

19

NORSE Operating Manual & Parts List 9683113

(∆) Not shown.

(N/A) Not available as repair part.

(*) Standard hardware item, available locally.

1 Wheel Drive Shaft 9618935.00 1

2 7 × 7 × 15mm Key 9608661.00 1

3 8-1.25 × 20mm ex ead Bolt * 6

4 8mm Lock Washer * 10

5 Lower Cabinet Support 9618936.00 1

6 3AMI-25 Retaining Ring 9601900.00 2

7 6905ZZ Ball Bearing 9608498.00 2

8 3BMI-42 Retaining Ring 9607904.00 2

9 8-1.25 × 30mm ex ead Bolt * 8

10 Shaft Support 9621030.00 1

11 25 × 42 × 7mm Oil Seal 9618968.00 1

12 Seal 9618938.00 1

13 Plug 9617591.00 2

14 Grease Fitting 9620078.00 1

15 Gear Box 9635769.00 1

16 Seal 9635770.00 1

17 8-1.25 × 20mm Socket ead Bolt * 9

18 6 × 20mm Dowel Pin 9608338.00 2

19 Gear 9635771.00 1

20 3AMI-22 Retaining Ring 9601861.00 1

21 Bracket 9624946.00 1

22 6-1.0 × 12mm ex ead Bolt * 2

23 6200ZZ Ball Bearing 9607062.00 2

24 3BMI-47 Retaining Ring 9618121.00 2

25 6906ZZ Ball Bearing 9635772.00 4

26 Idler Gear 9635773.00 1

27 3AMI-30 Retaining Ring 9601465.00 1

28 Clutch 9635774.00 1

29 3AMI-15 Retaining Ring 9600533.00 1

30 Idler Gear 9635775.00 1

31 6002ZZ Ball Bearing 9601543.00 2

32 3BMI-32 Retaining Ring 9618365.00 2

33 Gear Shaft 9635776.00 1

34 Pulley Drive Shaft 9635777.00 1

35 5 × 5 × 30mm Key 9608438.00 1

36 Gear Box Cover 9635778.00 1

37 30 × 42 × 7mm Oil Seal 9635779.00 1

38 Idler Pulley 9635780.00 1

39 6-1.0 × 6mm Set Screw * 2

40 Motor Pulley 9635781.00 1

41 10mm Flat Washer * 1

42 10mm Lock Washer * 1

43 10-1.5 × 20mm ex ead Bolt * 1

44 V-Belt 9635782.00 1

45 Air ose 9635783.00 1

46 Air Pump Assembly 9635784.00 1

47 Air Pump Pulley 9635785.00 1

48 Shroud 9635786.00 1

49 Window 9624944.00 2

50 Threadforming Screw 9624945.00 8

51 5-0.8 × 8mm Pan ead Screw * 4

52 Shroud Cover 9635787.00 1

53 Knob 9635788.00 1

54 Air Pump Mount Plate 9635789.00 1

55 8mm Flat Washer * 2

56 V-Belt 9635790.00 1

57 8-1.25mm ex Nut * 2

58 Roll Pin 9635791.00 1

59 P15 Oil Ring 9635792.00 2

60 Knob 9635793.00 1

61 6-1.0 × 35mm Socket ead Bolt * 1

62 Speed andle 9635794.00 1

63 8 × 15mm Ball Plunger 9635795.00 1

64 Screw 9635796.00 4

65 Shield Plate 9635797.00 1

66 Crank Shaft 9635798.00 1

67 Stud 9635799.00 1

∆ Gearbox Assembly 9635800.00 1

∆ ardware Bag 9624958.00 1

∆ Operating Manual & Parts List 96xxxxx.xx 1

REPLACEMENT PARTS LIST FOR GEAR BOX

Ref.

o. Description Part o. Qty.

Ref.

o. Description Part o. Qty.

NORSE Operating Manual & Parts List 9683113

NORSE - a C. . anson brand

2000 N. Aurora Rd., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

NORSE by C. . anson warrants their products to be free of defects in material or workmanship. This

warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure

to properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than

that for which it was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives, jaws), damage to

tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The

duration of this warranty is expressly limited to the terms noted below beginning from the date of

delivery to the original user.

The NORSE branded items carry the following warranties on parts:

All NORSE branded Tools and Accessories 1 YEAR

The obligation of NORSE by C. . anson is limited solely to the repair or replacement, at our option, at its

factory or authorized repair agent of any part that should prove inoperable. Purchaser must lubricate and

maintain the product under normal operating conditions at all times. Prior to operation become familiar

with product and the included materials, i.e. warnings, cautions and manuals.

Failure to follow these instructions will void the warranty.

This warranty is the purchaser's exclusive remedy against C. . anson for any inoperable parts in its

product. Under no circumstances is C. . anson liable for any direct, indirect, incidental , special or

consequential damages including loss of profits in any way related to the use or inability to use our

products. This warranty gives you specific legal rights which may vary from state to state.

SERVICE & REPAIR

1. If a NORSE product requires a repair or warranty service DO OT return the product to

the place of purchase.

2. All warranty related work must be evaluated and approved by NORSE.

3. Prior to returning any item the user must obtain factory approval and a valid RGA number.

4. For instructions and RGA number call toll free (800) 827-3398.

NORSE WARRANTY

18-0307

Table of contents

Other CH Hanson Saw manuals