INSTALLATION & OPERATION

OPERATION

When the external controls are calling

for heat,and the temperature in the

monotube is below the temperature set

on the thermostat, the pump will run.

Once the flow through the boiler is

established and the temperature in the

boiler is below the one set on the boiler

thermostat, the water pressure switch

will allow the grey safety solenoid and

the blue first stage solenoid to open.

The ignition sequence begins. A

continuous, high speed stream of

sparks ignites the gas. Once the

ionisation circuit detects the flame the

orange secondary solenoid opens to

allow the full, or set, gas rate to the

burner. If a flame is not detected within

8 - 10 seconds the security solenoid

will close and shut off the gas. The red

lockout indicator bulb will light. The

temperature of the primary circuit is

sensed by the thermostat in the

monotube and the flow temperature of

the boiler is detected by the thermistor

in the flow pipe. These two thermostats

interact with each other and the boiler

thermostat must always be set above

the monotube temperature.

INSTALLATION REQUIREMENTS

Location

The Moduloflame 140 is wall mounted

and the position chosen should allow

adequate space for servicing and for

sufficient air flow around the boiler.

The location must permit the

satisfactory routing and termination of

the flue. The surface should be flat and

non combustible and able to

adequately support the weight of the

boiler and ancillary controls.

For guidance, a wall area of:

900 mm (36 ins) wide and 1185 mm

(47 ins) high would provide the

necessary clearances for case removal

and for air movement.

As it is an open flued appliance certain

locations are banned, for example

bedroom, bedsitting rooms, private

garages or rooms containing a bath or

a shower. A cupboard or compartment

used to house the boiler must have

been designed and constructed, or

modified, specifically for the purpose.

Refer to BS 6798 for further guidance.

Flue

The following notes are for general

guidance only. For detailed

recommendations refer to BS 5440:

pt 1.

There should be at least 600 mm of

vertical flue after the boiler before the

use of any bends. The flue must take

the most direct route practicable. The

number of bends must be kept to a

minimum. Long external runs and

Horizontal or slightly inclining runs

must be avoided.

Ventilation

The following notes are for general

guidance only. For detailed

recommendations refer to BS 5440:

pt 2.

The boiler must have a permanent air

supply. This may come from an

adjacent room or internal space which

must also have permanent ventilation

to outside or direct from outside. If the

supply is from another internal space

or room, that room must have a

permanent air supply at least the size

as required for the boiler. If installed in

a room, the boiler requires a vent with

175 cm2 free air space.

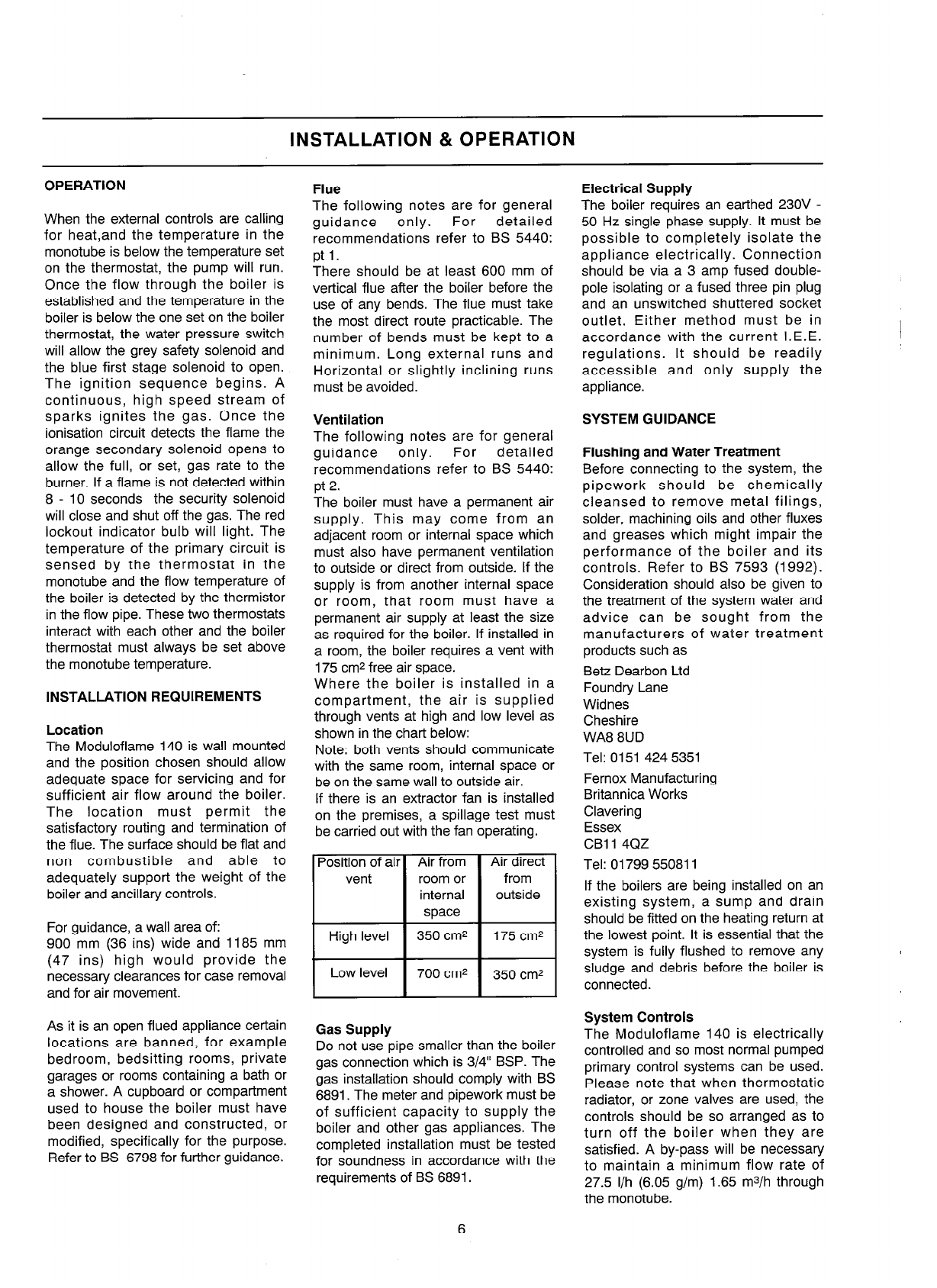

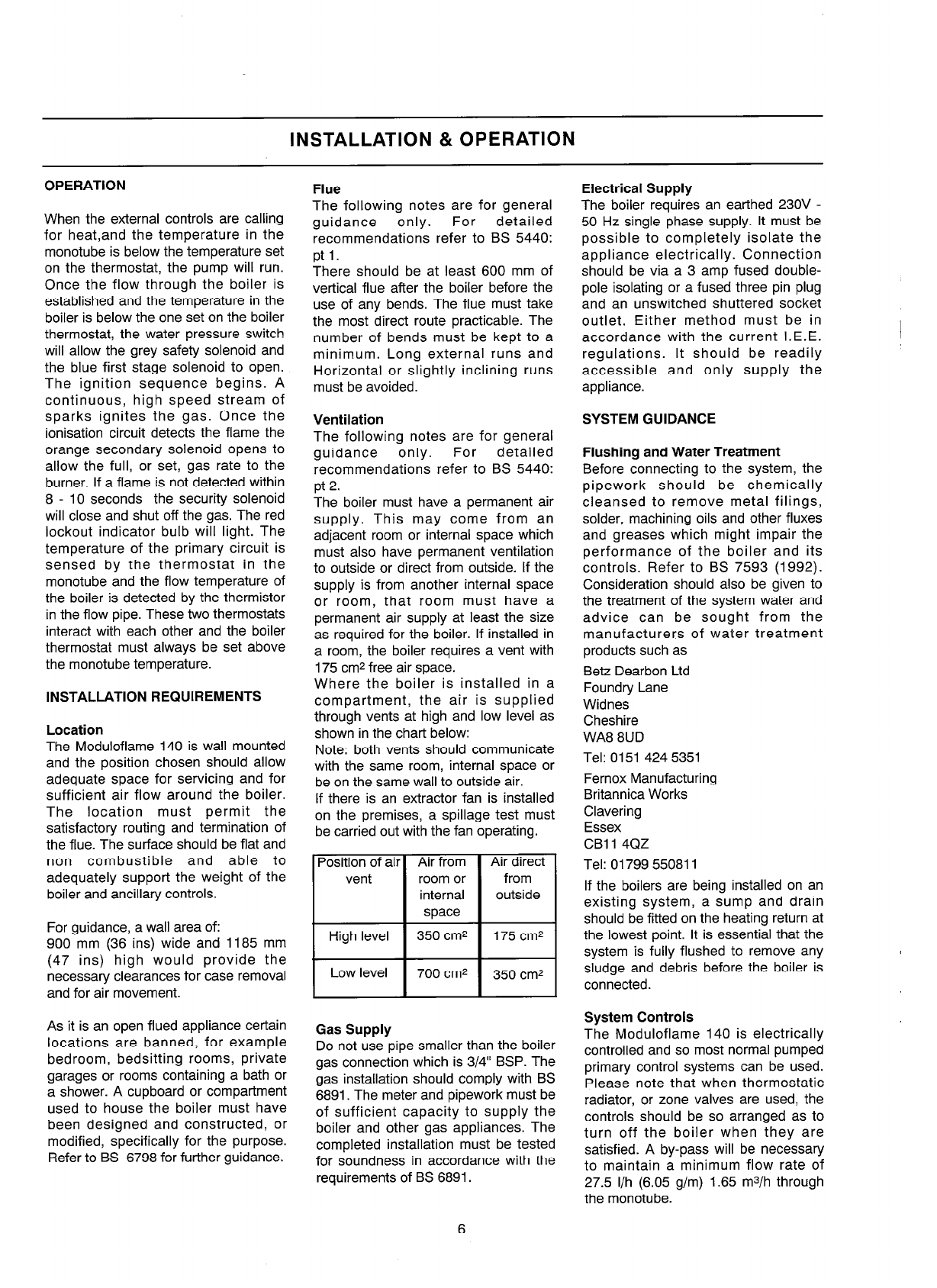

Where the boiler is installed in a

compartment, the air is supplied

through vents at high and low level as

shown in the chart below:

Note: both vents should communicate

with the same room, internal space or

be on the same wall to outside air.

If there is an extractor fan is installed

on the premises, a spillage test must

be carried out with the fan operating.

Position of air

vent Air from

room or

internal

space

350 cm2

700 cm2

Air direct

from

outside

175 cm*

--I

350 cm*

Gas Supply

Do not use pipe smaller than the boiler

gas connection which is 314” BSP. The

gas installation should comply with BS

6891. The meter and pipework must be

of sufficient capacity to supply the

boiler and other gas appliances. The

completed installation must be tested

for soundness in accordance with the

requirements of BS 6891.

Electrical Supply

The boiler requires an earthed 230V -

50 Hz single phase supply. It must be

possible to completely isolate the

appliance electrically. Connection

should be via a 3 amp fused double-

pole isolating or a fused three pin plug

and an unswitched shuttered socket

outlet. Either method must be in

accordance with the current I.E.E.

regulations. It should be readily

accessible and only supply the

appliance.

SYSTEM GUIDANCE

Flushing and Water Treatment

Before connecting to the system, the

pipework should be chemically

cleansed to remove metal filings,

solder, machining oils and other fluxes

and greases which might impair the

performance of the boiler and its

controls. Refer to BS 7593 (1992).

Consideration should also be given to

the treatment of the system water and

advice can be sought from the

manufacturers of water treatment

products such as

Betz Dearbon Ltd

Foundry Lane

Widnes

Cheshire

WA8 8UD

Tel: 0151 424 5351

Fernox Manufacturing

Britannica Works

Clavering

Essex

CBI1 4QZ

Tel: 01799 550811

If the boilers are being installed on an

existing system, a sump and drain

should be fitted on the heating return at

the lowest point. It is essential that the

system is fully flushed to remove any

sludge and debris before the boiler is

connected.

System Controls

The Moduloflame 140 is electrically

controlled and so most normal pumped

primary control systems can be used.

Please note that when thermostatic

radiator, or zone valves are used, the

controls should be so arranged as to

turn off the boiler when they are

satisfied. A by-pass will be necessary

to maintain a minimum flow rate of

27.5 I/h (6.05 g/m) 1.65 m3/h through

the monotube.

6