installation

Remove the flue bend from the top of the heat exchanger by

releasing the fixing clip and removing the two screws.

N.B.

: If the optional top fixing bracket is to be used this

should now be attached to the top of the rear casewith the

screwsalready fitted to the case(fig. 3).

Using the heater as a template, locate the spigot of the ap-

pliance in the wall liner, check that the appliance is vertical

and mark the four or five fixing holes. Drill and plug the

wall and fasten the top studs in position. These studs can be

screwedinto the wall by locking two nuts together on the pa-

rallel thread and using a spanner.

Attach the self adhesive foam gasketto the flat surface of the

heater around the air inlet spigot of the rear case. Remove

the protective paper while sticking down the gasket. Lift the

heater into position on the wall, locating on the studs and

the wall liner. Secure the heater to the wall using the nuts

and screwsprovided. The hooks fit under the nuts of the top

fixing studs(fig. 4).

Transfer the terminal fixing chains from the wall linq to

these hoods. The terminal chains should not be left fixed to

the wall liner hooks.

Slide the flue duct through the rectangular hole in the rear

case and engageinto the central spigot of the terminal so

that it touches the two end stops. Relit the flue bend sothat

the flue duct engagesby at least 25 mm (1 in), it may be ne-

cessaryto cut the flue duct to the correct length, and ensure

that the flue bend is seatedcorrectly on the heat exchanger

with the gasketin place. Replace the two screwsand clip se-

curing the flue bend.

Do not relit the front cover until the appliance has been

commissioned.

GAS CONNECTION

Remove the plastic cover from the gasinlet which is the cen-

tre connection on the bottom of the heater.

Fit the gasservice tap provided using the fine filter washer to

seal the connection. Fit the 15 mm dia. copper tail nut and

washer provided to the inlet of the gas service tap and

connect this to the gassupply.

The size of the gassupply pipe from the meter to the heater

only should be asfollows.

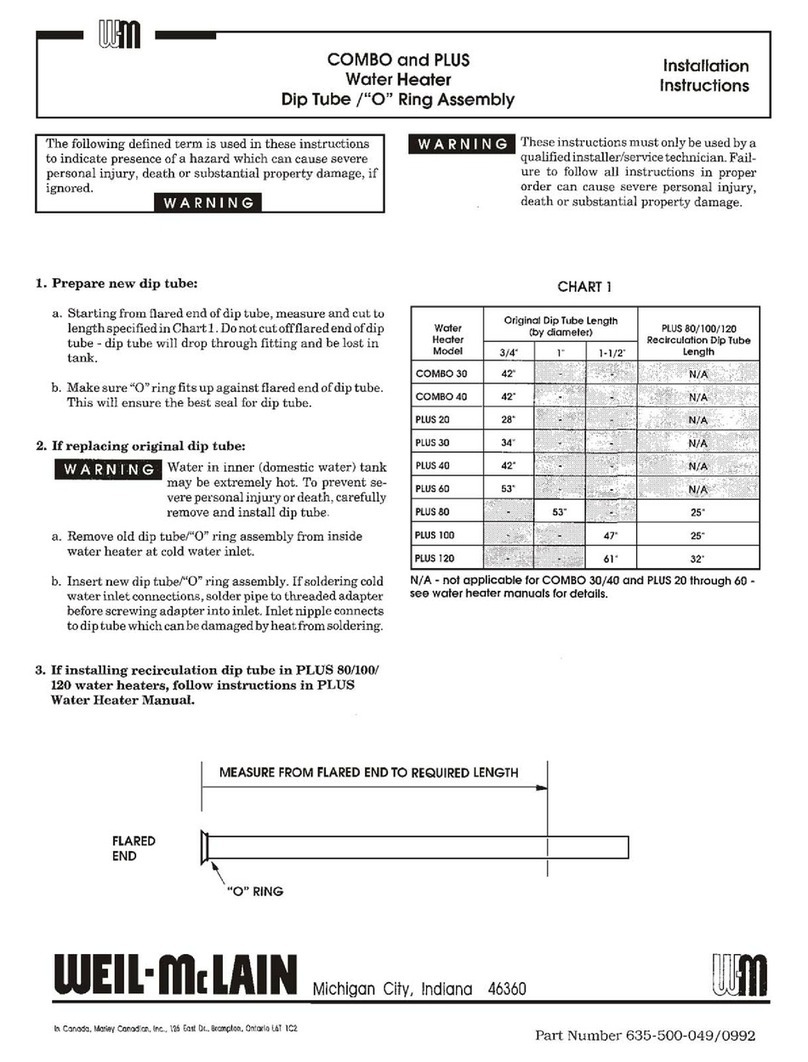

Distance from Meter

outlet to heater

O-3

m (O-10It)

3-20

m (lo-65 ft)

20 m and above

Gas Supply

15mm

22

mm

contact British Gas

These sizesare for the heater only and do not take account

of any other gas appliances that may be connected to the

samegasservice pipework.

WATER CONNECTIONS

Remove the plastic covers protecting the water inlet and ou-

tlet connections.

Fit the water service tap provided to the right hand connec-

tion at the bottom of heater using the coarsefilter washer to

sealthe connection.

Fit the 15 m dia. copper tails and washers provided to the

inlet of the water service tap and to the outlet of the heater

(left hand connection).

The water service tap supplied with the heater incorporates

a drain plug.

APPLICATIONS OF THE CORVEC BRITONY II T

The heater is designed to serve a variety of hot water draw-

off points including washing machines and showers. The

heater can be connected to all the hot water draw-off points

in the installation. If more than one.outlet is open simulta-

neously the total flow of water cannot exceedthat quoted in

the Technical data.

The heater is compatible with most current automatic was-

hing machines, but care should be taken to ensure that the

machine is capable of accepting water at the design flow rate

of the heater. Hot and cold fill machines normally require a

hot water temperature of 60” C (140” F), the heater produ-

cing approximately 6.5 l/m (1.44 g.p.m.) at this temperatu-

re. The advice of the washing machine manufacturers

should be sought, but generally it is only necessaryto remo-

ve the water flow restrictor (if fitted) in the hot water inlet

connection of the machine to obtain a satisfactory heater

operation.

ALTERNATIVE

,,,,,,,,, ,,,,,,,, *, ,,,, * ,,,,,,,,,,,m de/j ,,,,,,,, A,,, ,,,,,,, :,

POSITION

5