EuropAce EWH 5451T User manual

WATER HEATER

EWH 5451T

Instruction Manual

Thank you for purchasing EuropAce Oscillating Power Fan.

For safety purpose, please read this operating instruction manual carefully before using and

keep it for future reference.

MADE IN MALAYSIA

anual Reset

rated in

Water Heater

EWH 5451T

Thank you for purchasing EuropAce Water Heater.

future reference.

PART IDENTIFICATION

1

11

12

1

2

3

1) Front Cover

2) LED Indicator

3) Temperature Control Knob

4) Heater Base

5) Thermostat

6) Heater Tank

7) Water Outlet Connection

9) Main PCB Board

8) Rubber grommet

10) Water Inlet Connection

11) Pressure Relief Valve

12) Mesh Filter

13

9

10

4

5

6

7

11

12

8

13) Terminal Block

PART IDENTIFICATION

1

11

12

1

2

3

1) Front Cover

2) LED Indicator

3) Temperature Control Knob

4) Heater Base

5) Thermostat

6) Heater Tank

7) Water Outlet Connection

9) Main PCB Board

8) Rubber grommet

10) Water Inlet Connection

11) Pressure Relief Valve

12) Mesh Filter

13

9

10

4

5

6

7

11

12

8

13) Terminal Block

2

SAFETY INFORMATION

Products manufactured by us are safe provided they are installed, used and maintained in

refer to this manual if you have any doubt.

The appliance must be earthed. Improper grounding could cause electrical shock.

If the Heater begins to make an odd noise, smell or smoke.

Heater Indicator does not light up.

Water temperature cannot be controlled.

If found water leakage from inside.

When the Shower is used by someone such as child,elderly person, sick person and

and adjust the water temperature before using.

to protect the shower unit against possible damage.

to all exposed metal parts of other appliances and services in the room which in the heater

When removing the unit from package, small amount of water may found inside.

This is normal as the unit is tested during manufacturing process.

Note:

1.4

1.5

1.6

This Undersink Heater must be permanently connected to the direct main line supply.

A plug and socket is not recommended to be used.

For the correct size of wire conductor corresponding to di erent electrical loadings,

please refer to Table 1.

This Undersink Heater operates at a minimum wat ow rate of 3.0 liter/min and

maximum inlet water pressure of 6 Bar.

liter/min) to trigg ow switch.

abnormal rise in water temperature.

2.6

2

SAFETY INFORMATION

Products manufactured by us are safe provided they are installed, used and maintained in

refer to this manual if you have any doubt.

The appliance must be earthed. Improper grounding could cause electrical shock.

If the Heater begins to make an odd noise, smell or smoke.

Heater Indicator does not light up.

Water temperature cannot be controlled.

If found water leakage from inside.

When the Shower is used by someone such as child,elderly person, sick person and

and adjust the water temperature before using.

to protect the shower unit against possible damage.

to all exposed metal parts of other appliances and services in the room which in the heater

When removing the unit from package, small amount of water may found inside.

This is normal as the unit is tested during manufacturing process.

Note:

1.4

1.5

1.6

This Undersink Heater must be permanently connected to the direct main line supply.

A plug and socket is not recommended to be used.

For the correct size of wire conductor corresponding to di erent electrical loadings,

please refer to Table 1.

This Undersink Heater operates at a minimum wat ow rate of 3.0 liter/min and

maximum inlet water pressure of 6 Bar.

liter/min) to trigg ow switch.

abnormal rise in water temperature.

2.6

3

TABLE 1-ELECTRICAL LOADING TABLE

HEATER UNIT INSTALLATION

1) Installation instruction f

1.1) Install the Undersink Heater as close as possible to the main hot water dra points.

1.2) Leave a minimum of 5’’of clearance on all sides for servicing.

1.3) Remove plastic cover. (Fig. 3 )

1.4) Mount unit securely to wall by putting two screws through mounting holes.

Screws and plastic wall plugs for mounting are provided. (Fig. 4)

2) The unit is to be installed in a closed, frost-free room.The unit is to be installed vertically

(Hot water connection downwards).

3) The unit can be installed in any location, conceal in the ceiling, below washbasin or even wall mounted.

HEATER UNIT INSTALLATION DIAGRAM

Mounting hole (A)

Fig. 4

Fig. 1 Fig. 2

248mm

155mm

Fig. 3

83mm

Mounting hole (B)

Voltage Power Current

(AC) (kW) (A)

Conductor Size (csa)

mm Conduit Cable Flexible Cable

On/ O Fuse /

Switch (A) MCB (A)

240V

50/60 Hz

2.4 10.0 2.5 7 / 0.67mm 50 / 0.25mm 20 20

3.6

4.9 20.4 4.0 7 / 0.67mm 56 / 0.25mm 32 32

230V

50/60 Hz

3.3 14.4 2.5 7 / 0.67mm 50 / 0.25mm 20 20

4.5 19.6 2.5 7 / 0.67mm 50 / 0.25mm 32 32

6.0 25.0 4.0 7 / 0.85mm 56 / 0.30mm 32 32

220V

50/60 Hz

2.4 10.9 2.5 7 / 0.67mm 50 / 0.25mm 20 20

3.5 15.9 2.5 7 / 0.67mm 50 / 0.25mm 20 20

4.5 20.5 2.5 7 / 0.67mm 56 / 0.25mm 32 32

6.0 27.3 4.0 7 / 0.85mm 50 / 0.30mm 32 32

5.5 25.0 4.0 7 / 0.85mm 56 / 0.30mm 32 32

(Malaysia Modal)

15.0 4.0 7 / 0.85mm 50 / 0.30mm 20 20

3

TABLE 1-ELECTRICAL LOADING TABLE

HEATER UNIT INSTALLATION

1) Installation instruction f

1.1) Install the Undersink Heater as close as possible to the main hot water dra points.

1.2) Leave a minimum of 5’’of clearance on all sides for servicing.

1.3) Remove plastic cover. (Fig. 3 )

1.4) Mount unit securely to wall by putting two screws through mounting holes.

Screws and plastic wall plugs for mounting are provided.(Fig.4)

2) The unit is to be installed in a closed, frost-free room.The unit is to be installed vertically

(Hot water connection downwards).

3) The unit can be installed in any location, conceal in the ceiling, below washbasin or even wall mounted.

HEATER UNIT INSTALLATION DIAGRAM

Mounting hole (A)

Fig. 4

Fig. 1 Fig. 2

248mm

155mm

Fig. 3

83mm

Mounting hole (B)

Voltage Power Current

(AC) (kW) (A)

Conductor Size (csa)

mm Conduit Cable Flexible Cable

On/ O Fuse /

Switch (A) MCB (A)

240V

50/60 Hz

2.4 10.0 2.5 7 / 0.67mm 50 / 0.25mm 20 20

3.6

4.9 20.4 4.0 7 / 0.67mm 56 / 0.25mm 32 32

230V

50/60 Hz

3.3 14.4 2.5 7 / 0.67mm 50 / 0.25mm 20 20

4.5 19.6 2.5 7 / 0.67mm 50 / 0.25mm 32 32

6.0 25.0 4.0 7 / 0.85mm 56 / 0.30mm 32 32

220V

50/60 Hz

2.4 10.9 2.5 7 / 0.67mm 50 / 0.25mm 20 20

3.5 15.9 2.5 7 / 0.67mm 50 / 0.25mm 20 20

4.5 20.5 2.5 7 / 0.67mm 56 / 0.25mm 32 32

6.0 27.3 4.0 7 / 0.85mm 50 / 0.30mm 32 32

5.5 25.0 4.0 7 / 0.85mm 56 / 0.30mm 32 32

(Malaysia Modal)

15.0 4.0 7 / 0.85mm 50 / 0.30mm 20 20

4

continue from “HEATER UNIT INSTALLATION DIAGRAM”

Fig. 5

Pressure Relief Valve must be

installed to inlet every time.

Note: When connecting the Pressure Relief Valve to the water inlet, please make sure the discharge nozzle is facing

downward .Connect a discharge pipe (PVC tube of dia. 8.0mm) to the discharge nozzle in a continuosly

downward direction and this pipe must be left open t rain exhaust or discharge pipe.

In abnormal condition where pressure gets higher than 6.0 bars, water will drip from this discharge pipe.

PLUMBING PROCEDURE

A) Connect Pressure Relief Valve to INLET of water heater . Use sealing tape for the connection

to prevent water leakage. DO NOT apply excessive force when tightening the Pressure Relief Valve.

B) Insert Mesh Filter Washer before connecting the incoming water supply to the Pressure Relief Valve.

C) If in any case, make sure to put the Mesh Filter between the heater unit inlet pipe (Pressure Relief Valve)

Note :

- When connecting the Pressure Relief Valve to the water inlet, please make sure the discharge nozzle

is facing downward. Connect a discharge pipe (PVC tube of dia. 8.0mm) to the discharge nozzle in a

continuously downward direction and this pipe must be left open to the floor drain exhaust or discharge

pipe. In abnormal condition where pressure gets higher than 6.0 bars, water will drip from this discharge

and incoming water pipe.

pipe.

4

continue from “HEATER UNIT INSTALLATION DIAGRAM”

Fig. 5

Pressure Relief Valve must be

installed to inlet every time.

Note: When connecting the Pressure Relief Valve to the water inlet, please make sure the discharge nozzle is facing

downward . Connect a discharge pipe (PVC tube of dia. 8.0mm) to the discharge nozzle in a continuosly

downward direction and this pipe must be left open t rain exhaust or discharge pipe.

In abnormal condition where pressure gets higher than 6.0 bars, water will drip from this discharge pipe.

PLUMBING PROCEDURE

A) Connect Pressure Relief Valve to INLET of water heater . Use sealing tape for the connection

to prevent water leakage. DO NOT apply excessive force when tightening the Pressure Relief Valve.

B) Insert Mesh Filter Washer before connecting the incoming water supply to the Pressure Relief Valve.

C) If in any case, make sure to put the Mesh Filter between the heater unit inlet pipe (Pressure Relief Valve)

Note :

- When connecting the Pressure Relief Valve to the water inlet, please make sure the discharge nozzle

is facing downward. Connect a discharge pipe (PVC tube of dia. 8.0mm) to the discharge nozzle in a

continuously downward direction and this pipe must be left open to the floor drain exhaust or discharge

pipe. In abnormal condition where pressure gets higher than 6.0 bars, water will drip from this discharge

and incoming water pipe.

pipe.

continue from PLUMBING PROCEDURE

5

- Connections to the Multi-point hot water system should be limited to 2 or at

the most 3 outlet usage points and they should be near to each other, e.g. in

the same bathroom but only ONE OUTLET POINTS IS TO BE USED AT ANY

ONE TIME. Extensive distance between the appliance and usage point(s) will

result not only loss but also slow response of obtaining the hot water at the

point(s) (fig.5).

-

TURN ON THE WATER MAINS TO DRAIN OUT ALL PLUMBING DIRTS BEFORE CONNECTING

THE WATER SUPPLY TO THE INSTANT HOT SHOWER, THE WATER SUPPLY TO THE WATER

HEATER MUST BE FREE FROM MUD AND DIRT. ALWAYS KEEP THE WATER SUPPLY TO THE

WATER HEATER FREE FROM MUD AND DIRT AT ALL TIME DURING USAGE.

THE WATER INLET AND OUTLET MUST BE INSTALLED CORRECTLY , OTHERWISE THE HEATER UNIT WILL NOT FUNCTION.

DO NOT APPLY PLUMBING CEMENT ON CONNECTION.WHENEVER NECESSARY, USE ONLY THREAD OR SEALING TAPE.

-

-

THE HEATER TANK MUST BE FILLED UP WITH WATER BEFORE TURNING ON THE ELECTRICITY SUPPLY

TO PREVENT ANY DRY BURNT DAMAGE TO THE HEATING ELEMENT. - CHECK IF ANY WATER LEAKAGE.

UNIT MUST BE INSTALLED IN A VERTICAL POSITION WITH THE WATER FITTINGS POINTING DOWN- WARD. DO NOT

INSTALL UNIT WHERE IT WOULD ROUNTINELY BE SPLASHED WITH WATER. ELECTRIC SHOCK MAY RESULT.

-

ELECTRICAL INSTALLATION

2

6.

5.

3.

2.

1.

4.

All electrical work must comply with national and applicable state and local electrical codes.

Remember to SWITCH OFF the mains before carrying out any electrical work.

Refer to TABLE 1 for the correct cable size.

Use double insulation cable of over 2.5mm .

Lead the power cable from MCB to a“ON/OFF”double pole Linked Switch having a contact

separation of at least 3mm in all poles outside the bathroom,then lead a cable to the terminal

block inside the Heater Unit. (Fig. 6)

This appliance must be earthed. Improper grounding could cause electrical shock.

Fig. 6

(*)

To ensure the power cord NOT

touch c e.

Fig. 7

(*)

A

6

continue from ELECTRICAL INSTALLATION

T FUNCTION.

OT

PROCEDURE :

Insert the wall embedded cable through Side Entry ‘A’ by

cord rubber holder and lead the cable to Cable Bracket ‘B’. (Fig. 7)

Connect the cable as following:

BROWN or RED -- LIVE (L)

BLUE or BLACK -- NEUTRAL (N)

GREEN or GREEN/YELLOW -- EARTH ( )

Clamp the cable to the correct position. CHECK IF THE WIRING CONNECTION IS CORRECT AND SECURE.

- Reinstall the cover.

When putting back the Front Cover, please take note of the procedure shown below :

The‘’live’’wires must be connected to the slots on Terminal Block marked L.

The‘’neutral’’wires must be connected to the slots on Terminal Block marked N.

The ground wire must be connected to the at marked with the

3.

4.

Method of Alignment When Replacing Front Cover

Fig. A Fig. B

R rew ‘A’

5.

Terminal Block

Position

this way

(Off Position)

cutting a hole at the

source

ground symbol. ( )

TEST RUN

Turn on the water supply and Stop Valve, the wat ow through the outlet.

Switch on the electrical supply. (LED indicator will light up in Blue Color)

Turn the Temperature Control Knob to‘ON’, the LED Indicator will light up in Purple Color, hot water will

ow out within a few seconds.The more Temperature Control Knob being turned in clockwise direction,

the hotter is the water.

LED Indicator function :

The shower bath, long bath, wash basin might not be hot enought even at the ‘MAX’position if

incoming water supply from the mains is too cold or the pressure of water is too high. In this case, you

may adjust the incoming cold water mixer valve to reduce the wat ow in order to get the desired

water temperature.

It is unnecessary to turn the Temperature Control Knob to“OFF”position when the Heater is not in use.

Explain to the user how the unit works and familiarise him or her with its use.

- Advise the user about possible hazards (high water temperature)

- Hand over these instructions,to be kept in a safe place.

5.

6.

1) BLUE - ON

2) PURPLE - POWER ON

3) LED OFF - POWER OFF

Position

this way

(Off Position)

MADE IN MAL

230Va.c. 4.5kW 50/60Hz

ELECTRICAL LOADING

TYPE

WATER CONNECTION

DIMENSIONS 155mm x 83mm x 248mm

WEIGHT

1/2’’ BSP MULTI POINT SYSTEM

1.5 Kg

ELECTRONIC POWER CONTROL

Min. INLET WATER PRESSURE

Max. INLET WATER PRESSURE

0.1 Bar ( 10kPa)

6.0 Bar ( 0.6MPa)

EN L

G

N1

T2

TRIAC

Manual

Reset

Thermal

Cut-Out

(2Poles)

Heater

Tank

Power ON/OFF

Temp. Control

RC CB/ POWER

Turbine Flow Switch

TR FS

Thermistor

Inlet

Outlet

ELECTRICAL SPECIFICATION

WIRING DIAGRAM

MAINTENANCE

MAINTENANCE

CLEAN THE FILTER REGULARLY

Read the section ‘ SAFETY INFORMATION ’

If any abnormal condiiton to the water heater, switch OFF the mains

for repair service. Special skill is required for repairing. NEVER try to repair the unit by yourself.

CLEANING PRECAUTION !

Do not use thinner, alcohol, petrol or any other organic solutions to clean the set. Use only damped

cloth with mild detergent.

supply and contact sales agent

Clean the Mesh Filter regularly to prevent blockage. When carrying out any work,

Note : Water heater must be permanently connected to the electricity supply through a Manual Reset

Thermal Cut Out (2 Poles) having a contact sepration of at least 3mm in all poles incorporated in

the circuit.

MADE IN MALAYSIA

Water Heater

EWH 5451T

Thank you for purchasing EuropAce Water Heater.

future reference.

Product Warranty

The Warranty Card is not provided in the product packaging. You can register the product

warranty online at our website https://www.europace.com.sg/ewarranty/ within 7 (seven)

days from the date of purchase. You will enjoy an additional 3 months of the product

standard warranty when you register online. Please produce your E-warranty registration

when requesting for repair and service at our Service Centres nearest to you.

In the event, if you are unable to register the product warranty online you must produce your

purchase receipt/tax invoice and such other documentary proof of purchase of the appliance

when requesting for repair and service.

Product Warranty Coverage

You may nd out your product warranty coverage at the link below before calling our Cus-

tomer Service Hotline (65) 6457 3678 or visiting our Service Centre.

http://europace.com.sg/ewarranty/src/cupload/settings_pd-

f/1/1-1-2c899-1563960978-WARRANTY-COVERAGE-19_0221.pdf

TERMS & CONDITIONS OF WARRANTY (THIS WARRANTY IS VALID IN SINGAPORE

ONLY)

Your appliance is warranted against faulty design, workmanship or materials for a period of

12 months unless otherwise stated from the date of purchase, subject to the following terms

& conditions herein below:-

1) That the owner shall register the product warranty online at our website www.eu-

ropace.com.sg within 7 (seven) days from the date of purchase.

2) That the appliance shall be used solely for domestic purposes and not for commercial

purposes or any other purposes whatsoever and used strictly under the instruction for

operation as provided by the manufacturers or the appliance.

3) That if any time during the warranty period any part or parts of this appliance is removed,

tampered, modied, adjusted, altered, handled or repaired in any way whatsoever by any

persons other than those authorized by Strategic Marketing (S) Pte Ltd, this warranty shall

immediately cease to be valid and become void.

4) That the owner shall produce the E-warranty registration or tax invoice/receipt and such

other documentary proof of purchase of the appliance to our satisfaction as we may deem

necessary when requesting for repair and service.

5) That our decision on all queries relating to complaints as to defects either of workmanship

or of materials shall be conclusive and the owner shall agree to abide by such a decision. Any

appliance or defective part which has been replaced shall become our property.

6) The terms and conditions of this warranty shall be contained exclusively in this document

and no other presentation of provision, either written or otherwise, regardless of the origin of

the same, shall be accepted as either adding or removing from these terms and conditions.

7) That this warranty shall cease to be valid and void if the appliance is exported or

relocated from Singapore.

8) That there shall be no removal, alteration, defacement, or made illegible/tampered or any

kind of the serial number on the appliance.

9) That the owner shall be fully responsible for the due delivery and collection of the appli-

ance for any work done according to this warranty. Transportation expenses incurred for

delivery or handling the appliance are chargeable to the owner.

10) Transportation and labour charges apply after the full parts warranty expires. Refer to

https://www.europace.com.sg/ewarranty/ for more information.

In addition to the above, this warranty shall be subjected to the following limitations and

exclusions:-

a)The appliance shall be warranted by STRATEGIC MARKETING (S) PTE. LTD. from date of

purchase only for a period of:-

10 years - Heating Element warranty applies to selected models of Storage Water Heaters.

- Tank Leakage warranty applies to selected models of Storage Water Heaters.

8 years - Motor warranty applies only to selected models of Stand Fans (Walk-in warranty).

10 years - Compressor warranty applies to selected models of Refrigerators.

6 years - Motor warranty applies only to selected models of Stand Fans (Walk-in warranty).

- Compressor warranty applies only to selected models of System Air Conditioners

and Portable Air Conditioners.

5 years - Compressor warranty applies to Refrigerators, Freezers, Wine Coolers, Portable

Air Conditioners & Casement Air Conditioners (Outdoor warranty). Transportation is

chargeable from the 2nd year to 5th year.

- Compressor warranty applies to Dehumidiers (Walk-in warranty)

- Motor warranty applies only to selected models of Stand Fans (Walk-in warranty).

3 years - Full parts warranty applies only to selected models of Air Puriers & selected

models of Dehumidiers (Walk-in warranty).

- Heating Element warranty applies only to selected models of Garment Steamers

(Walk-in warranty).

- Motor warranty applies only to selected models of Jet Turbine Fans & selected

models of Air Coolers (Walk-in warranty).

2 years - Motor and internal parts warranty applies only to selected models of Stand Fans,

selected models of Oscillation Power Fans & selected models of Air Puriers

(Walk-in warranty).

- Heating Element warranty applies to selected models of Electric Ovens &

selected models of Kettle Jugs. (Walk-in warranty)

- Motor warranty applies only to selected models of Jet Turbine Fans

(Walk-in warranty).

- Full parts warranty applies only to Wine Coolers of 34 Bottles & above.

1 year - Full parts warranty applies to *Lifestyle Products (cash & carry items), Small

Kitchen Appliances, Fans, Air Coolers, Wine Coolers of 20 Bottles & below, Mini

Bar Fridge (Walk-in warranty)

- Full parts warranty apply to Refrigerators, Air Conditioners & Freezers

(Outdoor warranty).

Check out the warranty coverage of your appliance at www.europace.com.sg

b) The owner waives all or any claims to compensation monetary or otherwise which

he/she may be entitled to and shall agree to accept any compensation whatsoever by

way of additional repairs or otherwise which we in our absolute discretion may deem t

to oer. The giving of compensation shall be subjected to the other provisions of the

warranty.

c) This warranty shall not be transferable, negotiable or assignable to any third party.

d) The warranty does not include transport delivery or handling charges incurred in the

transportation of the appliance to and from Strategic Marketing (S) Pte Ltd.

e) Damage caused during transit where the appliance is transported for servicing, repair,

or in relation thereof or connection therewith.

f) In respect of refrigerator and air conditioner only, upon the expiry of 12 months from

the date of purchase, this warranty will not cover transport, refrigerant and labour to

install a new compressor.

g) This warranty will not cover chemical cleaning, maintenance service, general service and

overhaul, which if conrm is chargeable.

h) Defects or fault in the appliance which has been used for commercial purposes or which

have been rented/leased or which have been otherwise subject to other than household

use.

i) Claims for damaged/missing parts after 3 days from the original date of goods received

will not be valid.

j) This warranty and the Replacement Scheme does not particularly cover damages and/or

defects arising from

• Usage of wrong electrical supply/voltage.

• Usage not according to the Instruction Manual provided by the manufacturers.

• Misuse, accidents, negligence, abuse, improper installation, or any manner of tampering.

• Normal wear and tear.

• Corrosions rusting or stains.

• Scratches, dents on the unit body, casing or paintwork of the appliance.

• Act of God, re, ood and civil unrest.

• We shall not under any obligation, legal or otherwise to repair this appliance or one to one

exchange if the same shall be required as a result of losses, damages, and malfunctions

arising from any of the causes mentioned in the paragraph.

k) All accessories, external parts and extruded parts such as front panel, casing, door, glass

cover, glass door, cable/cord assembly, batteries, adaptor, plug, remote control, control

knob, buttons, lter, UV lamp, oven tray, wooden rack, exhaust hose, xtures, panels, cover,

lid and lever, plastic parts, fan blades, blade guard, inner pots, brushes, water tanks, attach-

ments made of glass, plastic and/or porcelain, detachable parts, and other option items are

excluded from this warranty.

All services provided after the warranty period will be chargeable at standard rates deter-

mined by STRATEGIC MARKETING (S) PTE. LTD.

The terms and conditions of this warranty shall be varied except with the written and

express consent or agreement of Strategic Marketing (S) Pte. Ltd. While Strategic Marketing

(S) Pte. Ltd. endeavours to repair any defects after the warranty period, it is subject to avail-

ability.

It is hereby expressly provided that any liability of Strategic Marketing (S) Pte. Ltd. for any

loss or damage whatsoever arising from, relating to or in connection with the purchase of

the appliance shall not exceed the purchase price (excluding installation costs) of the appli-

ance. Similarly, Strategic Marketing (S) Pte. Ltd.’s liability for any breach of this warranty shall

be limited to the purchase price (excluding installation costs) of the appliance.

* Lifestyle Products - Garment Steamer, Humidier, Dehumidier, Air Purier, Mini

Bar-Fridge.

* Walk-in warranty - Customers are obliged to bring the warranted products to Strategic

Marketing (S) Pte. Ltd. Service Centre for repair/service during the warranty period.

Ver. 20 _0312

Scan QR Code for

the online Warranty

Registration

Ver. 20 _0312

System Split Aircons | Tel: 6858 0801| Email: systemac@strategic.com.sg (Twin City)

Refrigerators, Washing machines, Cookers & other major appliances |

RELATED PRODUCTS & MAIN CONTACT HOTLINE

Table of contents

Other EuropAce Water Heater manuals

Popular Water Heater manuals by other brands

Rheem

Rheem TRITON GHE80SU-130A quick start guide

Grant

Grant HPMONO/IND125 Installation & user's instructions

Bosch

Bosch Tronic 1000 T Installation and operating instructions

GSW

GSW Electric Water Heater P/N 61515 REV. G... Installation and operating instructions

Rommelsbacher

Rommelsbacher RT 350 instruction manual

Takagi

Takagi T-K1 Installation manual and owner's guide

Drazice

Drazice NADO 300/20v11 OPERATING AND INSTALLATION Manual

Buderus

Buderus SF300.5 Installation and maintenance instructions

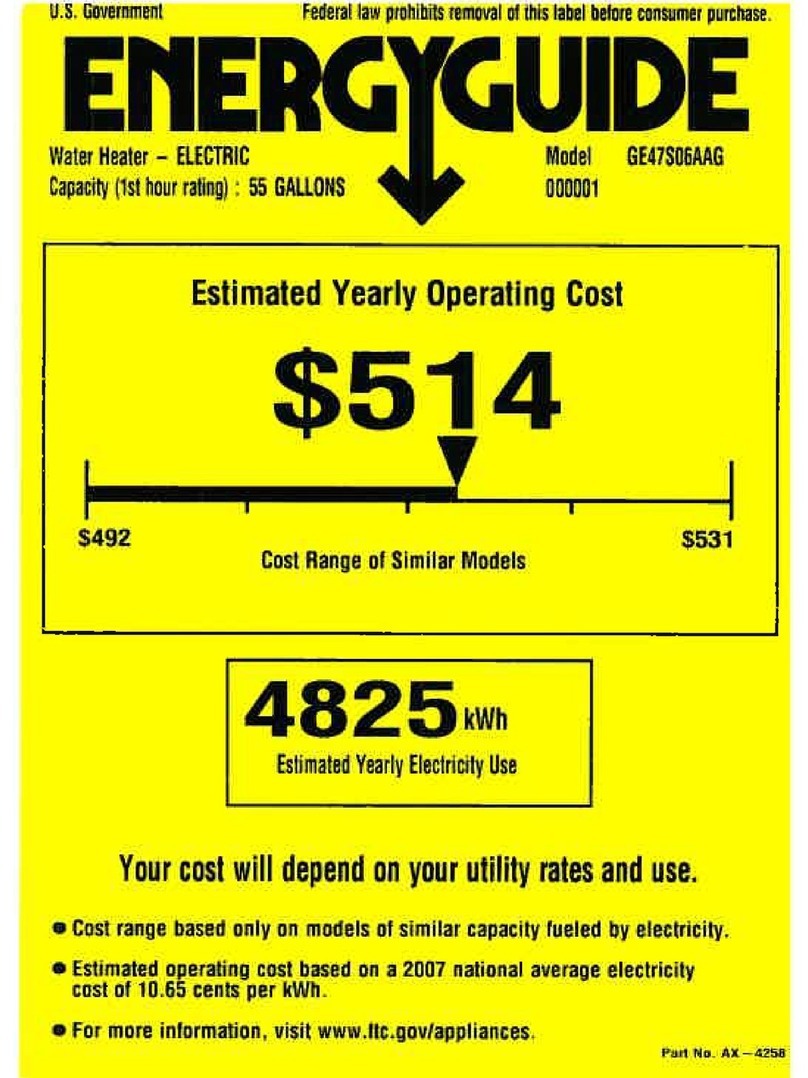

GE

GE 47S06AAG Energy guide

A.O. Smith

A.O. Smith POWER VENT GAS Installation and operating manual

DeDietrich

DeDietrich UNO BSL 150 user manual

Wolf

Wolf SPU-2 Assembly instructions