Chaffoteaux & Maury Duo 200 Instruction Manual

Supplied By www.heating spares.co Tel. 0161 620 6677

Installation and Maintenance

Instruction Manual

Including User Instructions

CaNI

CHAFFOTEAUX8Md”RY

Supplied By www.heating spares.co Tel. 0161 620 6677

Chaffoteaux & Maury Ltd., as a leading manufacturer of

domestic and commercial water heating appliances, as

well as domestic unvented direct and indirect storage

cylinders, is committed to providing high quality products

and a first class after sales service. If it is necessary to

contact an engineer, then telephone your local

Chaffoteaux Service Centre.

LOCAL CHAFFOTEAUX SERVICE CENTRE

Tel: 0807 243 0224

Advice on installation or servicing can also be obtained

by contacting the Chaffoteaux Customer Services

Department.

CUSTOMER SERVICES DEPARTMENT

Tel : 01952 222288 Fax. 01952 22402

The manufacturer’s guarantee against faulty construction

or materials for the cylinder is 5 years and for the electrical

components, thermal controls and safety valves is for

12 months, from the date of purchase.

The guarantee will be invalidated if the factory fitted

temperature and pressure relief valve is tampered with

or removed. The Manufacturer or Distributors cannot

be held responsible for any damage howsoever caused

and which is a consequence of the removal or tampering.

The guarantee may also be invalidated if the appliance

is not installed by a competent person in accordance

with the recommendations made herein, current

standards, regulations or in a manner not approved by

the manufacturer, modified in any way, subjected to frost,

misuse or neglect and that factory fitted parts have had

unauthorised repairs or replacements carried out.

Evidence of purchase and the date of supply must be

made available at the time of any claim.

To assist us in providing you with an efficient after

sales service, please return the guarantee

registration card enclosed with the cylinder without

delay.

Installation must be carried out by a suitably qualified

installer and in accordance with current regulations

and codes of practice.

Only the safety valves supplied with the cylinder

should be used.

The cylinder must not be used without the safety

valves and expansion vessels.

The cylinder must not be used with a boiler without

thermostatic control.

The cylinder and ancillary controls must be adequately

maintained.

l

The installation must have a sufficient and constant

supply of mains fed cold water.

l

No valve should be fitted between the expansion relief

valve and the storage cylinder.

l

Only Chaffoteaux and Maury approved replacement

parts should be used.

l

The discharge pipe must be terminated where it is

visible and will not cause danger to people in the

vicinity of the discharge.

Note: The discharge could consist of scalding water and

steam.

1 m

C&M

Supplied By www.heating spares.co Tel. 0161 620 6677

page

Customer Care and Guarantee.. ................... .I

Safety Notice .................................................. 1

Contents ........................................................ .2

Table of Figures.. ........................................... .2

Introduction ................................................... .3

Specifications ................................................ .3

Dimensions ................................................... .4

Location of Components ............................... .5

The Cylinder.. ..................................................... .5

Installation ..................................................... .7

Planning ..............................................................

7

Installation ...........................................................

7

Fitting Safety Components ................................. .7

Discharge Pipes ................................................. .7

iwe

Wiring ............................................................ .8

Direct System ...................................................... 8

Indirect system .................................................... 9

Britony System Plus Boiler .................................. 9

Britony System Boiler ......................................... 11

Commissioning.. ........................................... 12

Filling the Cylinder.. ........................................... 12

Check the operation of the safety valves .......... 12

Direct Heating Units .......................................... 12

Indirect Heating ................................................. 12

Post Commissioning .................................... 12

Handing Over to the Householder.. ................... 12

Maintenance ................................................. 13

Routine Maintenance ........................................ 13

Fault Finding Charts ..................................... 14

Spare Parts List.. .......................................... 17

Spare Parts Short List .................................. 17

User’s Instructions.. ...................................... 18

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

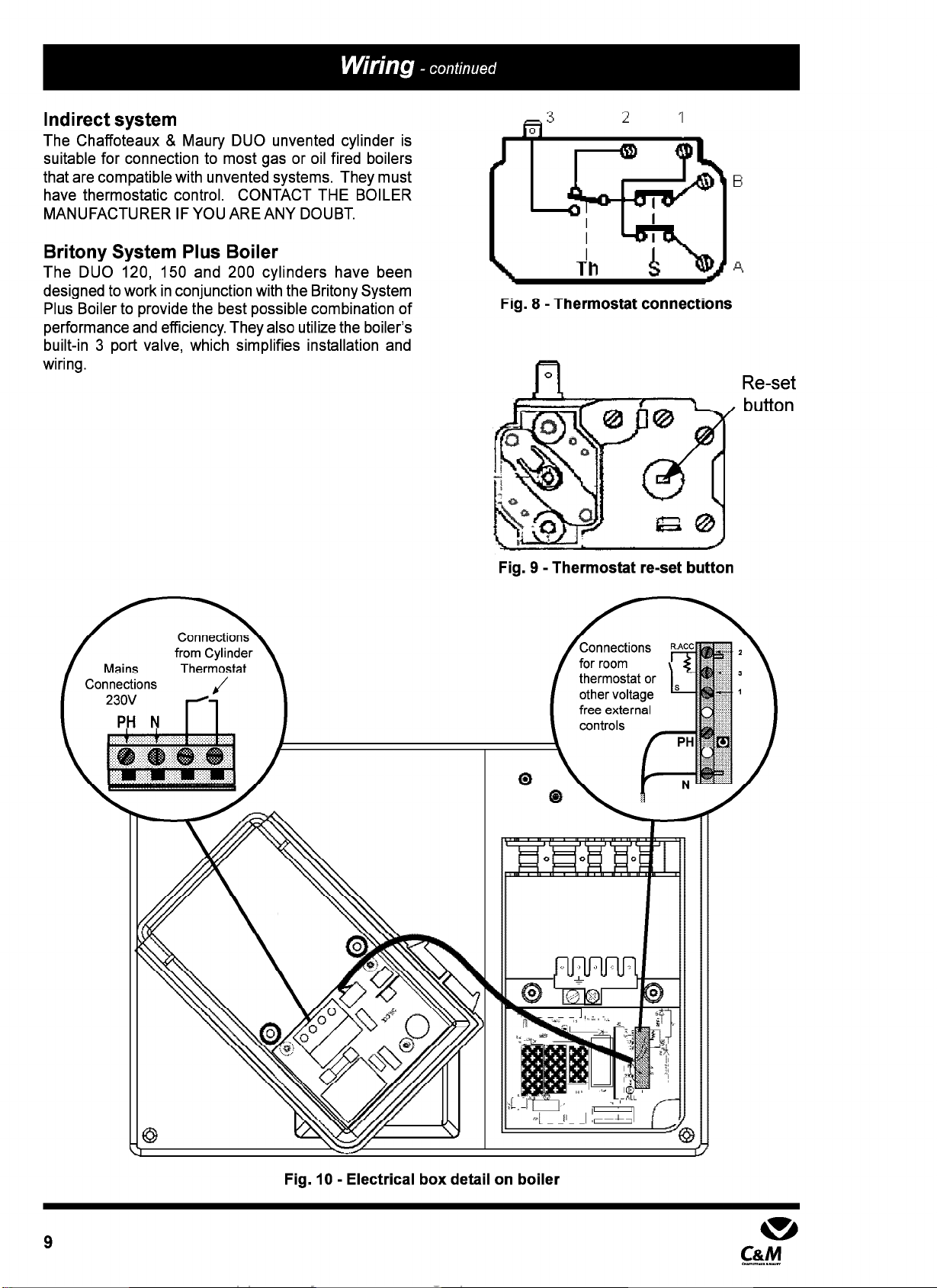

Fig. 8

Fig. 9

Fig. 10

paw

Dimensions.. ............................................ 4

Combination safety control valves ........... 5

Cylinder connected to System

Plus Boiler ............................................... 5

Cylinder connected to System Boiler.. ..... 6

Discharge pipe arrangement ................... 7

Discharge pipe sizing .............................. 7

Wiring for electrical element .................... 8

Thermostat connections .......................... 9

Thermostat re-set button ......................... 9

Electrical box detail on boiler.. ................. 9

Fig. 11

Fig. 12

Fig. 13

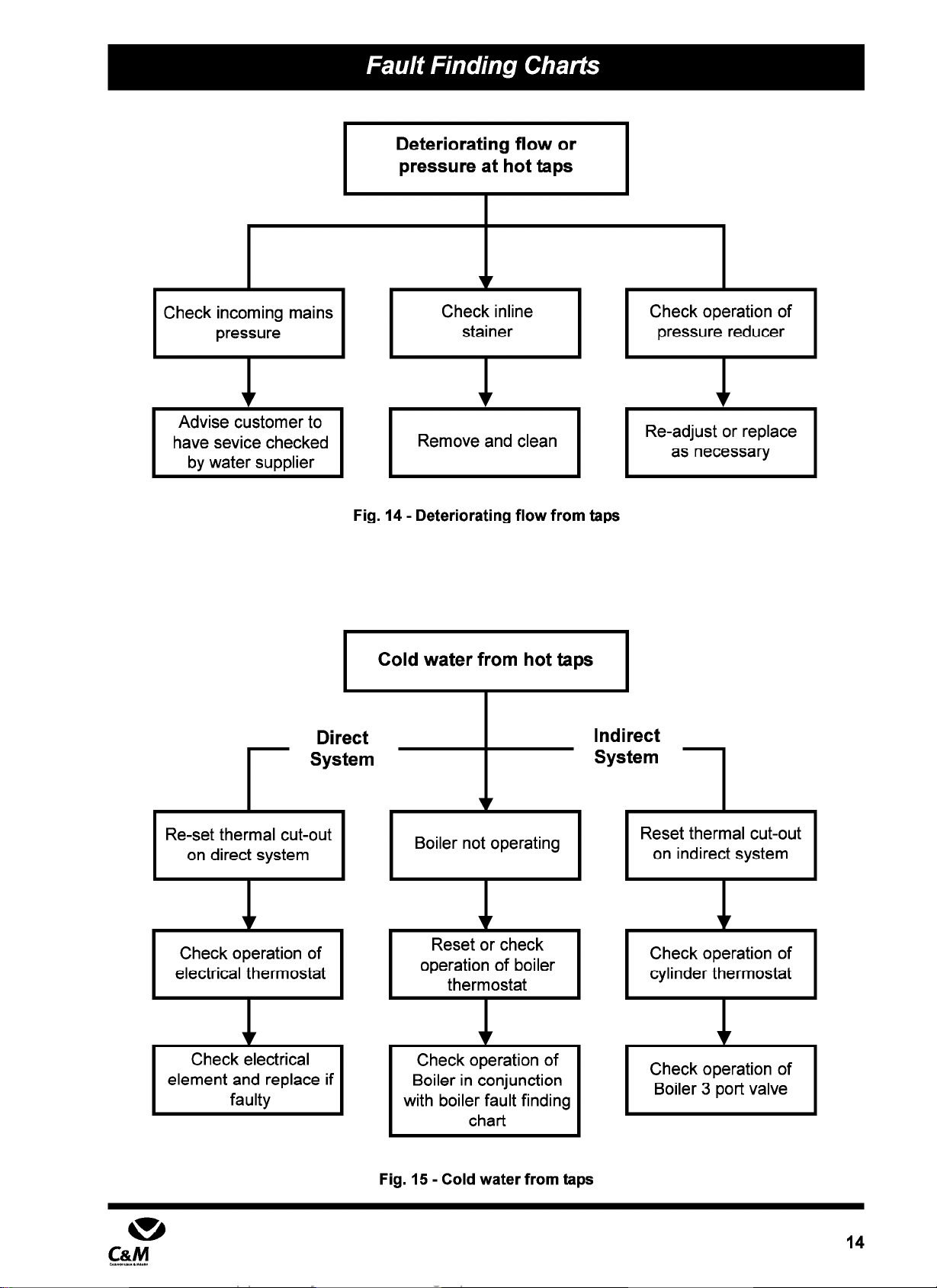

Fig. 14

Fig. 15

Fig. 16

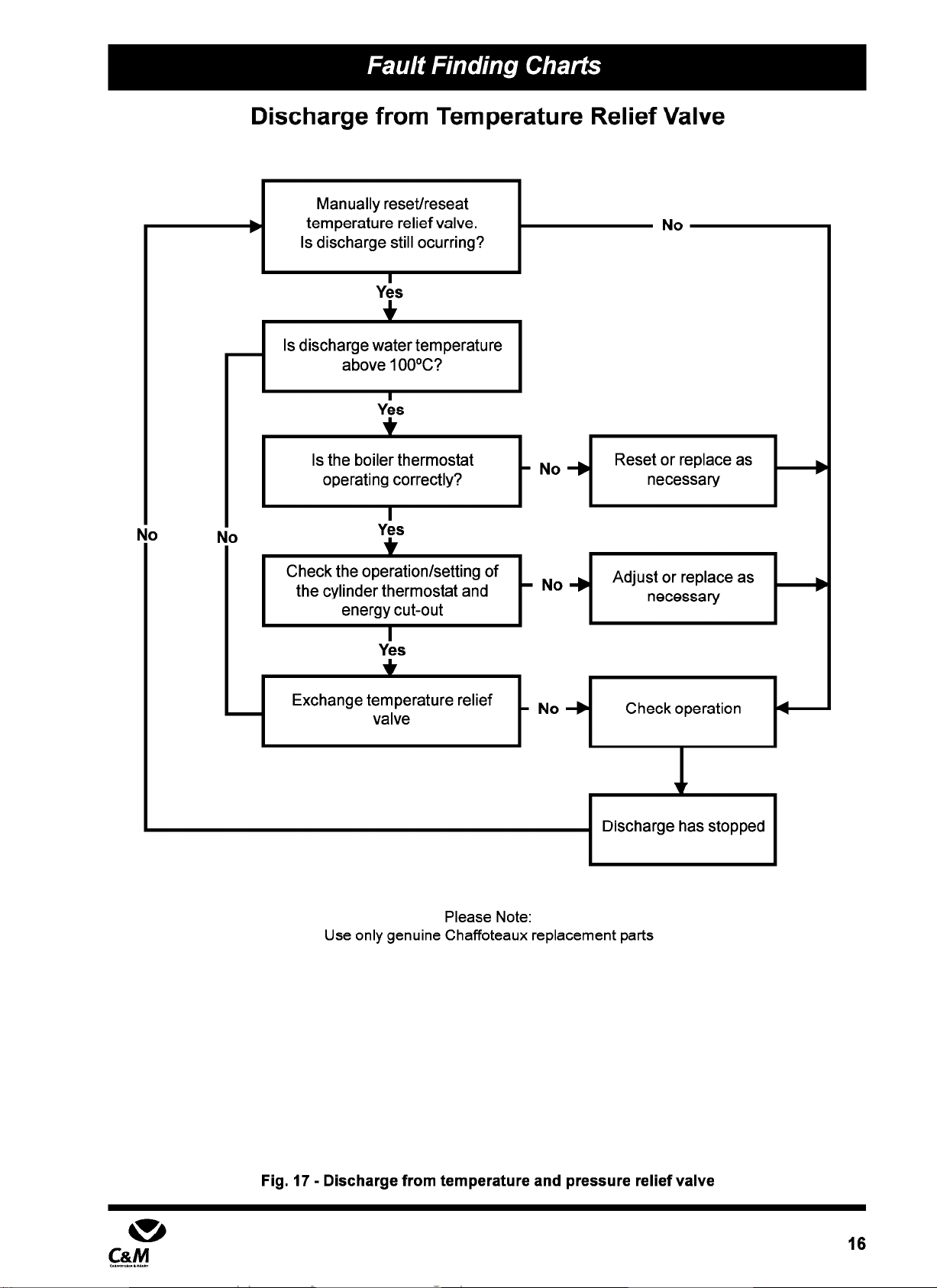

Fig. 17

paw

Hot water on constant and central

heating timed 10

Hot water and heating timed 10

Britony System boiler using

2 x two port valves 11

Deteriorating flow from taps 14

Cold water from taps 14

Discharge from expansion relief valve.. 15

Discharge from temperature and

pressure relief valve 16

2

Supplied By www.heating spares.co Tel. 0161 620 6677

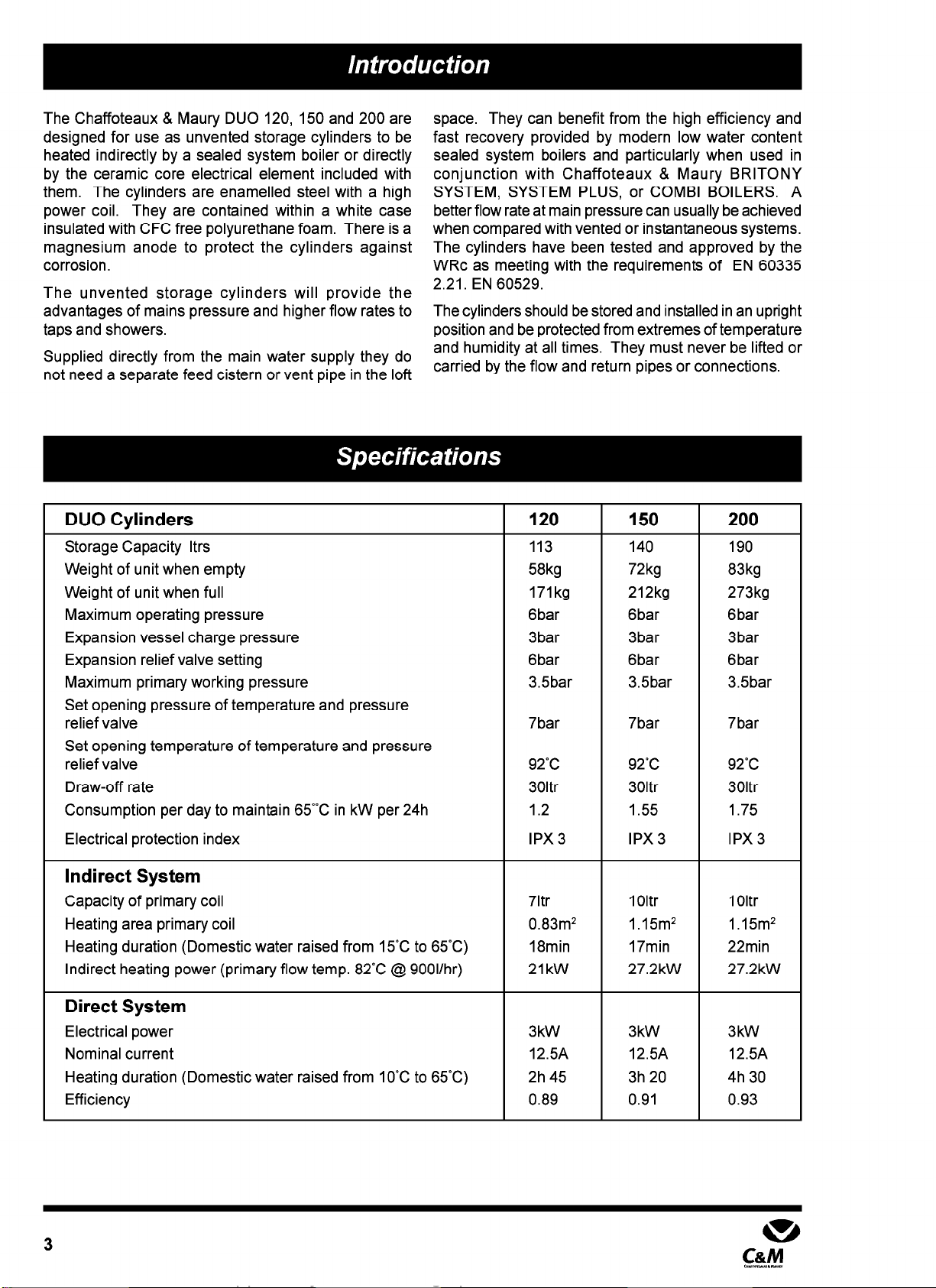

The Chaffoteaux & Maury DUO 120, 150 and 200 are

designed for use as unvented storage cylinders to be

heated indirectly by a sealed system boiler or directly

by the ceramic core electrical element included with

them. The cylinders are enamelled steel with a high

power coil. They are contained within a white case

insulated with CFC free polyurethane foam. There is a

magnesium anode to protect the cylinders against

corrosion.

The unvented storage cylinders will provide the

advantages of mains pressure and higher flow rates to

taps and showers.

Supplied directly from the main water supply they do

not need a separate feed cistern or vent pipe in the loft

space. They can benefit from the high efficiency and

fast recovery provided by modern low water content

sealed system boilers and particularly when used in

conjunction with Chaffoteaux & Maury BRITONY

SYSTEM, SYSTEM PLUS, or COMBI BOILERS. A

better flow rate at main pressure can usually be achieved

when compared with vented or instantaneous systems.

The cylinders have been tested and approved by the

WRc as meeting with the requirements of EN 60335

2.21. EN 60529.

The cylinders should be stored and installed in an upright

position and be protected from extremes of temperature

and humidity at all times. They must never be lifted or

carried by the flow and return pipes or connections.

DUO Cylinders

Storage Capacity ltrs

Weight of unit when empty

Weight of unit when full

Maximum operating pressure

Expansion vessel charge pressure

Expansion relief valve setting

Maximum primary working pressure

Set opening pressure of temperature and pressure

relief valve

Set opening temperature of temperature and pressure

relief valve

Draw-off rate

Consumption per day to maintain 65°C in kW per 24h

Electrical protection index

Indirect System

Capacity of primary coil

Heating area primary coil

Heating duration (Domestic water raised from 15°C to 65°C)

Indirect heating power (primary flow temp. 82°C @ 900Vhr)

Direct System

Electrical power

Nominal current

Heating duration (Domestic water raised from 10°C to 65°C)

Efficiency

120 150

113 140

58kg 72kg

171kg 212kg

6bar 6bar

3bar 3bar

6bar 6bar

3.5bar 3.5bar

7bar 7bar

92°C 92°C

301tr 301tr

1.2 1.55

IPX3 IPX3

71tr 1Oltr

0.83m2 1.15m2

18min 17min

21kW 27.2kW

3kW 3kW

12.5A 12.5A

2h 45 3h 20

0.89 0.91

200

190

83kg

273kg

6bar

3bar

6bar

3.5bar

7bar

92°C

301tr

1.75

IPX3

1Oltr

1.15m2

22min

27.2kW

3kW

12.5A

4h 30

0.93

Supplied By www.heating spares.co Tel. 0161 620 6677

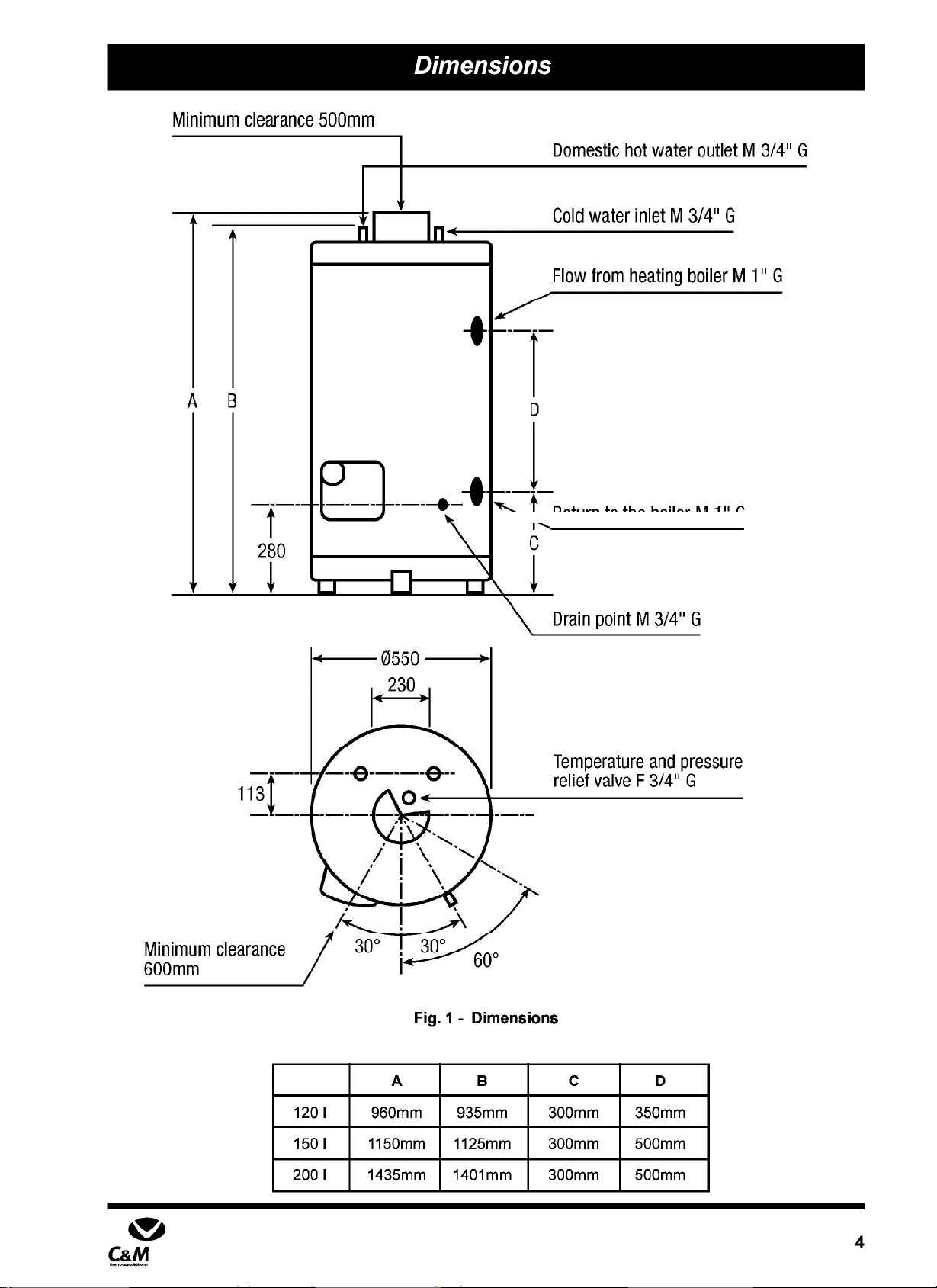

Minimumclearance500mm

-

----.

t

280

J

DomestichotwateroutletM3/4” G

v

f

nl Coldwater inletM3/4” G

ll4

c

1

+0550-i , 230 ,

FlowfromheatingboilerM1” G

1

\

DrainpointM3/4” G

-y--I---yq-q--- .

Minimumclearance

600mm

Fig. 1 - Dimensions

reandpressure

/I=‘2/J”G

A B C D

120 I 960mm 935mm 300mm 350mm

150 I 1150mm 1125mm 300mm 500mm

200 I 1435mm 1401mm 300mm 500mm

4

Supplied By www.heating spares.co Tel. 0161 620 6677

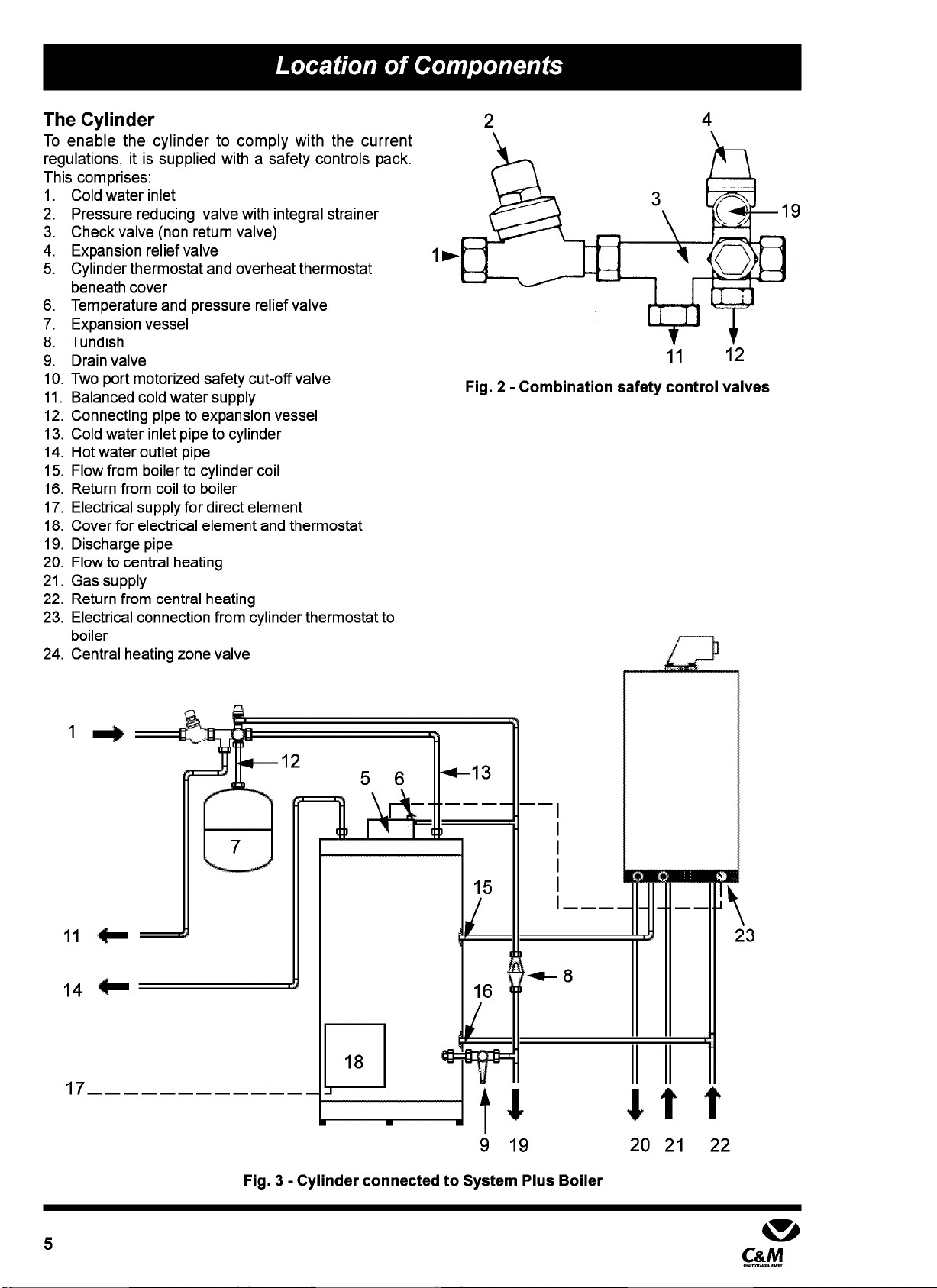

The Cylinder

To enable the cylinder to comply with the current

regulations, it is supplied with a safety controls pack.

This comprises:

1. Cold water inlet

2. Pressure reducing valve with integral strainer

3. Check valve (non return valve)

4. Expansion relief valve

5. Cylinder thermostat and overheat thermostat

beneath cover

6. Temperature and pressure relief valve

7. Expansion vessel

8. Tundish

9. Drain valve

10. Two port motorized safety cut-off valve

11. Balanced cold water supply

12. Connecting pipe to expansion vessel

13. Cold water inlet pipe to cylinder

14. Hot water outlet pipe

15. Flow from boiler to cylinder coil

16. Return from coil to boiler

17. Electrical supply for direct element

18. Cover for electrical element and thermostat

19. Discharge pipe

20. Flow to central heating

21. Gas supply

22. Return from central heating

23. Electrical connection from cylinder thermostat to

boiler

24. Central heating zone valve

2 4

Fig. 2 - Combination safety control valves

Fig. 3 - Cylinder connected to System Plus Boiler

23

5

m

C&M

c.y~.“x.“y”

Supplied By www.heating spares.co Tel. 0161 620 6677

Fig. 4 - Cylinder connected to System Boiler

Please note: the motorised two port safety cut off

valve is only necessary if the cylinders are linked to a

boiler other than the Britony System Plus Boiler.

The Electrical Element

The cylinder contains an alternative source of power.

It is fitted with a 230~ 3 kW ceramic core element with

a factory set thermostat and a manually re-settable

thermal cut-out.

6

Supplied By www.heating spares.co Tel. 0161 620 6677

Planning

The efficient operation of this appliance depends upon a

well-designed system and correct connection to the

boiler. Please familiarise yourself with these installation

instructions as well as the relevant British Standards and

Statutory Regulations. For example, please consult

current versions of the Building Regulations, The Building

Standards for Scotland, the IEE Regulations, the Model

Water Bylaws and the Health and Safety Document No.

635 (The Electricity at Work Regulations 1989) Approved

Document G3. The domestic hot water pipework must

be in accordance with BS 6700. All capillary joints must

be made using lead free solder.

Check that the kit of components is complete.

l

The cylinder must be installed vertically.

l

All pipe runs should be kept as short as possible for

economy.

l

Allow a minimum of 600 mm frontal clearance to allow

the removal of the electrical element and access to

the thermostat.

l

Allow 500 mm access to the top of the appliance to

allow the removal of the sacrificial anode.

l

Provision must be made for the positioning of the

safety valves, expansion vessel and discharge pipes.

l

Ensure that the floor is level and capable of supporting

the weight of the cylinder when full (see page 3).

l

Check that there is sufficient mains pressure and flow

to cater for the combined demands of hot and cold

water for the premises.

Installation

To obtain the best performance from the Chaffoteaux &

Maury DUO, the lowest main working pressure (when

demand on the main supply is at its highest and with a

tap running) should not fall below 20 l/min at 1.5 bar.

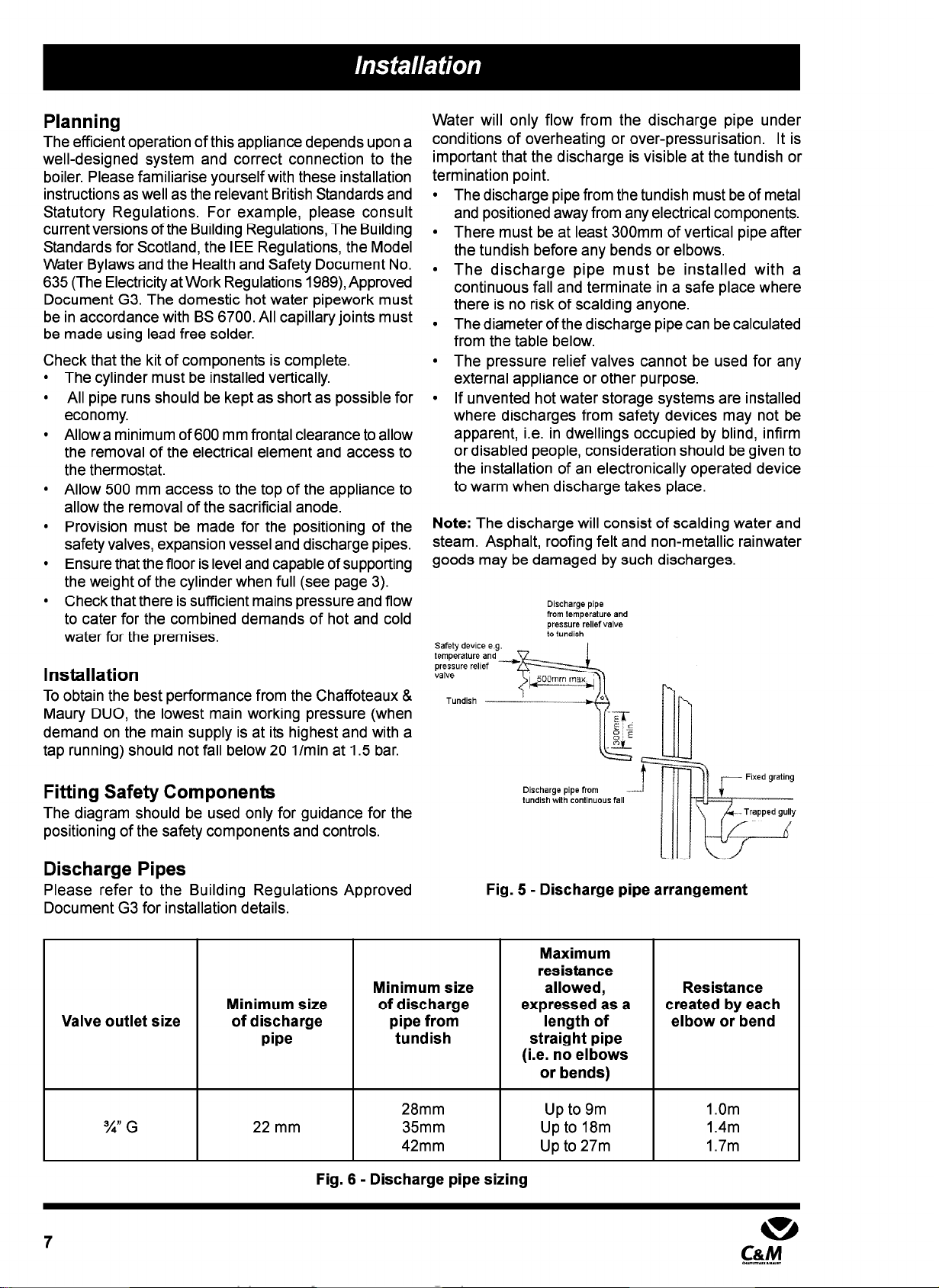

Fitting Safety Components

The diagram should be used only for guidance for the

positioning of the safety components and controls.

Water will only flow from the discharge pipe under

conditions of overheating or over-pressurisation. It is

important that the discharge is visible at the tundish or

termination point.

l

The discharge pipe from the tundish must be of metal

and positioned away from any electrical components.

l

There must be at least 300mm of vertical pipe after

the tundish before any bends or elbows.

l

The discharge pipe must be installed with a

continuous fall and terminate in a safe place where

there is no risk of scalding anyone.

l

The diameter of the discharge pipe can be calculated

from the table below.

l

The pressure relief valves cannot be used for any

external appliance or other purpose.

l

If unvented hot water storage systems are installed

where discharges from safety devices may not be

apparent, i.e. in dwellings occupied by blind, infirm

or disabled people, consideration should be given to

the installation of an electronically operated device

to warm when discharge takes place.

Note: The discharge will consist of scalding water and

steam. Asphalt, roofing felt and non-metallic rainwater

goods may be damaged by such discharges.

Discharge pipe

from temperature and

pressure relief valve

to tundish

Safety de”lce e g. I

Discharge pipe from

tundish with continuous fall

Discharge Pipes

Please refer to the Building Regulations Approved

Document G3 for installation details. Fig. 5 - Discharge pipe arrangement

Valve outlet size Minimum size

of discharge

pipe

22 mm

Minimum size

of discharge

pipe from

tundish

28mm Up to 9m

35mm Up to 18m

42mm Up to 27m

Maximum

resistance

allowed,

expressed as a

length of

straight pipe

(i.e. no elbows

or bends)

Resistance

created by each

elbow or bend

1.Om

1.4m

1.7m

Fig. 6 - Discharge pipe sizing

7

m

C&M

Supplied By www.heating spares.co Tel. 0161 620 6677

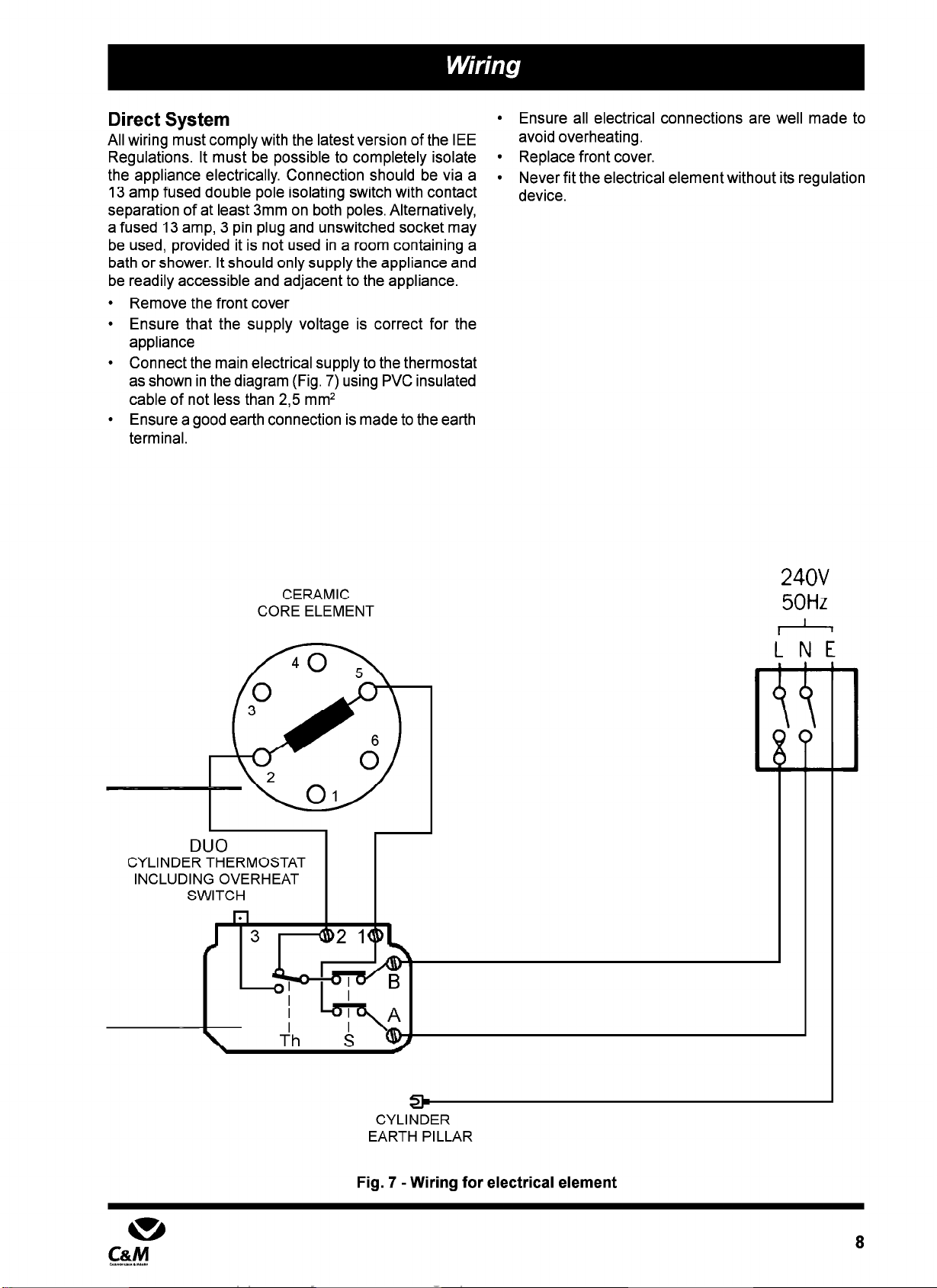

Direct System

l

Ensure all electrical connections are well made to

All wiring must comply with the latest version of the IEE avoid overheating.

Regulations. It must be possible to completely isolate

l

Replace front cover.

the appliance electrically. Connection should be via a

l

Never fit the electrical element without its regulation

13 amp fused double pole isolating switch with contact device.

separation of at least 3mm on both poles. Alternatively,

a fused 13 amp, 3 pin plug and unswitched socket may

be used, provided it is not used in a room containing a

bath or shower. It should only supply the appliance and

be readily accessible and adjacent to the appliance.

l

Remove the front cover

l

Ensure that the supply voltage is correct for the

appliance

l

Connect the main electrical supply to the thermostat

as shown in the diagram (Fig. 7) using PVC insulated

cable of not less than 2,5 mm2

l

Ensure a good earth connection is made to the earth

terminal.

CERAMIC

CORE ELEMENT

240V

50Hz

1

I

CYLlrJbER

EARTH PILLAR

Fig. 7 -Wiring for electrical element

8

Supplied By www.heating spares.co Tel. 0161 620 6677

Indirect system

The Chaffoteaux & Maury DUO unvented cylinder is

suitable for connection to most gas or oil fired boilers

that are compatible with unvented systems. They must

have thermostatic control. CONTACT THE BOILER

MANUFACTURER IF YOU ARE ANY DOUBT.

Britony System Plus Boiler

The DUO 120, 150 and 200 cylinders have been

designed to work in conjunction with the Britony System

Plus Boiler to provide the best possible combination of

performance and efficiency. They also utilize the boiler’s

built-in 3 port valve, which simplifies installation and

wiring.

/

co

from Cylinder

Mains Thermostat

“-nnections J

Fig. 8 -Thermostat connections

Fig. 9 - Thermostat re-set button

Reset

button

Fig. 10 - Electrical box detail on boiler

9 m

C&M

Supplied By www.heating spares.co Tel. 0161 620 6677

Option 1

Using a hot water priority system with the hot water on

constantly and the heating timed. Asimple time clock

can be use such as the Randall 103.

Timeclock

(for example Randall 103)

er

q

Interface PC

Fig. 11 - Hot water on constant and central heating timed

Option 2

Using hot water priority with a timed facility for both hot

water and central heating. A twin channel clock such

as the Horstman Channelplus Model H27 must be used.

Two Channel Programmer

For example

Horstman Channelplus

IhJl

resistor

Model H27

Thermostat

Fig. 12 - Hot water and heating timed

10

Supplied By www.heating spares.co Tel. 0161 620 6677

Britony System Boiler

When the Britony System boiler (or a boiler from another

manufacturer) a two port safety cut off valve must be

used. This is supplied with the cylinder. It can be used

together with another two port valve, to provide timed

control over the heating and hot water circuits.

Fused

Spur

Fig. 13 - Britony System boiler using 2 x two port valves

Supplied By www.heating spares.co Tel. 0161 620 6677

Filling the Cylinder

l

Do not turn on electrical power to the immersion

heater without water in the cylinder.

l

Ensure that all fittings, valves and the immersion

heater are correctly installed and are watertight.

l

Flush all debris from the supply pipes before

connecting to the cylinder.

l

Open the furthest hot water tap from the cylinder.

l

Open the main valve and allow the cylinder to fill

steadily. Allow water to flow from the tap for a few

minutes to ensure any installation debris is flushed

through the system.

l

Open all other taps in turn to purge any remaining

air from the system.

l

Check all connections for leaks.

Check the operation of the safety valves

l

Manually open the temperature and pressure relief

valve (6 Fig. 3) for a few seconds.

l

Check that the water flows away through the tundish

and discharge pipework and does not overflow.

l

Ensure that the flow of water has stopped and that

the valve has reseated itself.

l

Repeat the above check for the expansion relief

valve.

Direct Heating Units

l

Carry out an electrical test for earth continuity, correct

polarity, short circuit and fuse continuity.

l

Turn on the electrical supply and allow the water to

heat up.

l

Check the correct operation of the cylinder

thermostat.

l

Check that water is not discharged from either the

expansion relief or the temperature and pressure

relief valves.

Indirect Heating

l

Refer to the boiler commissioning instructions.

l

Ensure that the cylinder heating coils are filled and

purged of air.

l

Light boiler and allow the cylinder to heat up.

l

Check the correct operation of the cylinder

thermostat.

l

Check that water is not discharged from either the

expansion relief or the temperature and pressure.

Handing Over to the Householder

l

Ensure system pressure has been set correctly

l

Set boiler and cylinder thermostat and controls

l

Demonstrate the lighting and operation of the boiler

l

Demonstrate how to maintain system pressure

l

Explain to the customer :

1. the operation of the appliance and safety

controls

2. things to look out for such as a continual leak of

water noticed at the tundish

3. Explain the necessity for annual maintenance

by a competent person

4. what to do in an emergency

l

Leave instruction manual with the customer

l

Fill out guarantee card and return to Chaffoteaux &

Maury Ltd.

12

Supplied By www.heating spares.co Tel. 0161 620 6677

In order to ensure that the cylinder continues to operate

efficiently and safely, it is essential that it is serviced

and inspected annually. This may be timed to coincide

with the annual boiler maintenance.

l

Servicing and repairs should only be carried out by a

competent engineer.

l

Any part replaced should be genuine Chaffoteaux &

Maury spare parts.

Routine Maintenance

Before continuing with any maintenance, ensure

that the boiler has been turned off and that the

electrical supply has been isolated.

1. Electrical Element

Check the operation of the electrical element thermostat

by turning off the boiler and running off some hot water.

Allow the electrical element to reheat the water to its set

temperature. Check that no water is discharged from

the expansion or temperature relief valves. As the

electrical element is not indirect contact with the water,

it is not necessary to check it for scaling.

2. Sacrificial Anode

Drain the cylinder by turning off the main water inlet valve

and opening the lowest hot water tap to depressurise

the system. Open the drain valve (9 Fig. 3) and drain

approximately 5 litres.

The anode is located at the top of the cylinder. Remove

the cover. Disconnect the outlet pipe to from the T+P

valve. Unscrew 6 screws and lift the top plate clear.

When new the diameter of the anode is 26mm. If at

any point along its length the diameter has reduced to

half or less than half its original diameter, then it should

be replaced by unscrewing from the top plate.

Replace components in the reverse order using a new

gasket for the top plate.

3. Strainer

While the cylinder is partially drained the strainer can

be removed and cleaned.

4. Expansion Vessel

While there is no pressure in the system the pressure

in the expansion vessel can be checked against the

pressure on the data badge.

Refill and Re-pressurise the system as set out in the

commissioning instructions.

5. Safety Valves

Manually operate the temperature, pressure and

expansion relief valves. Check that water runs freely

through the tundish and at the discharge point without

overflowing. Check that the flow of water stops and that

the valves reseat satisfactorily.

13

m

C&M

c.y~.“x.“y”

Supplied By www.heating spares.co Tel. 0161 620 6677

Deteriorating flow or

pressure at hot taps

I 1 I v 1 I

I

Check incoming mains

I I

Check inline

pressure stainer Check operation of

pressure reducer

Advise customer to

have sevice checked

by water suoolier

Re-adjust or replace

as necessary

Remove and clean

Fig. 14 - Deteriorating flow from taps

I

Cold water from hot taps I

+

Boiler not operating

Reset or check

operation of boiler

thermostat

1

Check operation of

Boiler in conjunction

with boiler fault finding

chart

Fig. 15 - Cold water from taps

Indirect

System

1

Direct

r

System

I

Reset thermal cut-out

on indirect system

Re-set thermal cut-out

on direct system

Check operation of

electrical thermostat Check operation of

cylinder thermostat

I

Check operation of

Boiler 3 port valve

Check electrical

element and replace if

faulty

14

Supplied By www.heating spares.co Tel. 0161 620 6677

Discharge from Expansion Relief Valve

-I

Reset pressure

Manually reset/reseat

valve.

Is discharge still

4

ocurring?

I

Yes

4

conditions? I

Adjust or replace

faulty component + No Are the boiler and

cylinder thermostats

operating correctly?

Yes

I Service or exchange

expansion relief valve

Is the pressure

downstream of the

pressure regulator

correct?

Service or replace

pressure regulator

Please Note:

Use only genuine Chaffoteaux replacement parts

Fig. 16 - Discharge from expansion relief valve

m

C&M

c.y~.“x.“y”

Supplied By www.heating spares.co Tel. 0161 620 6677

D

Discharge from Temperature Relief Valve

Manually reset/reseat I

I

Is discharge still ocurring? I

Yes

Is discharge water temperature

above 1OOOC?

Yes

Check the operation/setting of

Yes

+

- No +

Reset or replace as

necessary

Adjust or replace as

necessary t+

]]/ No -) Checkoperation e

I I

Discharge has stopped

Please Note:

Use only genuine Chaffoteaux replacement parts

Fig. 17 - Discharge from temperature and pressure relief valve

Supplied By www.heating spares.co Tel. 0161 620 6677

9

10 -

11 -

12

6

17

m

C&M

Supplied By www.heating spares.co Tel. 0161 620 6677

There are no user adjustable controls on the DUO. The

immersion heater thermostat will have been set on

installation. A suitably qualified engineer, installer or

electrician must carry out any adjustments or

maintenance.

If water is seen discharging from the DUO Safety

Valves

l

Turn off the electrical supply to the immersion heater

l

Turn off the boiler

l

Do not turn off the water supply

l

Contact the installer or other suitably qualified

engineer.

In order to ensure that the cylinder continues to operate

efficiently and safely, it is essential that it is serviced

and inspected annually. This may be timed to coincide

with the annual boiler maintenance.

l

Servicing and repairs should be carried out by a

competent engineer.

l

Any part replaced should be genuine Chaffoteaux &

Maury spare part.

If the thermal cut out is activated, it is necessary to reset

and check the operation of both thermostats fitted to

the cylinder (immersion heating and indirect heating

thermostats).

Chaffoteaux & Maury Ltd are continuously improving

their products and therefore reserve the right to change

specifications without prior notice and accept no liability

for any errors or omissions in the information contained

in this document.

18

Supplied By www.heating spares.co Tel. 0161 620 6677

Chaffoteaux et Maury are contunuously improving their products and therefore reserve the right to change specifications without

prior notice and accepts no liability for any errors or omission in the information contained in this document.

0 Chaffoteaux & Maury Limited 1999 +

Chaffoteaux & Maury Limited, Trench Lock, Trench, Telford, Shropshire TFI 4SZ. 3

Telephone: 01952 222727 / Facsimile: 01952 243493 0

Technical Helpline: 01952 222288 /Technical Fax:01952 2609151 In Warranty Service: 0870 2430224

Table of contents

Popular Water System manuals by other brands

US Water Systems

US Water Systems L1-200 manual

Watts Premier

Watts Premier 5 SV DELUXE Installation, operation and maintenance manual

Filtrete

Filtrete 4US-MAXS-S01 Installation and operating instructions

EnerWorks

EnerWorks EWRA2 installation manual

Davey

Davey Dynajet X50 Installation and operating instructions

Zip

Zip HydroTap G5 Touch-Free Wave Quick start installation guide

Watts

Watts BA 009MC Installation and operation manual

SolarArk

SolarArk Solar Hot Water Systems installation manual

Marlo Incorporated

Marlo Incorporated RO-25T operating manual

clage

clage Zip HydroTap G5 CS 100 operating instructions

Everpure

Everpure ExuberaPRO Premium Carafe Water System brochure

Kärcher

Kärcher WPC 600 BW operating instructions