blupura PANTAREI Specification sheet

1

6

0

0

5

1

1

6

0

5

E

N

PANTAREI

U

s

e

&

M

a

i

n

t

e

n

a

n

c

e

M

a

n

u

a

l

3

Index

• BEFORE INSTALLING THE WATER COOLER 4

• RECOMMENDATIONS FOR SAFEGUARDING THE ENVIRONMENT 5

• DECLARATION OF CONFORMITY 6

• ASSOCIATIONS 7

• INTERNATIONAL AWARDS 7

• PRECAUTIONS AND GENERAL RECOMMENDATIONS 8

• DESCRIPTION OF THE UNIT 9

• TECHNICAL FEATURES 12

• INSTALLATION 15

• INSTALLATION OF THE CO2CYLINDER (FIZZ MODEL) 18

• HANDLING THE GAS CYLINDERS 19

• FILTRATION (OPTIONAL) 20

• SANITIZATION – NOTES 22

• ORDINARY MAINTENANCE 23

• SERVICE HISTORY 24

• WARRANTY CONDITIONS 25

4

Before installing the water cooler

Congratulations for choosing a BLUPURA product.

We have designed and manufactured this product with great care to ensure that

it will dispense water of the highest quality.

In order to get the most out of your water cooler, please read the instructions in

this manual and retain the manual for future reference.

5

Recommendations for safeguarding the environment

Packaging materials

The packaging materials are 100% recyclable.

Please follow the local guidelines on waste

disposal. For safety reasons keep the packaging

material out of the reach and sight of children.

Scrappage

The water cooler is made using recyclable material.

This unit is marked in compliance with European Directive 2002/96/EC

on Waste Electrical and Electronic Equipment (WEEE). By ensuring that

the product is scrapped correctly, you are helping to prevent potential

negative consequences for the environment and for health. The symbol

on the unit indicates that the product should not be treated as domestic waste

but should be taken to a dedicated recycling centre for electrical and electronic

equipment. Immediately prior to scrapping, cut off the power cable.

For more information on the treatment, recovery and recycling of this product,

please contact the appropriate local office, the waste disposal service or the

reseller from which the product was purchased.

Information on the natural, eco-friendly refrigerant gas used in

this cooler

This product contains no CFCs or HFCs, which contribute to global warming.

Indeed, it is the first water cooler on the market to use natural refrigerant.

The refrigerating system is filled with HC R290 – Propane: a natural gas that does

not contribute to global warming and that, thanks to its specific characteristics,

allows for substantial energy savings to be made.

6

Declaration of conformity

Materials compliant for contact with drinking water

This unit is intended for the dispensing of drinking water, and so the materials

that enter into direct contact with water meet the criteria for food-grade

components pursuant to the current legislation. In addition, the unit is

manufactured in compliance with Italian Ministerial Decrees 174 of 06/04/2004

and 25 of 07/02/2012.

Electrical safety

This water cooler is designed, manufactured and marketed in compliance with:

• the safety objectives of the Low Voltage Directive 2006/95/EC;

• the protection requirements of the Electromagnetic Compatibility Directive

2004/108/EC.

The electrical safety of the product is ensured only when it is properly connected

to an efficient, legally compliant grounding circuit.

D.M. 174

1

0

0

%

M

A

D

E

I

N

I

T

A

L

Y

C

E

R

T

I

F

I

C

A

T

E

I

T

P

I

rosso032 c

UNI EN ISO 9001:2015

UNI EN ISO 14001:2015

7

Associations

International Awards

2015 - BEST PROMOTION OF HEALTH AND HYDRATION

EUROPEAN AQUA AWARDS 2015, ROME

2015 - BEST ENVIRONMENTAL PRACTICE/GREEN INITIATIVE

EUROPEAN AQUA AWARDS 2015, ROME

2014 - BEST PROMOTION OF HEALTH AND HYDRATION

EUROPEAN AQUA AWARDS 2014, BUDAPEST

2013 - BEST PRODUCT INNOVATION

EUROPEAN AQUA AWARDS 2013, BERLIN

2012 - BEST ENVIRONMENTALLY FRIENDLY PRACTICE

EUROPEAN AQUA AWARDS 2012, ISTANBUL

2011 - BEST PRODUCT DESIGN/INNOVATION

EUROPEAN AQUA AWARDS 2011, ODESSA

2010 - BEST ENVIRONMENTALLY FRIENDLY PRACTICE

EUROPEAN AQUA AWARD 2010, PRAGUE

8

Precautions and general recommendations

Always connect the water cooler to a water main that supplies

drinking water only.

Before each installation, the unit must be sanitized by an

authorized technician.

After installation, ensure that the unit is not resting on the

power cable.

Check that the unit is level and that it is resting on a floor with

sufficient load-bearing capacity, in an environment that is

suitable for its dimensions and its use.

Before any maintenance or cleaning operation is carried out, remove the plug from the

socket or disconnect the power supply.

Ensure that the product is not sited close to sources of heat.

To guarantee adequate ventilation, leave at least 10 cm of space around the unit.

Install the product in a clean, dry, well-ventilated environment. The water cooler is designed

to function in environments with a temperature range of between 5°C and 32°C - Climate

Class N.

Take care not to damage the cooling fluid circuit: it is filled with HC R290 which is a

flammable gas. It is essential to ensure that the tubes of the refrigerant circuit are not

damaged.

The unit is not intended for use by children.

If the power cable is damaged, it must be replaced by the manufacturer, by its technical

support service or by a qualified technician. Do not use extension cables or multi-plugs.

Ensure that it is possible to disconnect the power supply either by removing the plug or via

a two-pole circuit-breaker placed upstream of the plug.

Check that the voltage shown on the serial number plate corresponds to the voltage being

supplied at the installation site.

The unit must not be cleaned with a water jet. Do not position other electrical equipment in

the immediate vicinity of the water cooler.

Turn off the main water inlet tap if the unit is not to be used for a long period.

Keep the areas surrounding the unit dry to avoid the risk of people slipping.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety. Children should be supervised to ensure that they

do not play with the appliance .

The Appliance shall be protected by a ground-fault circuit interrupter.

9

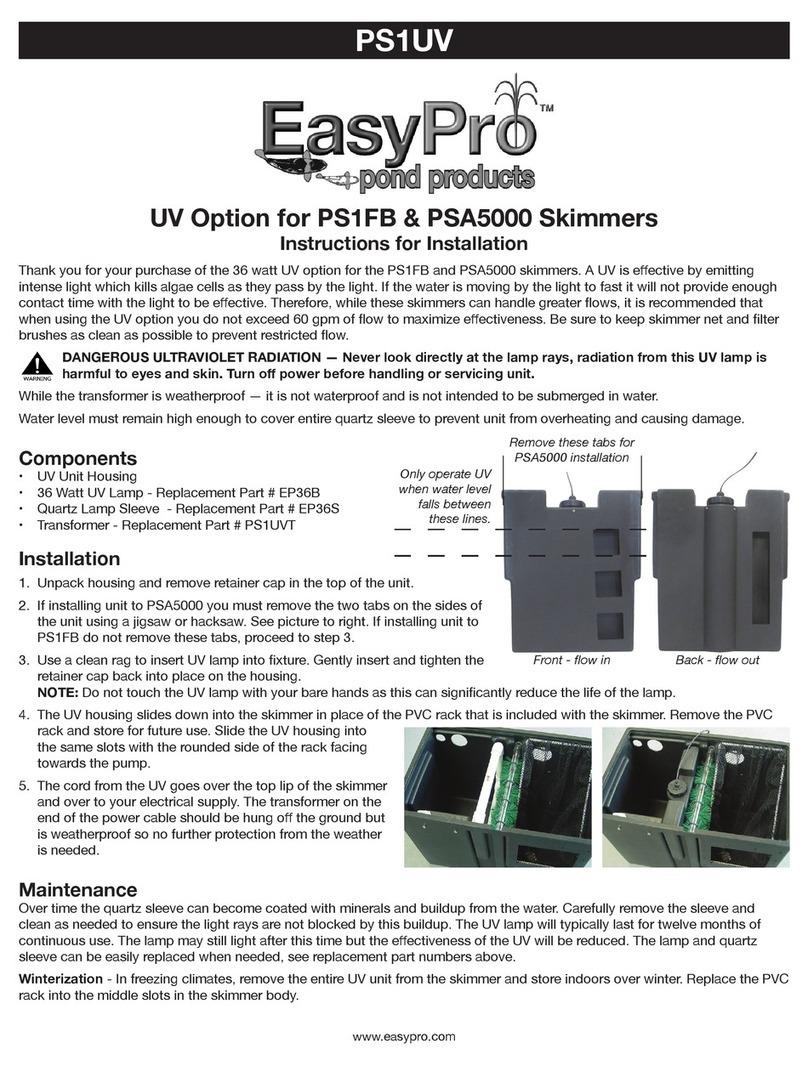

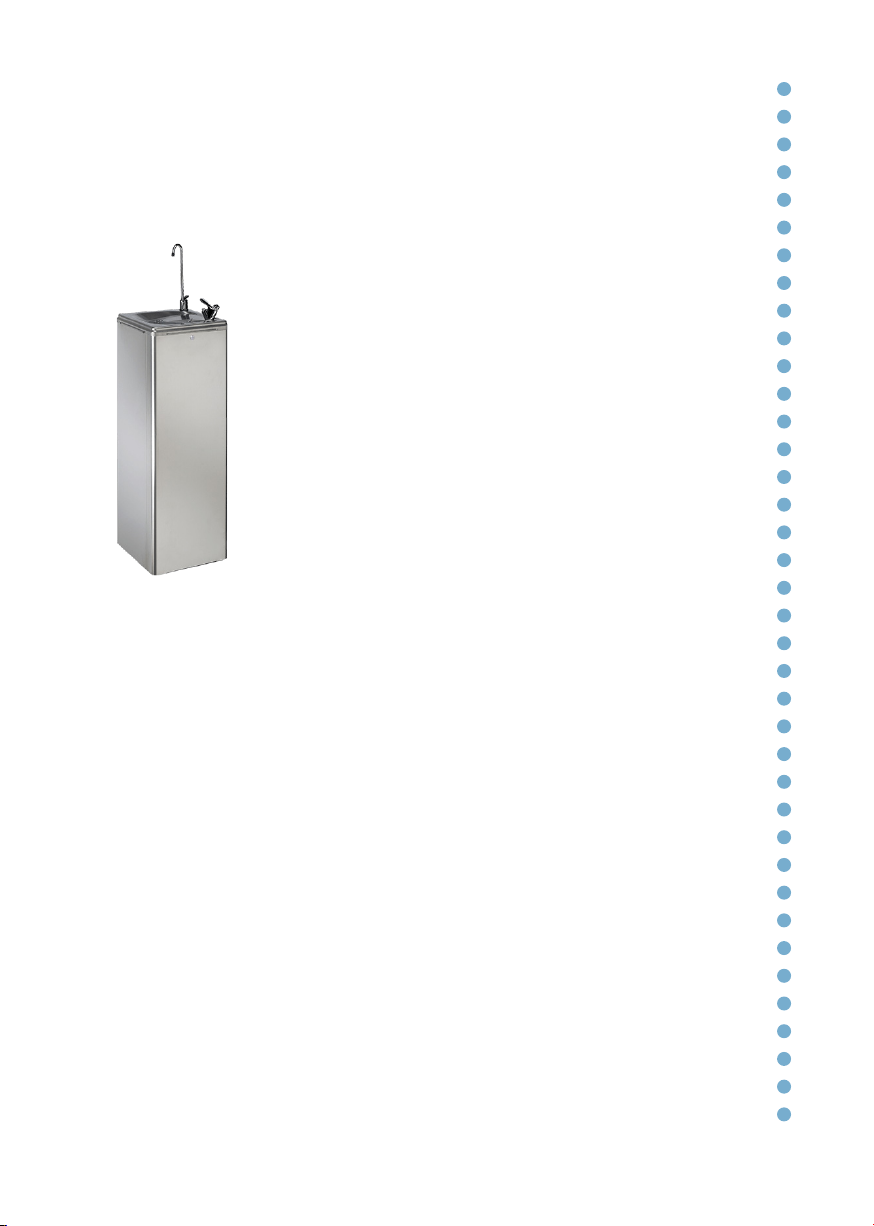

Description of the unit

PANTAREI - The first water-fountain water-cooler on the market with the

sparkling water option! Available, on request, with natural refrigerant gas.

The main features of the unit are as follows:

• Modern design and natural materials like ecological

gas, high quality construction, front opening.

• Tank type ice bank with internal coil. Entirely made of

AISI 316 stainless steel.

• Cabinet and drainer in stainless steel.

• Heavy Duty professional, high quality taps.

• Condenser.

• Removable front panel.

• Fitted with internal filter (active carbon + UV).

• Exclusive FIZZ version for sparkling water.

• Internal space for 2kg CO2cylinder.

• Temperature regulation thermostat.

10

Front view

1

4

3

2

1

6

5

2

3

5

4

6

Front panel security lock

Still water dispensing swan neck

tap (removable) or sparkling water

tap (removable)

Stainless steel sink

Water dispensing bubbler tap

(removable)

Removable stainless steel door

Feet

11

1

2

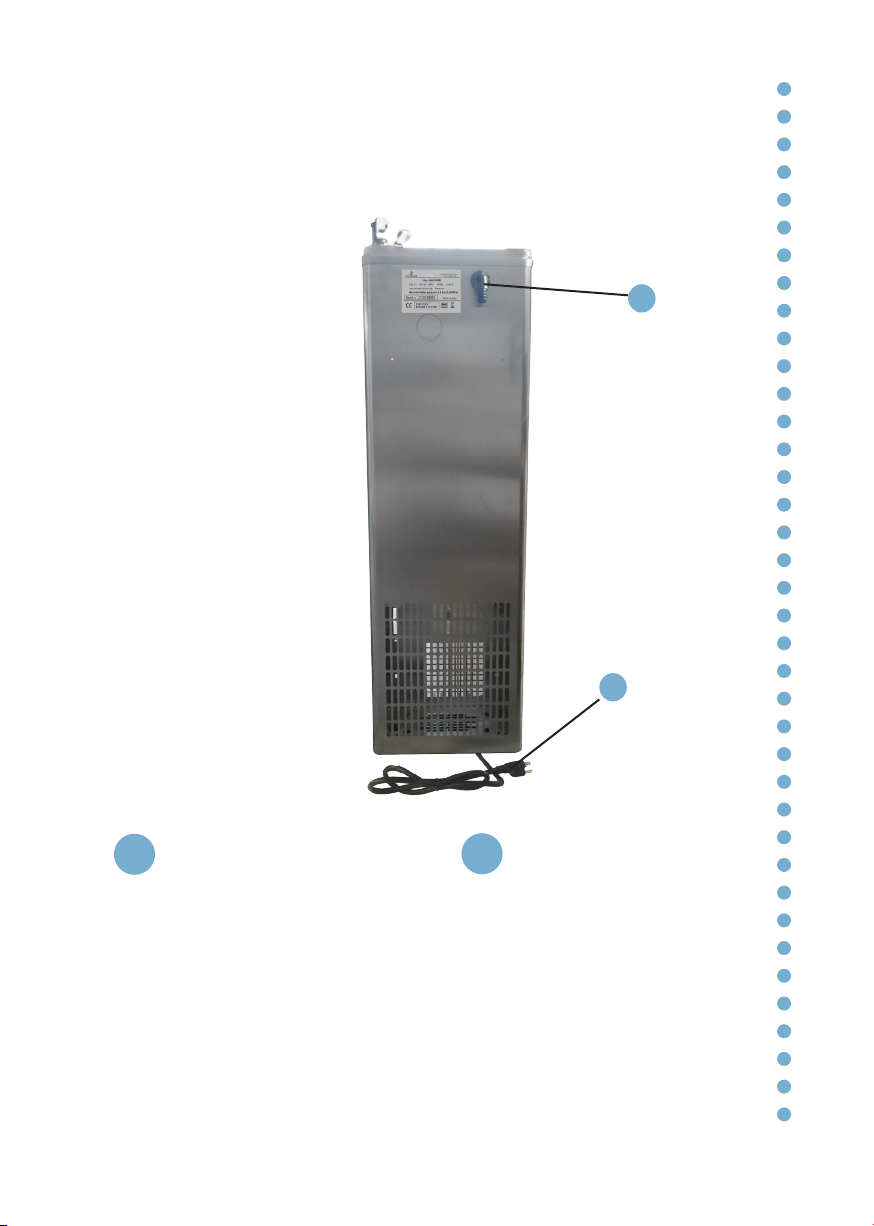

Rear view

12

Sink drain Ø18mm Power cable

12

Technical Features – Technical Data Plate

13 Year of manufacture

12 Month of manufacture

00000 Serial number

[mod. Pantarei]

13

Technical Features - dimensions (mm)

[mod. Pantarei]

Dimensions Mod. PANTAREI Mod. PANTAREI FIZZ

L x W x H (mm) 310 x 310x h 1270 310 x 310 x h 1270

14

Technical data

sheet Pantarei Pantarei FIZZ

Cooling capacity 20 lt/h

Max continuous

dispensing 3 lt

Water temperature 5°-12°C *

Cooling system Direct cooling tank

Tank capacity 4 lt

Power supply Single-phase 230V-50Hz

Power consumption 185 W 205 W

Pump -150 W

Cooling Forced ventilation

Refrigerant gas HFC R290

Ambient cooling

temperature Min 5°C - Max 35°C

Sound pressure level < 70dB

Dimensions LxDxA (mm) 310 x 310 x 1270

Packaging dimensions (mm) 350 x 350 x 1275

Net weight (kg) 23 25

Gross weight (kg) 25 27

* rated at a room temp. of 25°C and inlet water temp. of 20°C

15

Installation

Unpacking

Remove the two plastic tape. Remove the

cardboard box and the internal protective

packaging by sliding them up and over

the top.

Once you have unpacked the unit, ensure

that it is not damaged. You must inform

the reseller about any damages as soon

as possible after delivery.

If the unit has been shipped horizontally

or at an angle, it will be necessary to wait

at least 8 hours before setting it up, in

order to allow the cooling circuit to reset

itself.

Ensure that the unit is installed and

connected to the main supply by a

qualified technician in compliance with

the manufacturer’s instructions and the

local safety guidelines.

The end user is not permitted to access

the internal service parts of the unit. Only

technical personnel should carry out

operations of this nature.

Siting the unit

Wear safety gloves when handling the

unit. Take care when touching the metal

parts, which could be sharp.

Site the unit away from sources of heat.

Leave at least 4 inch around the unit to

allow for aeration.

Mount the swan neck tap (2) putting it into

the bayonet. Insert the tap (2) by screwing

it clockwise into its housing and secure it

with the screw located on the base (3).

Fig. 15.2

Fig. 15.1

1

2

16

Fig. 16.1

Connection to the mains water

supply

Check that the mains pressure is between

1 bar and 3,5 bar. To enhance the quality

of the sparkling water dispensed, an

incoming flow rate in excess of 3,5 lt/min is

recommended.

Use a food grade pipe (1, Ø8mm) to

connect the incoming water tube to the

drinking-water main, ideally with a tap

upstream of the unit.

Connect the sink drain using the supplied

tube (2).

The unit is NOT equipped with a water

pressure reducer, that must be assembled

upstream. The non-return valve is included.

Once the pipes are attached, turn on the

tap. Ensure there are no leaks.

Caution!

To connect the water cooler to the mains

water supply, you will need to use a new set

of connectors (joints, gaskets and pipes).

Do not use a set of connectors that has

already been used elsewhere.

The water pressure entering the unit must

be between a minimum of 1,0 bar (0.10

MPa) and a maximum of 3,5 bar (0.35 MPa)

1

Fig. 16.2

1

2

17

Electrical connection

The connections must comply with local

regulations. The grounding of the unit is

a legal requirement.

Connect the power cable (1) to a socket.

The compressor and fan are now

activated. On the FIZZ models, the pump

for filling the carbonator with water is

also activated.

Use the tap in order to release any air in

the circuit and to allow the pump to fill

the carbonator with water.

After around 1-2 minutes, the sparkling

water pump stops.

Thermostat

The thermostat (2) is set in the maximum

position to control the cooling circuit.

To reduce the cooling, turn the

thermostat screw at least 1/4” anti-

clockwise.

Fig. 17.2

2

1

Fig. 17.1

18

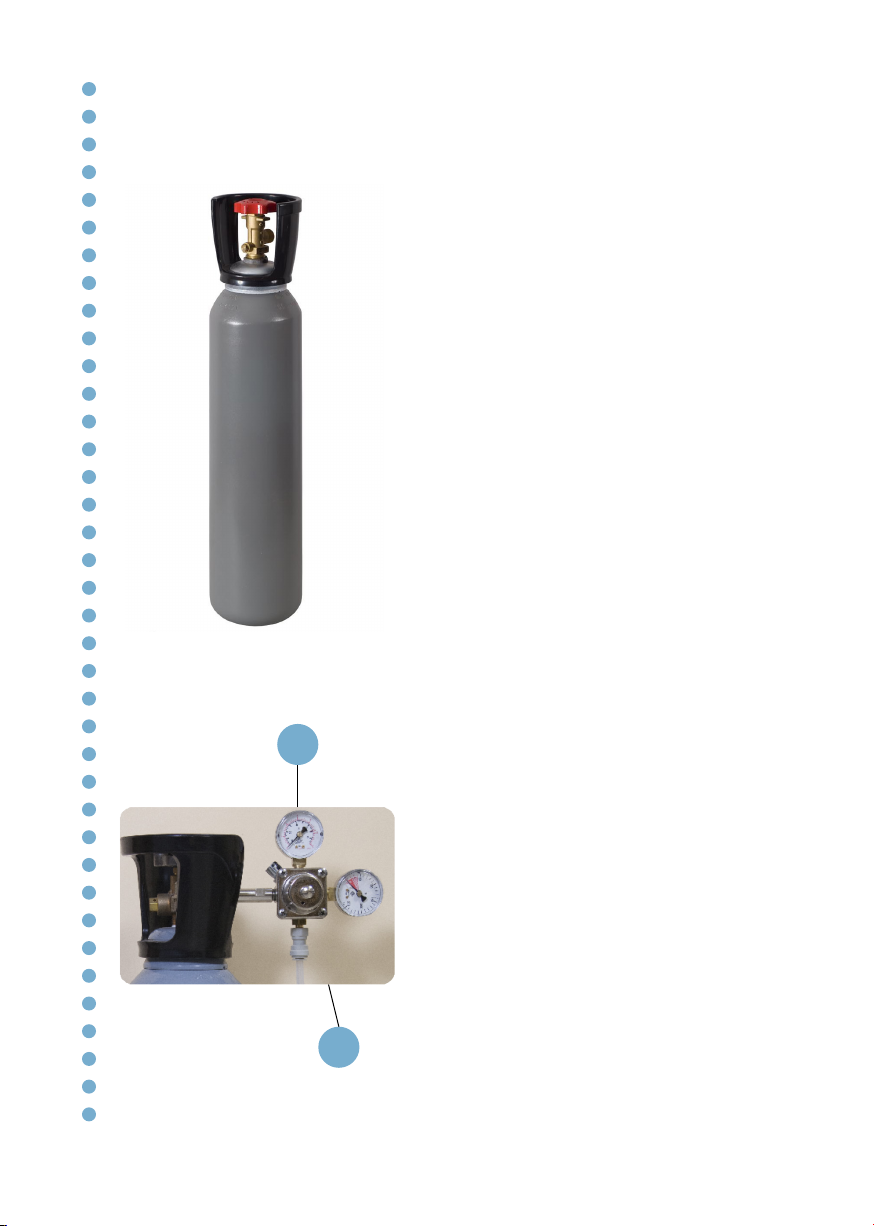

Once the unit is connected to the mains

water and electricity, and the cooling

tank has been filled, you can install the

E290 food-grade carbon dioxide (CO2)

cylinder.

The machine is NOT equipped with

the CO2pressure reductor, which must

be ordered separately. Also, the CO2

cylinder is not provided.

Inside you can install cylinders up to 2kg

or of the same size.

To increase or decrease the level of

carbonation of the water, you need to

adjust the screw (1). Turning it clockwise

increases the level of carbonation. We

recommend that you do not exceed 4

bars of pressure (2).

To reduce the carbonation level, turn

the screw anti-clockwise. The level will

decrease as soon as sparkling water is

dispensed.

To achieve a good level of carbonation,

you need to wait until the water is

sufficiently cold – i.e. at least one hour

after installation.

Installation of the CO2cylinder (FIZZ model)

1

2

Fig. 18.1

Fig. 18.2

19

* Replacement of the CO2cylinder. All of the operations

must be carried out exclusively by qualified technical

personnel. To view the video tutorial, scan the QR code.

* Suggestions for optimal carbonation. All of the operations

must be carried out exclusively by qualified technical

personnel. To view the video tutorial, scan the QR code.

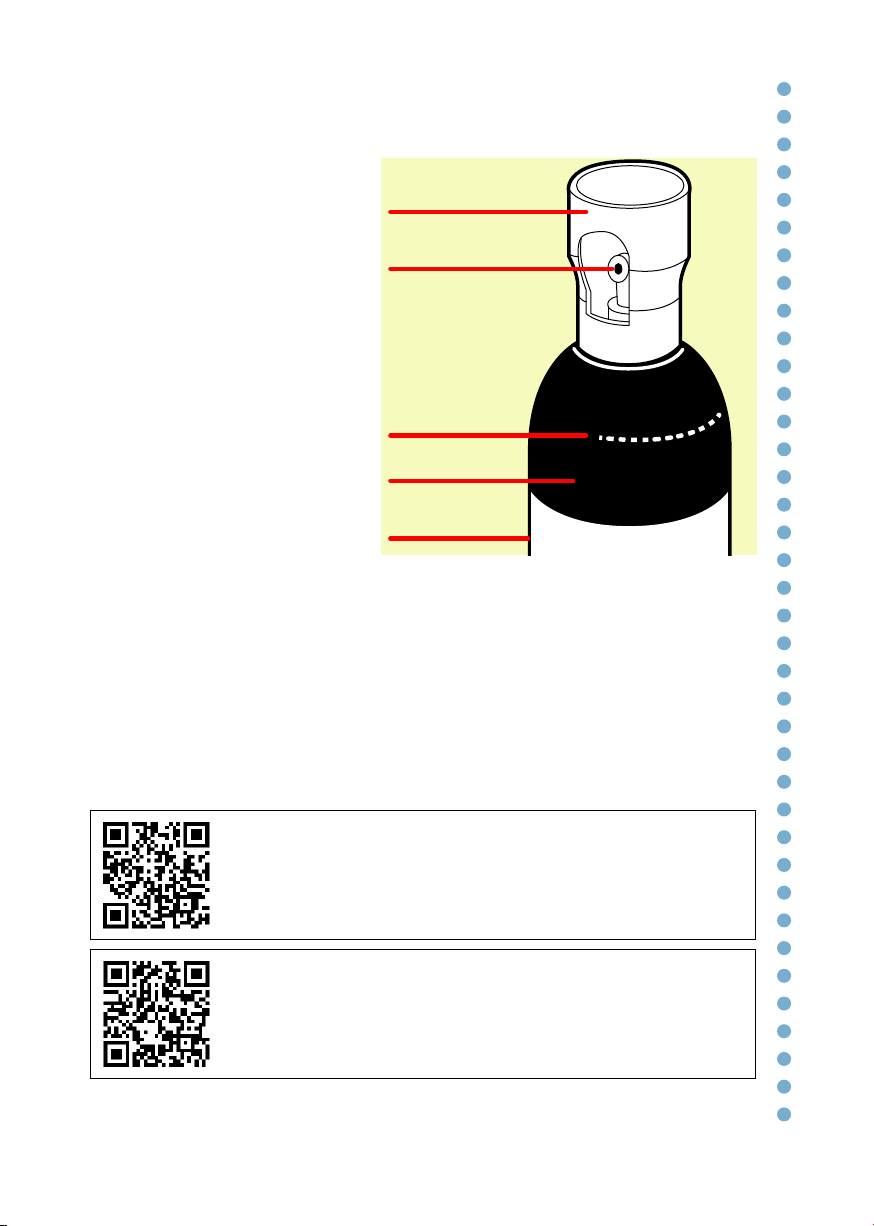

Handling the gas cylinders

All of the cylinders must be fitted

with a valve protector cap, which

must be on tight at all times when

the cylinder is not in use.

The cylinders must be handled

with care. It is essential to avoid:

clashes with other cylinders or

surfaces; dropping the cylinders;

or subjecting them to mechanical

stress. All of the above may

compromise their integrity and

resistance.

The cylinders must not be lifted

by the cap, or dragged, rolled or

slid along the floor. Even if only

being moved for short distances,

an appropriate hand cart or other

suitable means of transport should

be used.

Do not use magnetic lifters or slings with ropes or chains to lift the cylinders.

If the cylinders are to be lifted with cranes, hoists or fork-lift trucks, ensure that

appropriate cages, metal baskets or pallets are used.

The cylinders must not be moved or handled with greasy hands or gloves. This is

particularly important in relation to cylinders containing oxidising gases.

Cap

Valve connection

Shoulder

Markings

Body

20

Filtration (optional)

Everpure 4C filter

On request, the unit can be fitted with an Everpure

4C filter.

MAIN FEATURES

This filter removes the odour and flavour of chlorine

and other contaminants that can alter the taste

of the water. The Precoat microfiltration system

removes impurities and particles with dimensions of

0.5 microns and above.

It also reduces the levels of any contaminants such

as asbestos fibres and micro-organisms such as

Cryptosporidium and Giardia.

It protects gaskets, pumps, tubes and valves against

blockages, corrosion and abrasions.

Approved by the Italian Ministry of Health and

the Water Regulations Advisory Scheme (UK), it is

certified compliant with the NSF/ANSI standards 42

and 53.

The cartridge should be changed every 6 MONTHS.

Its maximum capacity is 11.000 litres.

* Filter replacement and sanitization. All of the

operations must be carried out exclusively by qualified

technical personnel. To view the video tutorial, scan the

QR code.

Table of contents

Other blupura Water System manuals

Popular Water System manuals by other brands

RIDGID

RIDGID RSWS Series Operating instructions and parts manual

AQUAPHOR

AQUAPHOR A800 Owner's manual & installation guide

Everpure

Everpure Exubera Pro UC EV9333-50 Specification sheet

Watts

Watts FEBCO 860 Small Series installation instructions

Weightworld

Weightworld CIRCULATOR user manual

Zip

Zip HydroTap G5 Touch-Free Wave Quick start installation guide