2REVISION 1.0, 1-19-15

TABLE OF CONTENTS

INTRODUCTION...............................................................................................................................3

SAFETY.............................................................................................................................................4

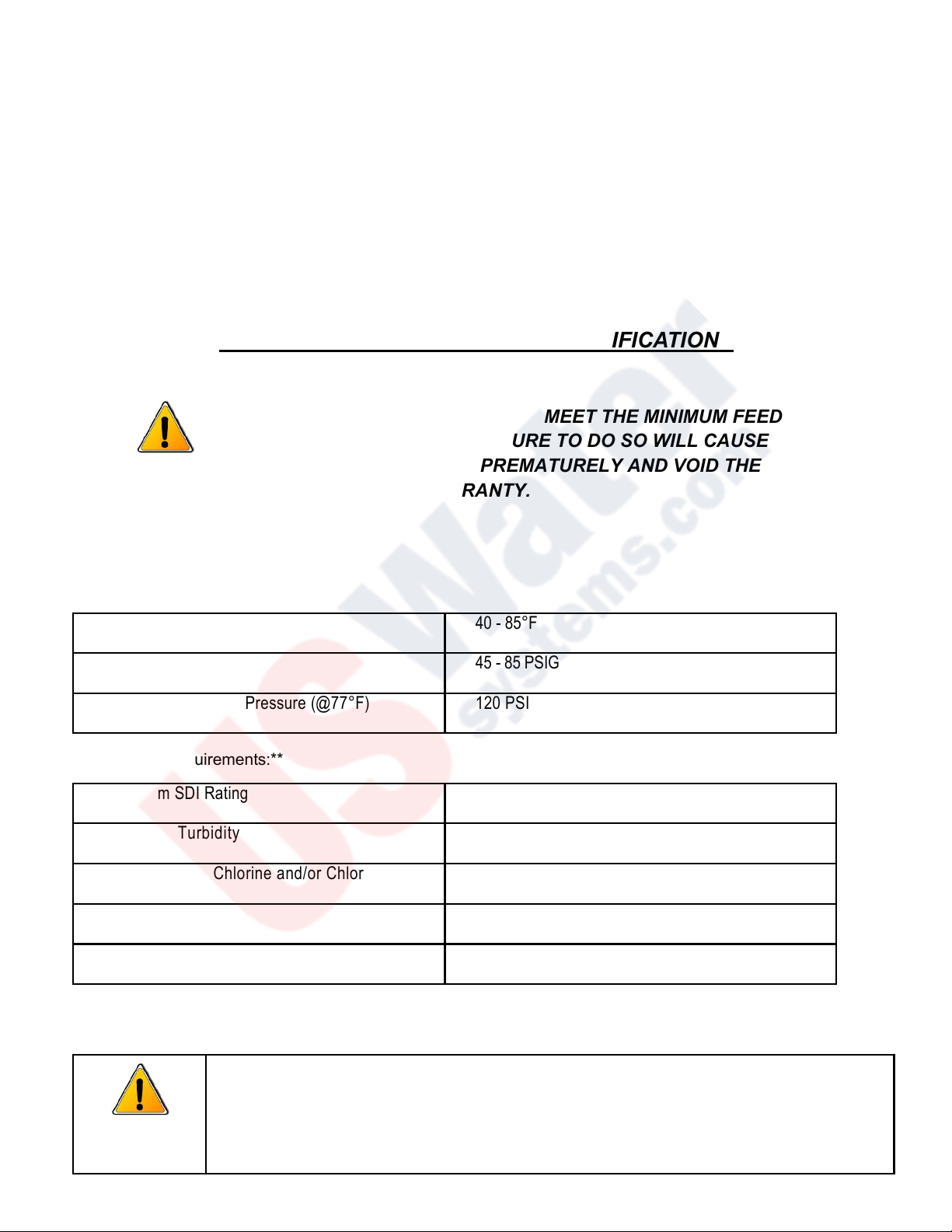

FEED WATER AND OPERATION SPECIFICATIONS ....................................................................5

REJECTION, RECOVERY AND FLOW RATES ..............................................................................6

SYSTEM INSTALLATION AND START-UP PROCEDURES ..........................................................7

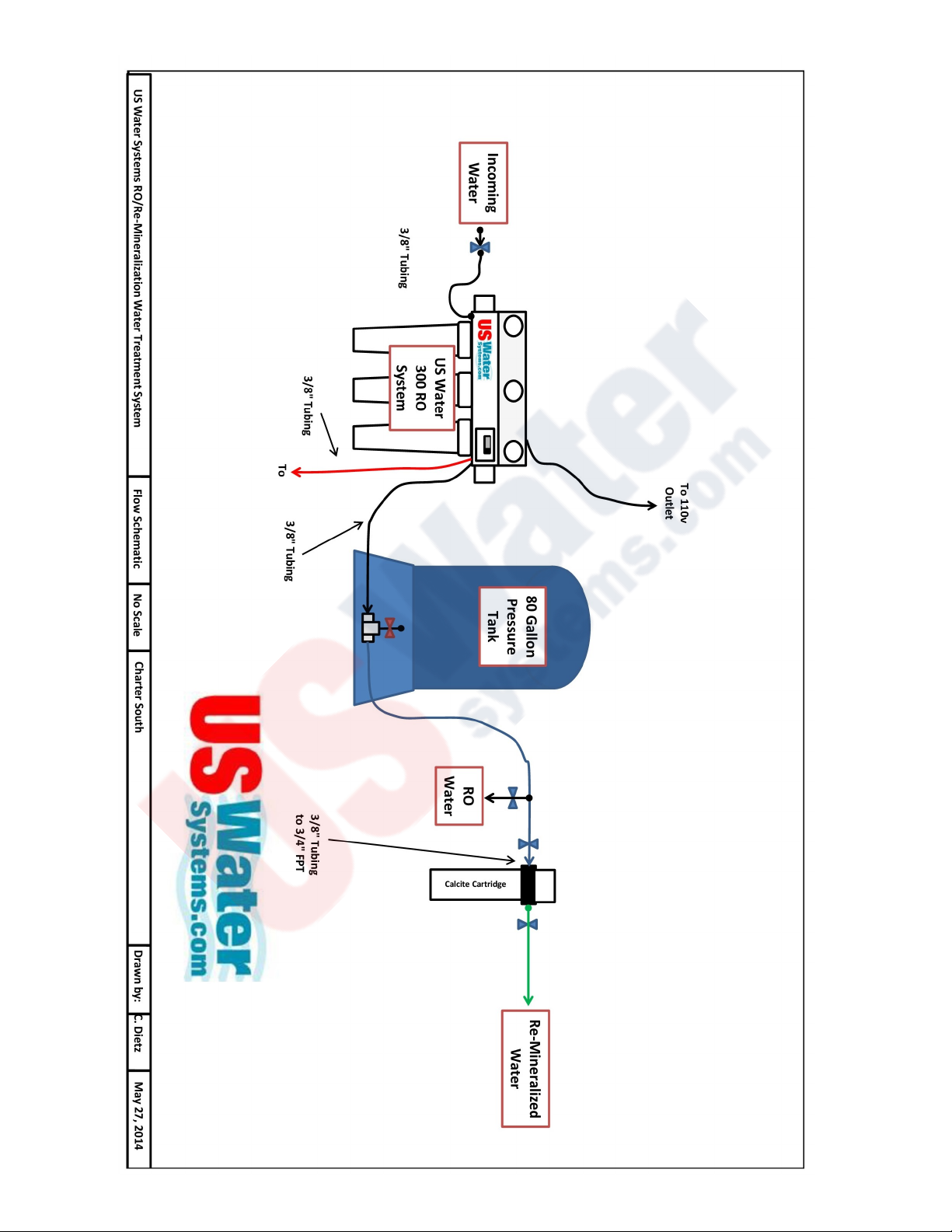

SYSTEM CONFIGURATION DRAWINGS…..…………………………………………………………..9

MEMBRANE ELEMENTS ...............................................................................................................10

SYSTEM IDENTIFICATION............................................................................................................11

MEMBRANE INSTALLATION, REMOVAL AND REPLACEMENT................................................12

OPERATION DO’S AND DON’TS ..................................................................................................15

SPECIFICATIONS...........................................................................................................................16

OPERATION AND MAINTENANCE ...............................................................................................18

PREPARING UNIT FOR STORAGE OR SHIPMENT ....................................................................19

REVERSE OSMOSIS TROUBLESHOOTING................................................................................20

TEMPERATURE CORRECTION FACTORS FOR MEMBRANE...................................................21

SERVICE ASSISTANCE.................................................................................................................21

OPERATION LOG...........................................................................................................................23

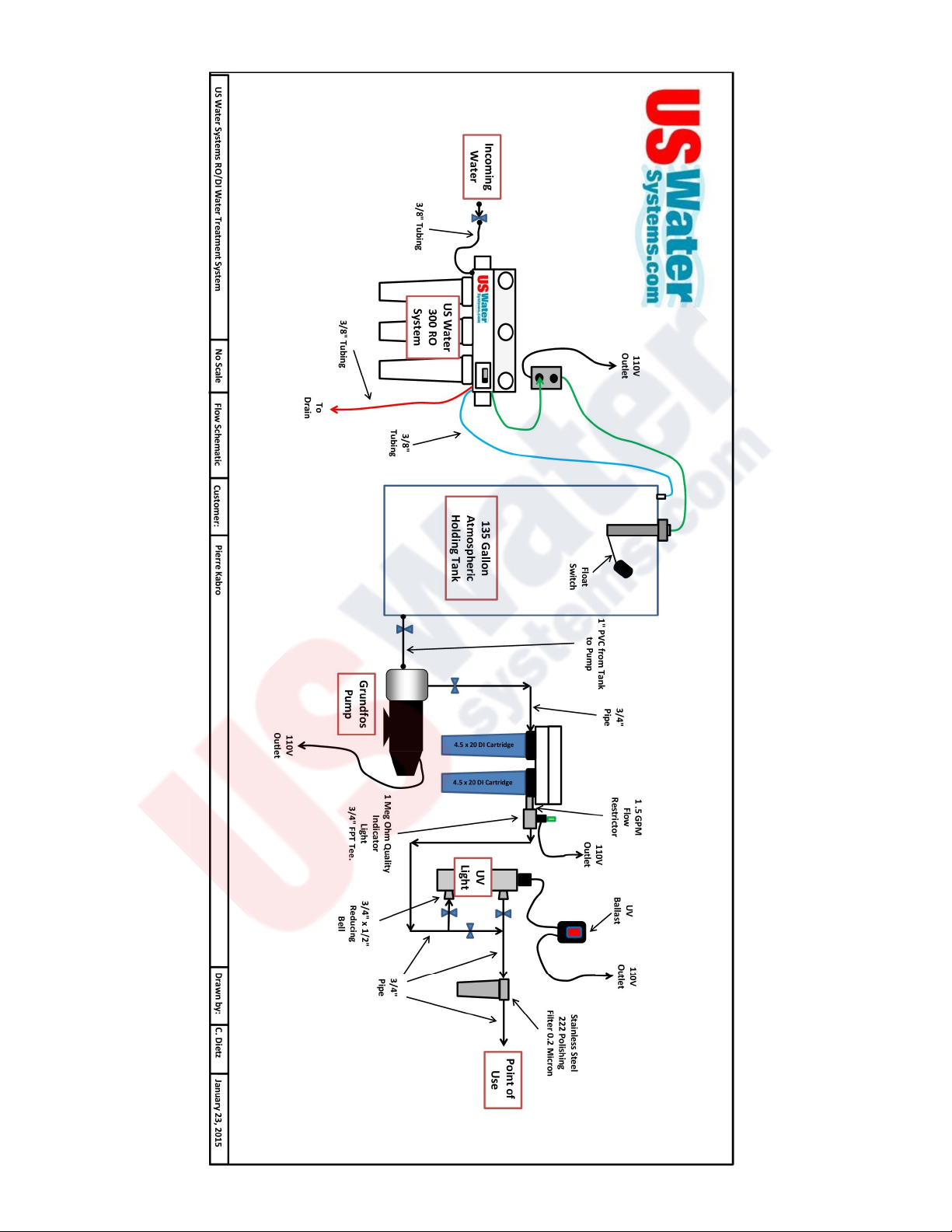

SYSTEM DRAWING .......................................................................................................................24

L1-200 SERIES FLOW DIAGRAM..................................................................................................25

L1 - SERIES ELECTRICAL SCHEMATIC 110V/60HZ...................................................................26

L1 - SERIES ELECTRICAL SCHEMATIC 220V/50HZ...................................................................27

REVERSE OSMOSIS SYSTEM WARRANTY................................................................................28