Watts Premier 5 SV DELUXE User manual

Page 1

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

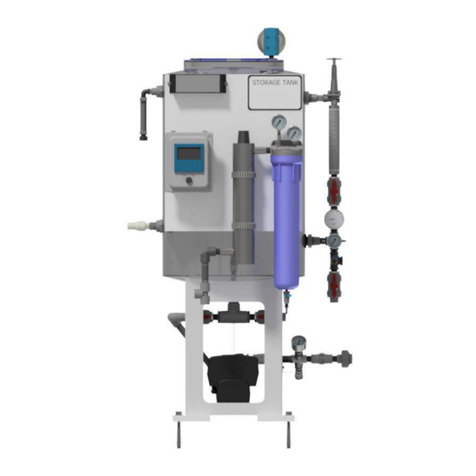

5 SV DELUXE

WATTS PREMIER 25

CRO-TFM-5SV

ULTRA 5

RO-TFM-4SV

RO-TFM-5SV

PUR-TEK

Refertoenclosedwarrantyforoperatingparameterstoensureproperusewithyourwatersupply.

WattsPremier, Inc. 1725 W. Williams Drive C-20 Phoenix,AZ 85027

Phone:800-752-5582 www.wattspremier.com Fax: 623-931-0191

Save manual for future reference

MODELS

Warning

Pleasereadcarefullybeforeproceedingwithinstallation. Yourfailuretofollowanyattachedinstructions

oroperating parameters may lead tothe product’sfailureand possible damage toproperty.

SystemTestedandcertifiedbyNSFInternationalagainst ANSI/NSF

Standard 58 for thereduction of claims specified onperformance datasheet.

Page 2

Thankyouforyour purchase of a Premier ReverseOsmosissystem.With proper installation and mainte-

nance,thissystemwillprovideyouwithhighqualitywaterforyearsto come.AllofPremier'swaterenhance-

mentproducts are rigorously tested by independent laboratories forsafety and reliability.If you have any

questionsorconcerns,pleasecontactourcustomerservicedepartmentat1-800-752-5582(outsideUSA

623-931-1977)orrefertoouronlinetroubleshootingatwww.wattspremier.com.

Table of Contents

OperationalParameters........................................................................................................................ 4

ContentsofReverseOsmosisSystem .................................................................................................. 4

ToolsRecommendedForInstallation ..................................................................................................... 4

Drill a Hole for the Faucet in a Porcelain Sink ........................................................................................ 5

PunchaHole for the Faucetina StainlessSteel Sink ............................................................................ 5

FaucetInstallation ................................................................................................................................. 6

AdaptaValve Installation ....................................................................................................................... 7

ReverseOsmosisModule Mounting ...................................................................................................... 7

DrainSaddleInstallation........................................................................................................................ 8

TankTeeInstallation............................................................................................................................... 8

GreenTubeConnection ........................................................................................................................ 9

BlueTubeConnection ........................................................................................................................... 9

BlackTubeConnection ....................................................................................................................... 10

RedTubeConnection.......................................................................................................................... 10

6”FinalFilter Installation...................................................................................................................... 10

10"FinalFilterInstallation.....................................................................................................................11

StartupInstructions ............................................................................................................................. 12

6Month System Maintenance.............................................................................................................. 13

AnnualMaintenance ............................................................................................................................ 14

MembraneMaintenance...................................................................................................................... 15

CheckAir Pressure in theTank............................................................................................................ 16

5Stage Reverse Osmosis System ...................................................................................................... 19

CaliforniaCertification ........................................................................................................................ 21

OtherProductsfrom Watts Premier ..................................................................................................... 22

WarrantyRegistration.........................................................................................................................................25

ServiceRecord ................................................................................................................................... 27

LimitedWarranty.................................................................................................................................................28

Page 3

Hardness: Recommendedhardnessnottoexceed10grainspergallon,or120ppm. Systemwilloperate

with hardness over 10 grains but the membrane life may be shortened.Addition of a water softener may

lengthenthe membranelife.

Do not use with water that is microbiologically unsafe or of unknown quality, without adequate

disinfection before or after the system.

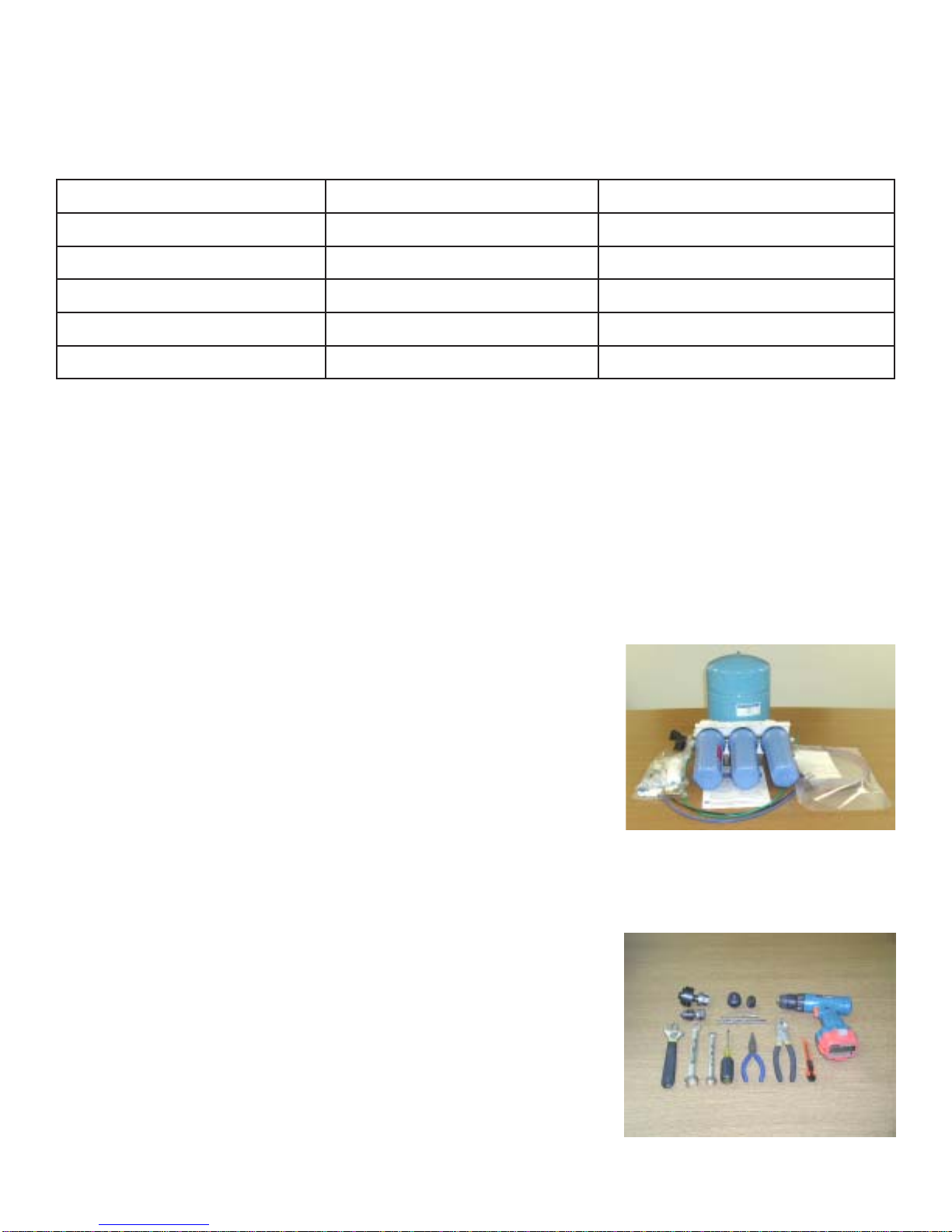

1Tank – Blue or White

1Module – Blueor White

1 Parts Bag – With a 6" or 10" Final Filter

1 Faucet Bag

1Manualand WarrantyCard

5StageRO System has 3 bowls. 4 StageROSystem has twobowls.

If any of the items are missing please contact Premier prior to installing.

Tools Recommended For Installation

√ 1 1/4" Hole Saw Bit for Faucet opening

√Round Knock outPunchfor StainlessSinks,½”& 1 ¼”

√AdjustableWrench

√ Sharp Knife

√ 1 / 2" - 5/8" Open End Wrenches

√Phillips Screw Driver

√ Needle Nose Pliers –Adjustable Pliers

√ Electric Drill

√ 1/8", 1/4" & 3/8" Drill Bits

Contents of Reverse Osmosis System

:serutarepmeTgnitarepO)C°8.73(F°001mumixaM)C°4.4F°04muminiM

:erusserPgnitarepO)2mc/g34.7(isp001mumixaM)2mc/gk08.2(isp04muminiM

:sretemaraPHp11mumixaM3muminiM

:norImpp2.0mumixaM

:)sdiloSdevlossiDlatoT(SDTmpp0081<

:ytidibruTUTN5<

Note: ReverseOsmosiswatershouldnotberun through copper tubing as the purity of the waterwill

leachcopper and cause an objectionaltaste in water andcausepin holes to formin tubing. Be sure to

followanystate or local regulations.

Operational Parameters

Note: Theoperatingpressure in your homeshouldbe tested over a24hour period to attainthe

maximumpressure. Ifit is above 100 psithena pressure regulator willberequired.

Page 4

Note:

Makesurethesurroundingsofthesinkarecooled before mounting the

faucettothesink after drilling. Remove all sharp edgeswithafile.

Step 3

Step 4

Determinedesired location forthe faucet onyour sink andplace a piece

ofmasking tape on location where the holeis to bedrilled. Mark the

centeroftheholeonthetape.

Step 1

Using a variable speed drill on the slowest speed, drill a 1/8" Pilot

holethroughbothporcelainandmetalcasingofsink at the center of the

desiredlocation. (If drill bit gets hot it maycause the porcelainto crack

orchip).

Using a 1 ¼" hole saw, proceed to drill the large hole. Keep drill speed

on the slowest speed and use lubricating oil or liquid soap to keep the

holesawcoolduring cutting.

Step 2

Drill a Hole for the Faucet in a Porcelain Sink

Porcelainsinksurface material is extremelyhard and can crack orchip quite easily. Use

extremecautionwhendrilling. PremierManufacturedSystemsacceptsnoresponsibilityfor

consequentialdamageresultingfrom the installation of faucet.

Adrippingorgurgling sound may be heard comingfromtheAirGap hole in the faucetwhenthe

systemisrunning. Thisis normal and in compliance withUPCPlumbingCodes.

Most sinks are predrilled with 1 ½" or 1 ¼" diameter holes (if you are already using it for a

sprayer or soap dispenser, see step 1).

See the Faucet Installation section for the proper size hole to drill for a non air gap faucet.

Punch a Hole for the Faucet in a Stainless Steel Sink

Drilla¼”pilothole. Usea½”HolePunchandan adjustable wrench

topunchthe hole in the sink.

Step 5

Thefaucetcannow be installed.

Ifmountingfaucet to a StainlessSteel Sink you willneeda ½" & 1¼"

HolePunch. Thefaucetopeningshouldbecenteredbetweenthe

back splash and the edge of the sink, ideally on the same side as the

verticaldrain pipe.

Note:

Page 5

•Faucetassembly

•BlackShankNut

•Slottedwasher

•Gasket

•3'BlueTube

Ifusingthe WaveAir Gap Faucet (included),a11/4" hole will be required.

Ifusinga Wave non air gapfaucet,a3/4” hole will be required.

Wave Faucet Installation

Removeblackstemnutandinsertthethree tubes (air gap faucet)

throughthewhitegasket withthegrooveonthegaskettowardthe

faucetbase.

Insertthethreetubesthroughthe11/4"hole in the sink. The white gasket

must be on top side of the sink.

Step 6

Step 7

Step 8

GatherandidentifytheWavefaucetpieces.

Viewfromunderthe sink and insert thewhiteplasticspacer as shown. (A

slotted washer is used if it is a non air gap faucet.)

Threadtheblackstemnutbackontothewhitethreadedstemand thighten

within¼”ofplastic spacer. Check theorientationofthefaucetabove the

sinkandtightenthe black plastic washer until white plasticspacerissnug

andfaucetstands securely on top of thesink. (Fora non air gap faucet,

thebluetubewillhavetobepushedinto the faucet fitting at the bottom of

thefaucet. Pushthetubeallthewaytothe“tubestop”insidethefitting.)

Step 9

Step 10

Note:

Air Gap Faucet

Non Air Gap Faucet

Adrippingor gurgling sound maybe heard coming from theair gap hole

onthefaucetorthedrainwhenthesystem is running. This is normal and

incompliancewithUPC(UniversalPlumbing Code).

Note:

•Faucetassembly

•BlackShankNut

•Spacer

•Gasket

Page 6

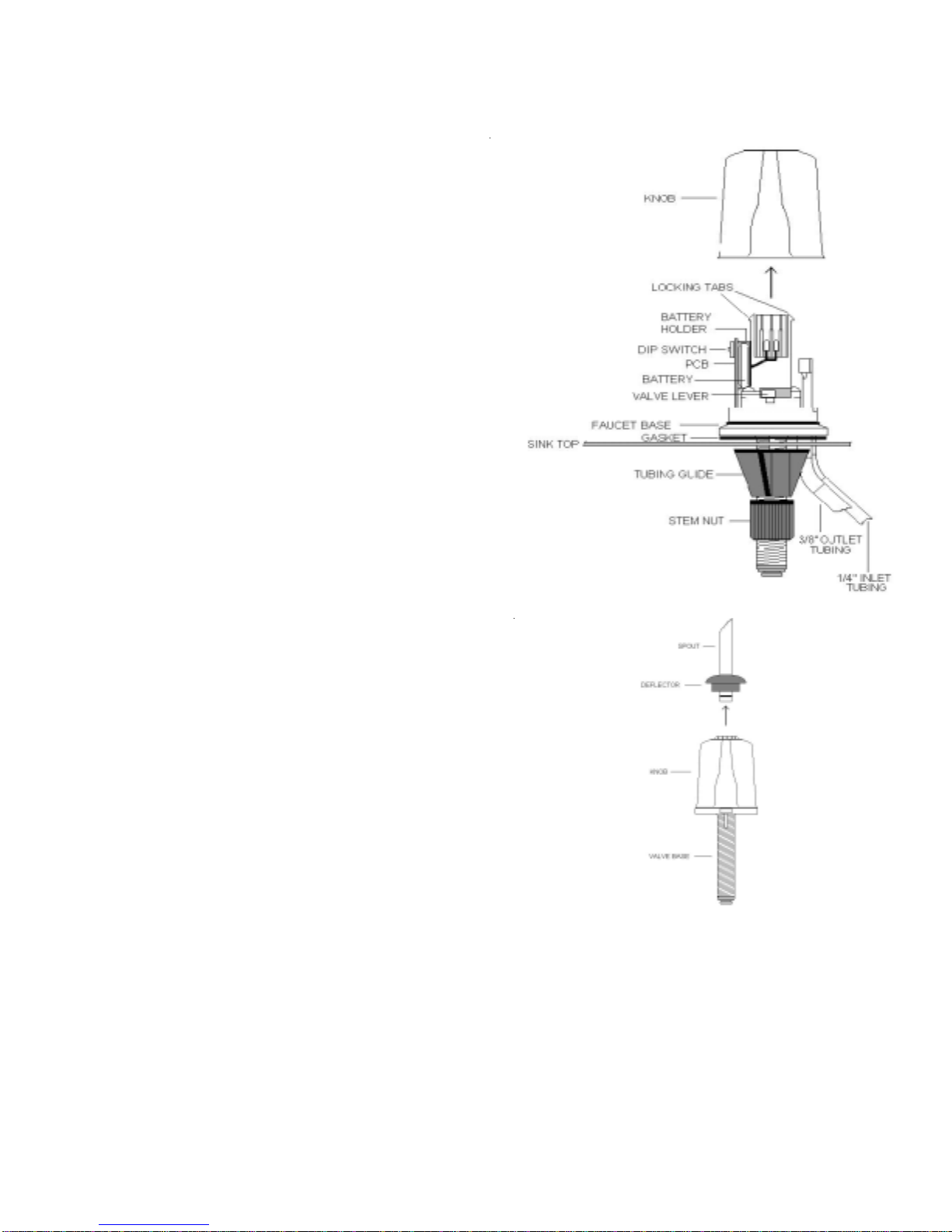

AG-SS with Monitor Faucet Installation

Step 6

Step 7

Step 8

Gather and identify the M-500 faucet pieces.

Step 10

Note:

Adrippingor gurgling sound may be heardcomingfrom the air gap holeonthefaucet or

the drain when the system is running. This is normal and in compliance with UPC

(UniversalPlumbingCode)requirements.

If using the AG-SS MonitorAir Gap Faucet , a 1 1/4" hole will be

required.

Remove Faucet and small parts from plastic bag.

Slip the Gasket over the threaded Stem to the Faucet Flange.

From above the sink, feed the tubing and Faucet Stem down

through the 1¼ inch mounting hole in the Sink.

From below the sink, slide the Tubing Guide up the threaded Stem

and follow it with the Mounting Nut, turning the nut clockwise until

fullytightened.

Press the blue colored Product Water Tubing, coming

from the RO purification system into the end of the

threaded Stem. Push it all the way in and then pull on it

firmly to verify it is locked in place.

Refer to Black Tube Connection and Red Tube

Connection steps in this manual to complete the faucet

installation.

.

Remove the Spout from the top of the Faucet by pulling it straight

upward.SEE DRAWING

Remove the Faucet Knob by pinching the two locking tabs inward

and then pulling upward on the Knob while the tabs are pinched

inward. Push the coin cell Battery into the Battery Holder behind the

Circuit Board. NOTE: the + side of the Battery goes against the

Gold metal bracket.

Replace the Knob by centering it over the Faucet and aligning the

troughontheinsideoftheFaucetKnobwiththeValveLever.

LowertheKnobmakingsuretheValve Lever slides into the trough,

making sure the Knob top hole is centered over the locking tabs.

Push the Knob all the way down until it locks in place.

Push the Spout back into the top of the Faucet so that it is fully

seated and push the frosted Deflector down until fully seated. You

may have to rotate the Deflector until it is in position to be fully

seated.

With the Knob rotated to the Right about ½ inch, turn the source

water to your RO purification system on and check for leaks. You

should see the Green light flash at the base of the Faucet while water

is flowing through the Faucet (red light may flash when system is

initially producing water, this will turn green following the

initial tank flush). When you see the Red light flash, it means it is

time to replace your filter cartridge(s).

Turn the Knob to the left until water stops flowing and check for leaks.

Step 9

Step 11

Step 12

Step 13

Note:

Page 7

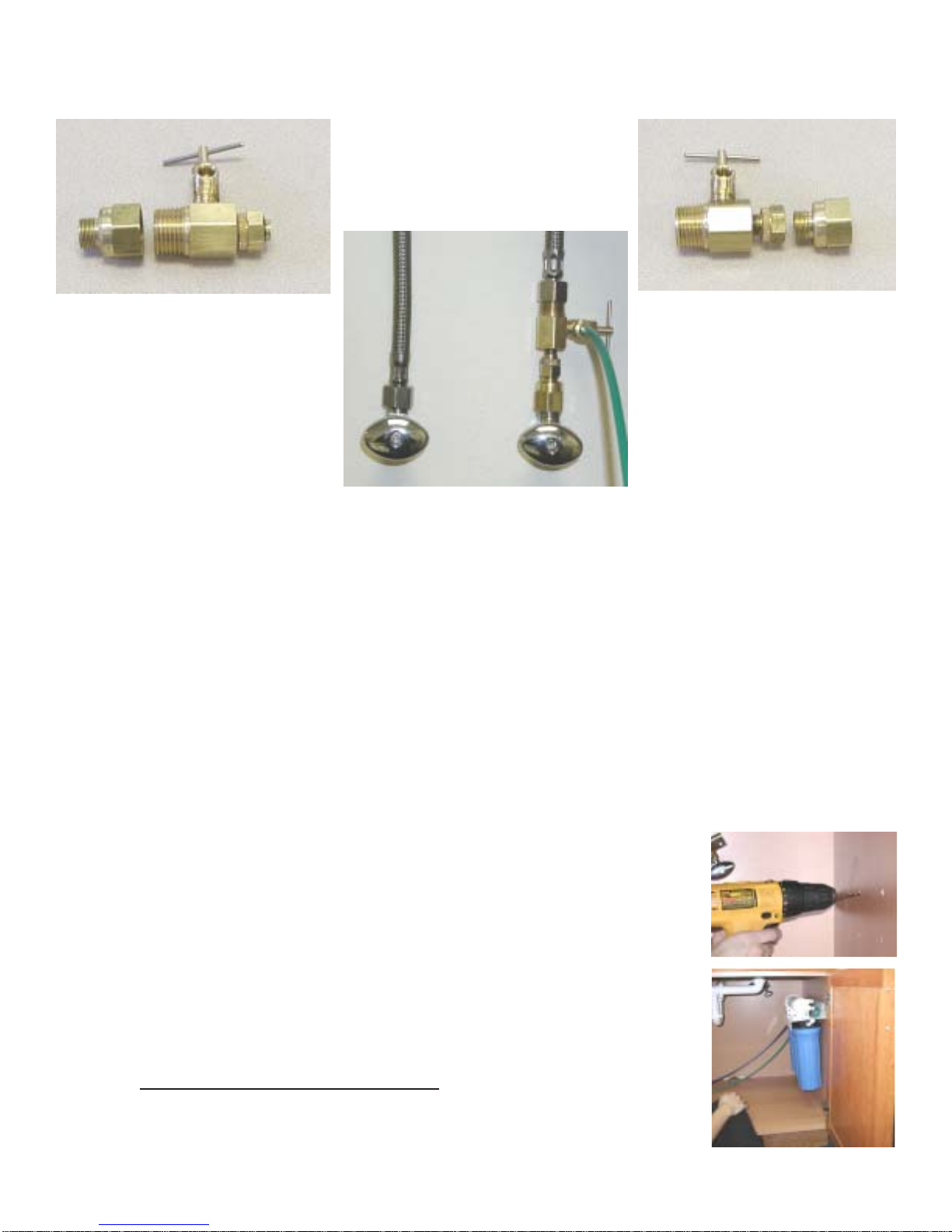

Adapta Valve Installation

Turnoffthecoldwatersupply to thefaucetbyturningtheanglestop valve

completelyoff.

Reverse Osmosis Module Mounting

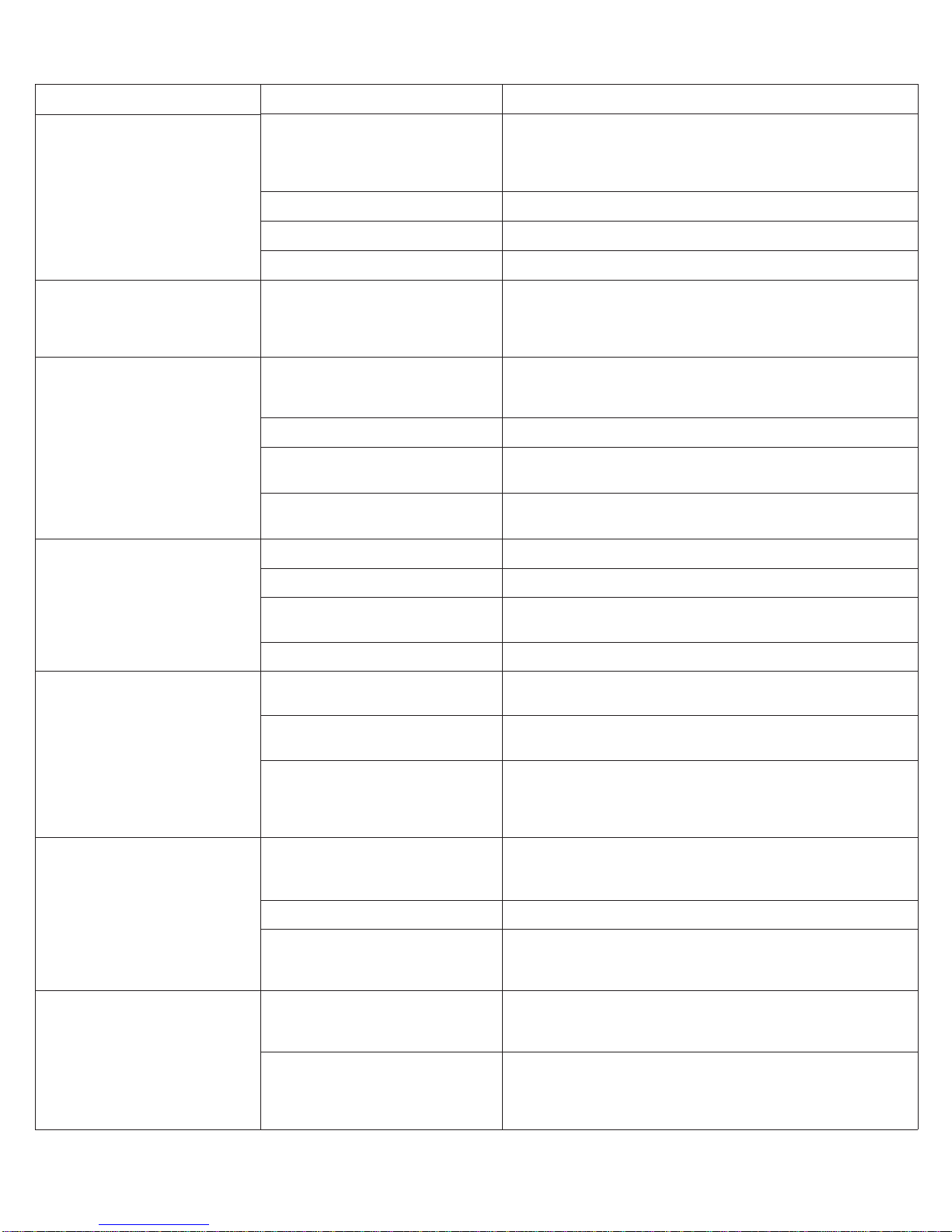

Step 13 Determinebestlocation for the RO module tobemounted to allow for

futuresystemmaintenance. Thepartsbaghas2 self tapping screws.

Usingaphillipsscrewdriver,screw them into the cabinet wall10¾”

apartand16" from the bottomofthe cabinet.

Step 11

Step 12 Attachadaptavalveasillustrated in the three photos above, choosing the

configurationthatfits your plumbing. (When attaching theadaptavalveto

straightpipe threads, useTeflon tapeon the treads.) The green tubefrominlet side of RO

modulewillbecuttolengthandattachedlater intheinstallation.

Do not cut these tubes at this timeNote:

Caution: Watersupplylinetothesystemmustbefromthecoldwatersupply line. Hot water will

severelydamage your system.

Configurationfor3/8”

compressionfittings Configurationfor1/2”

compressionfittings

Page 8

Drain Saddle fits standard 1 ¼” – 1 ½” drain pipes

Drain Saddle Installation

Step 14

Step 15

Step 16

Threadthebrass tee (supplied intheparts bag) onto the brass

connectiononthetop of tank. Tightenusinganadjustablewrench.

Step 17

Step 18

Teflon tape must be applied in a clockwise direction. Wrap (7 to 12

turns)aroundthemalepipethreads(MPT)ontheStainlessSteel

fittingontop of the tank.

Drilla¼” hole through the drainpipeatleast 1 ½” above thenutof

theP-traptoallowfortheremoval of the P-trap if necessary.

Assemble the drain saddle around the drain pipe. Position the

drainsaddleover the drilled hole in pipe. Insertscrewdriver into

theopeningof the drain saddle andalignwith drilled hole in drain

pipe. UsingPhilipsscrew driver tighten screws evenlyand

securelyon both sides of thedrain saddle. Attachblack

compressionnut,butdonottightenatthistime. The black tubing

willbeinstalledlater.

Thesmallsquare black foam gasket withacircle cut out of themiddle

mustbe applied to the inside of thedrain saddle. Remove sticky tape

backingand stick to thedrain saddle as shown.

1Blackcompression nut

1Semi-circle bracket with opening

2 Screws

1Foam washer

2Nutsforscrews

1 Semi-circle bracket

Gatherthe pieces of the drainsaddle

Tank Tee Installation

Caution: Donotovertightenthescrews. It may crack the drain saddle.

Donotteflontape the compression fitting threads. Iftapeditwill leak.Caution:

Page 9

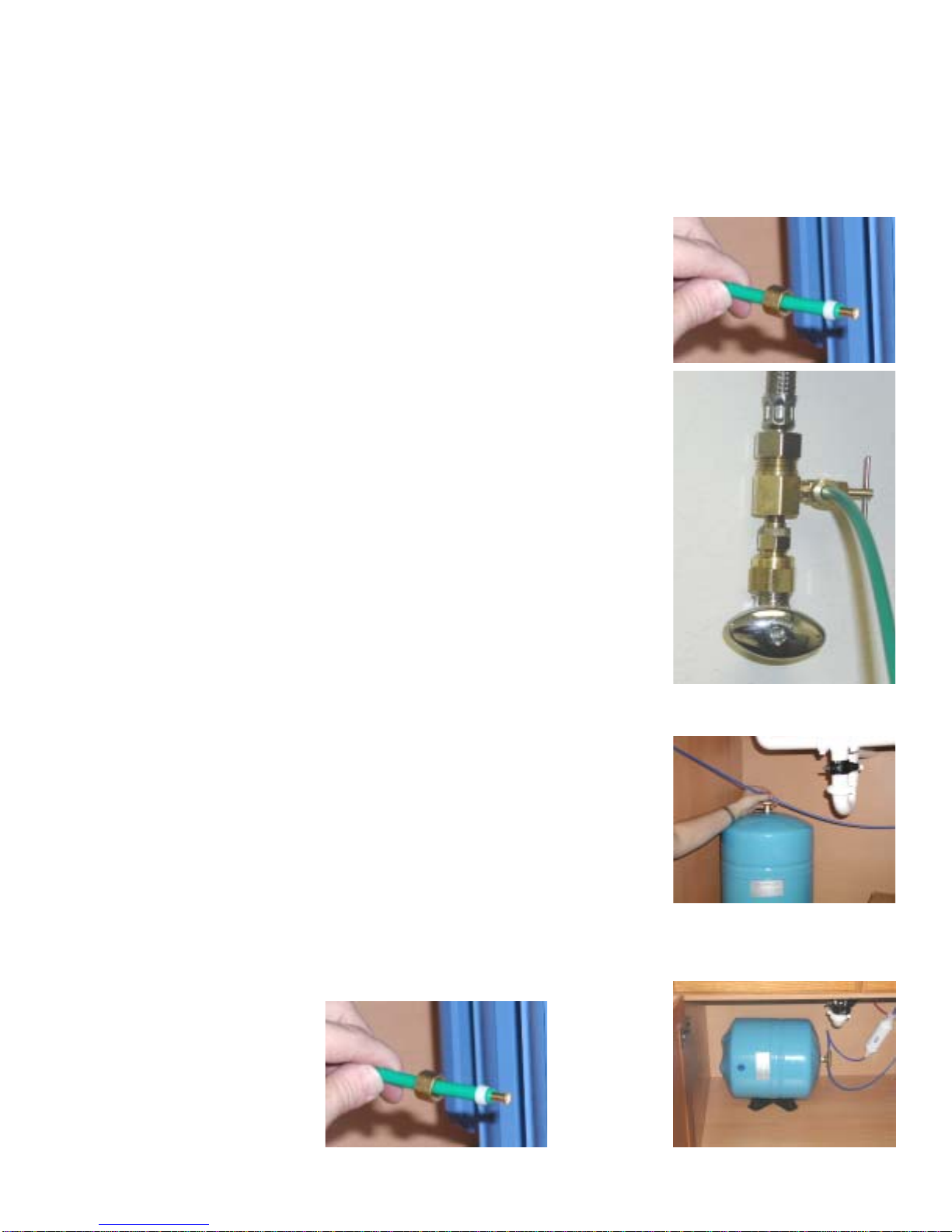

Green Tube Connection

Drape the green tube connected to the 90° Inlet white plastic elbow on the left side of the

Reverse Osmosis Module over to the adapta valve attached to the cold water sink faucet or

attached to the Angle Stop Valve, leaving a gentle curve in the tubing. Cut to desired

length using a sharp knife.

Insertthegreentubeintothe¼”openinguntilit stops. Slide nut

andsleeve down and thread ontothe male pipe threads. Usea

½”wrench tosecurelytighten.

Step 19

Step 21

Blue Tube Connection

Position tank in desired location. Stand it upright or lay it on its

side(usingtheblack plastic stand). Measure the blue tubefrom

theROmoduleovertothe tank and cut it to length.

Removeabrassnut, plastic delrin sleeve and brassinsertfrom

thepartsbag. Placenuton thetube first, then the Delrin sleeve

andtheninsertthe brass Insert into the end of thetube.(Small

taperendofDelrin sleeve must point to the endoftube).

Pushbluetubeinto the brass tee until itstops.Slidebrass nut and

plasticDelrinsleevedown until you can thread nut ontothetee.

Usewrench tosecurelytightenthenut.

Step 20

Step 23

Step 22

Page 10

Black Tube Connection

Measuretheblacktubefrom faucet to the black drain

saddleandmake a straight cutwith a sharp knife

thoughtube.

Removeblack plastic nut from drainsaddle. Slip black tube

throughblacknut. Insert black tube into theopeninginthe

drainsaddleandtightenthe black nut securely.

Thisisa gravity fed line, ifthereisany bend in the tubethe

rinsewaterwillnotflow into the drain properly. Water will back

upand come out the airgap hole in thebackof the faucet

base.

Thetubingmustbeas SHORT and STRAIGHT as possible, making adownwardslopefrom

faucettodrain saddle to allowforproperdrainage.

Step 25

Note:

Step 26

Step 27

Red Tube Connection

Usingthewhiteplasticunioninthe parts bag, determine where

theredtubingfromthefaucetand theblacktubingfromtheRO

membranehousingwouldjoin together comfortably. Cutthe

tubesleavingastraightcutonbothtubes. Inserttheredtubein

oneendofthewhiteplasticunionand the black tube in the other

end. Usea5/8"wrenchtotightenboth of the white plastic nuts

securely.

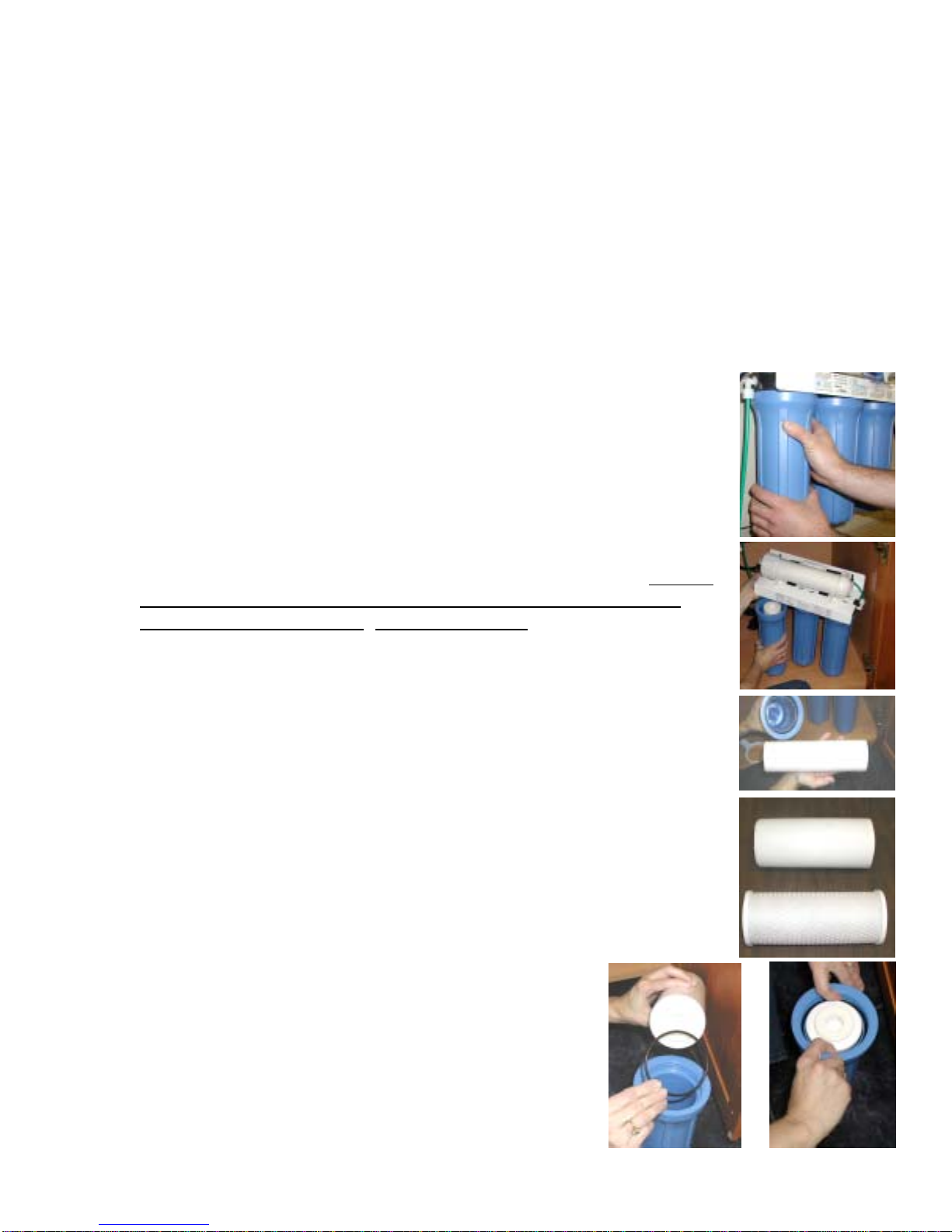

Gatherthepieces needed for the Final Filterinstallation. Each

unitissuppliedwith a final filter and 2whiteplasticconnectors.

Removethebluecapsfrom the finalfilter.

6”Final Filter Installation

Step 28

Note:

Step 24

Page 11

Threadthe2whiteplasticconnectorsintothefinalfilterandtighten.Step 29

Toinstallthe6"filtercutthebluetubefromthefaucetapproximately

inhalf. Insertthebluetube attached to the faucet into the “out” port

ofthefilter. Theflowarrowshouldbepointingtowardthefaucet.

Taketheleftoversectionofblue tube and insert it into the other

whiteconnector.Tightenthewhitecompressionnutswitha5/8"

wrench.

Step 30

Slipthebrassnutoverbluetubingfromfaucet, then slip the white

Delrinsleeveoverthetubingandinsertthe brass insert into the end

ofthebluetubing.(SameasintheGreenTube Connection section.)

Step 31

10" Final Filter Installation

Ifthesystemhasa6"finalfilter, refer to the 6” inch final filter

installation. Ifthe6"finalfilterhasalready been installed skipthis

section.

Removethe2 blue caps from the10" final filter and attachaplastic

connectortoeachendofthefilter.

Step 33

Snapthe 2 white clips fromthe parts bag ontothetop of the

membranevessel. Snapthe 10" final filter into theclips.

Step 32

Measurethebluetubefromthefaucet to the end of the 10" final filter

thattheflow arrow points toward. Useasharp knife to makea

straightcut through thetubing. Insertthetubeinto thewhite

connectorandtightenwith a 5/8" wrench.

Step 34

Insertthetubinginto the brass tank tee until itstops. Slidethebrass

nutanddelrin sleevealongthetubeuntilyou canthreadthenutonto

thetanktee. Use a½”openendwrenchtotightenthenutsecurely.

Note:

Page 12

Start up Instructions

Filloutpostage paid warranty card (phoneno. is necessary for registration)anddrop it in the

mail. Premierusesthis information to provideafree filter change reminderservice. Pre-filters

shouldbechangedeverysixmonths. You may also register your warranty via our website at

www.wattspremier.comor call 1-800-752-5582 (within USAonly).

Step 7

Ifsystemishookedup to an Ice Maker,turnIceMakeroff until tankhasfilled,thenflushedand

refilledbeforeallowingwatertoflowtoIceMaker. The system should have a ball valve

installedbefore the Ice Maker soitcan be closed to prevent waterflowingto the Ice Maker.

Your tankmustbeallowedtofillupinorderfortheunittoshutoff. (Ifyou are installinganIce

MakerKit,teeoffafter the final filter).

Note:

Thetankwilltakebetween4 to 6 hours to fill completely (dependingonthesizeofthe

membrane,localwatertemperatureandpressure).AftertheTankhasfilled,opentheRO

FaucetandflushtheTank completely and to remove carbon particlesfromfinalfilter.

Thereisanaverage of 4 gallons of rejectwaterforevery 1 gallon of product waterproduced.

Step 6

OpentheROfaucetandleaveitopenuntilwater begins to trickle out. (it will come out slowly)Step 5

Turnontheincomingcoldwater. Check the system for leaks and tighten any fitting as

necessary. (Check over the next 24 hourstoensurenoleaksarepresent).

Step 4

Reconnectthegreentube to theAutomatic Shut-OffValveandtightenwith5/8"wrench. (If the

systemishooked up to an IceMakersee the note below.)

Step 3

Turnonthecoldwatersupplyandallowwatertoflowintothebucketuntilthewaterisclear (as

showninthe6monthSystemMaintenancesectionsteps10and11.) Then turn offthe

incomingwatersupply.

Step 2

Disconnectthegreentubethatrunsfromthe3rd StageFilter Housing to theAutomatic Shut- Off

Valve and place it in a bucket.

Step 1

Ifunit is supplied withGAC Carbon Filters (hardplastic case) you willneed to startat step # 1

inthissection. If unit is supplied withCarbonBlockFilters (mesh covering) you mayskipto

Step 4 of this section.

Note:

Inspectthereverseosmosissystemperiodically to ensure the unit is functioning properly.Step 8

Page 13

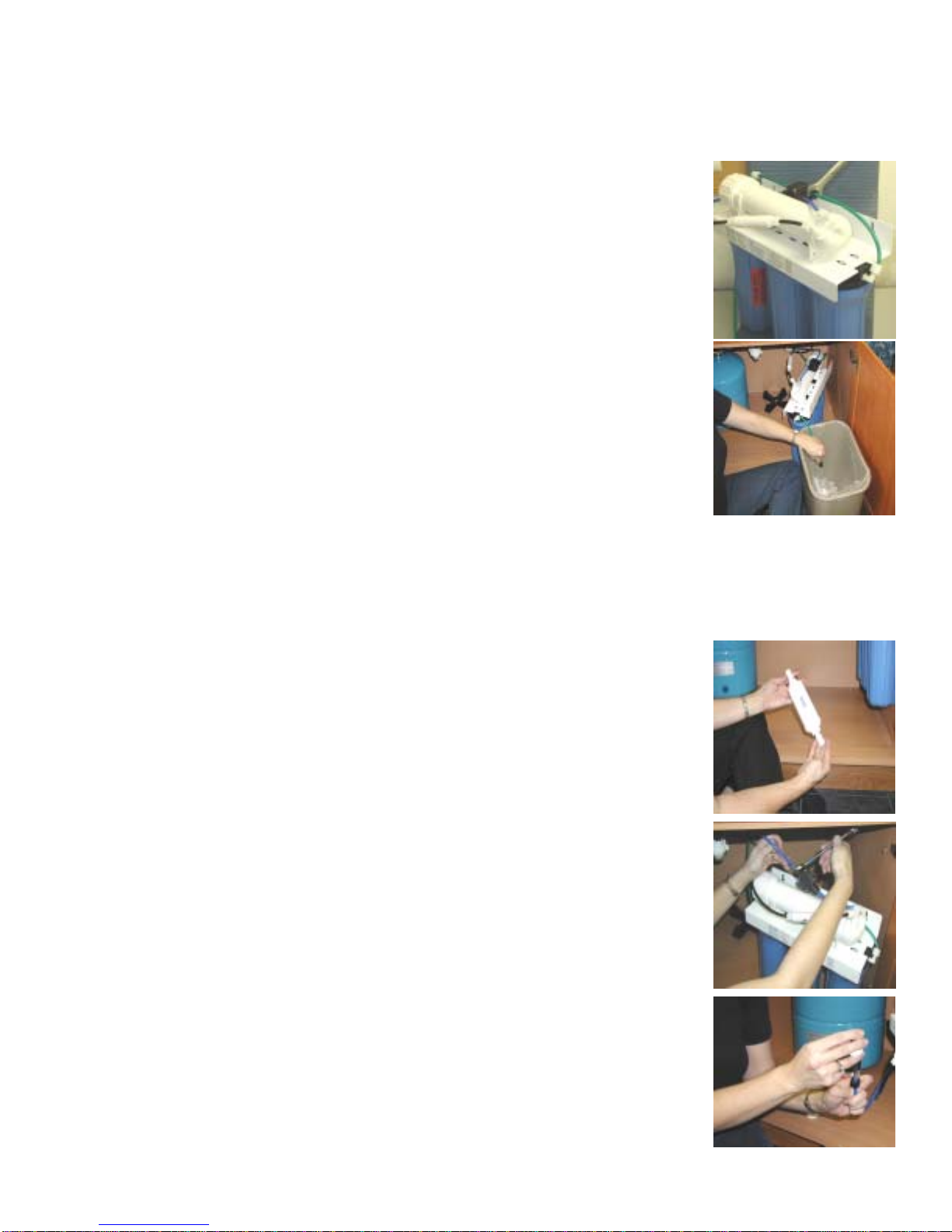

√One 10” sedimentfilter

√Two10” carbon filters

√Bucket to catch water from filter housings.

√Wrenchtoloosen filter bowls. (WattsPremieralso sells a double sided wrench).

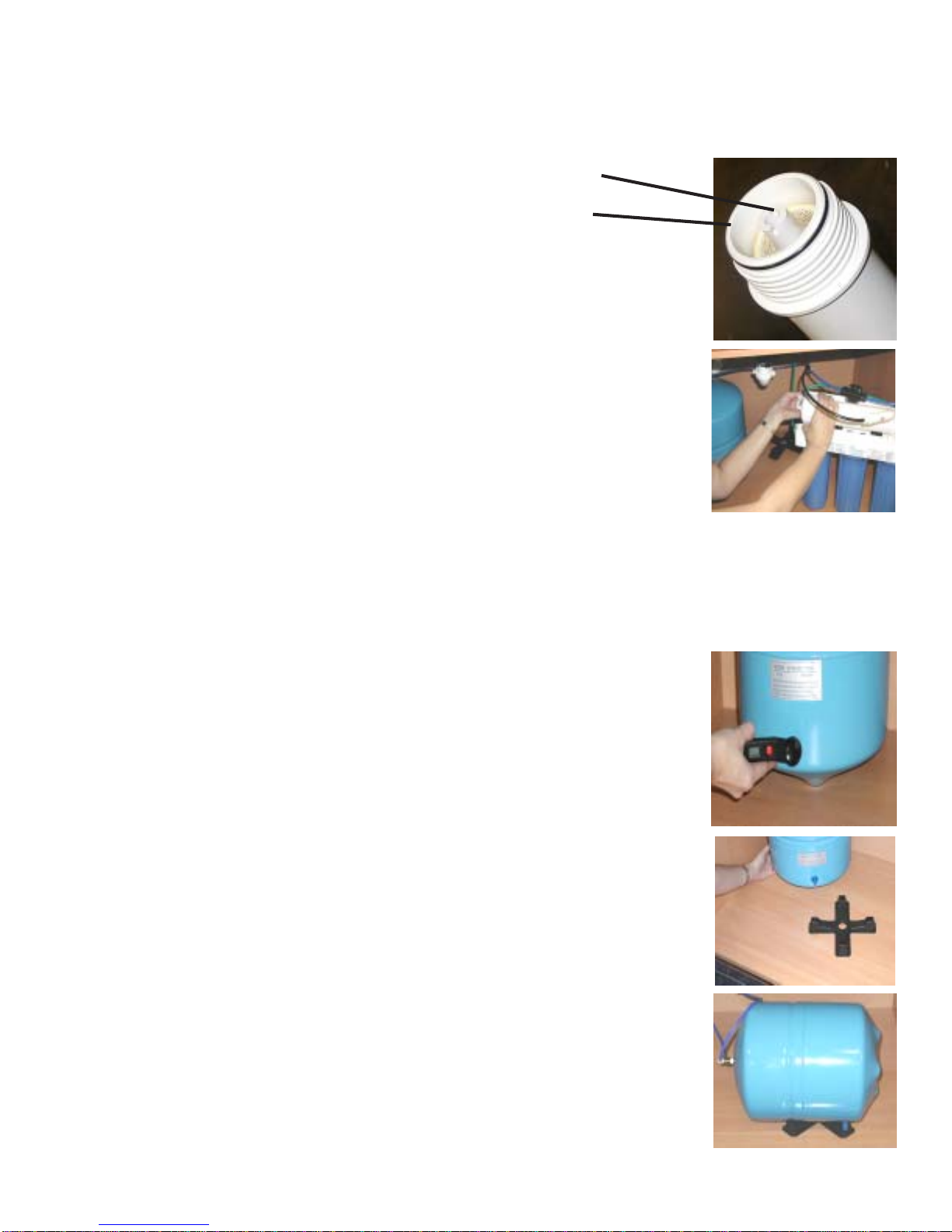

Cleanallfilterhousings(bowls)witha mild soap solution and rinse with

water. CheckO-ringsand lubricate with water soluble lubricant. KYJelly®

andotherwaterbased lubricants can be used, butpetroleumbased

lubricants(such as Vaseline®)mustnotbeused.

Formoreleverage,leaveROmoduleattached to wall of cabinet. If you are

unabletoaccessthemodule you may remove it to changefilters. Starting

withtheclosesthousing,removeand empty water,thendiscardfilters.

Continueontothe2nd and/or 3rd Bowls.

Thesedimentfilter has a clothlikeappearance. It must be in the1st

Housingonthe left(wherethewaterinletconnects).

6 Month System Maintenance

TurnoffincomingwatersupplytotheRO at needle valve on adaptavalve.

Step 1

Step 3

Step 4

Step 5

Step 6

Letsystem sit for 10 –15 minutes after tankis empty to depressurize beforeattempting to

removefilterhousings.

OpenROFaucettoallowthewatertodrainfromtankuntil completely empty. Watercan

besaved in a container fordrinking or to rinsesystem parts.

Items needed:

GAC Carbon filter is encased in a hard plastic shell and has a white

rubbergasketononeendonly.

CarbonBlockfilter has a meshcovering and a white rubbergasket on

eachend.

KeepROModule in an uprightpositionwhile replacing bowl inorderto

keepO-ringsproperlyseated.

Note:

InserttheCarbonFilter with gasket facing up. (GAC filter

hasa gasket onone end only. Carbon Block filter has a

gasket on each end). Be sure to Seat Black the O-ring

properlyinthe housing bowl.

Step 7

Step 8 Repeatthisstepfor3rd housing(5Stageunitsonly).

Step 2

Page 14

Important: Follow Step 10 –11 only ifyou have GAC (hardplastic carbon filter.)If carbon particles are

notrinsedouttheymayclog theflowrestrictorwhichcould then foul the membrane. The carbon block

filterdoesnotneed to be flushed.

Performsteps4, 5 and 6 inthestart up instruction section.

Holdgreentubeovera bucket. Turnon incoming water atAdapta

Valveand flush out all carbon particlesfromthefilters. Assoon as the

waterrunsclear,turn offtheincomingwaterandre-attachgreen tube to

theAutomaticShut-Off Valve.Usinga5/8" wrench tighten black nut

securely.

Afterchanging pre-filters, disconnect the green tube at theAutomatic

Shut-Off Valve,using a5/8"wrenchtoloosennut.

Step 9

Step 10

Step 11

Annual Maintenance

Watts Premier sells a filterchangekitwhichincludespre-filters,orings, a final filter,connectors, and a

wrench. Call1-800-752-5582orbuyonlineat www.wattspremier.com.

Perform6monthsystemmainenance. (previous section)

TheFinalFiltershouldbereplacedannually. Remove White Nutsat

bothendsof the filter to replace theoldFinal Filter. Replace with new

filterandconnectors.

AnnualSanitizingofunitisrecommendedtopreventbacteriagrowth.

RemovetheBlueTubefromtheleftside of theAutomatic Shut Off

Valve (Marked“OUT”).

Usingaclean eye dropper insert½teaspoon of 3% hydrogenperoxide

orcommonhouseholdbeachintothebluetube. Thiswill flow into the

tankoncewateristurnedback on to unit. Reattach blue tube to

AutomaticShutOff Valve. Followstartup procedure.

Step 1

Step 2

Step 4

Step 5

Note: FlowArrow on final filter must be pointinginthedirectionofthe out flow

ofwater.

Page 15

Membrane Maintenance

Membraneshavealifeexpectancy of between 2 and 5 years,dependingontheincoming water

conditionsandtheamountofuseof the RO system.

Normally, a membrane would be replaced during a semiannual or annual filterchange. However, if at any

timeyou noticeareduction in water production oranunpleasanttastein thereverseosmosiswater, it

could be time to replace the membrane. Asample may be sent into Premier for a free test or a TDS

(totaldesolvedsolids)monitorcan be purchased from WattsPremier to test the incomingandreverse

osmosiswater.

To send awatersample, include ½ cupoftapwater and ½ cup ofthe system’sreverse osmosis water in

cleancontainers.Clearly mark each container. WattsPremierwill test the water and call ormailyouthe

results.

To change the membrane, use a 5/8" wrench to remove the Green

Tubeontheleftside of themembranehousing(theendwithonlyone

elbow).

Removethecap from thewhitehorizontalmembrane housing. Turn

Capcounterclockwiseto loosen.

Usingapair of pliers, grip andpullfirmlyon the membrane to remove

fromthehousinganddiscard.

Unwrapnewmembraneand lubricate the o-rings with water soluble

lubricationsuchasKYJelly® before inserting into housing. Insert

endwiththetwoblackO-rings into the membrane housing.

Oncemembranehasbeeninsertedintothehousingyoumusttake

yourthumbsandgiveafirmpushtoproperlyseatthemembrane.

Replacemembranehousingcapandtighten.

Step 1

Step 2

Step 3

Step 4

Step 5

Adoublesided wrench can be purchasedfromPremier.

Note:

Page 16

To be properly seatedthetip of the Membrane mustbebelow the

housingedge.

Afterreplacingmembranehousingintoclips,attach the green tube to

theelbowoncapusing5/8"wrench.

Theflowrestrictormustbechangedeachtimeyouchangethe

Membrane. Replacetheexistingflowrestrictorwiththenewoneby

removing theWhiteCompression Nuts. Be sure to orientate theFlow

withthearrowpointingtoward the faucet.

Step 8

Step 9

Tip of Membrane

Edge of Housing

Note:

Step 10 Followthe StartUpInstructions.

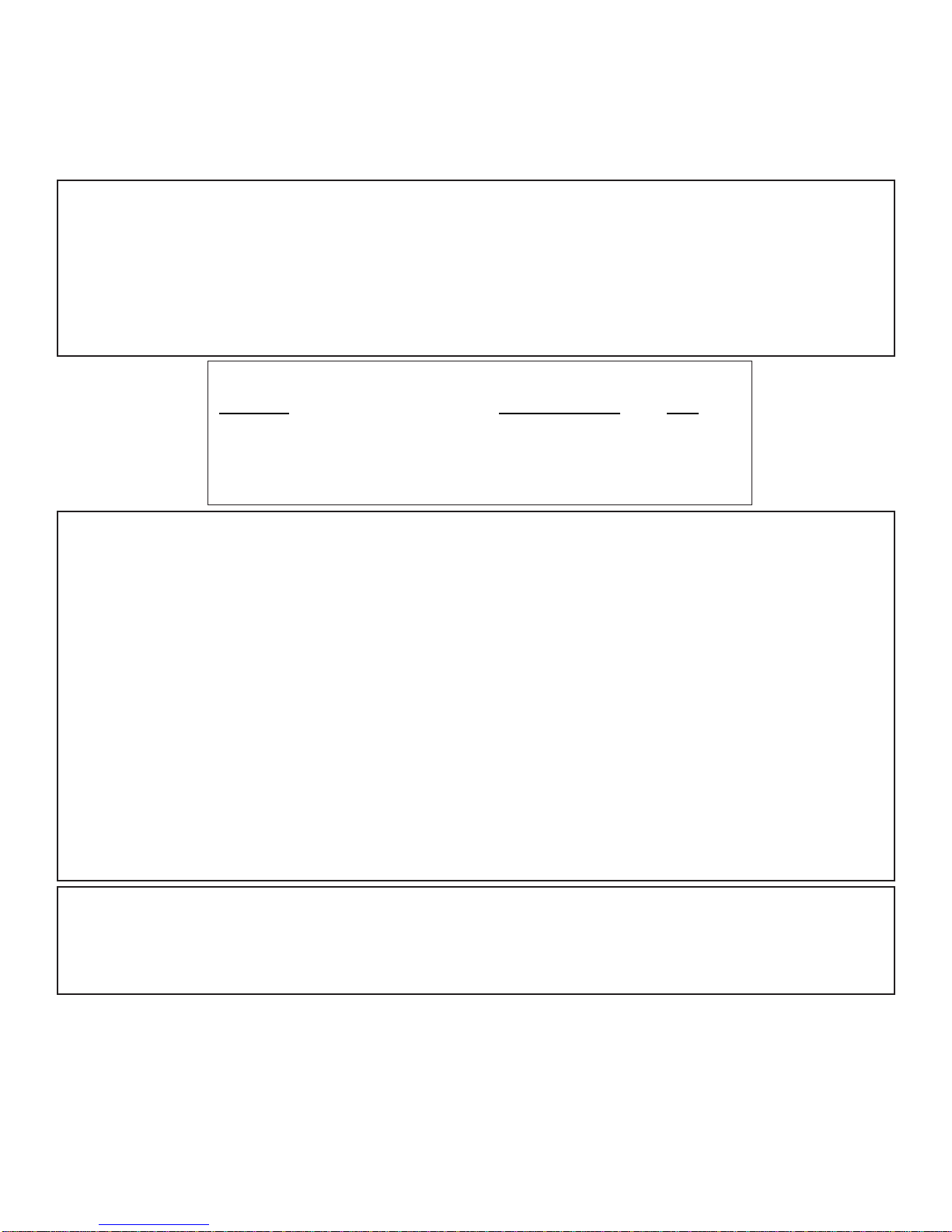

Checkairpressure when tank is empty!

Check Air Pressure in the Tank

Usingadigitalair gauge check the airpressure in the tank. You should

alwayshavebetween 5 -7 psi. If youhavemore than 7 psi releaseair

andrecheck. Ifyou have less than 5 psi,addair. Air can be addedwith

abicyclepump.

Yourunitcomeswithastandfor yourstoragetanktositonifyouneed

toturntheunitonitsside.

Thisallowsforairflowunderthetankkeeping moisture and standing

waterfromrusting on the bottomofyourtankwhichwouldvoidyour

warranty.

Step 1

Step 2

Step 3

Note:

Membrane Maintenance (Continued)

Page 17

TROUBLE SHOOTING

MELBORPESUACSNOITULOS

noitcudorPwolS/woL.1erusserPretaWwoL .erusserpretawgnimocniisp04fomuminimaerussA sierusserpretawemohfipmupretsoobasllesreimerP atpadAdnanodenrutsiylppusretawerusekaM.wol .nepoyawehtllasievlaV

gnibutnispmirC .yrassecensariaperronethgiartsdnagnibutkcehC

sretlif-erpdeggolC.sretlif-erpecalpeR

enarbmemdeluoF.rotcirtseRwolFdnaenarbmemecalpeR

retaWderoloCykliM.2metsysniriA tratslaitinihtiwecnerruccolamronasimetsysehtniriA gnirudraeppasidlliwkoolyklimsihT.metsysORehtfopu retfasruccoernoitidnocfI.skeew2-1nihtiwesulamron .semit2ot1knatniard,segnahcretlif

yltnatsnocretaW.3 tinu/gninnur ffotuhstonlliw

erusserpretawwoLevoba1#eeS

ebutylppusnipmirC .yrassecensariaperronethgiartsdnagnibutkcehC

erusserpretawhgiH tonseodtierusekamoterusserpretawgnimocnikcehC .yrassecenebyamevlavfeilererusserpA.isp08deecxe

nierusserphgiH 5oterusserpriaknatteS.retawfoknategarotsytpmE .egapsuoiverpeeS.isp

niardrotecuafmorfesioN.4tecuafpagriA.stecuafpag-riahtiwdnuostnerehnI

elddasniardfonoitacoL .elddasniardfonoitacolreporprofmargaideeS

ebutniardninoitcirtseR morfsirbedybdesuacsemitemosegakcolbraelC .rehsawhsidrolasopsidegabrag

erusserpretawhgiH .isp08sdeecxeerusserpfideriuqerrotalugererusserP

morfskaeltecuaF.5 erutaefpagriaeht enilniardnipmirC.gnibutkcehC

enilniardninoitcirtseR ynaffotuC.egakcolbraelC.senilniardllanethgiartS .gnibutssecxe

deggolcebutniarD .lasopsidegabragrorehsawhsidmorfdesuaC "8/3ehtnaelc,niardehttaenilkcalb"8/3ehttcennocsiD riagniwolB.tcennoc-erneht,eriwahtiwtuoenilkcalb .golcehtevomersyawlatonlliwenilehthguorht

niretawfotnuomallamS.6 knategarots pugnitratstsujmetsyS woL:etoN.knatllifotsruoh01-6sekattiyllamroN ecuderyllacitsardnacerutarepmetro/dnaerusserp .etarnoitcudorp

erusserpretawwoLevoba1#eeS

reddalbknatniriaevissecxE isp5ebdluohsdnayrotcafehttatessierusserpknaT .isp5evobafideelbdnaisp5wolebfiddA.ytpmenehw .egapsuoiverpeeS.ytpmesiknatnehwylnokcehC

ehtmorfskaelretaW.7 gnisuohretlifetihw/eulb denethgitylreporptoNlwobehtnethgiT

gnirodekniK .erusserpehtesaelerdnaylppusretawehtffonruT dnatietacirbulnehT.yrassecenfigniroehtecalpeR ylreporplwobretlifehtnidetaessigniroehterusekam .lwobretlifehtgnillatsniererofeb

Page 19

Item # Part # Description

16 125041 UNI-PL-1/4CX1/4C

17 131002 NUT-BR-1/4C”

18 131012 SLEEVE-DELRIN-1/4"

19 131017 INSERT-BR-1/4"

20 131021 HEX NIPPLE-BR-1/4 HEAVY DUTY

21 131023 TEE-TANK-BR-1/4CX1/4CX1/4F

22 134002 VALVE-SHUT OFF 1/4MPT (RES.)

23 a 134007 VALVE-ADAPTA VALVE

24 134011 VALVE-CHECK-PLA-ELBOW1/4CX1/8M

25 a 137013 BRACKET-4SV-STEEL-WHITE

25 b 137026 BRACKET-5SV-STEEL-WHITE

26 146001 SCREW-#10-3/4" PHIL PANHEAD

27 146004 SCREW-#10-1" PHIL PANHEAD

28 164006 CLIP-MTG-MEM-VESSEL

29 164010 CLIP-DOUBLE-MEM TO IL (OPTIONAL)

30 164016 DRAIN SADDLE 3/8"

31 119028 TANK STAND

32 113029 O-RING FILTER HOUSING

33 199328 MANUAL 4SV & 5SV PR-14

34 140007 GREEN TUBING

35 140005 BLACK TUBING

36 140004 BLUE TUBING

Item # Part # Description

1 a 100004 GAC-IL-6"-1/4 F (1M-6)

1 b 100014 GAC-IL-10"-1/4 F (PREMIER)

2 104017 SED-SPUN-10"-5M-CTG(5M-10)

3 a 101009 CARBONBLOCK-10"-5M-CTG

3 b 100036 GAC 10” - 56 Cu In CPG

4 a 110004 *MEM-TFM-18 GPD

4 b 110005 *MEM-TFM-25 GPD-DRY

5 a 113004 LID-BLACK 1/4" FPT UNASSEMBLED

5 b 113007 LID-WHITE 1/4" FPT UNASSEMBLED

6 a 113017 HOUSING-FILTER 10" BLUE

6 b 113024 HOUSING-FILTER 10" WHITE

7113032 VESSEL-MEM-HOUSING-RES

8 a 116001 FAUCET-AG-CHROME (TF)

8 b 116002 FAUCET-AG-WAVE BLK ON SS

8c116007 FAUCET-AG-WAVE WHT ON SS

9 a 119004 TANK-PRES-3 GAL-BLUE

9 b 119007 TANK-PRES-3 GAL WHITE

10 a 122004 FLOW RESTRICTOR 150 ML

10 b 122017 FLOW RESTRICTOR 250 ML

11 125002 NUT-PL-1/4C-WHITE-CELCON

12 125005 NUT-PL-1/4C-BLACK-NYLON

13 125017 CON-PL-1/4CX1/4M

14 125031 ELB-PL-1/4CX1/8M-90

15 125034 ELB-PL-1/4CX1/4M-90

* The reverse osmosis system contains a replaceable treatment component, critical for the effective reduction of total

dissolved solids and that the product water shall be tested periodically to verify that the system is performing properly

Parts List for 5 Stage Reverse Osmosis System

Rev 1/31/02

3 32

8

9

20 20

21

22

24

55 5

14

1011 11

12 12

12

12

17

18

19

23

171819

17 18 19

1

30

15

15

28 28

4 7

14

32

3232

BLACK

RED

BLUE

BLUE

BLUE

BLUE

GREEN GREEN

GREEN

Serial # NSF Premier ........

27 26 27

16

25

29

29

31

13

13

BLACK

6 6 6

Page 19

California Certification

Page 20

RECOMMENDED REPLACEMENT PARTS AND CHANGE INTERVALS:

Note: Depending on incoming feed water conditions replacement time frame may vary.

Description Change time Frame Price

Sediment Pre-filter: #5m-10 6 Months $4.50

Carbon Pre-filter: #GAC-410-56/#5MCB 6 Months $9.00/10.50

Final Carbon filter #1m-6/#1M-10 12 Months $9.00/11.95

R.O. Membrane: #TFM-24 2 to 5 years $82.95

This system has been tested according to NSF/ANSI 58 for reduction of the substances below. The concentration of the indicated substances in water

entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system as specified in NSF/ANSI 58.

This system has been tested for the treatment of water containing pentavalent arsenic (also known as As (V), As (+5), or arsenate) at concentrations

of 0.30 mg/L or less. This system reduces pentavalent arsenic, but may not remove other forms of arsenic. This system is to be used on water

supplies containing a detectable free chlorine residual at the system inlet or on water supplies that have been demonstrated to contain only pentavalent

arsenic. Treatment with chloramine (combined chlorine) is not sufficient to ensure complete conversion of trivalent arsenic to pentavalent arsenic,

Please see the Arsenic Facts section of the Performance Data Sheet for further information.

Avg. In. Avg. Eff. % Reduction pH Pressure Max Eff. Inf. challenge Max Allowable

concentration concentration

mg/L mg/L

Arsenic (Pentavalent) 334.615 ug/L 5.0385 ug/L 98.4% 50psi 19 ug/L 0.30±10% 0.010 mg/L

Barium Reduction 10.2 mg/L 0.207 mg/L 97.9% 7.24 50psi 0.3 mg/L 10.0±10% 2.0

Cadmium Reduction 0.036 mg/L 0.0005 mg/L 98.6% 7.49 50psi 0.0007 0.03±10% 0005

Chromium (Hexavalent) 0.15 mg/L 0.013 mg/L 91.3% 7.24 50psi 0.03 0.03±10% 0.1

Chromium (Trivalent) 0.17 mg/L .01 mg/L 94.1% 7.24 50psi 0.01 0.03±10% 0.1

Copper Reduction 3.1 mg/L 0.03 mg/L 99.0% 7.64 50psi 0.04 3.0±10% 1.3

Cysts 222,077#/ml 10 #/ml 99.99% 58 minimum 50,000/mL

Fluoride Reduction 8.0 mg/L 0.5 mg/L 93.9% 7.49 50psi 0.7 8.0±10% 1.5

Lead Reduction 0.15 mg/L 0.002 mg/L 98.6% 7.49 50psi 0.003 0.15±10% 0.010

Radium 226/228 25pCi/L 5pCi/L 80.0% 7.24 50psi 5pCi/L 25pCiL±10% 5pCiL

Selenium 0.10 0.008 92.0% 50psi 0.011 0.10±10% 0.05

TDS 96.8% 7.84 750±40mg/L 187

Turbidity 10.2 mg/L 0.26 mg/L 97.5% 0.83 11±1 NTU 0.5 NTU

Note: Depending on water chemistry, water temperature, and water pressure Watts Premier’s R.O. Systems production and performance will vary.

Efficiency rating means the percentage of the total water required to operate the system that is treated and available to the user.

REFER TO OWNER’S INSTALLATION/SERVICE MANUAL FOR FURTHER MAINTENANCE REQUIREMENTS AND WARRANTY INFORMATION.

GENERAL USE CONDITIONS:

1. System to be used with municipal or well water sources treated and tested on regular basis to insure bacteriological safe quality. DO NOT use with

water that is microbiologically unsafe or unknown quality without adequate disinfection before and after the system. Systems certified for cyst

reduction may be used on disinfected water that may contain filterable cysts.

2. Operating Temperature: Maximum: 100°F (40.5°C) Minimum: 40° (4.4°)

3. Operating Water Pressure: Maximum: 100 psi (7.0kg/cm2) Minimum: 40 psi (2.8kg/cm2)

4. pH 3 to 11

5. No iron present in incoming feed water supply.

6. Hardness of more than 7 grains per gallon (120 ppm) may reduce TFM membrane life expectancy.

7. Recommend TDS (Total Dissolved Solids) not to exceed 1800 ppm.

Model No. Avg. Avg. Avg. TDS DPR

Influent Effluent IN/EFF RECOVERY GALLONS EFFICIENCY

TDS TDS REDUCTION

765 mg/l 23mg/l 96.8% 15.5% 9.06gpd 8.35%

Watts Premier Inc.

1725 W. Williams Drive C-20

Phoenix, AZ 85027 USA

California Certification # 00-1452

Watts Premier Product Data Sheet

5 SV Deluxe, CRO-TFM-5SV, Ultra 5 and Pur-Tek, Watts 25, Watts RO-4, Watts RO-5, RO-TFM-4SV, RO-TFM-

This manual suits for next models

6

Table of contents

Other Watts Premier Water System manuals

Popular Water System manuals by other brands

Hog Technologies

Hog Technologies SK5500 Operation manual

Reverse Osmosis

Reverse Osmosis Economy RO75 owner's manual

Yamato

Yamato CF800 instruction manual

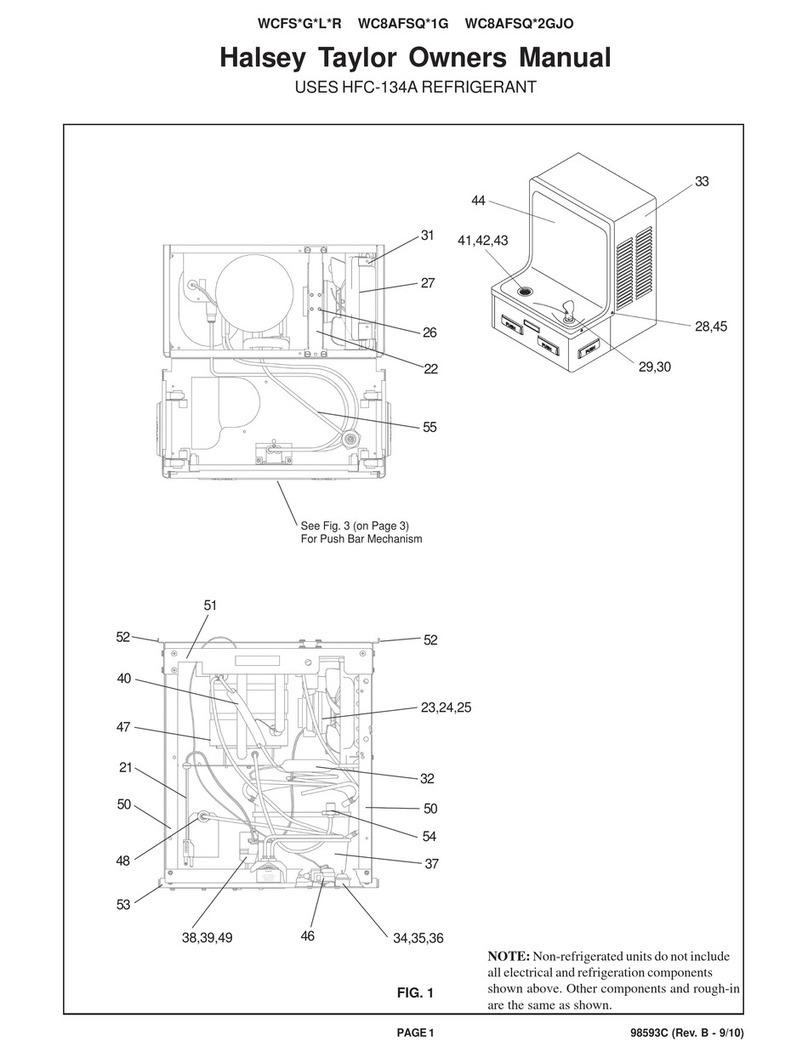

Halsey Taylor

Halsey Taylor WCFS G L R Series owner's manual

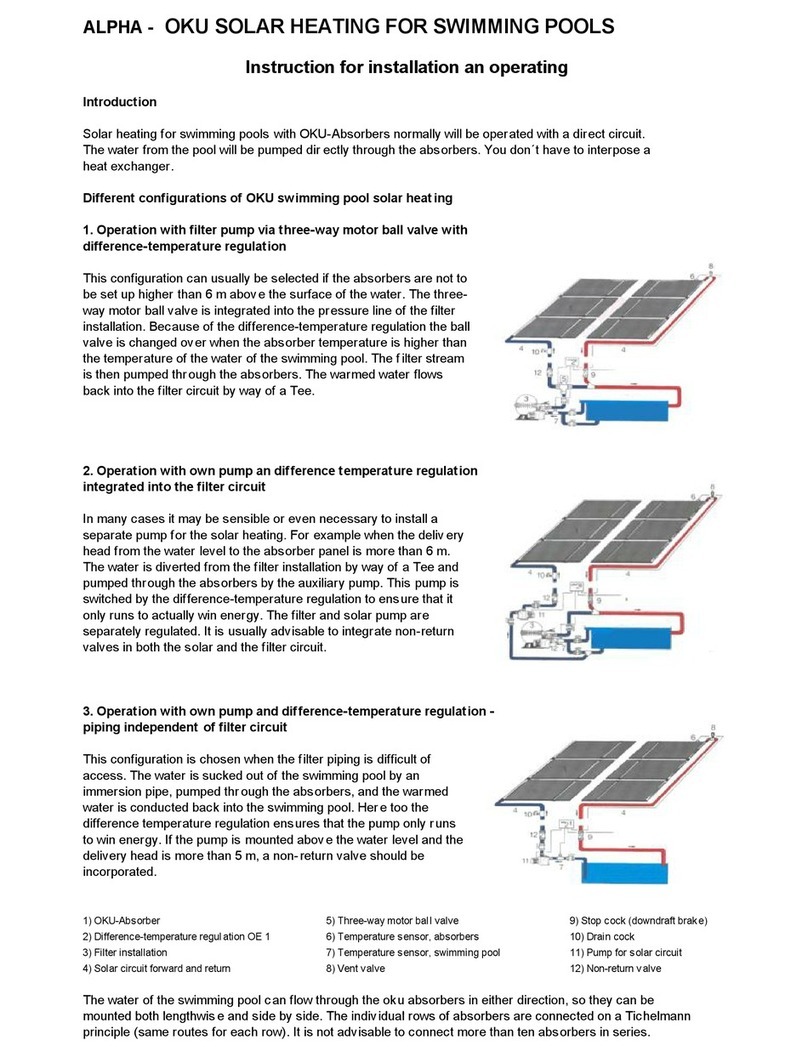

Alpha

Alpha OKU Instructions for installation, use and maintenance

RadonAway

RadonAway AIRaider EZ95 Installation instructions manual