OPERATING AND

COMMISSIONING INSTRUCTIONS

IO) Filling the system - Fill the system slowly. The filling

operation should be carried out with the flow and return

isolating valves on each module (8 and 9 - Fig. 1) fully

open.

11) Lighting the pilots - Open the gas valve on each mo-

dule by turning gas cock in line with pipe (1 - Fig. 5). Press

the gas control spindle (2 - Fig. 5) and hold in. Light the pi-

lot by pressing piezo ignitor (3 - Fig. 5) and wait for ap-

proximately 20 seconds.

Release the gas control spindle (2 - Fig. 5) and the pilot

should remain alight. If the pilot will not establish, check

that the gas supply to each boiler is purged of air.

Repeat the lighting procedure.

12) Firing the modules - Establish the pilots on all modu-

les as in 11.

Set the boiler thermostat on each boiler (Fig. 6) to a mini-

mum, and check that all module isolating switches are off

(18 - Fig. 1). The switches are wired to be on when at (*)

and off when at ” STOP ”

Check that pumps are free by using screwdriver on end of

spindle.

Set the primary circulation pump in operation, and check

that all system circuits are open and will allow circulation.

Turn up the boiler thermostat (Fig. 6) to the required value,

and switch on the individual modules at the isolating swit-

ches. The modules should now fire. Check for gas leaks

and flue spillage.

13) Checking the gas rate-The burner pressure of each

module should be checked before completing the com-

missioning.

Turn off the module to be checked at the isolating switch

(18 - Fig. 1) and remove the cap from the volume governor

(1 - Fig. 7).

Remove the plug from the pressure test point on the end

of the burner manifold and connect a suitable pressure

gauge.

Turn on the module at the isolating switch and adjust the

gas pressure to the value given in Technical Data on page

3.

Earlier models of the Flexiflame 280 and 420 have a knur-

led ring fitted around the gas control spindle.

Where this is fitted, screw in to reduce the gas rate, and

screw outto increase the gas rate (2 - Fig. 5).

14) Setting the boiler thermostats - Where the modules

are operated by an external control signal set the boiler

thermostat to 50 OC above the maximum expected return

temperature.

Where the modules are to be controlled in sequence by

the boiler thermostats, the following table details the inter-

vals between thermostat settings for various design tem-

perature drops around the system.

N” of Interval between thermostat settings OC

Boilers T=SOoC T=lSoC T=lloC T=80C

: 10 7.5 5.5

; 5

2 : i i

2.5

2.5 -

6 34.5 2.5 - -

i 23.5 I - -

- -

Where the interval would be less than 2.5 oC, it is recom-

mended that boilers be grouped in pairs or threes, depen-

ding on the total number.

e.g. 1 - If 5 boilers were installed to provide a flow tempe-

rature of 82 OC at a system drop of 11 oC, the thermostat

settings would be 82, 79.5, 77, 74.5 and 72 oC. The boiler

nearest the flow would be set at 82 OC and the boiler nea-

rest the return at 72 0C.

e.g. 2 - If 8 boilers were installed to provide a flow tempe-

rature of 90 OC at a system drop of 20 oC, the thermostat

settings would be 90, 87.5, 85, 82.5, 80, 77.5, 75, 72.5 OC.

The boiler nearest the flow would be set at 90 0C and the

boiler nearest the return at 72.5 oC.

e.g. 3 - If 12 boilers were installed to provide a flow tem-

perature of 82 OC at a system drop of 11 oC, the thermo-

stat settings would be 82 for boilers 1 and 2, 79.5 for boi-

lers 3 and 4, 77 for boilers 5 and 6, 74.5 for boilers 7 and

8, 72 for boilers 9 and 10, and 69.5 for boilers 11 and 12.

SERVICING REQUIREMENTS

Chaffoteaux Limited recommend that boilers are serviced

annually.

Installers and clients are reminded that the boilers are

guaranteed for twelve months from the date of installation.

Spare parts lists and prices are available from the manu-

facturers.

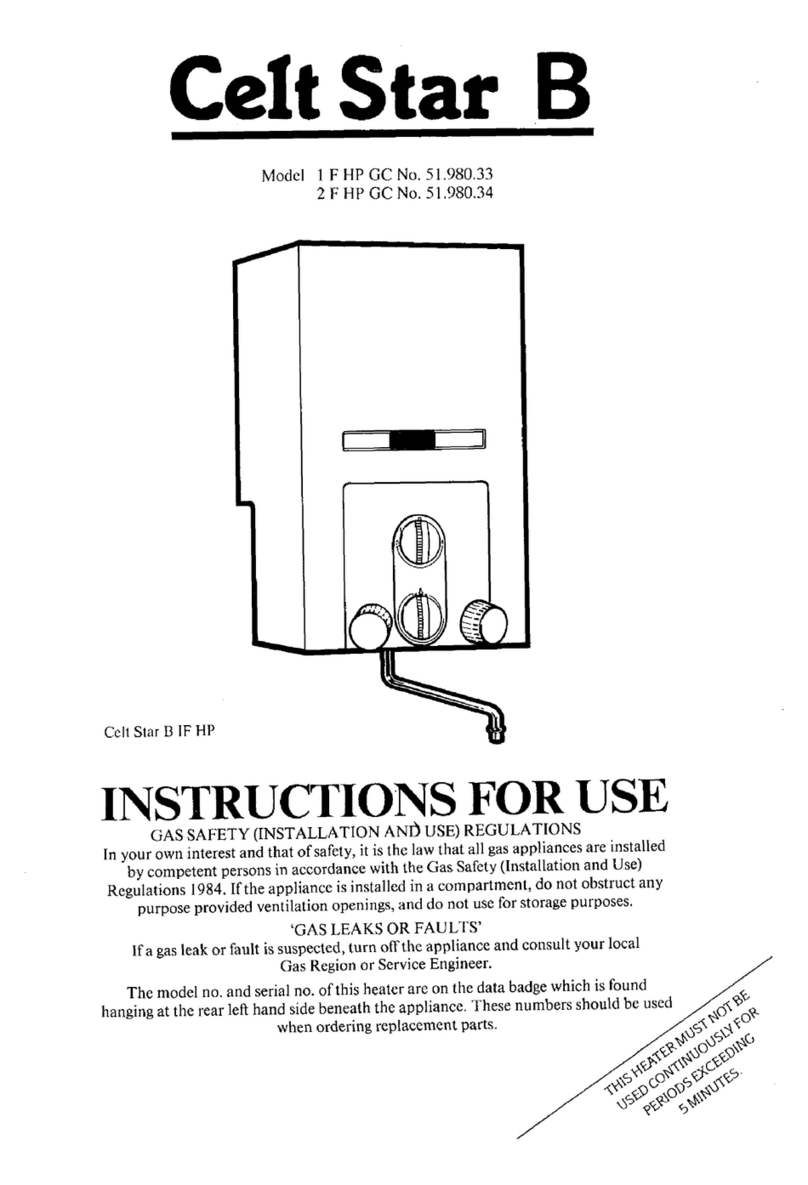

15-I Remove the boiler doors by removing lower hinge

pin and pulling forwards at the bottom.

Isolate the module to be serviced by turning the isolating

switch off (24 - Fig. 1).

Close the gas isolating valve turning gas cock across pipe

(6 - Fig. 1).

Release the screw (1 - Fig. 8) holding the pilot supply pipe

and remove the pipe (2 - Fig. 8).

Unscrew the union securing the thermocouple to the elec-

tromagnet at the rear of the gas section (4 - Fig. 1). Remo-

ve electrode lead from piezo, remove both overheat and

skirt overheat from heat exchanger, remove complete

electrode and thermocouple bracket assembly from ap-

pliance with the burner assembly.

Remove the screws holding the burner to the back plate

(1 - Fig. 9).

Unscrew the union nut securing the burner to the gas sec-

tion (2 - Fig. 9).

Clean the burner by removing any deposits with a brush.

Fig. 8 Fig. 9