Challenger EPS0412 User manual

Imported exclusively by Pacific Hoists Pty. Ltd. & Pacific Hoists Ltd.

In support of cancer charities in Australia & New Zealand

INSTRUCTION

MANUAL

ELECTRIC LIFTER

TROLLEY

www.jbstools.com

2WWW.CHALLENGERHOISTS.COM.AU

www.jbstools.com 33

INTRODUCTION

Thank you for purchasing your new Challenger Electric Lifter Trolley. The Challenger Electric Lifter

Trolley is made of high quality steel which is designed to be durable, reliable and easy-to-use. Also

choosing the Challenger brand directly supports cancer charities in Australia and New Zealand.

It is important that this manual be kept in a safe place where any operator of the Challenger

Electric Lifter Trolley can refer to it and understand the operating principles of this device. All

users of this Challenger Electric Lifter Trolley should read this manual in full and understand the

safe operating principles of the device.

IMPORTANT

PLEASE READ THIS OPERATION MANUAL BEFORE USING THIS PRODUCT. THIS MANUAL CONTAINS

IMPORTANT INFORMATION REGARDING SAFETY, OPERATION, INSTALLATION & MAINTENANCE.

ALWAYS OPERATE, INSPECT AND MAINTAIN THIS PRODUCT IN ACCORDANCE WITH

INSTRUCTIONS IN THIS MANUAL,

Model EPS0412 EPS0415 EPS0417

Stock code CES120 CES150 CES170

Rated capacity (kg) 400

Max. height (A) x width (B) (mm) 1425 x 600 1725 x 600 1925 x 600

Max. platform height (C) (mm) 1200 1500 1700

Min. platform height (D) (mm) 85

Platform length (E) x width (F) (mm) 650 x 576

Lifting height (mm) 1115 1415 1615

Lifting speed with load (mm/sec) 0 - 80

Lowering speed with load (mm/sec) 0 - 115

Storage battery DC12V - 60AH

Motor DC12V - 700W

Max. trolley length (G) (mm) 1100

Net weight (kg) 118 126 130

SPECIFICATIONS

www.jbstools.com

4WWW.CHALLENGERHOISTS.COM.AU

SPECIFICATIONS

www.jbstools.com 55

GENERAL PRECAUTIONS

■The operator should read the instructions before using this electric lifter trolley to avoid any

injuries

■This electric lifter trolley is used to lift and lower loads within it’s rated capactiy

■The electric lifter trolley should only be operated by persons who are authorised to do so

■Examine the electric lifter trolley before use

■Do not overload the electric lifter trolley

■Pay attention to and ensure all loads are secured correctly

■If the load moves when the electric lifter trolley is in use, brake immediately

■Distribute the weight of the load across both forks evenly, do not use a single fork only

■Do not load the electric lifter trolley with imbalanced or unstable loads

■Ensure correct maintenance of the electric lifter trolley according to the service instructions

■Do not modify or repair the electric lifter trolley without first consulting the distributor

■Check the battery before use and recharge in case of low power in a dry, well ventilated area

■Lower the forks once loading has been completed to avoid any injuries

■When servicing the electric lifter trolley ensure all loads are removed and use the safety

stopper to prevent the platform from lowering

■This electric lifter trolley is not designed to be weather resistant. When not in use store in

dry conditions and ensure the forks are lowered

www.jbstools.com

6WWW.CHALLENGERHOISTS.COM.AU

MAINTENANCE

REGULAR INSPECTION OF YOUR CHALLENGER ELECTRIC LIFTER TROLLEY WILL HAVE A

TWOFOLD RESULT BY ENSURING THE UNIT IS SUITABLE FOR SAFE OPERATION AND WILL

ASSIST WITH EXTENDING THE OPERATING LIFE OF THE UNIT. THE FOLLOWING INSPECTION

SHOULD BE PERFORMED BOTH PRIOR TO, AND AFTER, EVERY USE:

■Check for any bending or cracking on the electric lifter trolley

■Check for any oil leakage from the cylinder

■Check the subside of the electric lifter trolley while the platform is lifted to the highest position

■Check that the wheel movement is smooth

■Check the function of the brake

■Check all the bolts and nuts are tightened firmly

■Check the voltage of the battery indicator

■Check the hydraulic oil and lubrication periodically

■Check the oil mass every month

■Ensure equipment is serviced and maintained

CAUTION: DO NOT use the electric lifter trolley if any malfunction or fault is found

WARNING

■Do not place hands or feet under the platform

■Do not move the electric lifter trolley when the forks are lifting

■Do not move the electric lifter trolley unless the forks are lowered to a safe position

■Do not place feet in front of the swivel wheel, this may cause harm as the load is being

lowered

■Do not overload the electric lifter trolley

■Do not use the electric lifter trolley on uneven surfaces

■Never use the electric lifter trolley for the trasportation or movement of personel

www.jbstools.com 77

OPERATING INSTRUCTIONS

■To brake, press the brake pedal located on the left side of the swivel caster

■To release the brake, lift the brake pedal

■To lift the forks, turn the emergency stop button on the control panel clockwise and operate

the up button in the centre of the control panel

■To immediately stop the forks rising or lowering, push the emergency stop button

■To lower the forks, press the down button on the control panel

■To stop the forks lowering, release the down button on the control panel

■Do not overload the electric lifter trolley, ensure the load is within the rated capacity

■Do not side or end load. The load must be distributed on at least 80% of the platform area

CHARGING THE BATTERY

■Charge the battery when the voltage of the storage battery is low

■The electric lifter trolley uses a maintenance free storage battery, which does not involve

adding water

■Charge the battery in a dry, well ventilated area away from sparks and ignition sources

■To charge the battery, pull out the charger plug on the left side of the electric lifter trolley and

insert into a socket with the specified voltage. Remove when the full charge indicator light on

the panel goes on

■During charging, the voltage display on the indicating gauge should be lower than 16V

■Do not use the electric lifter trolley during charging

www.jbstools.com www.jbstools.com

8WWW.CHALLENGERHOISTS.COM.AU

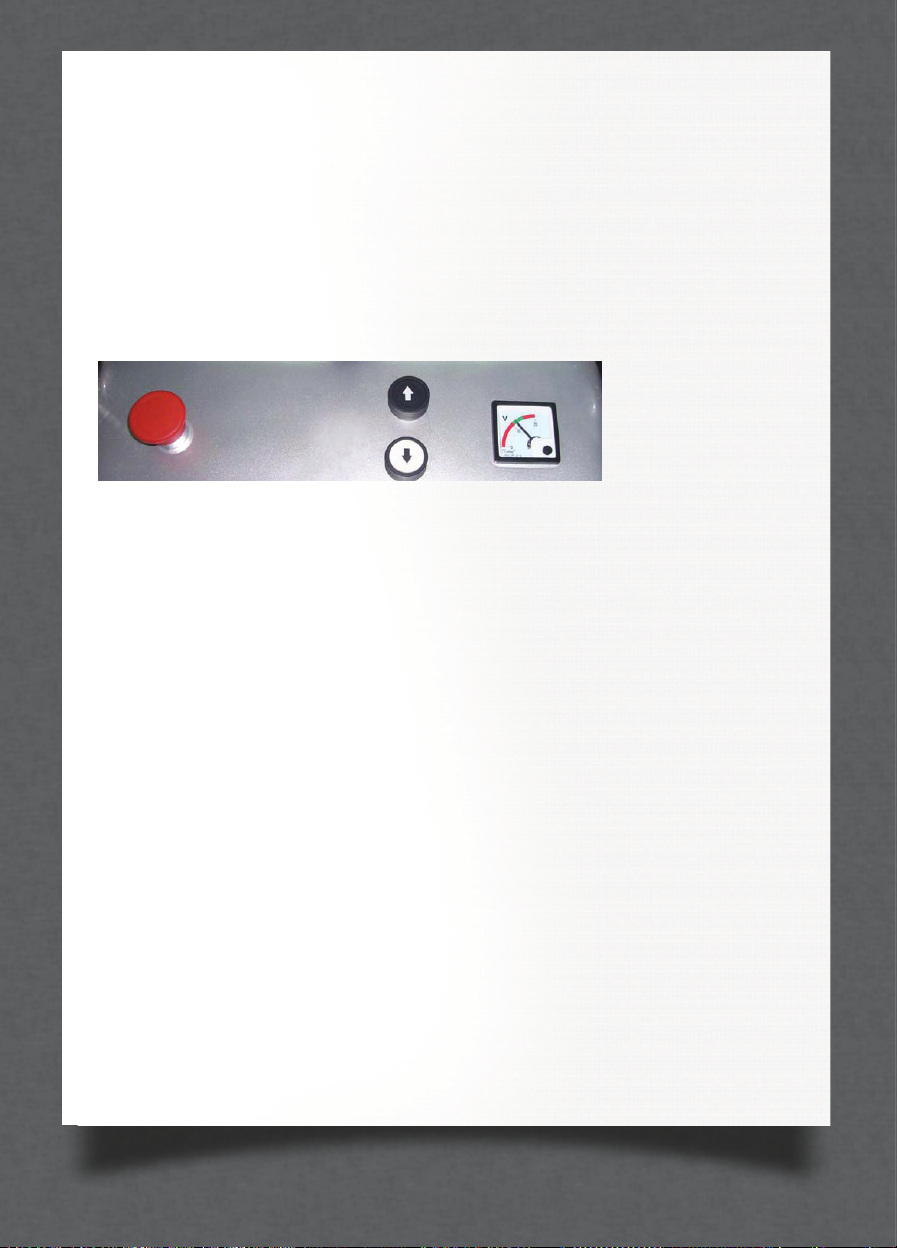

CONTROL PANEL

■Press the emergency button, to disconnect the power supply of the pump station motor

■Turn the emergency button clockwise to connect the motor

■When the voltmeter is below 10V, the storage battery must be charged

■The up/ down buttons are used to raise or lower the forks

EMERGENCY BUTTON UP/ DOWN BUTTONS VOLTMETER

www.jbstools.com www.jbstools.com www.jbstools.com

99

TROUBLE SHOOTING

No. Fault Cause Countermeasures

1The forks cannot

reach the max. height

• Low hydraulic oil level • Inject hydraulic oil

2The forks cannot be

raised

• No hydraulic oil

• Hydraulic oil is impure

• Check hydraulic oil

• Replace the hydraulic oil

3Pump station motor

cannot run

• Emergency button is not

switched on

• Low voltage of the storage

battery

• Wiring terminal of the power

line is loose

• Motor contactor is damaged

• Turn the emergency button

clockwise

• Charge the battery

• Fasten the wiring terminal

• Replace the parts

• Contact you distributor

4The forks will not

lower

• Uneven centre of gravity

of goods or overloading

causes deformation of the

large piston rod or the oil

tank body

• The forks are rusted

and hard to move due to

long-term exposure to air

when the platform stays in

the higher position for an

extended period of time

• The release valve of the

hydraulic pump station is

worn or damaged and thus

cannot be opened

• Replace the large piston

rod or the oil tank body

• Lower the forks to the

lowest position when not

using the crane and make

sure to lubricate the piston

rods

• Replace the release valve

of the pump station

• Contact you distributor

5Oil leakage • Sealing parts are aged or

damaged

• Some parts are broken

• Replace the parts

• Replace the parts

• Contact you distributor

6Forks lower itself • The relief valve is unable to

be shut tightly due to impure

hydraulic oil

• Sealing parts are aged or

damaged

• Release valve is damaged

• Replace the hydraulic oil

• Replace the parts

• Replace the parts

• Contact you distributor

7Storage battery

cannot be charged

• Storage battery is damaged

• Charging plug is loose

• Replace the parts

• Check connections

www.jbstools.com www.jbstools.com 1010

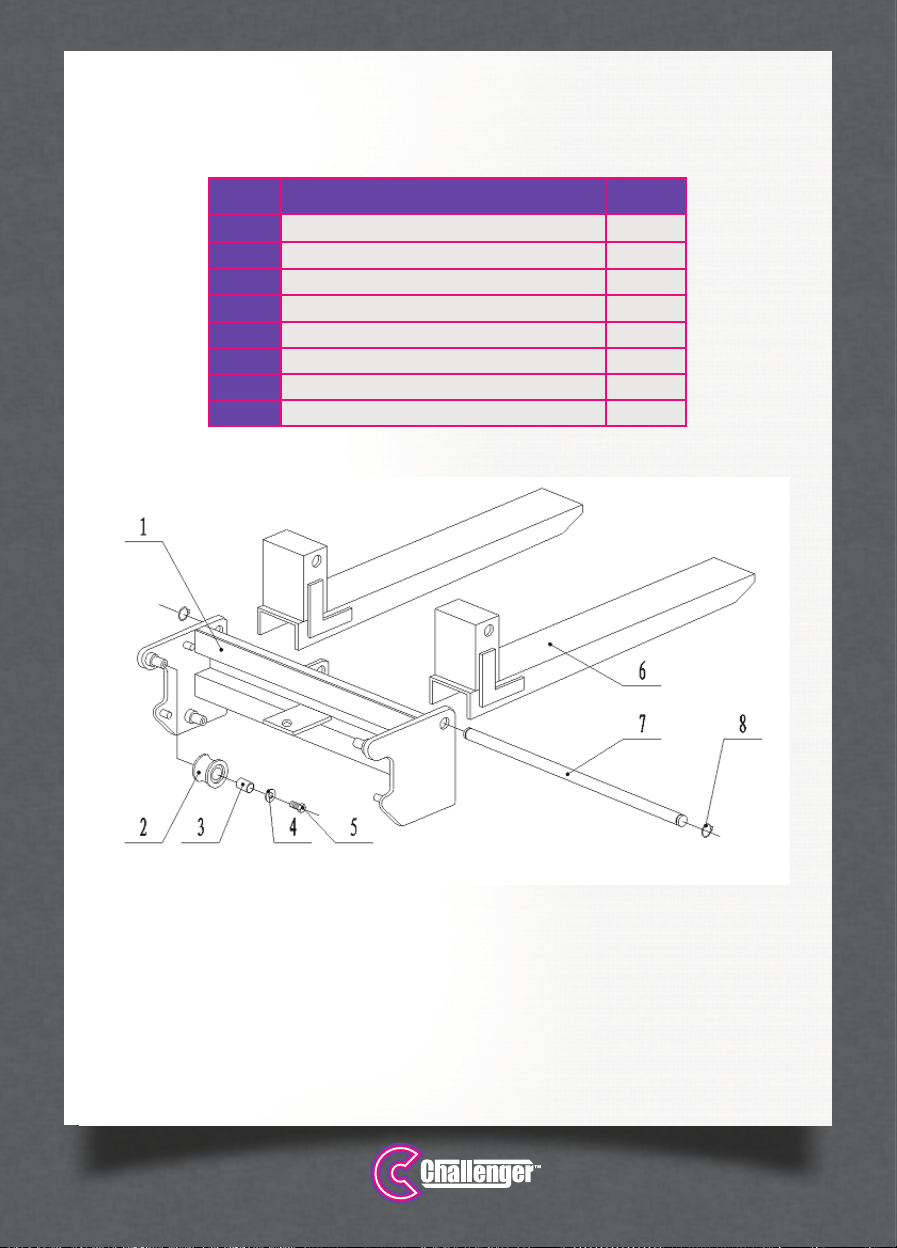

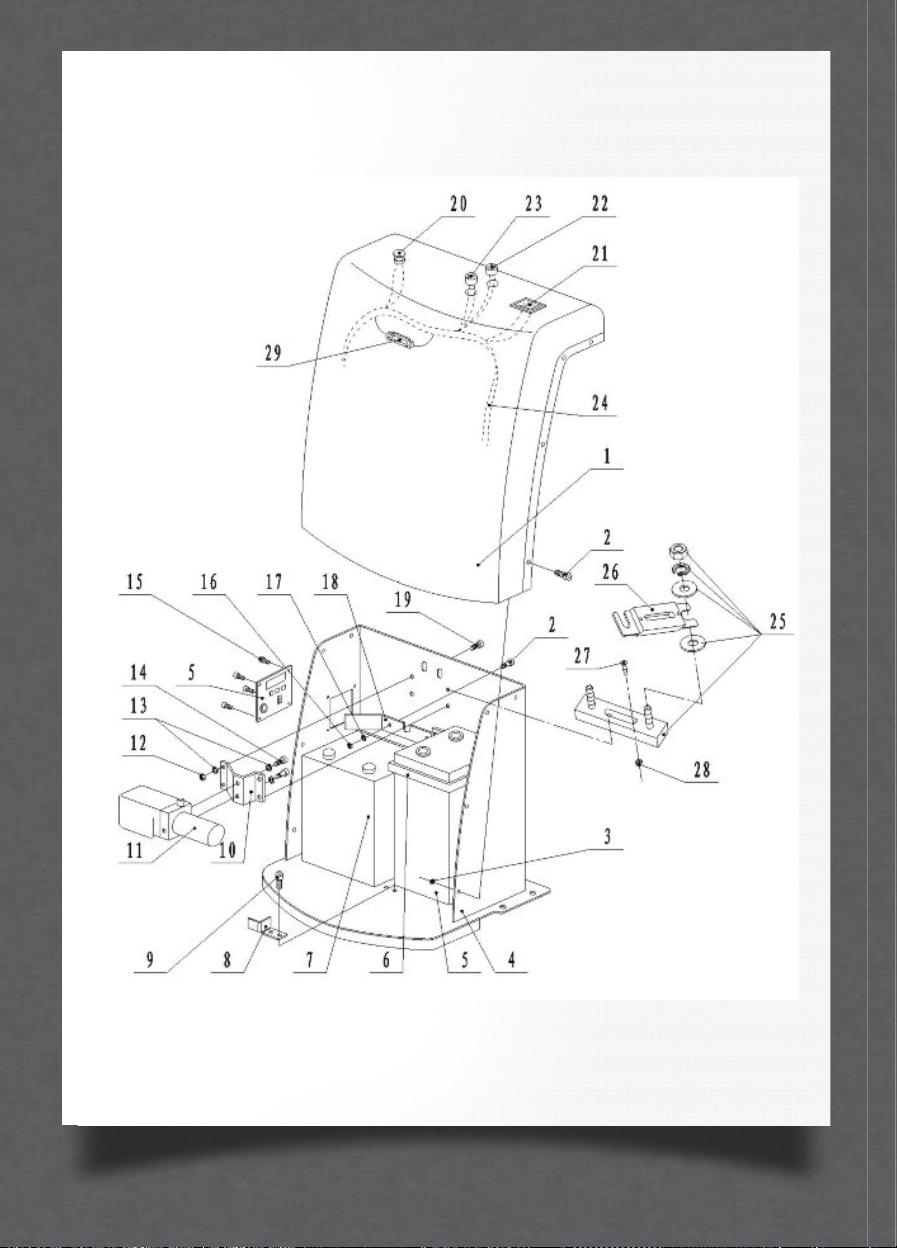

SPARE PARTS

No. Description Qty.

1Bracket 1

2Roller 4

3Composite sleeve 4

4Ultra big washer 4

5Full thread hexagon headed bolt M6X16 4

6Tyne 2

7Long axis 1

8Spring washer for shaft 2

www.jbstools.com 1111

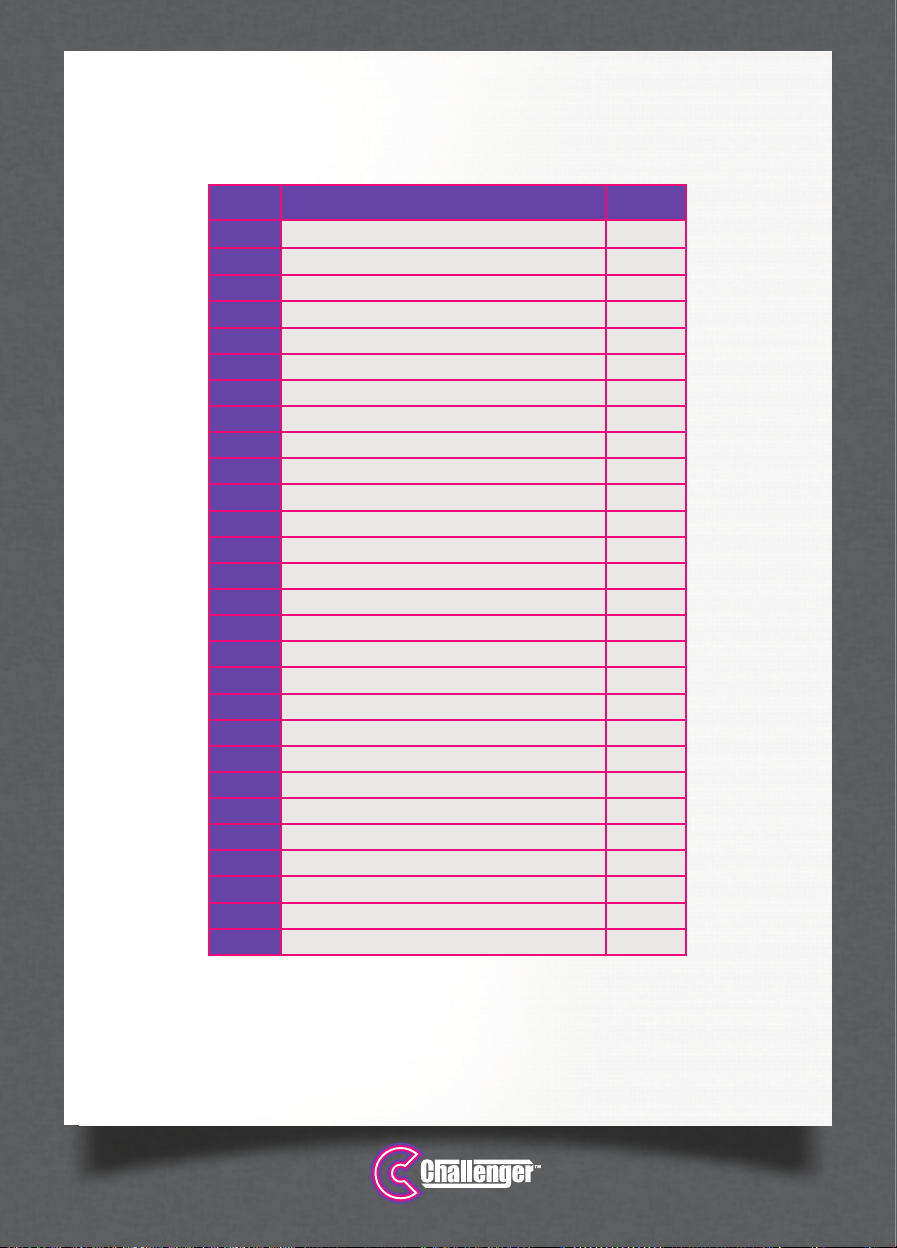

SPARE PARTS

No. Description Qty.

1Handle 1

2Split washer 2

3Chain wheel 1

4Composite sleeve 2

5Chain wheel cap 1

6Chain wheel cap 1

7Chain wheel shaft 1

8Hexagon socket set screws with flat point 1

9Chain 1

10 Chain joint 2

11 Chain tie rod 2

12 Hexagon nut 6

13 Non-metal hexagon lock nut 2

14 Full thread hexagon headed bolt 4

15 Spring washer 4

16 Hexagon nut 4

17 Full thread hexagon headed bolt 4

18 Flat washer 8

19 Spring washer 4

20 Split washer 4

21 Front wheel axel 2

22 Gasket 4

23 Bearing 4

24 Front rollers 2

25 Chasis 1

26 Steering wheel (with brake) 2

27 Cap nut 2

28 Internal tooth lock washer 2

www.jbstools.com

12 WWW.CHALLENGERHOISTS.COM.AU

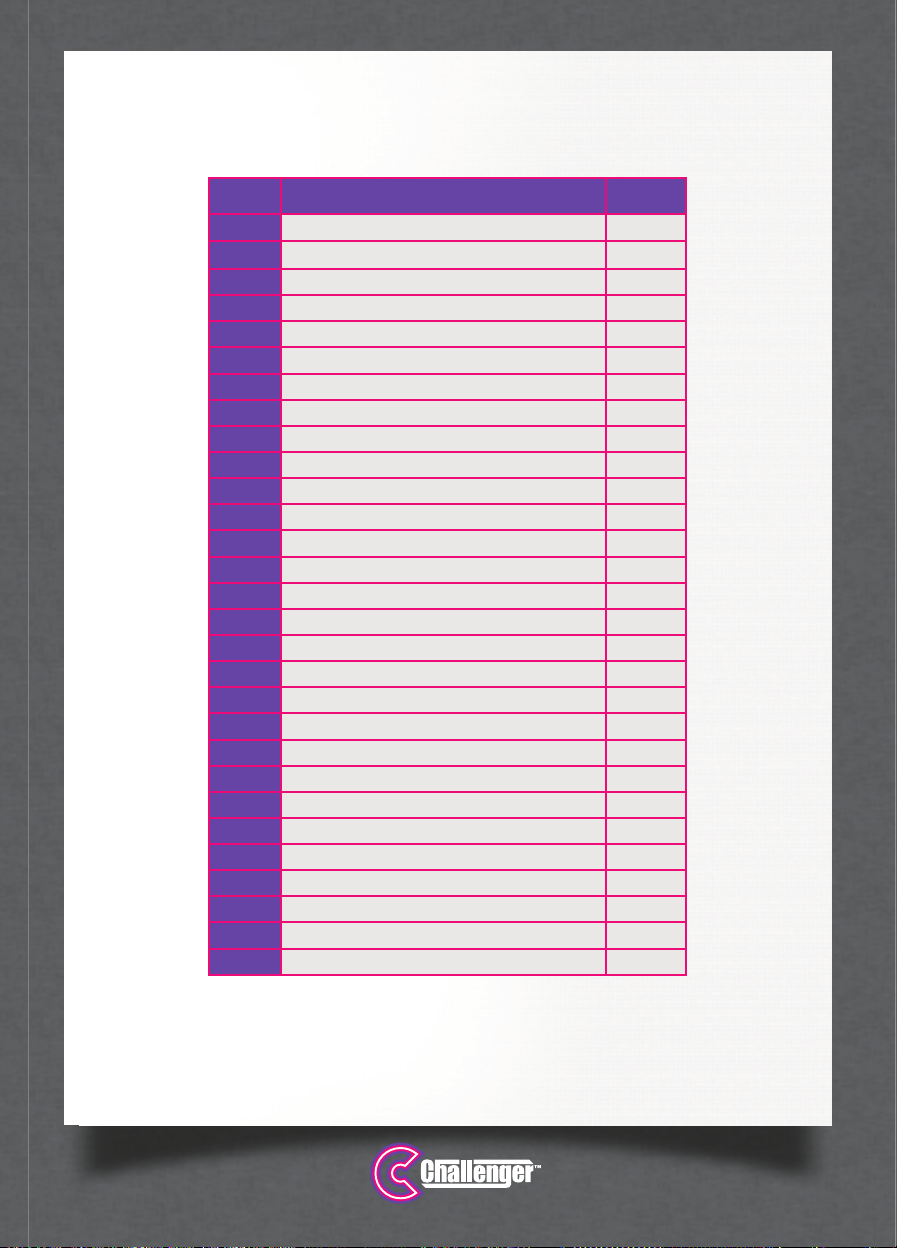

SPARE PARTS

www.jbstools.com 1313

SPARE PARTS

No. Description Qty.

1Electric appliance cap 1

2Cross recess head screw M6X16 11

3Embedded nut 8

4Electric cabinet 1

5Charger 12V/10A 1

6Anchor ear 1

7Storage battery 1

8Fixture 1

9Hexagonal socket head cap screw 2

10 Oil pump installation board 1

11 Pump station 1

12 Hexagon nut 4

13 Spring washer 6

14 Hexagonal socket head cap 2

15 Cross recess head screw 4

16 Hexagon nut 3

17 Flat washer 6

18 Conductor board 1

19 Full thread hexagon headed bolt 4

20 Emergency stop button 1

21 Voltmeter 1

22 Up switch 1

23 Down switch 1

24 Control wiring harness 1

25 Fuse holder 1

26 Fuse 1

27 Screw 2

28 Nut 2

29 Fuse 1

www.jbstools.com

14 WWW.CHALLENGERHOISTS.COM.AU

SPARE PARTS

www.jbstools.com 1515

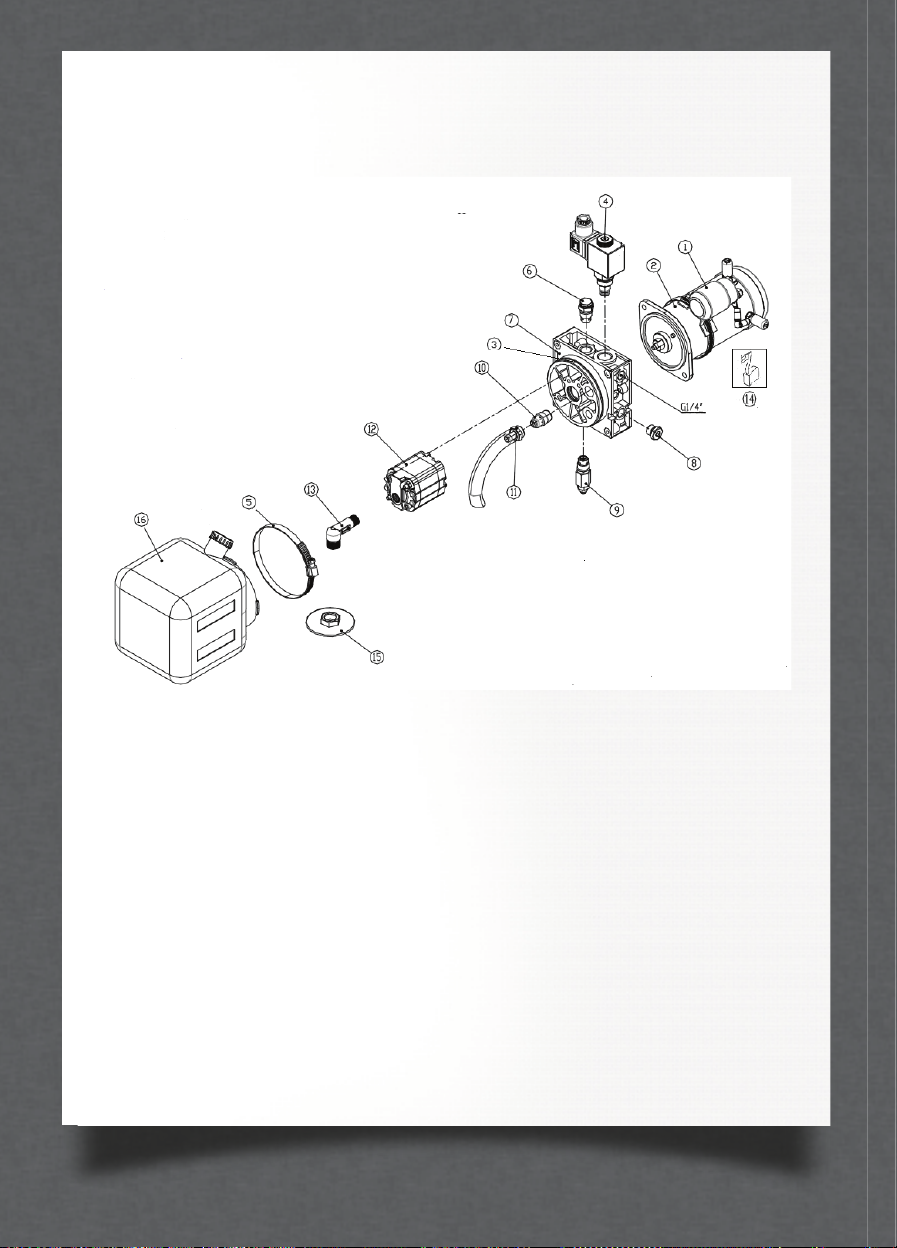

SPARE PARTS

No. Description Qty.

1Start switch 1

2Motor 1

3O-ring 1

4Solenoid pilot actuated valve 1

5Clamp 1

6Stop valve 1

7Central valve body 1

8Screw 1

9Safety valve 1

10 Flow control valve 1

11 Fuel return tube 1

12 Gear pump 1

13 Fuel suction tube 1

14 Carbon brush 1

15 Filter 1

16 Fuel tank 1

www.jbstools.com

16 WWW.CHALLENGERHOISTS.COM.AU

SPARE PARTS

www.jbstools.com 1717

SPARE PARTS

No. Description Qty.

1Piston rod 1

2Steel wire washer for shaft 1

3Piston 1

4Spring washer for shaft 1

5Dustproof ring 1

6Y sealing ring for shaft 1

7End cover 1

8O-ring 1

9Oil tank body 1

10 Composite gasket 1

11 Oil release screw plug 1

12 Composite gasket 2

13 Long joint 1

14 Safety valve 1

15 Joint body 1

16 Single 90° high-pressure oil pipe 1

17 Right angle adjustable joint 1

www.jbstools.com

18 WWW.CHALLENGERHOISTS.COM.AU

SPARE PARTS

www.jbstools.com 1919

INITIAL SERVICE DATE: SERIAL NO:

DATE NOTES AUTH SIGNATURE

Imported exclusively by Pacific Hoists Pty. Ltd. and Pacific Hoists Ltd.

For further information in relation to this product,

please contact the branch where the product was purchased.

HEAD OFFICE

24 Foundry Road, Seven Hills NSW 2147

National Sales & Service P: 02 8825 6900

www.challengerhoists.com.au

INSPECTION LOG

Thank you for choosing the Challenger brand. Not only are you

choosing a quality and reliable brand but you are also helping

to support cancer charities in Australia & New Zealand.

This manual suits for next models

2

Table of contents

Popular Forklift manuals by other brands

NIFTYLIFT

NIFTYLIFT SD50 Operation?and safety

EP Equipment

EP Equipment IMOW ICE251 Operation manual

Dieci

Dieci Apollo 25.6 Operation and maintenance manual

Xtreme Manufacturing

Xtreme Manufacturing XRM945 Operation & safety manual

Daewoo

Daewoo D20S-2 Specifications Systems Operation Testing & Adjusting Disassembly & Assembly

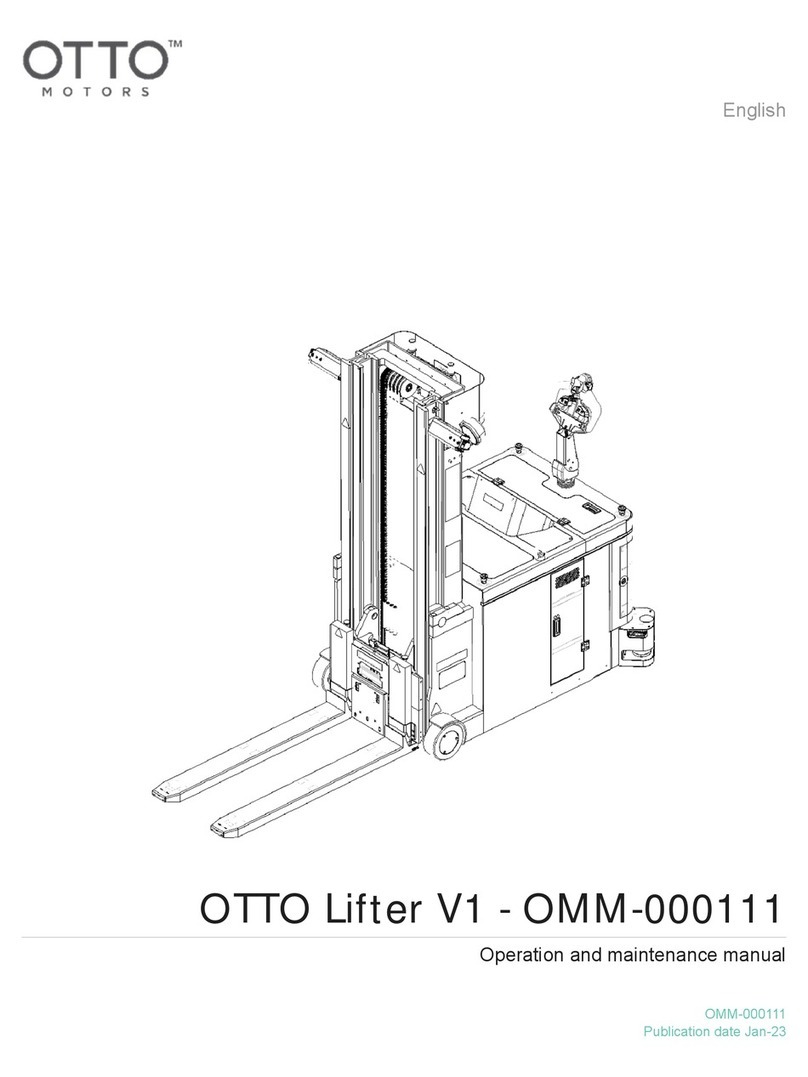

OTTO MOTORS

OTTO MOTORS Lifter V1 Operation and maintenance manual