Challenger 9316S User manual

Workshop Service Manual

Rotary Disc Header

9316S

9316D

North America

4205 River Green Parkway, Duluth GA 30096 USA

Challenger is a registered trademark of Caterpillar

Inc. and is used under license by AGCO.

© AGCO 2019

October 2019

79037417A

NA

English

CALIFORNIA

Proposition 65 Warning

WARNING: Diesel engine exhaust and some of its constituents are known to the State of

California to cause cancer, birth defects, or other reproductive harm.

WARNING: Battery posts, terminals and related accessories contain lead and lead compounds,

chemicals known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

Find manuals at https://best-manuals.com

1 General

1.1 General information .................................................... 1-3

1.1.1 Introduction to this service manual .......................................1-3

1.1.2 How to Use this Manual .............................................. 1-3

1.1.3 Units of measurement ............................................... 1-3

1.1.4 Table of contents ................................................... 1-4

1.1.5 Page numbers ..................................................... 1-4

1.1.6 Intended use ...................................................... 1-4

1.1.7 Proper disposal of waste .............................................. 1-4

1.2 Safety ................................................................. 1-5

1.2.1 Safety symbol ...................................................... 1-5

1.2.2 Safety messages ................................................... 1-5

1.2.3 Information messages ................................................1-5

1.2.4 Safety signs ....................................................... 1-5

1.2.5 A word to the technician .............................................. 1-6

1.2.6 The service manual .................................................. 1-7

1.2.7 Operation ......................................................... 1-7

1.2.7.1 Prepare for operation ....................................... 1-7

1.2.7.2 General information ........................................ 1-8

1.2.7.3 Personal protective equipment ................................ 1-9

1.2.7.4 Seat instructions .......................................... 1-9

1.2.7.5 Shield and guards ..........................................1-9

1.2.7.6 Exhaust warning .......................................... 1-10

1.2.7.7 Flying debris .............................................1-10

1.2.7.8 Handrails ............................................... 1-11

1.2.7.9 Agricultural chemicals ...................................... 1-11

1.2.7.10 Travel on public roads ...................................... 1-11

1.2.8 Maintenance ...................................................... 1-12

1.2.8.1 General maintenance information ............................. 1-12

1.2.8.2 Fire prevention and first aid .................................. 1-14

1.2.8.3 High pressure leaks ....................................... 1-15

1.2.8.4 Accumulator safety ........................................1-15

1.2.8.5 Tire safety .............................................. 1-16

1.2.8.6 Replacement parts ........................................ 1-16

1.2.8.7 Weld on the machine precautions ............................. 1-16

1.3 Machine identification ................................................. 1-18

1.3.1 Serial number plate ................................................. 1-18

1.3.2 Serial number description ............................................ 1-18

1.4 Service schedule ...................................................... 1-20

1.5 Lubrication details .....................................................1-21

1.5.1 Inspection during lubrication .......................................... 1-21

1.5.2 Lubrication fittings ..................................................1-21

1.5.3 Cutterbed drive gearboxes ............................................ 1-23

1.5.3.1 Gearbox plug location ...................................... 1-23

1.5.3.2 Examine the gearbox oil level ................................ 1-23

1.5.3.3 Change the gearbox oil ..................................... 1-24

1.5.4 Conditioner gearboxes ............................................... 1-25

1.5.4.1 Plug location - conditioner gearbox ............................ 1-25

1.5.4.2 Examine the gearbox oil level ................................ 1-26

1.5.4.3 Change the gearbox oil ..................................... 1-27

1.5.5 Cutterbed ........................................................ 1-27

Table of contents

Rotary Disc Header 1-1

79037417A

Find manuals at https://best-manuals.com

1.5.5.1 Cutterbed oil level ........................................ 1-27

1.5.5.2 Change the cutterbed oil ....................................1-27

1.6 Maintenance .......................................................... 1-30

1.6.1 Bolt torque values .................................................. 1-30

1.6.2 Remove a lock collar ................................................ 1-32

1.6.3 Install a lock collar .................................................. 1-32

1.7 Specifications ......................................................... 1-33

1.7.1 Dimensions and weights ............................................. 1-33

1.7.2 Header specifications ............................................... 1-33

1.7.3 Cutterbed specifications ............................................. 1-33

1.7.4 Cutterbed bolt torque ............................................... 1-33

1.7.5 Maximum roading speed ............................................. 1-34

1.7.6 Conditioner specifications ............................................ 1-34

1.7.7 Lubrication specifications .............................................1-34

1.8 Description ........................................................... 1-36

1.8.1 Cutterbed ........................................................ 1-36

1.8.2 Conditioner ....................................................... 1-36

1.8.3 Swathboard ...................................................... 1-37

1.8.4 Forming shields ....................................................1-37

1.9 Troubleshooting ....................................................... 1-38

1.9.1 Header troubleshooting .............................................. 1-38

1.9.2 Cutterbed troubleshooting ............................................ 1-39

1.9.3 Conditioner troubleshooting ........................................... 1-41

1.9.4 Crop conditioning and windrow formation ................................. 1-42

1.9.5 Cuto quality ..................................................... 1-43

1.10 Component access .................................................... 1-45

1.10.1 Component access ................................................. 1-45

1.10.2 Component location ................................................ 1-45

Table of contents

1-2 Rotary Disc Header

79037417A

Find manuals at https://best-manuals.com

1.1 General information

1.1.1 Introduction to this service manual

This service manual gives information from engineering tests, operating data, and the latest service

techniques at the time of publication. Read this service manual carefully before doing any service on the

machine.

The photos and illustrations used in this service manual were current at the time of publication. Production

changes can cause machines to vary from the photos and the illustrations. The manufacturer reserves the

right to redesign and change machines as necessary without notification.

WARNING:

Some pictures in this manual show the machine with shields or guards removed to permit

for a better view of the subject of the picture. All shields and guards must be in position

before operating the machine.

Machine movement when in normal use determines right-hand and left-hand.

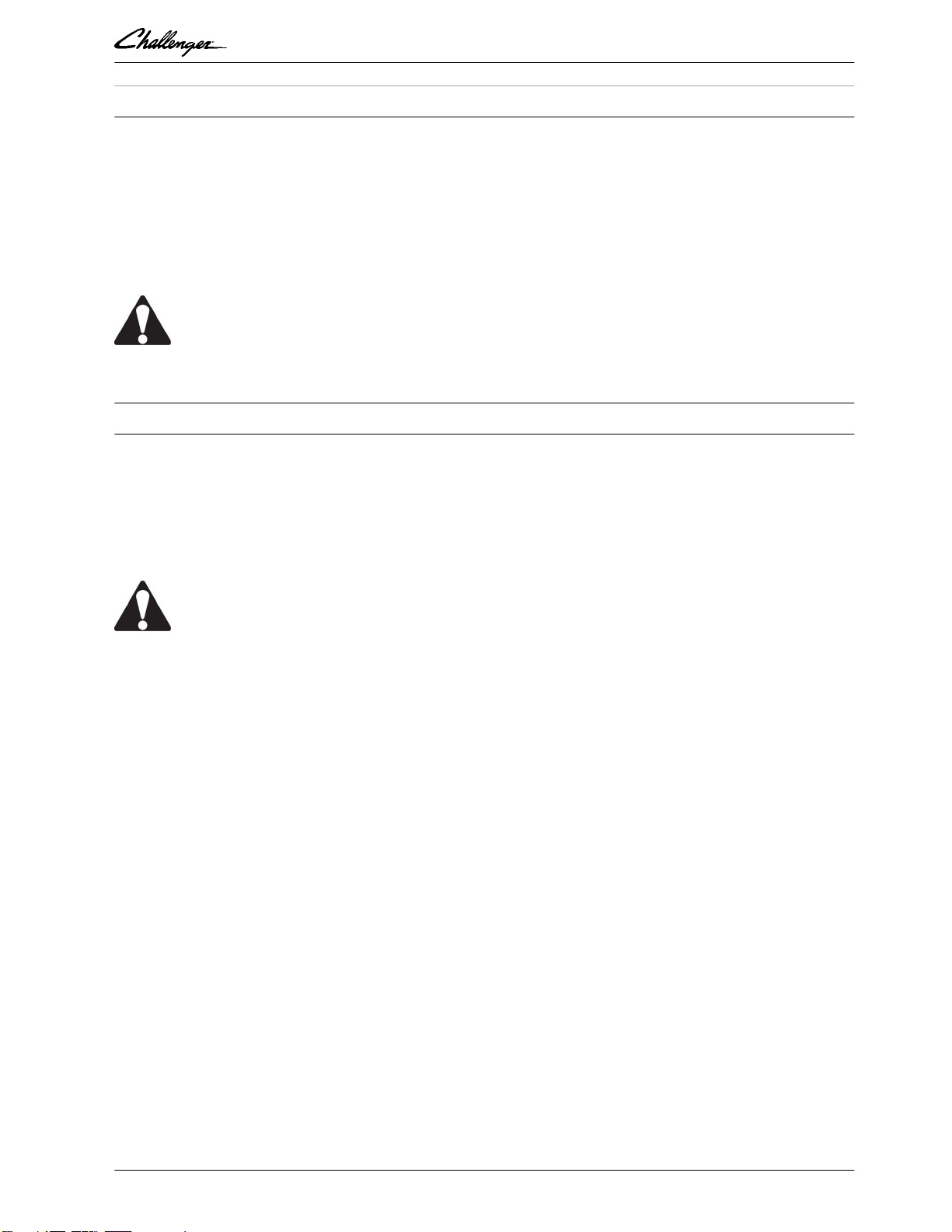

1.1.2 How to Use this Manual

Within this manual colour is put on images to aid the reader to further understand what to do with

components.

Task Colour Description Common Uses

Target/Focus Item

The main component that you use in the step is

this colour.

primary component, decal location,

component location

Connectors, Sealings, Fasteners, Fixings, Welds

All components that attach the primary component

to a dierent component.

bolts, nuts, electrical connector

First Alternative

If there are two primary components in the image,

one of the two components is this colour.

second main component

Second Alternative

If there are three primary components in the

image, one of the three components is this colour.

third main component

Special Tools

Where special tools or equipment are in an

illustration they are this colour.

pressure gauges, lifting equipment,

equipment specific tools

Parts that You Move

A part that you must move and that is not

necessary to remove from the machine.

electrical wires, hydraulic hoses

Sections

Where a cross section of a component is

necessary, this colour will show the component

that you see through.

component casings, gearboxes

1.1.3 Units of measurement

Measurements are given in metric units followed by the equivalent in US units. Hardware sizes are given in

millimeters for metric hardware and inches for US hardware.

[V]

GUID-D0FA2E94-0D28-42E9-A80B-6BB593BA9687 [V1]

GUID-1B0469EB-11DC-4D42-AAC1-A71974E3F602 [V1]

GUID-EBB3FCAE-8712-43A9-BB65-1DB48189C57C [V2]

1. General

Rotary Disc Header 1-3

79037417A

Find manuals at https://best-manuals.com

1.1.4 Table of contents

This manual has a table of contents at the front. The table of contents shows the divisions. The individual

divisions also have a table of contents.

1.1.5 Page numbers

All pages have two numbers, such as 01-25. The first number shows the division. The second number

shows the page in the division.

Page numbers occur on the lower right-hand or lower left-hand corner of each page.

1.1.6 Intended use

This machine is designed solely for use in customary agricultural operations.

Do not use this machine for any application or purpose other than those described in this manual. The

manufacturer accepts no liability for damage or injury resulting from misuse of this machine.

Compliance with the conditions of operation, service and repair as specified by the manufacturer constitute

essential elements for the intended use of this machine.

This machine should be operated, serviced and repaired only by qualified persons familiar with its

characteristics and familiar with the relevant safety rules and procedures.

All generally recognized safety regulations and road trac regulations must be obeyed at all times.

Any unauthorized modifications performed on this machine will relieve the manufacturer of all liability for

any resulting damage or injury.

1.1.7 Proper disposal of waste

Improper disposal of waste can pollute the environment and ecology. A few examples of potentially

harmful equipment waste can include, but not limited to, items such as oil, fuel, coolant, brake fluid, filters,

battery chemicals, tires, etc.

Use leak proof containers when draining fluids. Do not use food or beverage containers to collect waste

fluids, as food or beverage container(s) may mislead someone into drinking from them.

Do not pour or spill waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth's atmosphere. Government

regulations may require a certified air conditioning service center to recover and recycle used air

conditioning refrigerants.

Inquire with local environmental or recycling center on the proper way to recycle or dispose waste.

GUID-9BD2A110-651C-40FC-8D40-EDBAFD670A3C [V1]

GUID-6300C4A8-D25F-4B2F-BDC2-FAC58F99378B [V1]

GUID-939752D3-F912-4AFA-9CE0-FF5251AFAD3D [V3]

GUID-D27C9EFF-D3E3-4F5E-93ED-A6E5560C23DF [V3]

1. General

1-4 Rotary Disc Header

79037417A

Find manuals at https://best-manuals.com

1.2 Safety

1.2.1 Safety symbol

The safety symbol tells you about a potentially

hazardous area!

Look for the safety symbol in this manual and on

the machine. The safety symbols tell you that

there is important safety instructions in the

manual.

GUID-4C201302-DBD2-4BFB-8D98-1DDED263BD6E-high.jpg [High]

Fig. 1

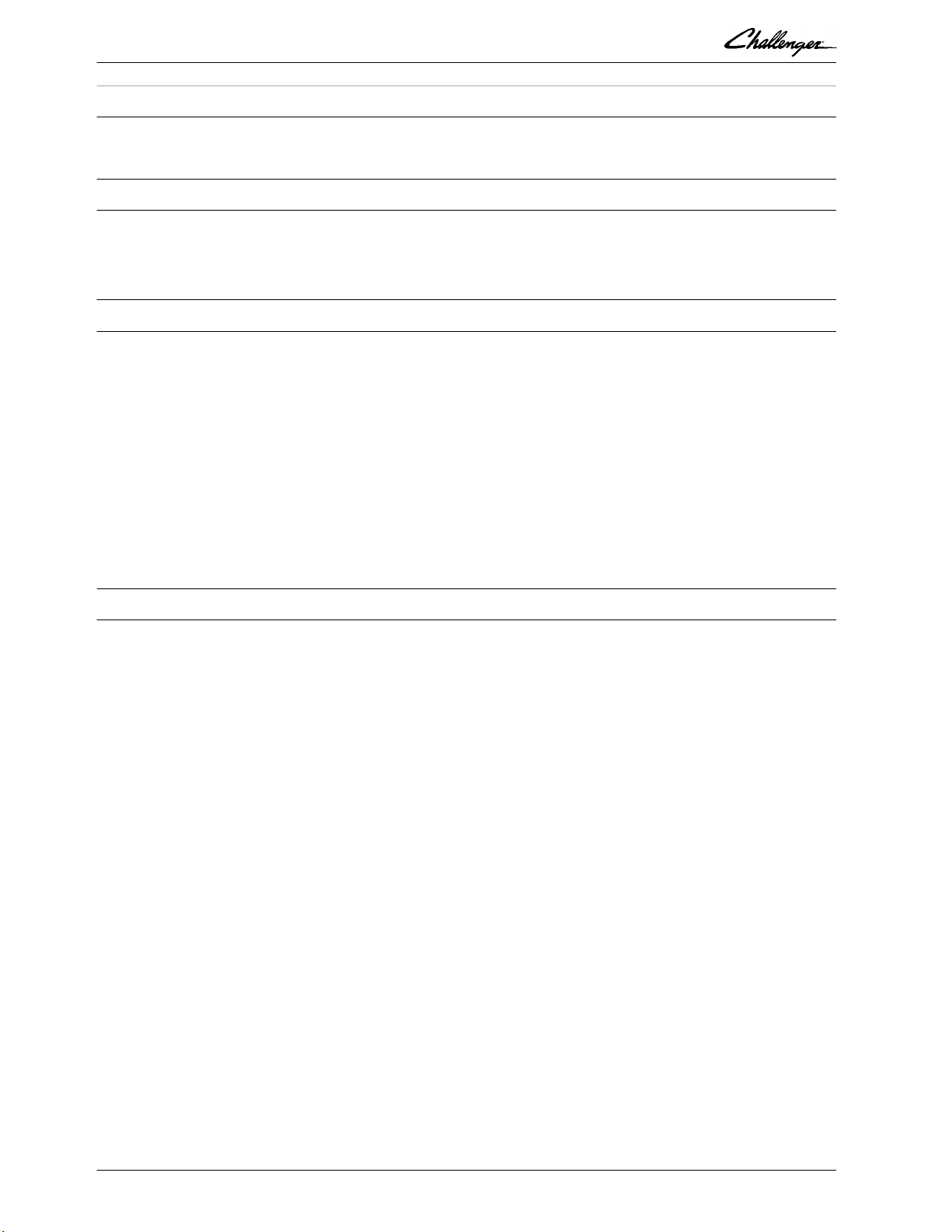

1.2.2 Safety messages

The words DANGER, WARNING or CAUTION are

used with the safety symbol. Learn these safety

messages and obey the recommended

precautions and safety instructions.

DANGER:

If you do not obey the recommended

precautions and safety instructions,

DEATH OR INJURY will occur.

WARNING:

If you do not obey the recommended

precautions and safety instructions,

DEATH OR INJURY can occur.

CAUTION:

If you do not obey the recommended

precautions and safety instructions,

INJURY can possibly occur.

GUID-73F05026-C37B-415A-8140-AD939A283378-high.jpg [High]

Fig. 2

1.2.3 Information messages

The words important and note are not related to personal safety, and are used to give information about

the operation and servicing of the machine.

IMPORTANT: Identifies special instructions or procedures which, if not followed, can cause damage to the

machine, the process, or the area around the machine.

NOTE: Information to make procedures easier.

1.2.4 Safety signs

WARNING:

Do not remove the safety signs. Replace safety signs that you cannot read, are damaged,

or are missing.

Clean the machine surface with a weak soap and water solution before you replace the safety signs.

Replacement safety signs are available from your dealer.

[V]

GUID-5D9F270E-D748-4741-82B1-BE49B78685F2 [V5]

GUID-E54F7740-C021-42A8-8784-4287BE4356C8 [V4]

GUID-9A909F52-D57E-4C30-8CC7-6FDB6D7E9982 [V3]

GUID-2FB17168-6A01-47C5-B298-234AF171520B [V7]

1. General

Rotary Disc Header 1-5

79037417A

Find manuals at https://best-manuals.com

Always make sure that safety signs are in the correct locations and that you can read the safety signs.

Illustrations of safety sign locations are in this section.

Keep the safety signs clean. If necessary, use a weak soap and water solution.

1.2.5 A word to the technician

Read and understand the safety section in this

service manual before operating or servicing the

machine. Read and understand the safety sections

in the manuals for all attachments before operating

or servicing attachments. The technician has the

key to safety. Good safety practices protect

everyone.

Study the safety information in this service

manual. Make the safety information a working

part of the safety program. The safety information

in this service manual applies specifically to this

type of machine. Always do all other usual and

customary safe working precautions. Remember -

The technician has the responsibility for safety.

Good safety practices can prevent serious injury or

death.

The safety section points out some basic safety

situations that can occur during the operation and

maintenance of the machine. The safety section

also suggests possible ways to deal with these

situations. The safety section does not replace

safety practices in other parts of this service

manual.

Practice good safety to help prevent injury or

death.

Learn how to operate the machine and how to use

the controls correctly.

Do not let other persons operate the machine

without instruction and training.

Follow all safety precautions and instructions in the

manuals and on safety signs axed to the

machine and all attachments.

Use only approved attachments and equipment.

Make sure the machine has the correct equipment

needed by the local regulations.

WARNING:

An operator should not use alcohol or

drugs which can aect their alertness

or coordination. An operator on

prescription or 'over the counter'

drugs needs medical advice on

whether or not they can properly

operate machines. If any attachments

used on this equipment have a

separate Operator Manual, see that

manual for other important safety

information.

GUID-AC91CCF6-1FF8-4A85-97A1-2D1562806825-high.jpg [High]

Fig. 3

GUID-3C35D58D-1F5D-4B85-A915-C7BB48F47262 [V1]

1. General

1-6 Rotary Disc Header

79037417A

Find manuals at https://best-manuals.com

1.2.6 The service manual

Read the table of contents and basic layout. Become familiar with all parts of this service manual. This

service manual gives the technician very important information.

Machine movement when in normal use determines right-hand and left-hand.

This manual covers general safety practices for this machine.

The photos, illustrations, and data used in this manual were current at the time of printing. Inline

production changes can make machines vary from the information in the service manual. The manufacturer

reserves the right to redesign and change the machine as necessary without notification.

WARNING:

In some of the illustrations and photos used in this manual, shields or guards may have

been removed for clarity. Never operate the machine with any shields or guards removed.

If the removal of shields or guards is necessary to make a repair, they must be replaced

before operation.

1.2.7 Operation

1.2.7.1 Prepare for operation

Read and understand the operating instructions and precautions in this manual before you operate or

perform service on the machine.

Make sure that you know and understand the positions and operations of all controls. Make sure that all

controls are in neutral and the parking brake is applied before you start the machine.

WARNING:

If the engine is running and the parking brake is not applied, the machine will turn if the

steering wheel is moved when the travel control lever is in neutral.

Make sure that all persons are a sucient distance from your area of work before you start or operate the

machine. Do checks on the controls and learn all controls in an area clear of persons and objects before

you start work with the machine. Know the dimensions of the machine and have sucient space available

for operation. Do not operate the machine at high speeds around persons, buildings, other equipment, etc.

Always use correct procedures when you do tasks around and operate the machine. Do not let children or

persons who do not know how to operate the machine operate the machine. Keep other persons away

from your area of work. Do not let other persons ride on the machine.

Make sure that the machine is in the good mechanical condition. Make sure that the machine has the

correct equipment as necessary by local regulations.

All equipment has a limit. Make sure you understand the speed, brakes, steering, stability, and load

characteristics of this equipment before you start.

GUID-0CC50E5C-AD62-4FFD-9435-62214FEFA5F4 [V1]

[V]

GUID-A9D74CBD-C409-4BEA-B8C1-A3DA5AE3C5EC [V5]

1. General

Rotary Disc Header 1-7

79037417A

Find manuals at https://best-manuals.com

1.2.7.2 General information

When parking, park the machine on a solid level

surface and lower the header to the ground. Put all

controls in neutral, and apply the parking brake.

Stop the engine and take the key with you.

WARNING: Whole body crushing

hazard. A loss of hydraulic pressure or

movement of the mechanism can

cause the raised machine component

to fall.

Personal injury or death can occur.

Install the lift cylinder stops before

working on the machine to prevent

movement.

Make sure the machine is in the proper operating

condition according to the Operator Manual.

Always operate the machine with the control

console turned on.

Do not dismount from moving machinery.

Stay o slopes too steep for operation.

Be aware of the size of the machine and have

enough space available to allow for operation.

GUID-E77631FB-0DC0-4637-9090-88018315176E-high.jpg [High]

Fig. 4

Stay o slopes too steep for operation. Keep the header as low as possible while going down hills. Never

suddenly reverse the wheels to stop or back up.

Where possible avoid operating the machine near ditches, embankments, and holes. Reduce ground speed

when operating on rough, slippery, or muddy surfaces and when turning or crossing slopes.

DANGER: Machine electrical shock

and electrocution hazard.

Personal injury or death can occur.

Keep the machine clear of overhead

electrical power lines.

GUID-DB0A93E4-AEB5-49D5-AC5F-DD1454F1CFC6-high.jpg [High]

Fig. 5

GUID-37023B41-C0ED-4F86-A909-1F42C1FE5D97 [V4]

1. General

1-8 Rotary Disc Header

79037417A

1.2.7.3 Personal protective equipment

Put on all personal protective equipment (PPE) and

protective clothes that are supplied to you or that

are necessary for the conditions and by applicable

laws. PPE includes equipment to prevent injury to

your eyes, lungs, ears, head, hands and feet.

Always keep hands, feet, hair, and your clothes

away from parts that move. Do not put on loose

clothing, jewelry, watches, or other items that can

tangle in parts that move. Tie up long hair that can

also tangle in moving parts.

GUID-1AEEBD1D-C71B-432C-9D23-52467D7C0BBF-high.jpg [High]

Fig. 6

1.2.7.4 Seat instructions

Put on the seat belt before you operate the

machine. Always sit in the seat and have the seat

belt on while you operate the machine. Replace

the seat belts when they become worn or broken.

Do not use a seat belt loosely. Make sure that

there is some tension on the seat belt. Do not

wear the seat belt in a twisted condition or

pinched between the structural parts of the seat.

Put on the seat belt if the instructional seat is

used. Use the instructional seat only to train new

operators or to find a problem. The instructional

seat is only for short periods of use.

Do not let children use the instructional seat or be

in the cab. Do not let other persons use the

instructional seat or be in the cab.

Drive the machine at slower speed and on level

ground when the instructional seat is used. Do not

start, stop, or turn quickly when the instructional

seat is used. Do not drive on highways or public

roads when the instructional seat is used.

GUID-5BA328EA-7732-4CE8-97B2-6511151E943C-high.jpg [High]

Fig. 7

1.2.7.5 Shield and guards

WARNING: Entanglement hazard.

Belts and components that rotate.

Severe personal injury or death can

occur.

Do not open, remove, or put your

hand behind shields if the engine is

running. Stop the machine before

doing service to the machine.

GUID-6163F2D6-39D6-48BF-871C-AC346EE022D2-high.jpg [High]

Fig. 8

GUID-7FEFA67B-E06F-4EFE-A23E-738FE96997E9 [V3]

GUID-F38524AD-E24F-4FCC-9154-E5357EFDE9D2 [V3]

GUID-9398BDE6-F83A-4855-B266-E86D0B48B9D7 [V10]

1. General

Rotary Disc Header 1-9

79037417A

All shields and guards must be in the correct position and in good condition. Keep away from the

components that rotate.

DANGER: Entanglement hazard.

Rotating components.

Severe personal injury or death can

occur.

Do not make adjustments or repairs

to components while they are

moving. Stop the machine before

doing service to the machine.

Do not operate the machine with the drive shaft

shields open or removed.

Keep away from the components that turn.

Make sure guards that turn are free.

GUID-CEB32148-1F4C-457C-ADF7-595DFC51AC25-high.jpg [High]

Fig. 9

Do not make adjustments to the roll tension with the header engaged.

When you make adjustments to the roll pressure, stop the header. Lower the header to the ground and

engage the parking brake. Set the engine to low idle.

1.2.7.6 Exhaust warning

WARNING: Inhalation hazard. Exhaust

gases.

Death or serious illness can occur.

Do not operate the engine in a closed

building unless the exhaust is

ventilated to the outside.

Do not tamper with or modify the exhaust system

with unapproved extensions.

GUID-55072A39-D882-4355-8ABA-05660F3F6EDA-high.jpg [High]

Fig. 10

1.2.7.7 Flying debris

WARNING:

Be careful when you operate along

the side of a road or structures. Rocks

and other materials can be thrown

from the machine during operation

and can cause injury.

If there are rocks and unwanted

objects in a field, tilt the header up.

This will lift the knives and reduce

other materials thrown by the knives.

Stay away from the machine during operation.

Some materials can be thrown from the machine

during operation and cause injury. GUID-1D480E10-339B-427D-9D05-37E84CC7A29A-high.jpg [High]

Fig. 11

GUID-AC6BA923-B398-43F4-BFAE-5130AFED6FC5 [V4]

GUID-3910D764-BEA7-4A1B-80BF-946E438C6212 [V5]

1. General

1-10 Rotary Disc Header

79037417A

1.2.7.8 Handrails

WARNING: Falling hazard.

Personal injury or death can occur.

Use appropriate safety precautions

when working o the ground.

Point your body in the direction of the ladder and

use the handrails when you are on the machine

ladders. Always keep three points of contact with

the ladder.

GUID-B4BF5956-B0F7-43A5-85C1-706D96BCA02B-high.jpg [High]

Fig. 12

1.2.7.9 Agricultural chemicals

Agricultural chemicals are very dangerous. Incorrect procedures with fertilizer, fungicides, herbicides,

insecticides and pesticides can cause injuries to plants, animals, soil and other persons property.

Always read and follow all manufacturers instructions before you open chemical containers.

Read and follow instructions each time you use a chemical.

Use the same precautions when you do adjustments, do servicing, clean or store the machine as used

when you put chemicals into the hoppers or tanks.

Tell all persons who are near chemicals of the possible dangerous results and the safety precautions that

are necessary.

Stay upwind and away from smoke from a chemical fire.

Keep or discard all chemicals that are not used as specified by the chemical manufacturer.

1.2.7.10 Travel on public roads

Make sure you understand the speed, brakes,

steering, stability, and load characteristics of this

machine before you travel on public roads.

Use good judgment when traveling on public

roads. Maintain complete control of the machine

at all times. Never coast down hills.

The maximum speed of farm equipment is

governed by local regulations. Adjust travel speed

to maintain control at all times. See the

specifications for the maximum speed for this

machine.

Familiarize yourself with and obey all road

regulations that apply to your machine. Consult

your local law enforcement agency for local

regulations regarding movement of farm

equipment on public roads. Use head lamps,

flashing warning lamps, tail lamps and turn signals,

day and night, unless prohibited by local law.

Make sure all the flashers are operating prior to

driving on the road. Make sure reflectors are

correctly installed, in good condition, and wiped

GUID-657D3002-48DB-436B-9B56-D3750095397D-high.jpg [High]

Fig. 13

GUID-DAAB4281-F045-467E-97A1-20DFD2BB692C [V4]

GUID-A494D2FA-1956-40C4-9743-052166A2A431 [V4]

GUID-9F5833EA-33BD-4C88-AA79-9433C36B3EF6 [V1.1.4]

1. General

Rotary Disc Header 1-11

79037417A

clean. If applicable, make sure the Slow Moving Vehicle (SMV) emblem is clean, visible, and correctly

mounted on the rear of the machine.

Be aware of other trac on the road. Keep well over to your own side of the road and pull over, whenever

possible, to let faster trac pass.

Be aware of the overall width, length, height, and weight of the machine. Be careful when transporting the

machine on narrow roads and across narrow bridges.

Watch for overhead wires and other obstructions.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

GUID-DB0A93E4-AEB5-49D5-AC5F-DD1454F1CFC6-high.jpg [High]

Fig. 14

1.2.8 Maintenance

1.2.8.1 General maintenance information

Before you do maintenance, lubricate, do

servicing, clean, or make adjustments:

• Park the machine on a solid, level surface.

• Make sure that all the controls are in the

neutral position and apply the parking brake.

• Make sure that the machine and the

attachments are lowered to the ground.

• Stop the engine and take the key with you.

• Look and Listen! Make sure that all parts that

move are stopped.

• Put chocks in front of and behind the wheels of

the machine before you do work on or below

the machine. GUID-DB4C2E27-9DAC-4734-83E4-BC4BB5C26EAF-high.jpg [High]

Fig. 15

Do not pull the crop or other object from the machine while the engine is in operation. Parts that move can

pull you into the machine before you can move out of the way.

After you do work on the machine, remove all tools from the machine.

Make sure that electrical connectors are clean before you connect them.

Do a check for loose, broken, missing, or damaged parts. Make sure that the machine is in good repair.

Make sure that all guards and shields are in position.

[V]

GUID-93C8628D-B392-4191-80DB-7D54BDAAF61B [V20]

1. General

1-12 Rotary Disc Header

79037417A

Do not do the servicing, examine or adjust chains

or belts while the engine is in operation.

GUID-7D1C9640-D737-4F38-8886-F1D2280DF613-high.jpg [High]

Fig. 16

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in drive

shafts that rotate can cause injury or death.

Stay clear of components that rotate.

Make sure that guards that rotate can rotate freely.

A loose yoke can come o a shaft and result in

injury to persons or damage to the machine.

When you install a quick disconnect yoke, the

spring activated locking pins must move freely and

be in the groove on the shaft. Pull on the driveline

to make sure that the quick disconnect yoke can

not be pulled o the shaft. GUID-CEB32148-1F4C-457C-ADF7-595DFC51AC25-high.jpg [High]

Fig. 17

Remove spilled oil, antifreeze or fuel immediately

from the steps, platform, and other access areas.

Keep all access areas clean of unwanted materials.

GUID-3B306DB1-0777-4FA6-86F1-895652B4C1DB-high.jpg [High]

Fig. 18

When you do work on the machine, make sure

that the header is lowered.

When it is necessary for the header to be in the up

position, lift the header to the full up position, stop

the engine, and take the key with you.

The header down valve on the windrower lift

cylinder keeps the header from lowering.

GUID-353ABA0B-44F7-4320-8E22-3E3CA612BD91-high.jpg [High]

Fig. 19

1. General

Rotary Disc Header 1-13

79037417A

1.2.8.2 Fire prevention and first aid

Be prepared for emergencies.

Keep a first aid kit available for use on small cuts

and scratches.

Keep one or more fire extinguishers of the correct

type. Examine fire extinguishers regularly as stated

by the manufacturer. Make sure that the fire

extinguishers are charged and in operating

condition.

Crop material is flammable, there is a risk of fire.

Use a water type fire extinguisher or other water

source for a fire in crop.

For fires in material other than crop, such as oil or

electrical components, use a dry chemical fire

extinguisher with an ABC rating.

Keep fire extinguishers easy to access where fires

can occur.

Frequently remove crop material from the machine

and examine for components that are too hot. Do

checks on the machine each day for noises that

are not usual. Unusual noises can indicate a worn

out component that can cause too much heat.

If flame cutting, welding, arc welding, or grinding

is to be done on the machine or attachments, clear

crop material and unwanted material from around

the area. Make sure that the area below the work

area is clear of flammable material because falling

molten metal and sparks can cause ignition in the

material.

GUID-FF34ACC9-D080-4CD5-9528-F426605803FF-high.jpg [High]

Fig. 20

If fire occurs, move upwind and away from the

smoke from the fire.

GUID-8FDCA67C-244A-40BA-967B-3FA4E7667A7E-high.jpg [High]

Fig. 21

GUID-9D716526-CF1A-4CD9-89A6-FD350D1B1E7A [V7]

1. General

1-14 Rotary Disc Header

79037417A

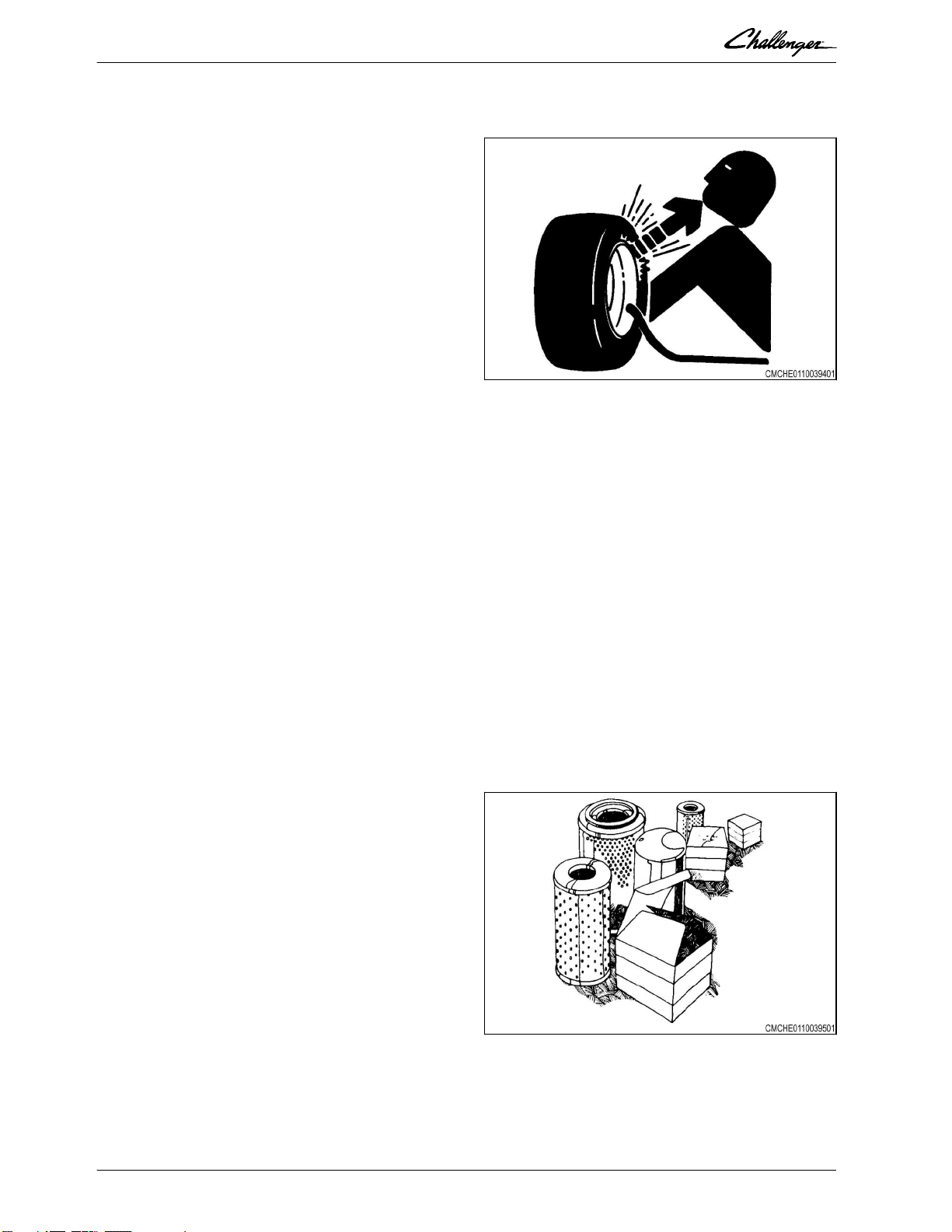

1.2.8.3 High pressure leaks

WARNING: Hydraulic fluid under

pressure can penetrate the skin or

eyes.

Serious personal injury, blindness, or

death can occur.

Relieve the pressure from the system

or component before disconnecting

components. Wear personal

protective gear while working on the

machine or equipment. Use a piece of

cardboard to check for leaks. Never

use your hand.

Fluid that leaks from the hydraulic system or the

fuel injection system is high pressure and is not

easily seen. The fluid can go into the skin causing

injury.

Fluid that is injected into the skin must be

surgically removed immediately. If not removed

immediately, infection and reaction can occur. Go

immediately to a physician who knows about this

type of injury.

GUID-CB450E2E-50DF-4D16-9E59-21C0B3E5B026-high.jpg [High]

Fig. 22

Use a piece of cardboard or wood to look for

possible leaks. Do not use your bare hand. Wear

leather gloves for hand protection and safety

goggles for eye protection.

Remove all pressure before you loosen hydraulic

lines. Lower equipment in the up position, close

the accumulator valve, and stop the engine.

Tighten all connections before you apply pressure.

GUID-9A83C5CD-95EC-445B-A3A7-1DCF8FACFE45-high.jpg [High]

Fig. 23

1.2.8.4 Accumulator safety

DANGER:

An authorized dealer must charge or

replace the accumulator.

The accumulator (1) is charged with dry nitrogen

gas. Use only dry nitrogen when the accumulator

is charged. Do not use air or oxygen or an

explosion will occur.

Nitrogen gas, when released can cause freezing.

Always wear protective gloves and glasses when

around nitrogen.

Do not let the accumulator fall. A charged

accumulator contains pressurized nitrogen. If the

shut o valve breaks away from the accumulator,

GUID-1CEC261C-CDBC-45D3-B0CD-6291C1CD0222-high.jpg [High]

Fig. 24

GUID-68111A90-0641-4B8F-9AB9-A5B05A044C46 [V4]

GUID-ACCC65E0-C566-4487-937B-F08D7800DB09 [V14]

1. General

Rotary Disc Header 1-15

79037417A

the nitrogen will make the accumulator move at a high rate of speed.

1.2.8.5 Tire safety

Examine tires for cuts, bulges, and correct

pressure. Replace worn or damaged tires. When

tire service is needed, have a qualified tire

mechanic service the tire. Tire changing can be

very hazardous and must be done by qualified tire

mechanic using proper tools and equipment.

Tire explosion and/or serious injury can result from

over inflation. Do not exceed the tire inflation

pressures.

Do not inflate a tire that is seriously under inflated

or has been run flat. Have the tire examined by

qualified tire mechanic.

Do not weld on the rim when a tire is installed.

Welding will make an air/gas mixture that can

cause an explosion and burn with high

temperatures. This hazard applies to all tires,

inflated or deflated. Removing air or breaking the

bead is not enough. The tire must be completely

removed from the rim prior to welding.

When preparing a calcium chloride solution for

fluid ballast the tractor tires, never pour water onto

the calcium chloride. A chlorine gas can be

generated which is poisonous and explosive. This

can be avoided by slowly adding calcium chloride

flakes to water and stirring until they are dissolved.

When seating tire beads onto rims, never exceed

2.4 bar (35 psi) or the maximum inflation pressure

specified on the tire. Inflation beyond this

maximum pressure may break the bead, or even

the rim, with explosive force.

GUID-CB65B01E-C8CB-43E0-A943-F2A9567A2E73-high.jpg [High]

Fig. 25

1.2.8.6 Replacement parts

Where replacement parts are necessary for

machine maintenance and servicing, you must use

original equipment replacement parts.

The manufacturer will not accept responsibility for

installation of unapproved parts and/or accessories

and damages as a result of their usage.

GUID-FA132350-A260-454E-8B83-2C8533C34BC4-high.jpg [High]

Fig. 26

1.2.8.7 Weld on the machine precautions

Before you weld on the machine:

• Disconnect battery terminals and put them out of the way.

GUID-E28CEEE8-E160-49B0-8080-8D193B1B4E86 [V7]

GUID-6AE94B75-99EC-4885-8B3D-0F13F3053F2B [V3]

GUID-7B2E9698-3825-4CA4-B43F-399992FDE1BF [V1]

1. General

1-16 Rotary Disc Header

79037417A

• Disconnect all controllers and monitors.

• Connect the welding ground as close as possible weld area.

If you do not disconnect the electrical components, the component can be damaged.

When you connect the electrical connections, connect the battery cables last.

1. General

Rotary Disc Header 1-17

79037417A

This manual suits for next models

1

Table of contents