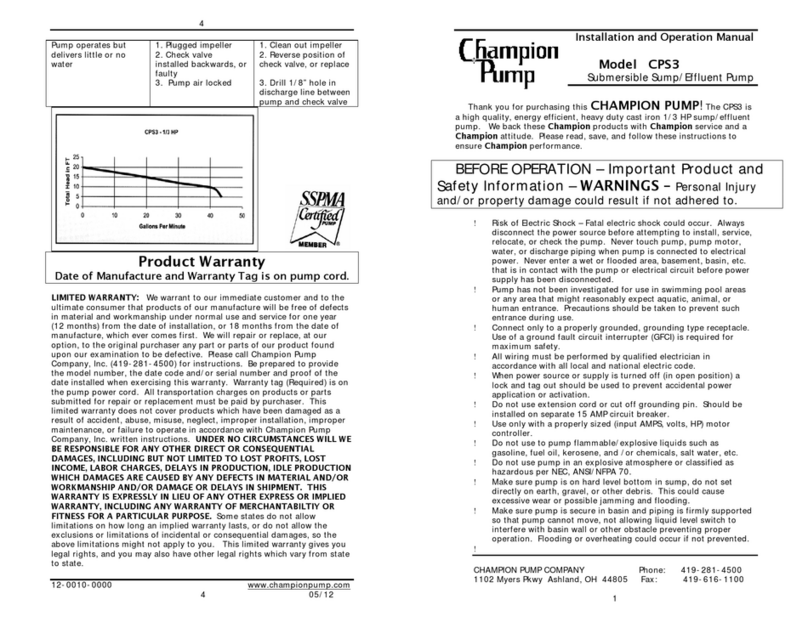

8

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

Pre-Operation

1. Check Voltage and Phase

Compare the voltage and phase

information stamped on the pump

name plate.

2. Check Pump Rotation - Improper

motor rotation can result in poor

pump performance and can damage

the motor and/or pump. Check

rotation on three phase units by

momentarily applying power and

observe the “kickback”.

Kickback should always be in a

counter-clockwise direction as

viewed from motor end or opposite

to impeller rotation. Incorrect rotation

for Single-Phase pumps is unlikely.

If the rotation is incorrect contact

factory.

3. Name Plate - Record the information

from the pump name plate to

drawing in front of manual for future

reference.

4. Insulation Test - An insulation

(megger) test should be performed

on the motor. Before the pump is put

into service. The resistance values

(ohms) as well as the voltage (volts)

and current (amps) should be

recorded.

5. Pump-Down Test - Be sure pump

has been properly wired, lowered into

the basin, sump or lift station, check

the system by lling with liquid and

allowing the pump to operate through

its pumping cycle. The time needed to

empty the system, or pump-down

time along with the volume of water,

should be recorded.

Maintenance

No lubrication or maintenance is required.

Perform the following checks when pump

is removed from operation or when pump

performance deteriorates:

a). Inspect motor chamber for oil level

and contamination.

b). Inspect impeller and body for

excessive build-up or clogging.

c). Inspect motor and bearings.

d). Inspect seal for wear or leakage.

Servicing

NOTE: Item numbers in ( ) refer to Figures

7 & 8.

Cooling Oil - Anytime the pump is

removed from operation, the cooling oil

in the motor housing should be checked

visually for oil level and contamination.

To check oil, set unit upright. Remove

pipe plug (30) from housing (8). With

a ashlight, visually inspect the oil in

housing (8) to make sure it is clean and

clear, light amber in color and free from

suspended particles. Milky white oil

indicates the presence of water. Oil level

should be just above the motor when

pump is in vertical position.

Oil Testing

• Drain oil into a clean, dry container by

placing pump on it’s side, remove pipe

plug (30), from housing (8).

• Check oil for contamination using an

oil tester with a range to 30 Kilovolts

breakdown.

• If oil is found to be clean and

uncontaminated (measuring above

15 KV. breakdown), rell the housing.

• If oil is found to be dirty or

contaminated (or measures below

15 KV. breakdown), the pump must

be carefully inspected for leaks at the

shaft seal, cable assembly, square ring

and pipe plug, before relling with oil.

Tolocate the leak, perform a pressure

test.

After leak is repaired, dispose of old oil

properly, and rell with new oil.

Pressure Test (If oil has been drained)

Remove pipe plug (30) from housing (8).

Apply pipe sealant to pressure gauge

assembly and tighten into hole. Pressurize

motor housing to 10 P.S.I. Use soap

solution around the sealed areas and

inspect joints for “air bubbles”.

If, after ve minutes, the pressure is still

holding constant, and no“bubbles”are

observed, slowly bleed the pressure and

remove the gauge assembly. Replace

oil. Leek must be located and repaired if

pressure does not hold.

Pressure Test (If oil has NOT been

drained) - Oil should be at normal level.

Remove pipe plug (30) from housing (8).

Apply pipe sealant to pressure gauge

assembly and tighten into hole. Pressurize

motor housing to 10 P.S.I. Use soap

solution around the sealed areas above the

oil level and inspect joints for“air bubbles”.

For sealed areas below oil level, leeks will

seep oil. If, after ve minutes, the pressure

is still holding constant, and no“bubbles”/

oil seepage is observed, slowly bleed the

pressure and remove the gauge assembly.

Replace oil. Leek must be located and

repaired if pressure does not hold.

Installation & Service

Figure 2