Champion Pump CPES Series User manual

Other Champion Pump Water Pump manuals

Champion Pump

Champion Pump CPSTEP5 Series User manual

Champion Pump

Champion Pump CPU 16 User manual

Champion Pump

Champion Pump CPG3022 User manual

Champion Pump

Champion Pump CPG 2HP Grinder Series User manual

Champion Pump

Champion Pump CPS5 User manual

Champion Pump

Champion Pump CPES5 User manual

Champion Pump

Champion Pump CPSE User manual

Champion Pump

Champion Pump CPS33V User manual

Champion Pump

Champion Pump CP4NC Guide

Champion Pump

Champion Pump CPS5HT User manual

Popular Water Pump manuals by other brands

Grundfos

Grundfos MTH Series Installation and operating instructions

IBO

IBO MAGI 2 25-80/180 manual

Grundfos

Grundfos UNILIFT AP35B Installation and operating instructions

Server

Server FP-1/9 manual

Xylem

Xylem LOWARA e-SV Series Additional Installation, Operation and Maintenance Instructions

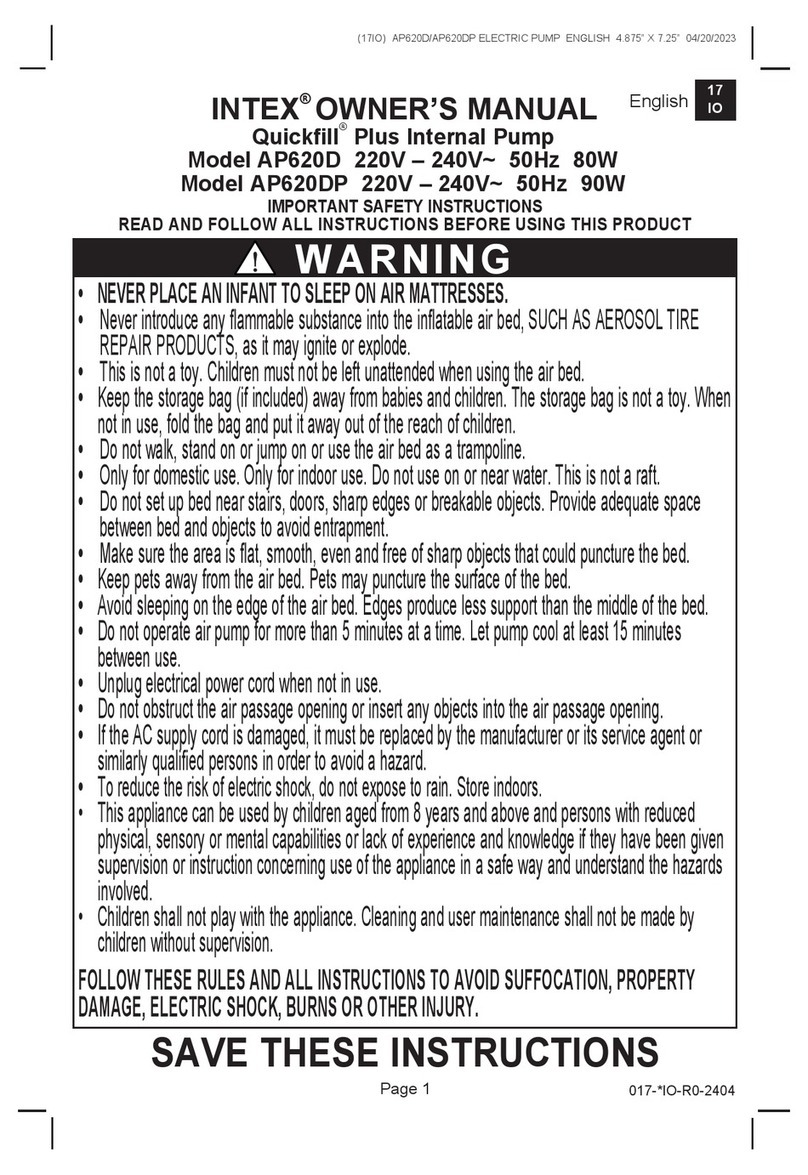

Intex

Intex Quickfill AP620D owner's manual

Scheppach

Scheppach GP1000 Jet LCD Translation of original instruction manual

SKF

SKF TMJG 100D Instructions for use

Utilitech

Utilitech PPSU33 user manual

Covidien

Covidien Kangaroo ePump Instructions for use

Yenen

Yenen LPG Installation, operation & maintenance manual

DIVERSITECH

DIVERSITECH CP-22LP-P Installation