Chang Fa 185 Series User manual

185 SERIES

DIESEL ENGINE

OPERATION MANUAL

Changfa Power Machinery Co.,Ltd

Changzhou, Jiangsu P.R. China

Please read this

operation Instructions,

before operating

CHANG FA

https://truckmanualshub.com/

1

Changfa Power Machinery Co., Ltd has met the ISO9002 Quality

Assurance System by authentication

https://truckmanualshub.com/

CONETENS

Precaution ………………………………………………………………………………………1

Section One Principal Technical Specification ………………………………………………2

Section Two Operation of Diesel Engine ……………………………………………………4

1. Preparation before Diesel engine ……………………………………………………………4

2. Examination ……………………………………………………………………………………4

3. Start –up of operation ……………………………………………………………………5

4. Examination during Operation ……………………………………………………………6

5. Shut-up of Engine ……………………………………………………………………6

Section Three preservation and Storage…………………………………………………………7

Section Four Maintenance and Service ……………………………………………………8

Section Five Matters Needing Attention in Operation …………………………………9

Section Six Dismounting and Re- assembly ………………………………………10

Section Seven Lighting Generator and Circuit ……………………………………………12

Section Eight Main parts Catalog ………………………………………………………12

1. Engine Body Assembly(Model R185)……………………………………………………13

2. Engine BodyAssembly(Model CF185N and JM185N)………………………………14

3. Condensing Cooling System (Model R185)……………………………………………15

4. Condensing Cooling System(Model CF185N,JM185N)……………………16

5. Cylinder Head Assembly ………………………………………………………………17

6. Piston Rod Assembly ……………………………………………………………………18

7. Crankshaft Assembly ……………………………………………………………………19

8. Camshaft Assembly ……………………………………………………………………20

9. Balance System ………………………………………………………………………21

10. Intake System ………………………………………………………………………22

11. Exhaust System ………………………………………………………………………23

12. Lubrication System ………………………………………………………………………24

13. Fuel System(Model R185)…………………………………………………………25

14. Fuel System(Model CF185N,JM185N)………………………………26

15. Governor System(Model R185)………………………………………………………27

16. Governor System(Model CF185N,JM185N)……………………………………28

17. Injection Pump Assembly ……………………………………………………………29

18. Injector Assembly ………………………………………………………………30

19. The part of Motor starting engine for R185M、CF185M and JM185M……31

Attachment: list of Spares Parts Supplied with the engine shipment ……………………32

https://truckmanualshub.com/

1

Precautions

1. Don’t touch the heating and turning parts.

2. Don’t let those people enter into the operating place, for the children, slow-action old man,

epileptic or the man who has no disposing capacity.

3. Don’t make the engine operate for a long time without operator.

4. As for the performance, please read the performance specification attached for reference Don’t

operate the engine in over-speed and over-load.

5. After starting, allow the engine idle operating in 3~5minutes and it is prohibited to run the

engine in high speed and over-load.

6. Don’t set the adjusting screw of governor system to make the engine operate in over speed.

7. Don’t shutdown the engine by means of push down decompression lever unless heavy accident

happens

8. Don’t feed the salt-water or dirty water into water tank.

9. Feed and replace the fuel and lubricating oil stipulated in Operation Manual.

10. Feed the lubricating oil in air filter according to the requirement of Operation Manual.

11. Ensure that the red(blue) floater is not below the hopper of water tank during its boiling water

operation.

12. As soon as engine starts, starting handle leave off automatically. It is necessary to hold the

starting handle to avoid it to fly out.

13. In the climate below 0℃, to prevent the cylinder block and head from breaking, the cooling

water should be drained in good time.

14. Firmly fasten the connections between the engine and the working machine and take the

necessary protecting measure in pulley belt area.

15. If there are some trouble occurring, keep the damaged site in original situation and settle it

after consultation between sales agent and repairman.

16. Run in and maintain the engine according to the requirements of Operation Manual.

As the diesel engine is now improving constantly, and there maybe some difference

between the manual and the diesel engine, and we will correct it when we revise the manual,

Please forgive us for this matter.

https://truckmanualshub.com/

2

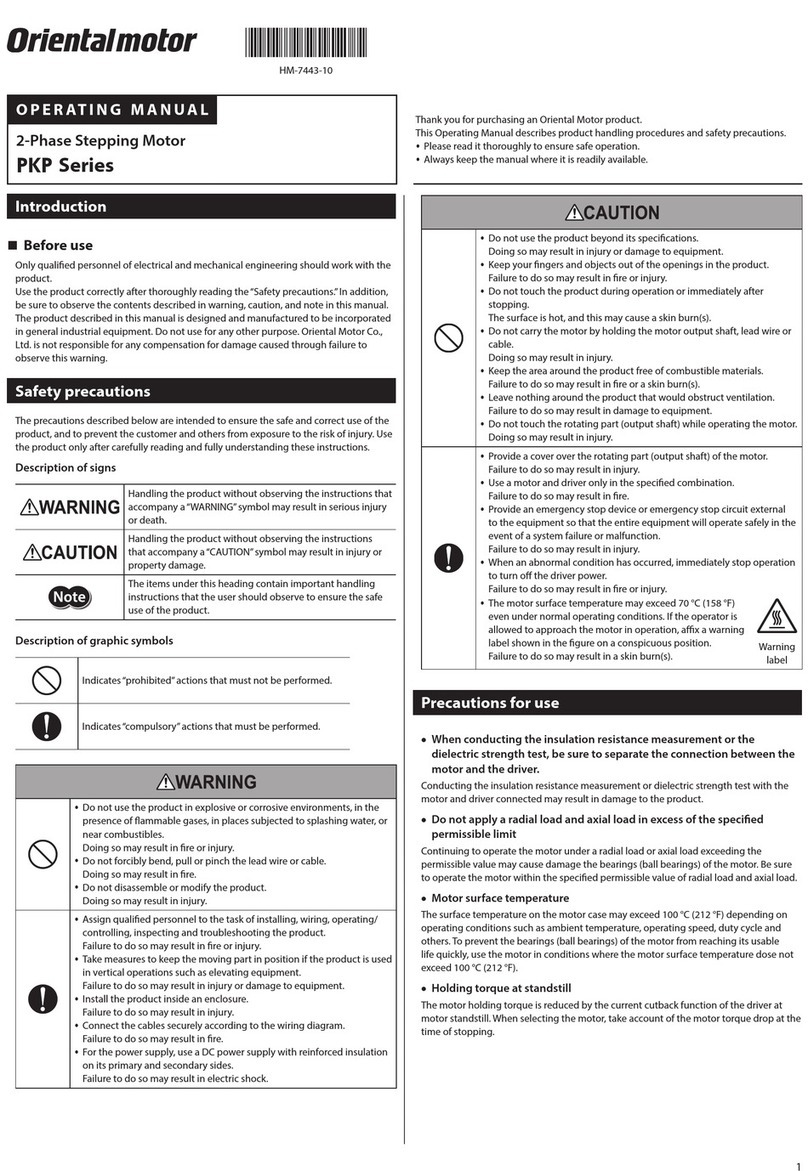

Overall and Mounting Dimensions of R185 Diesel Engine

Overall and Mounting Dimensions of CF185 Diesel Engine

700

https://truckmanualshub.com/

3

Section.one. Principal Technical Specifications

Model R185(M), CF185(M), JM185(M)R185N,CF185N, JM185N

Type Single-cylinder, horizontal, four-stroke, Water cooling

Cylinder bore 85mm

Piston stroke 90mm

Piston displacement 0.51L

12-hour power 5.88 kW

1-hour power 6.47kW

Rating rotation speed 2200r/min

Compression ratio 21

B.M.E.P.628kPa

Specific Fuel consumption ≤274.7g/kW·h ≤281.5g/kW·h

Injection pressure 13.5±0.5 MPa

Cooling method Water-evaporative Water-radiator

Starting method Hand starting (motorstarting) Hand starting

Net. Weight ≤95kg ≤98kg

Overall dimensions 700×390×570 730×390×570

Intake valve 0.25±0.05mm

Valve clearance (cold

engine) Exhaust valve 0.25±0.05mm

Torque of cylinder head nut 190 N·m 210N·m

Torque of flywheel nut 260N·m~300 N·m

Torque of connecting rod bolts 70 N·m ~90 N·m

Fuel injector type P664

Fuel injector nozzle ZS4S1A

Fuel injection pump

type B11-02A fuel injection pump

Generator Flywheel AC generator

Intake valve

open 16º before T.D.C.

Intake valve

close 38º after B.D.C.

Exhaust valve

open 50º before B.D.C.

V

alve

T

iming

Exhaust valve

close 14º after T.D.C.

Fuel injection timing 16º±1º before T.D.C.

https://truckmanualshub.com/

4

Section Two Operation of Diesel Engine

1. Preparation before Operation

1.1 Check the bolt of engine bed and tension of pulley

belt.

1.2 Remove the exhaust pipes. Put the starting crank

in the starting shaft, turn the De-compression

lever with your left-hand and crank the engine to expel

out the anti-rusting oil applied in the cylinder

until no oil flows out from the exhaust port. Then reinstate

the exhaust pipe (see Fig.1.)

1.3 Diesel fuel

Use light diesel fuel #0 in summer, # -10 or # -20 in winter.

Caution: Pour clean diesel fuel into fuel tank. Do not get into any dust.

1.4 Lubricating oil

Use lubricating oil # CC15W/40 in summer or #CC15W/30 in winter.

Caution : The level must not go over the upper line, nor fall down below the lower one on

the dipstick, when the engine is in operation.

1.5 Let the engine run in for 20 hours, subject to light load. After running fore a period, retighten

any bolts and nuts that are loose.

Renew the lubricating oil after 40 hours of operation. Renew again after 60 hours and

thereafter once every 100 hours.

2. Examination before Start-up

2.1 Cooling system

⑴Cooling water

①In high temperature operation, hard water and dirt water shall about the sediments, which

are stuck on the parts in the cooling system. They are low in diathermancy and block the pipes

resulting in bad cooling effect. The clean soft water shall be used in cooling system.

②Water Tank

Pour the cooling water into the water tank

Below the bottom of hopper.

(2) Condenser

①Unscrew the water-filling cover.

②Fill cooling water fully.

③Screw the water filling cover again.

④Check the tension of fan belt and

adjust by changing the position of tension

pulley. When adjusting , a force of 19.6N.m~

29.4N.m is exerted on the middle of belt with finger. It is Fig.2. Adjusting the

Decompression lever

Oil indicator

Fig.1 Expelling antirust oil

About10 m

m

https://truckmanualshub.com/

5

tension of belt

appropriate tensity for belt to leave away 10 mm distance from original

position(See Fig.. 2).

2.2 Lubricant oil

(1)Check the oil level in engine oil tank with oil dipstick, nearly

close to the upper scale line on oil dipstick (See Fig.. 3).

(2)When checking ,do not make the oil dipstick enter into screw

hole and keep the diesel engine in horizontal position.

(3)Check the lubricant flow in circulation. Hold the relief handle with left hand and slowly

crank the starting until the cap of oil indicator rises(See Fig .4).

if it does not rise , it means there some faulty in lubricating system.

Model CF185N or JM185N engine adopts a diaphragm

oil-indicator, it means the pipeline works normally.

2.3 Fuel

(1)Fill he cleaning diesel fuel in fuel tank as required

according to the ambient temperature. When filling, the tools for

filling should be clean. Don’t allow dust or dirt gets into the tank.

(2)Open the fuel switch on.

2.4 Air cleaner

Unscrew the cap of air cleaner and add the engine oil to the level

shown in Fig.5(or depending on the nameplate on housing).

3. START

3.1 Start-up diesel engine with the starting handle (See Fig.6).

(1)Insert the starting handle on starting shaft.

(2)Crank the starting handle and engine oil circulating.

(3)Pull the governor handle to“run”position. Move the Decompression lever and crank the

starting shaft at same time, hearing the injecting sound from the injector. If no injecting sound

Fig.3Checking engine oil

Fig .4 Indicator cap rising

Oil level Decompression level Startin

g

crank

Governor ha

ndle

Fi

g

.5 Oil Level inAir cleane

r

Fig.6 Starting engine with handle

https://truckmanualshub.com/

6

heard, it is necessary to drain the air form oil pipeline.

(4)When normally injecting, speed up rotation of starting shaft and Suddenly release the

compression lever to no-relief position, and then crank the starting handle two or three revolution,

the diesel engine can start.

(5)when the diesel engine has just started, it is necessary to continue to hold the starting

handle until it is pushed naturally from starting shaft.

3.2 Pull the governor handle to middle position and operate the engine for several minutes with no

load.

4. ExaminationduringOperation

4.1 Cooling water

Check the amount in water tank and add the water if

necessary.

As for the condensing engine, it is not necessary to add the water

in condenser. Don’t open the cover to avoid during.

4.2 Lubricating oil

Check the indicator cat rising up in normal condition, if not,

shut off the engine for checking (see Fig.7).

4.3 Exhausting

If the engine exhausts the black smoke, it means overload (See Fig.8).

4.4 Abnormal noise

If an abnormal noise is heard during the operation of engine,

shut off the engine immediately and check for remedy of trouble

5 Shut off of engine

5.1 Unload engine and pull the governor handle to right to allow

the engine to idle several minutes in unloading.

5.2 Pull the governor handle to “STOP” and engine stops(See Fig.9)

5.3 Turn the fuel cock to “OFF”(See Fig .10)

Fig.7Engine oil indicator

Fig.8 Engine exhausting black smoke

run

Sto

p

On

Off

Fig.9 Governor handle

Fig.10 Fuel cock

https://truckmanualshub.com/

7

5.4 If it is forecast that the frozen climate shall be, drain out

the cooling water in water tank, even for several hours (See

Fig 11).

5.5 When the engine has just stopped, Don’t open the cap of

condenser to avoid hurting by hot water.

Section Three Preservation and Storage

1. Drain out the cooling water, Lubricating oil and diesel

Fuel (See Fig.12)

2. Clean the certain parts and components.

3. Shut off intake and exhaust valves:

(1) Turn the flywheel slowly with hand until you feel dragging.

(2) Turn the decompression lever to pull the compressed air out turn the flywheel a further

quarter revolution until its TDC mark is in line with the pointer on the hopper or fan cover, it

denotes that two valves are closed (See Fig. 13).

4 A dust cover is put over the engine, which is cooled. The diesel engine should be stored in clean

and dry place.

Fig.11 Draining out cooling water

Fig.12 Draining lubrication oil and Fig 13 Piston located in top dead center

https://truckmanualshub.com/

8

Section four: Maintenance and service

Item Daily 100 hours 500 hours

(1) Check and fill fuel ···

(2) Clean fuel filter ··

(3) Clean fuel tank and pipeline ·

1.Fuel syste

m

(4) Check injection pump and injector ·

(1) Check and add oil ···

(2) Clean oil Strainer and sump ··

(3) Clean oil bath and pipeline ·

2. Lubricating

oil

(4) Replace Lubricating oil ··

(1) Clean intake pipe and air filter ···

(2) Clean exhaust pipe and silencer ·

(3)Check valve Clearance ※·

3.Exhaust and

intake

(4) Check valve leak tightness ·

(1) Check and add water ···

(2) keep cooling water running smoothly ··

(3) replace cooling water ※··

4.Cooling

water

(4)check fan-belt tightness ···

(1)Check all important bolts and nuts ·

(2) check piston ring ·

5.Others

(3) Clean carbon deposits of piston ·

Note: ※Daily check shall be made if required.

https://truckmanualshub.com/

9

Section Five Matters NeedingAttention in Operation

1 Condenser

1.1 Open the drain plug below cylinder head. unscrew the filling cap, crank the starting handle and

drain the cooling water in condenser.

1.2 Remove the guard net and clean up the dust and dirt form condenser and guard net with brush

or compressed.

2Filter element

2.1 De-dust strainer element of paper air cleaner with soft brush.

2.2 Clean up the fuel element and engine oil filter element with brush and diesel oil or kerosene.

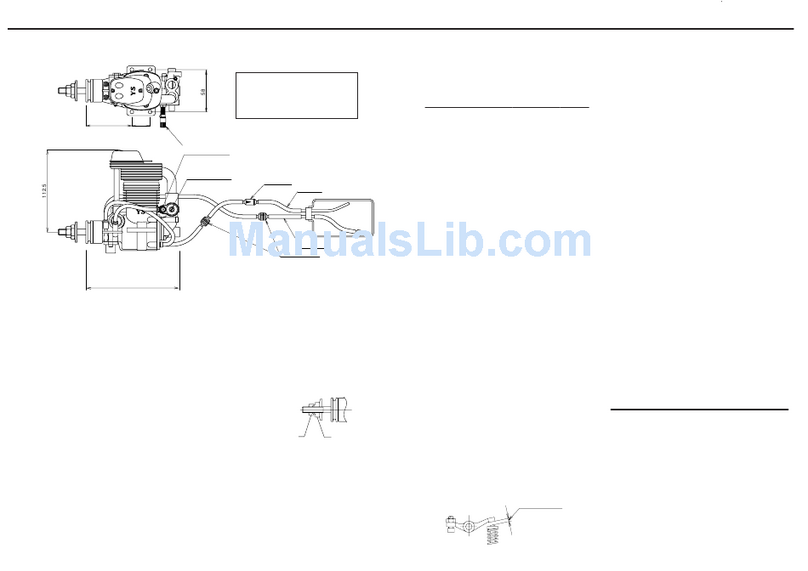

3Injection nozzle

3.1 Remove the couple parts of nozzle, draw out the needle valve and put them into the diesel oil

for cleaning.

3.2 Clean up the carbon deposit on needle couples with sharp wood stick or copper wire brush and

diesel fuel (See Fig.14 and Fig. 15).

3.3 Put the nozzle couples into cleaning diesel oil with rotating and drawing backward and forward

in needle valve body (See Fig. 16 ) .

3.4 Draw out the needle valve body, coat a little engine oil on the needle valve and insert it into

valve body again and polish several time, and then clean them with cleaning diesel fuel.

3.5 Check the spraying quality of injector that the injector

has a Fine atomized spraying and no oil drops exist around

the nozzle (See Fig. 17).

4 Inlet air valve and exhaust air valves

The clearance of inlet air valve and exhaust air valve is

0.25mm when the engine is cold.

5 Piston Ring

When the piston ring is fixed on piston, the sharp surface of

ring is directed to piston skirt and the marked with “ T ” is

faced to piston top.

6 rocker arms

The exhaust air valve rocker has no oil spit orifice, So don’t make wrong in mounting.

Fig. 14 Cleaning up the

carbon on

Fig. 15 brush out the carbon

deposit on needle valve

Fig.16 Cleaning needle

valve and body

Paper Injection trace Injection pump

Fig.17 Checking the spraying

https://truckmanualshub.com/

10

7 Diesel fuel filter

The hook-on fuel filter has a hand-operated air-bleed function. Turn the rod to dead point in

clockwise for 30 seconds to release the air. In addition, a red floating below fuller bowl indicates

the level of water depositing in filter bowl in order t remove the bowl for draining out water.

Section Six: dismounting and re-assembly

Dismount the diesel engine according to the following orderly sequence.

1 Open the drain cock and drain out the cooling water.

2Dismount cylinder head:

(1) At first, disassemble and remove the fuel return pipe, lubricating oil pipe, high pressure fuel pipe, the

air cleaner and silencer.

(2) Disassemble and remove the cover of cylinder head.

(3) Unscrew the nuts on cylinder head and remove the cylinder head.

When re- assembling, the fastening torque for the nuts of cylinder head is 190N.m~210N.m.

Tighten them step by step in a diagonal sequence with a torque wrench.

(4) Remove the cylinder head gasket.

3. Dismount the cover of gearbox, balance shaft, camshaft

3.1 Unscrew the forcing screws of injection pump and remove injection pump its adjusting shims.

3.2 Disassemble and remove cover of gearbox.

3.3 Unscrew the fixing screws with screwdriver and remove the components of balance shaft.

3.4 Disassemble and remove the flyweight component of crankshaft and gear of balance shaft.

3.5 Unscrew affixing screw below and remove the components of camshaft.

When re-assembling, pay attention to the arks of engagement for driving gears in alignment(See

Fig.18).

Fig.18 Gearengagementmarks

4 Dismount and remove rear cover of engine block.

Counterbalance shaft

g

ea

r

Counter balance shaft gear driven

Starting gear drive

Camshaft timing gear

Starting gear, driving

Crankshaft timing gear

https://truckmanualshub.com/

11

5 Dismount the piston connecting rod assembly

5.1 Turn the flywheel to make the big end of connection rod in the window of rear cover.

5.2 Flat the safety pad with screwdriver.

5.3 Unscrew the connecting rod bolts with special wrench.

5.4 Remove cover of connecting rod. Pay attention to the protection of rod bush.

5.5 Slowly turn the flywheel and push the piston to top deal center. Push out the connecting rod

against the big end with wood.

When re-assembling, the opening of each piston ring should be put in alternate position( See

Fig.19). The fastening torque of connecting rod bolt is 70N.m~90N.m. The shaft neck ,rod bush,

the surface of piston, cylinder jacket and oil holes of small rod end should be coated with a little oil.

The oil hole of rod small end is upward.

6 Dismount flywheel

Loose the nuts of flywheel with special wrench and knock the wrench with hammer (See Fig.20).

and then , remove the flywheel with puller (See Fig. 21).

7 Dismount crankshaft

7.1 Disassemble and remove the timing gear of crankshaft

form the end of gearbox.

7.2 Unscrew and remove all the fixing bolts from the bearing

cover of crankshaft.

7.3 Turn the crankshaft to make the counterbalance direct to

notch of engine block, under the which the flywheel key on

cone surface of crankshaft just is against the V-type bar above

the bearing cover of crankshaft from viewing outside.

7.4 Screw two bolts of M8×35 simultaneously into the screw holes of crankshaft bearing cover to

push the cover and crankshaft out from engine block(See Fig. 22).

Caution: The neck of crankshaft should be protect seriously from knocking, scaling and

polluting.

1st ring opening

Oil ring opening

Piston pin axis

3rd ring opening 2nd ring opening Flywheel wrench

Fig.19 Mounting the opening of piston ring Fig.20 Unscrewing bolts of flywheel

Flywheel puller

Fig. 21 Dismounting flywheel

https://truckmanualshub.com/

12

Section Seven Lighting Generator and Circuit

There are two kinds of lighting generator. One is micro-generator, another is flywheel generator.

The micro-generator is mounted in cooling fan seat with output voltage 12V and power 25W.The

rotor of flywheel generator is fixed in inside of flywheel and its stator winding is fixed on the main

bearing cover. The flywheel generator has two type one with one 30 W and voltage and one with

power 90W and voltage 12V . They can be ordered according to the user’s requirements. The

lighting circuit is shown in Fig.23 and Fig.24. The rating voltage and power of light bulb should be

in accordance wit those of generator. The intermediate tapping of the winding of 90 W flywheel

generator has been grounded, two lead-out wires are the ones under voltage. 30W Flywheel

generator has no intermediate tapping, the wiring way is same as that of micro-generator.

Section Eight Main parts Catalog

Model 185 Series Engine Diesel had been improving .The modification of this Main parts

Catalog shall be made in reprint. Please pay more attention to purchased the parts and components.

Vee mark

Two bolts of M8×35

Flywheel key

Fig.22 Dismounting crankshaft

Flywheel

rotorStator winding

Head lamp

fan

Micro-generator

Fig.23 90W flywheel generator Fig.24 Micro-generator

https://truckmanualshub.com/

13

1.Engine Body Assembly(Model R185)

Ref.

No. Part name Part Number Req. Ref.

No. Part name Part Number Req.

1 Pad Timin

g

g

earbox R185

—

01018 1 26 Bush for startin

g

shaft R185—01203 1

2 Screw

p

lu

g

R185

—

01012 1 27 Ca

p

Indicator R175—09204 1

3 Washer R185

—

01013 1 28 Seat. Indicator R175—09203 1

4 Bolt foroil sum

p

M6×14 GB/T5781 11 29 Pin. Indicator R175—09201 1

5 Washer 8 GB/T93 11 30 Washer R175—09202 1

6 Washer 8 GB/T848 11 31 Clam

p

in

g

p

late for breathe

r

R185—01203 1

7 Oil sum

p

R185

—

01300 1 32 Oil filter ca

p

R185—01204 1

8 Pad for oil sum

p

R185

—

01024 1 34 Ke

y

5×6GB/T1096 1

9 C

y

linder head stu

d

R185

—

01002 4 35 Parts for start shaft R185—01220 1

10 C

y

linder head

g

asket R185

—

01003 1 36 Bolt M6×12 GB/T5782 4

11 C

y

linder line

r

R185

—

010 07 1 37 Washer 6 GB/T859 8

12 C

y

linder liner O-rin

g

R185

—

01008 2 38 Washer 6 GB/T848 8

13 C

y

linder head nut R185

—

01001 4 39 Bolt M6×22 GB/T5783 8

14 Pad. crankshaft bearin

g

R185

—

01023 1 40 Timin

g

g

ear case cove

r

R185—01201 1

15 Bearin

g

Balance shaft R185

—

01022 1 41 Washer 6 GB/T859 1

16 C

y

linder bloc

k

R185

—

01004 1 42 Main drivin

g

g

ea

r

R185—01202 1

17 Bush R185

—

01014 1 43 Baffle 20 GB/T894.1 1

18 Breather

p

ackin

g

R185

—

01009 2 44 screw M6×16 GB/T65 1

19 Oil deflector

p

art R185

—

01102 1 45 Part Oil stic

k

R185—01206 1

20 Rear cover for breathe

r

R185

—

01120 1 46 Washer 4 GB/T859 6

21 Pad R185

—

01101 1 47 Bolt M4×16 GB/T5783 6

22 Cover

p

art R185

—

01110 1 48 Washer 6 GB/T93 8

23 Breather

p

iece R185

—

01114 1 49 Bolt M6×20 GB/T5781 8

24 O-rin

g

10×1.8 GB/T3452.1 1

25 Sleeve barrel R185

—

01017 1

45

https://truckmanualshub.com/

14

2.Engine Body Assembly(Model CF185N and JM185N)

Ref.

No. Part name Part Number Req. Ref.

No. Part name Part Number Req.

1 Pad Timin

g

g

earbox R185

—

01018 1 26 Bush for startin

g

shaft R175—01203 1

2 Screw

p

lu

g

R185

—

01012 1 27 Dead

p

late

,

fuel fifte

r

JM185N—01206 1

3 Washer R185

—

01013 1 28 BoltM8×20 GB/T5783 1

4 Bolt foroil sum

p

M6×14 GB/T5781 11 29 Bolt M6×12 GB/T5783 2

5 Washer 8 GB/T93 11 30 Washer R175—09202 1

6 Washer 8 GB/T848 11 31 Clam

p

in

g

p

late for breathe

r

R175—01203 1

7 Oil sum

p

R185

—

01300 1 32 Oil filter ca

p

R175—01305 1

9 C

y

linder head stu

d

R185

—

02002 4 34 Ke

y

5×6GB/T1096 1

10 C

y

linder head

g

asket R185

—

01003 1 35 Parts for start shaft R185—01220 1

11 C

y

linder line

r

R185

—

010 07 1 36 Bolt M6×12 GB/T5782 4

12 C

y

linder liner O-rin

g

R185

—

01008 2 37 Washer 6 GB/T859 8

13 C

y

linder head nut R185

—

01001 4 38 Washer 6 GB/T848 8

14 Pad. crankshaft bearin

g

R185

—

01023 1 39 Bolt M6×22 GB/T5783 4

15 Bearin

g

Balance shaft R185

—

01022 1 40 Timin

g

g

ear case cove

r

R185—01201 1

16 C

y

linder bloc

k

R185

—

01004 1 41 Washer 6 GB/T859 1

17 Bush R185

—

01014 1 42 Main drivin

g

g

ea

r

R185—01202 1

18 Breather

p

ackin

g

R185

—

01009 2 43 Baffle 20 GB/T894.1 1

19 Oil deflector

p

art R185

—

01110 1 44 Settin

g

screw M6×16 GB/T65 1

20 Rear cover for breathe

r

R185

—

01101 1 45 Part Oil stic

k

JM185N—01203 1

21 Pad R185

—

01105 1 46 Washer 4 GB/T859 6

22 Cover

p

art R185

—

01120 1 47 Bolt M4×16 GB/T5783 6

23 Breather

p

iece R185

—

01104 1 48 Washer 6 GB/T93 8

24 Decoration

p

late CFZS1100-10002 1 49 Bolt M6×20 GB/T5781 8

25 Sleeve barrel R185

—

01017 1

https://truckmanualshub.com/

15

3.Condensing Cooling System (Model R185)

Ref. No. Part name Part Number Req.

1 Pad. Water tank R185—02002 1

2 Water tank R185—02003B 1

3 Washer 8 GB/T97.1 4

4 Bolt M8×30 GB/T5783 4

5 Bolt .lift eye M10 GB/T825 1

6 Washer 6 GB/T97.1 4

7 Bolt M6×6 GB/T5782 4

8 Red indicator ball R185—02004 1

9 Funnel R185—02100 1

10 Float stem R185—02005 1

11 Washer 8 GB/T97.1 1

12 Bolt M8×16 GB/T5783 1

13 Nameplate R185—02001 1

14 Bolt M6×25 GB/T5781 2

15 Washer 6 GB/T97.1 2

https://truckmanualshub.com/

16

4.Condensing Cooling System(Model CF185 and JM185N)

Ref.

No. Part name Part Number Req. Ref.

No. Part name Part Number Req.

1 Cove

r

JM185N-02601 1 22 Bearin

g

80201 GB/T276 2

2 Plastic head Screw JM185N-02202 4 23 Part. Rotor WF25-100 1

3 Weldments

,

fan cover JM185N-02100 1 24 Pin B3×8GB/T119 1

4 Ca

p

p

arts for condenser JM185N-02300 1 25 Stato

r

WF25—200 1

5 Lift e

y

e screw M10×20 GB/T825 1 26 Su

pp

ort bod

y

WF25—001 1

6 Washer 10 GB/T97.1 1 27 Screw M6×25 GB/T67 2

7 Ma

j

or washer 6 GB/T96 4 Washer 6 GB

/

T93 2

8 Bush JM185N-02604 4 28 Fan JM185N-02201 1

9 Dam

p

in

g

washer JM185N-02603 4 29 Nut M12 GB/T6170 1

10 Connectin

g

bolt ⅡJM185N-02006 1 Washer 12 GB/T93 1

11 Connectin

g

bolt ⅢJM185N-02007 1 Washer 12 GB/T97.1 1

12 Washer 10 GB/T93 1 30 Sealin

g

cover JM185N-02501 1

13 Washer 10 GB/T848 1 31 Screw M4×6GB/T67 1

14 Weldments Radiator JM185N-02400 1 32 Shaft Tension

p

ulle

y

JM185N-02503 1

15 Bolt M6×20 GB/T5783 5 33 Bearin

g

6201 GB/T276 1

Washer 6 GB/T93 5 34 Tension

p

ulle

y

JM185N-02504 1

Washer 6 GB/T97.1 5 35 Bracket Tension

p

ulle

y

JM185N-02501 1

16 Bolt M6×20 GB/T5783 1 36 Bolt M10×40 GB/T5783 1

Washer 6 GB/T93 1 37 Nut M8 GB/T6170 1

17 Part Condenser JM185N-02300 1 38 Belt Fan 10×7×900 HG401 1

18 Pad water tankr R185-02002 1 39 Bolt M8×20 GB/T5783 1

19 Bolts M8×25 GB/T5783 1 Washer 8 GB/T93 1

Washer 8 GB/T93 1 40 Pulle

y

JM185N-02005 1

20 Fan seat JM185N-02200 1

21 Bolt M8×25 GB/T5783 2

Washer GB/T119 2

https://truckmanualshub.com/

17

5. Cylinder Head Assembly

Ref.

No. Part name Part Number Req. Ref.

No. Part name Part Number Req.

1

Nut M8

GB/T6175

2

23

Steel ball

φ

6

GB/T308

1

2

Claming plate

S195

—

03013

1

24

Adjusting screw

R185

—

03009

2

3

Stud AM8

×

70

GB/T898

2

25

Nut M8

GB/T802

1

4

Cylinder head

R185

—

03001

1

26

Washer 8

GB/T93

1

5

Valve spring seat

R185

—

03004

2

27

Decompression lever

R185

—

03107

1

6

Outer valve spring

R185

—

03008

2

28

Oilsealring9

×

1.6

1

7

Inner valve spring

R185

—

03

007

2

29

Decom

p

ression torsion s

p

rin

g

R185

—

03

103

1

8

Vavle guide

R185

—

03

02

2

30

Decom

p

ression lever shaft

R185

—

03

104

1

9

Pin B3

×

8

GB/T119

1

31

Pin 3.2

×

1.6

GB/T

91

1

10

Exhaust Valve

R185

—

03

005

1

32

Ad

j

ustin

g

screw

R185

—

03

108

1

11

Inlet valve

R185

—

03

006

1

33

Nut M6

GB/T

6170

1

12

Seat for inlet valve

R185

—

03

501

1

34

Oilsealring10.6

×

1.8

1

13

Seat for exhaust valve

R185

—

03

503

1

35

Nut M8

GB/T

923

1

14

Drain cock

R185

—

03

400

1

36

Pad

R185

—

03

106

1

15

Rockerarm

R185

—

03

201

1

37

Small cover

R185

—

03

105

1

16

Bush for rock

er arm

R185

—

03

202

2

38

Bolt M6

×

12

GB/T

5781

2

17

Snap ring 14

GB/T

894.1

2

39

Cylinder head cover

R185

—

03

101

1

18

Stud R185-03011B

1

40

Pad cover

R185

—

03

002

1

19

Set Pin

R1

85

—

03

1

03

1

41

Nut M10

GB/T

6170

1

20

Rocker arm shaft bracker

R185

—

03

301

1

42

Washer 10

GB/T

859

1

21

Nut M10

×

1

GB/T

6173

2

43

Valve retainer lock

R185

—

03

003

2

22

Rocker arm shaft

R185

—

03

302

1

44

Washer

R185

—

03

12

1

https://truckmanualshub.com/

This manual suits for next models

9

Table of contents

Other Chang Fa Engine manuals

Popular Engine manuals by other brands

UNITED POWER EQUIPMENT

UNITED POWER EQUIPMENT UP152 Operation manual

Rockwell Automation

Rockwell Automation MPL-B640 installation instructions

YS

YS 140LIMITED Operator's manual

Porsche

Porsche 944 Workshop manual

MTU

MTU 20V4000G44F operating instructions

Vemco

Vemco W41 Series Installation, operating and maintenance instructions