Chang Fa ZS1115G User manual

CHANG

FA

,

ZS1115G

DIESEL

ENGINE

OPERATION

MANUAL

Changfa

Power

Machinery

CO"Ltd,

Changzhou, Jiangsu P.R.China

CertifIcate

of

Quality License

for

export

product

No,(9R)

112005

To

dcvelod forcvcr,lI'ic Changhl.Changf'a makes you bcvclod.

'Ie,',>

opni1ling

pi<'w,e

rel\i!

ihis Operation lnstiueiions

CHANGFA-ZS1115G DIESEL

INSTRUCTIONS

FOR

USE

Preface

ZS1115G Diesel,a horizontal type,single-cylinder,double-roll and straightspurt

diesel with the greatest power in China,has joined the Changfa diesel family as the

newest product

of

the Company.

ZS1115G Diesel has alot

of

advantages such

as

fine appearance,new construction,

great power,steady operation,easy starting,low fuel and water consumption,wide co-

ordination and convenient maintenance.In short,ZS1115G Diesel embodies two fine

features-economy and reliability,both

of

which have achieved the advanced level

of

the I990S,Having the same connective size for set-forming intallation and the same

way

of

exporting power as S195,S1100 and some other diesels,ZS1115G Diesel is

suitable for powering small four-wheel tractors and for driving agricultural irrigation

and drainage pumps,as well

as

engineering machinery and ship-propulsion,It can also

be used as aprime mover for small eleertical generators and agricultural processing

machines.

Normal and reliable operation

of

this engine depends wpon acorrect service and

good maintenance which will prolong the life

of

the engine to the utmosUherefore,it

is

recommended that the operators,when operating the engine,pay spedial attention to

the following:

I.A fuel

of

aspecified grade

is

to be used,and before being poured into the fuel

tank,it should be completely prccipitated and thoroughly filtered.Any utensils used

herein should be kept clean.

2.A lubricating oil

of

aspecified grade

is

to be used,and must be kept clean and

periodically changed.

3.Thc air filter must be frepuently cleaned and given agood maintcnance,the oil

in

the filter must be periodically changed.

4.The engine

is

to

operate under the boiling conditions

of

the cooling water in the

hopper.The quantity

of

water should always be kept

in

such away that the red ball

of

the float must mot be allowed to go down below the mouyt

of

the funnel

of

the

hopper.

CONTENTS

PART ONE SERVICE INSTRUCTIONS

Drawing

of

Outline

and Installattion

Dimensions

of

Diesel

Engine

.1

I.Main

Specifications

of

the Diesel Engine 2

1.1

Technical

Data

2

1.2 Valve Timing 3

1.3

Fit

Clearance

of

the

Main

Parts 3

2.Selection

of

the Size

of

Pulleys 5

3.0peration

of

the Diesel

Engine

5

3.1 Preparation Works 5

3.2 Starting 6

3.3

Running

7

3.4 Stopping 7

4. Maintenance

of

the Diesel Engine 8

5.The

Method

of

Troubles Shooting

and

Removing

9

PART

TWO

PARTS LIST WITH ILLUSTRATIONS

Fig. ICylinder BlockAssembly-I

12

Fig.

II

Cylinder Block Assembly-2

14

Fig.III CamshaftAssembly :

16

Fig.

IV

Cylinder Head Assembly

18

Fig. VPiston and Connecting Rod Assembly 20

Fig.

VI

Flywheel Crankshaft and Balancing Mechanism

22

Fig.

VII

Flywheel Crankshaft and Balancing Mechanism

24

Fig.

VllI

Hopper Assembly

26

Fig.IXFuel System

28

Fig. XExhaust system 30

Fig. X I Lubrication System ;32

Fig. X

II

Gear Casing Assembly .34

Fig. XIII Intake System 36

Fig. X

IV

Fuel Injection Pump .38

Fig. X V PF68S

19

Fuel Injector .40

Appendix IList

of

Tools Supplied with the Engine .42

Appendix

II

List

of

Spare Parts Supplied with the Engine .42

.

~-~~

II

@1_Kst~~

I

853i6-6

=======11

I

8ni-

s

420,-

'~

'4S0

.In

2'7-

If

AS

D

Po

!--<L

J.

~

"

;::::=

,

,I

~Ji

'»1<'

~

,

"-

'01

lQ

I~

1

~

'T,

"-

A'/

~h-~

0-

jJ

1

;/~/T\'

\

-'56--4

I~S

280

3'10

A

I

~

_IJ

f~

==IF

A

:S-MJ2

c

611

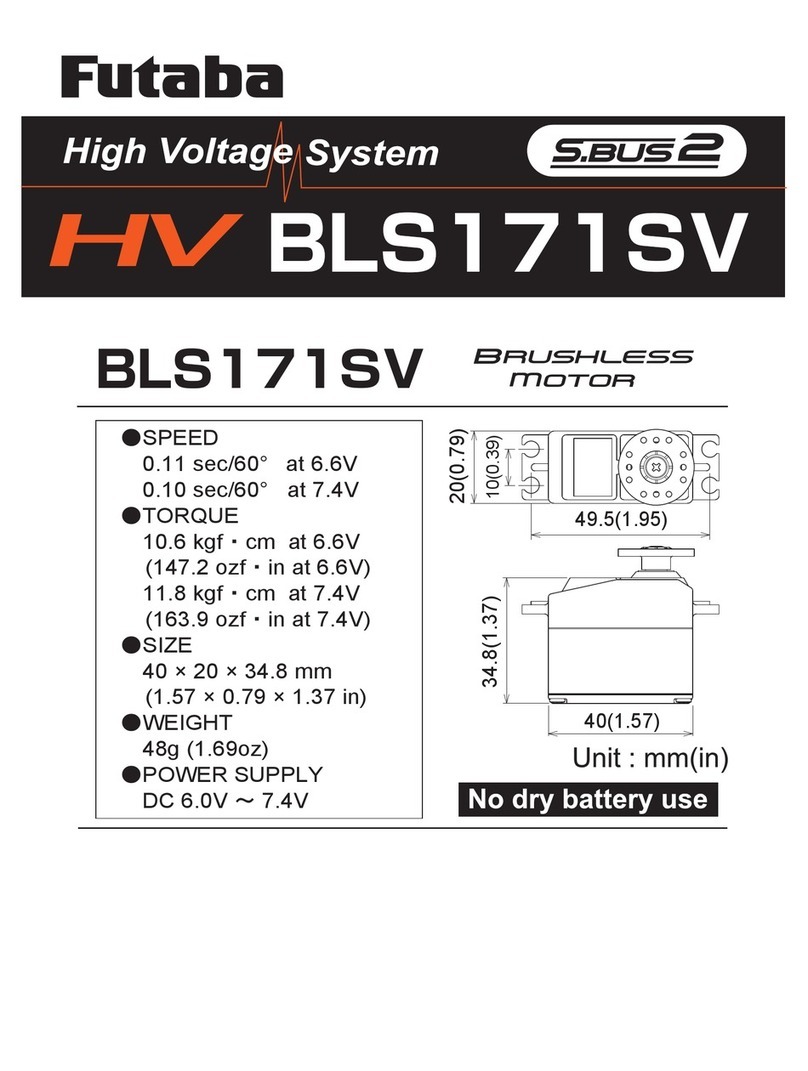

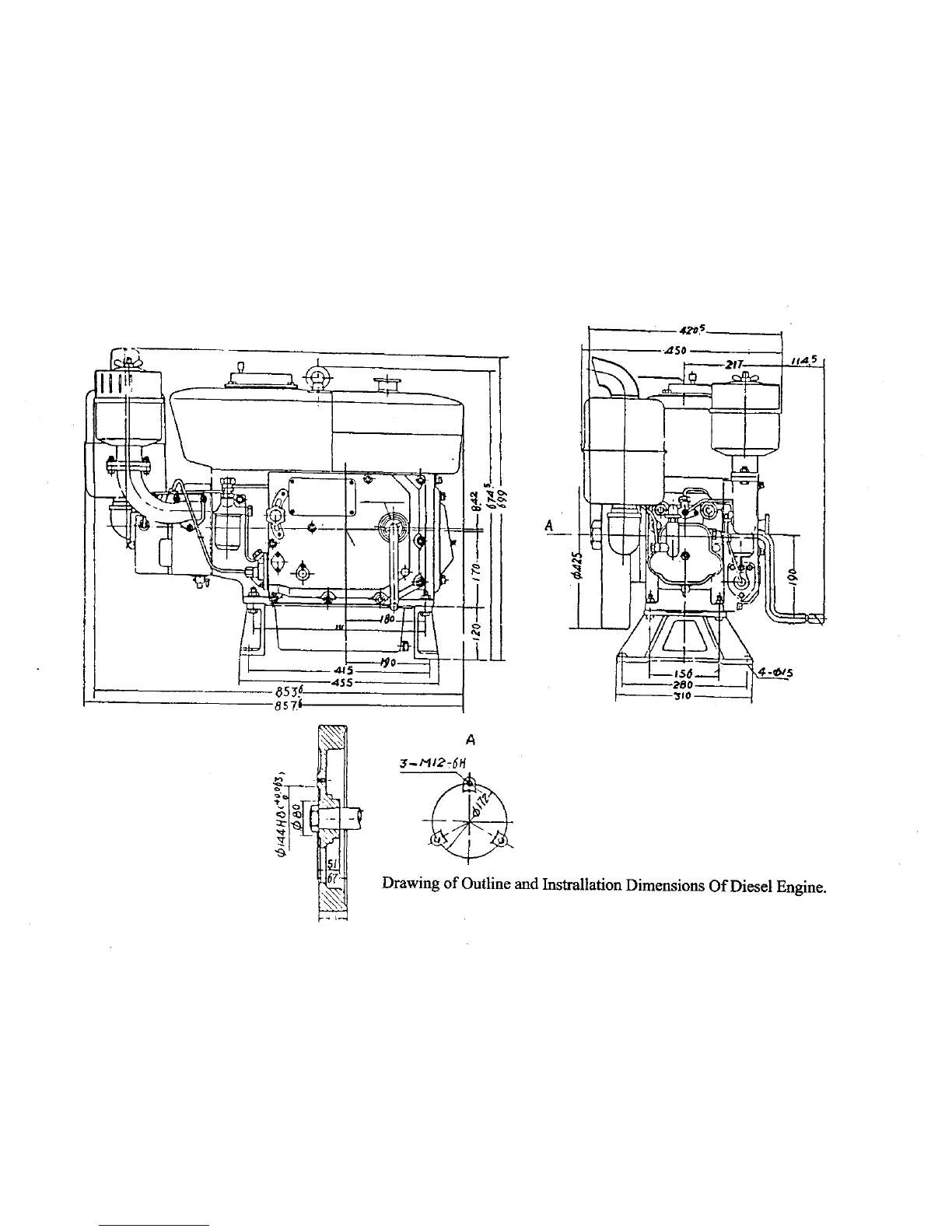

Drawing

of

Outline and Instrallation Dimensions

Of

Diesel Engine.

.,

l.Main

specifications

of

the

Diesel

Engine

1.1 Technical Data

Item Specifications

Model

Zsl115G

Type

single-cylinder,horizontal and

four-stroke circle

Type

of

combustion chamber direct injection

Cylinder bore 115mm

Piston stroke 115mm

Piston displacement 1.195L

Average speed

of

piston 8,44m/s

Compression ratio

17

Rated power 14.7kw/2200r/min

Average effedtive pressure 739.75Kpa

Fuel consumption ratio

~

238g/kw· h

Oil consumption ratio

~

1.47g/kw . h

Injection pressure 18.13 +0,49Mpa(185 +5kgf/cm2)

Cooling style water cool evaporation

Starting style hand cranking

Net weight

~

185kg

Outline dimensions 858 X450 X699

valve gaps (cold state) intake valve 0.35 +0.05mm

exhaust valve 0.45 +0.05mm

Type

of

injector PF68S19

Type

of

injector coupler ZCKI54S432A

Type

of

injector pump AKModle,single-piece and

separable rotor type

Oil pump rotor type rotor type

Diesel oil filter body model C0506C Model

Tightening torque

of

cylinder 274.4-313.6N· M

cover nut

Tightening rorque

of

cnnectingrod 78.4-[ 17.6N . M

nut

Tightening torque

of

flywheel nut 295-350N· M

--2--

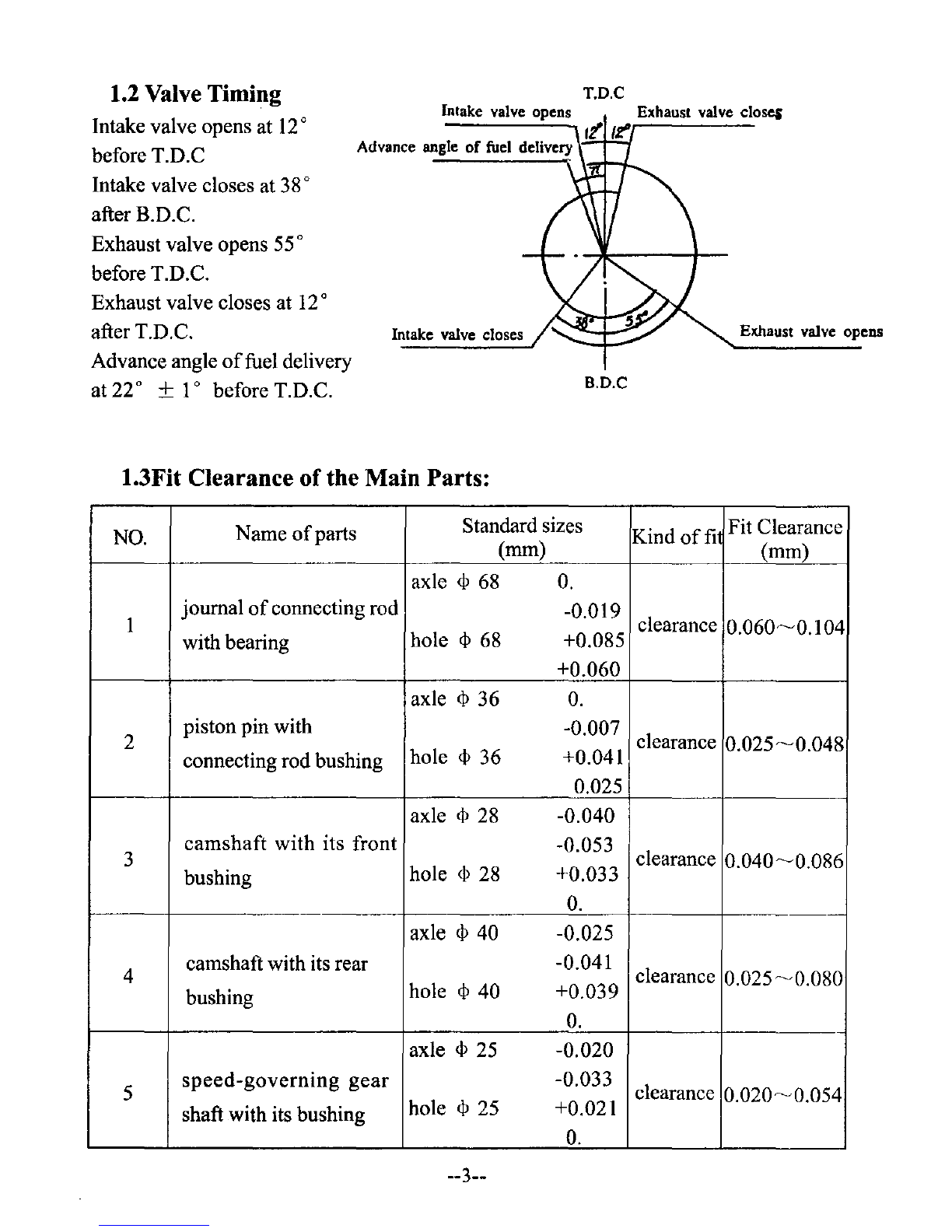

1.2 Valve Timing

Intake valve opens at

12

0

before T.D.C

Intake valve closes at

38

0

after B.D.C.

Exhaust valve opens

55

0

before T.D.C.

Exhaust valve closes at

12

0

after T.D.C.

Advance angle

of

fuel delivery

at 22" +10before T.D.C.

T.D.C

Intake

valve opens

Advance angle

of

fuel delivery \.:=-r:::..,

Intake valve closes

B.D.C

Exhaust valve opens

1.3Fit Clearance

of

the Main Parts:

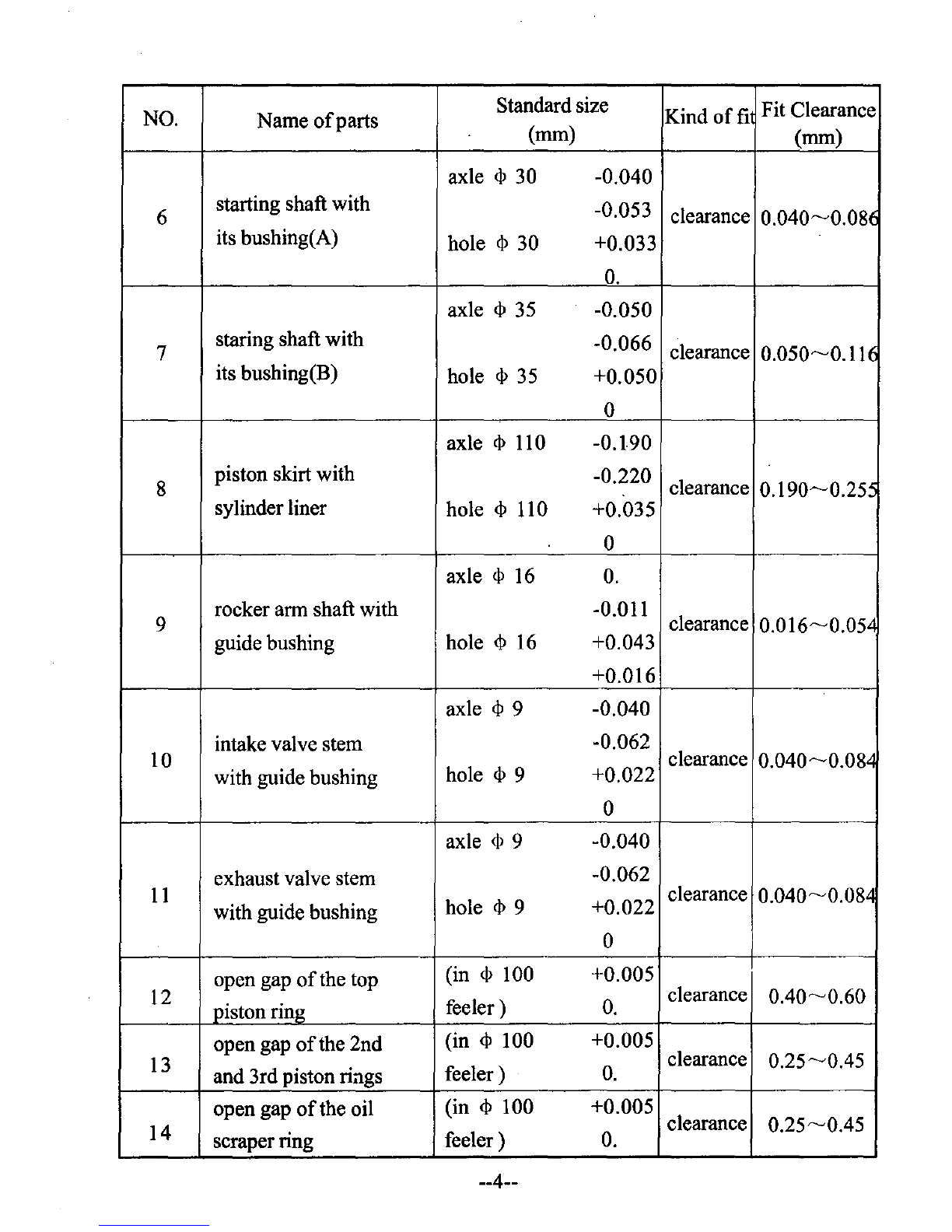

NO.

Name

of

parts Standard sizes Kind

offi

Fit Clearance

(mm) (mm)

axle

<I>

68

O.

1journal

of

connecting rod -0.019 clearance

with bearing hole

<I>

68 +0.085

0.060~0.I

04

+0.060

axle

<I>

36

O.

2piston pin with -0.007 clearance

connecting rod bushing hole

<I>

36 +0.041

0.025~0.048

0.025

axle

<I>

28 -0.040

camshaft with its front -0.053 clearance

3

0.040~0.086

bushing hole

<I>

28 +0.033

O.

-~

axle

<I>

40 -0.025

4camshaft with its rear -0.041 clearance

0.025~0.080

bushing hole

<I>

40 +0.039

O.

axle

<I>

25

-0.020

5

speed-governing

gear

-0.033 clearance

0.020~0.054

shaft with its bushing hole

<I>

25

+0.02I

O.

--3--

NO. Name

of

parts Standard size Kind

offi

Fit Clearan

(mm) ce

(mm)

axle

<P

30 -0.040

6starting shaft with -0.053

its bushing(A) clearance

0.040~0.0

8<i

hole

<P

30 +0.033

O.

axle

<P

35

-0.050

7staring shaft with -0.066

its bushing(B) hole

<P

35 clearance

0.050~0.11

(

+0.050

0

axle

<P

110 -0.190

8piston skirt with -0.220

sylinder liner hole

<P

110 clearance

0.190~0.25:

+0.035

0

axle

<P

16

O.

9rocker arm shaft with -0.011

guide bushing hole

<P

16

+0.043 clearance

0.016~0.05"

+0.016

axle

<P

9-0.040

10 intake valve stem -0.062

with guide bushing hole

<P

9+0.022 clearance

0.040~0.08~

0

axle

<P

9-0.040

11

exhaust valve stem -0.062

with guide bushing hole

<P

9+0.022 clearance

0.040~0.08~

0

12 open gap

of

the top (in

<P

100 +0.005

piston ring feeler)

O.

clearance

0.40~0.60

13

open gap

of

the 2nd (in

<P

100 +0.005

and 3rd piston riags feeler)

O.

clearance

0.25~0.45

open gap

of

the oil (in

<P

100 +0.005

14

scraper ring clearance

0.25~0.45

feeler)

O.

--4--

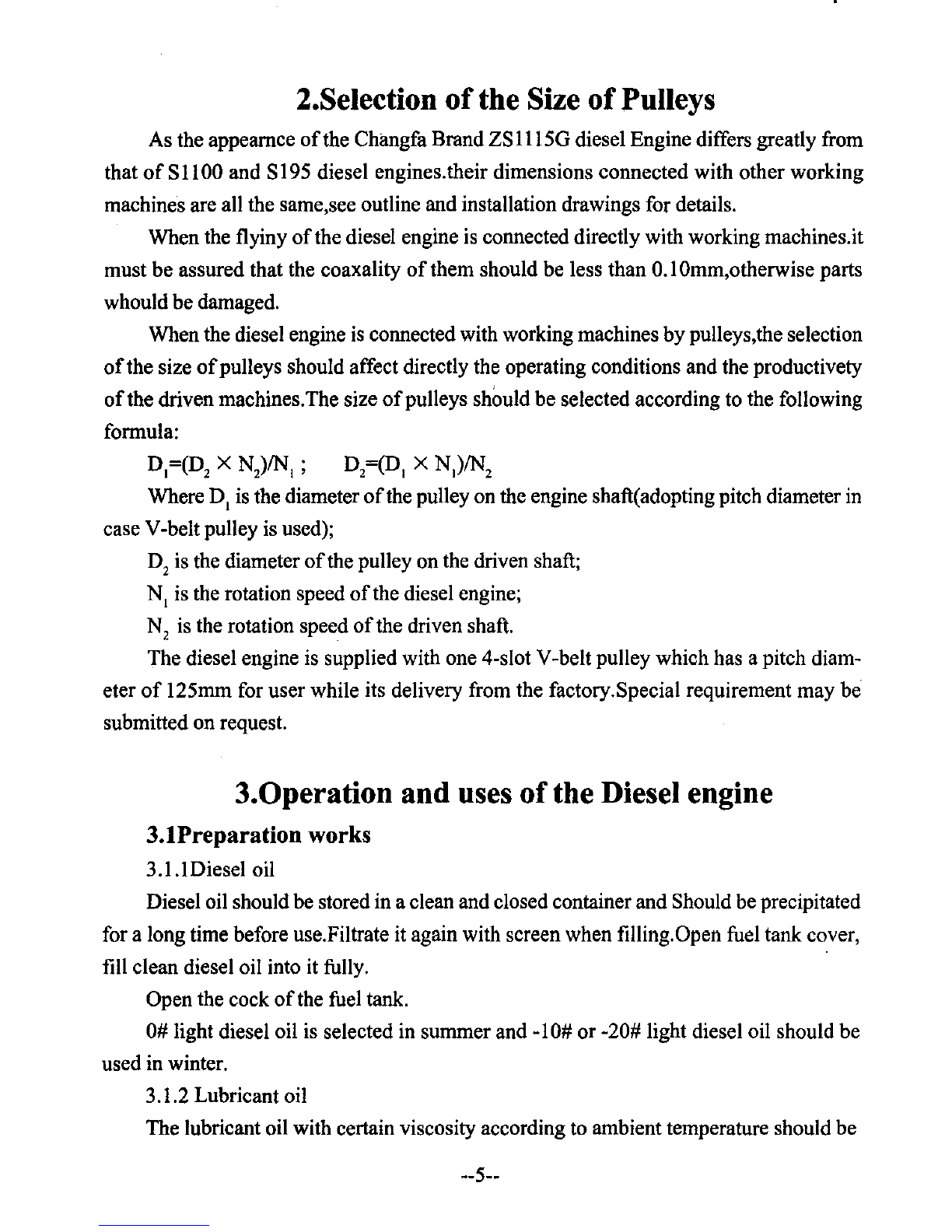

2.Selection

of

the Size

of

Pulleys

As the appearnce

of

the Chilngfa Brand ZS1115G diesel Engine differs greatly from

that

of

S

11

00

and S195 diesel engines.their dimensions connected with other working

machines are all the same,see outline and installation drawings for details.

When the flyiny

of

the diesel engine is connected directly with working machines.it

must

be

assured that the coaxality

of

them should be less than 0.1 Omm,otherwise parts

whould

be

damaged.

When the diesel engine

is

connected with working machines

by

pulleys,the selection

of

the size

of

pulleys should affect directly the operating conditions and the productivety

of

the driven machines.The size

of

pulleys should

be

selected according to the following

formula:

D,=(D2XN2

)1N,

;D2=(D, X

N,)1N

2

Where D, is the diameter

of

the pulley on the engine shaft(adopting pitch diameter in

case V-belt pulley is used);

D2is the diameter

of

the pulley onthe driven shaft;

N, is the rotation speed

of

the diesel engine;

N2is the rotation speed

of

the driven shaft.

The diesel engine is supplied with one 4-slot V-belt pulley which has apitch diam-

eter

of

125mm for user while its delivery from the factory.Special requirement may

be

submitted on request.

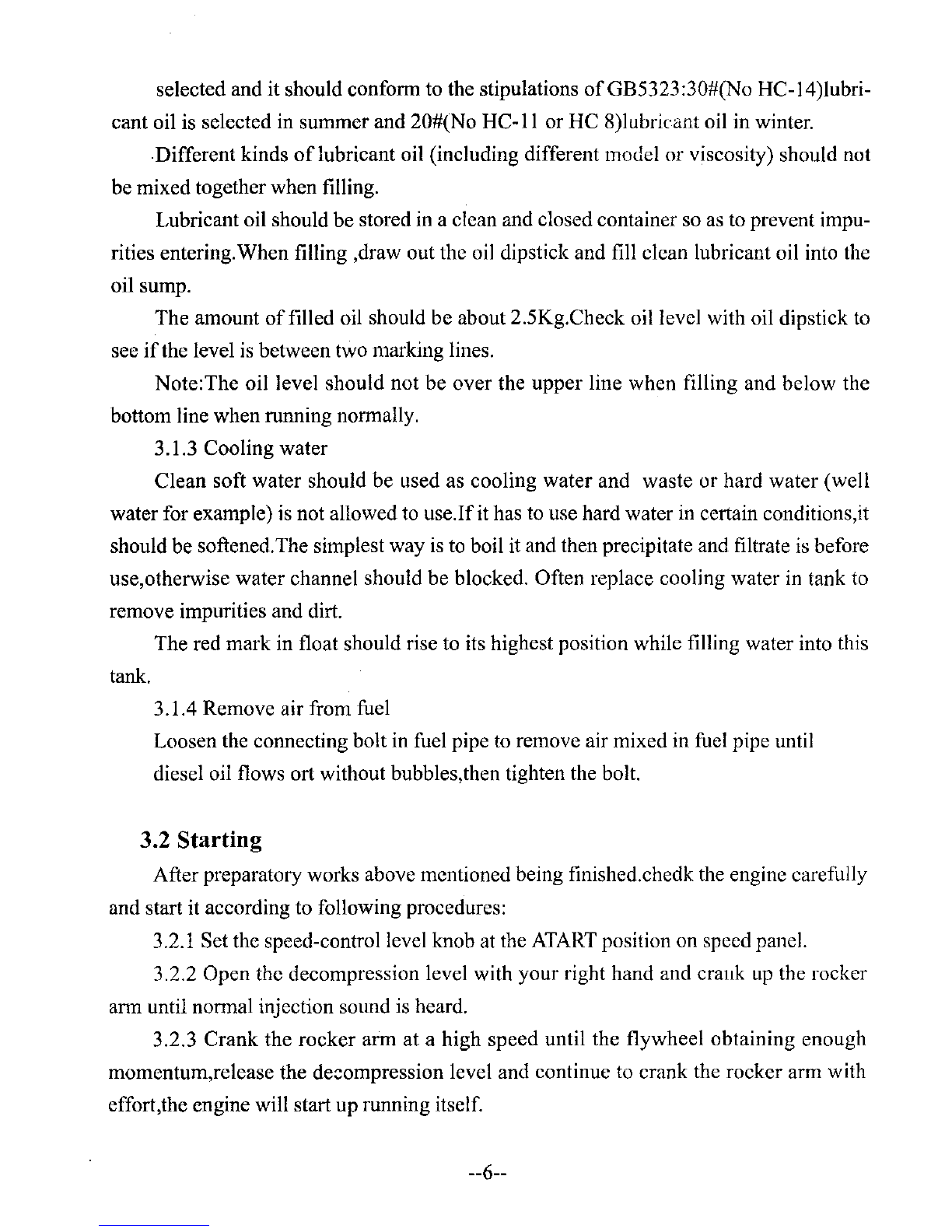

3.0peration and uses

of

the Diesel engine

3.1Preparation works

3.1.1Diesel oil

Diesel oil shouldbe stored in aclean and closed containerand Should be precipitated

for along time before use.Filtrate it again with screen when filling.Open fuel tank cover,

fill clean diesel oil into it fully.

Open the cock

of

the fuel tank.

0#

light diesel oil is selected in summer and -10#

or

-20# light diesel oil should be

used in winter.

3.1.2 Lubricant oil

The lubricant oil with certain viscosity according to ambient temperature should be

--5--

selected and it should conform to the stipulations ofGB5323:30#(No HC-14)lubri-

cant oil is selected in summer and 20#(No

HC-II

or HC 8)lubricant oil in winter.

·Different kinds oflubricant oil (including different model or viscosity) should not

be mixed together when filling.

Lubricant oil should be stored in aclean and closed container so

as

to prevent impu-

rities entering.When filling ,draw out the oil dipstick and fill clean lubricant oil into the

oil sump.

The amount

of

filled oil should be about 2.5Kg.Check oil level with oil dipstick

to

see

if

the level is between two marking lines.

Note:The oil level should not be over the upper line when filling and below the

bottom line when running normally.

3.1.3 Cooling water

Clean soft water should be used as cooling water and waste or hard water (well

water for example) is not allowed

to

use.Ifit has

to

use hard water

in

certain conditions,

it

should be softened.The simplest way

is

to

boil

it

and then precipitate and filtrate

is

before

use,otherwise water channel should be blocked. Often replace cooling water

in

tank to

remove impurities and dirt.

The red mark in float should rise

to

its highest position while filling water into this

tank.

3.1.4 Remove air from fuel

Loosen the connecting bolt in fuel pipe

to

remove air mixed in fuel pipe until

diesel oil flows ort without bubbles,then tighten the bolt.

3.2 Starting

After preparatory works above mentioned being finished.chedk the engine carefully

and start it according to following procedures:

3.2.1 Set the speed-control level knob at the

ATART

position on speed panel.

3.2.2 Open the decompression level with your right hand and crallk

up

the rocker

ann

until normal injection sound is heard.

3.2.3 Crank the rocker arm at ahigh speed until the flywheel obtaining enough

momentum,release the

de~ompression

level and continue

to

crank the rocker arm with

effort,the engine will start up running itself.

--6--

3.2.4

Once

the engine starts up running,the staring

handle

will disengage

and

silp

out.

Then

operator

should

keep

it

in

hand

firmly

to

prevent

any

possible

accident.

3.3 Running

3.3.lAfter starting,make the engine running for5-8 minutes at lower speed.then in-

crease speed gradually.The engine runs with full load only when the temperature

of

the

water tank is higher.

3.3.2 Check to see

if

the oil indicator is rising up.The lubrication system is abnormal

if

it does not rise up or drops suddenly,stop the engine at this time and fill lubricant oil

fully or remove troubles.

3.3.3

It

is normal that the cooling water is boiling when the engine is running.

Note:When the mark in float drops down

to

the inlet

of

the water tank,it is necessary

to

till water in time.

3.3.4 Often view the colour

of

exhaust air when the engine is running.!t is not al-

lowed to run the engine when black smoke occurs.This necessary to decrease load or

remove troubles in time.

3.3.5 It

is

not allowed

to

make the engine running with super10ad.Removing the fuel

corrector

to

increase the power

of

the engine is strictly prohibited.

3.3.6 Stop the engine immediately

of

abnormal sound is heard when the engine is

running,the check carethlly.

3.3.7During the period

of

first 50 hours when anew diesel engine is used,operate it

carefully and do not run the engine with the largest10ad,Check again and retighten all

loosened bolts and nuts after that period.

3.4Stopping

3.4.1 Unload the engine and run it at lower speed for awhile.

3.4.2Set

the

throttle

handle

at

the

STOP

position,the

engine

should

go

out

itself.

Note:Stopping the engine with the decompression level is strictly prohibited.

3.4.3Close the cock

of

the fuel tank

--7--

304o4Drain

out

all

cooling

water

in

winter

or

when

stopping

the

engine

for a

long

time.

Remove

drain

cock

regularly

to

dredge

water

channel

and

re-

move

dirt.

304.5Set

the

exhaust

valve

closed

to

prevent

vapour

or

impurities

enter-

ing

into

the

cylinder.The

method

so

as follows:

304.5.1

Turn

the

flywheel

until

it

can

not

be

turned

304.5.20pen

the

decompression

level to

continue

turning

the flywheel until

its

mark

ofT.D.C.is

directly

against

the

mark

on

the

water

tank.

304.6Emergency

stop

Loopen

the

connecting

nuts

on

high-pressure

fuel

pipe

or

open

the

decompress

or

to

stop

the

engine

running

at

once

if

abnormal

sound

is

heard

suddenly

or

flying

running

occurs.

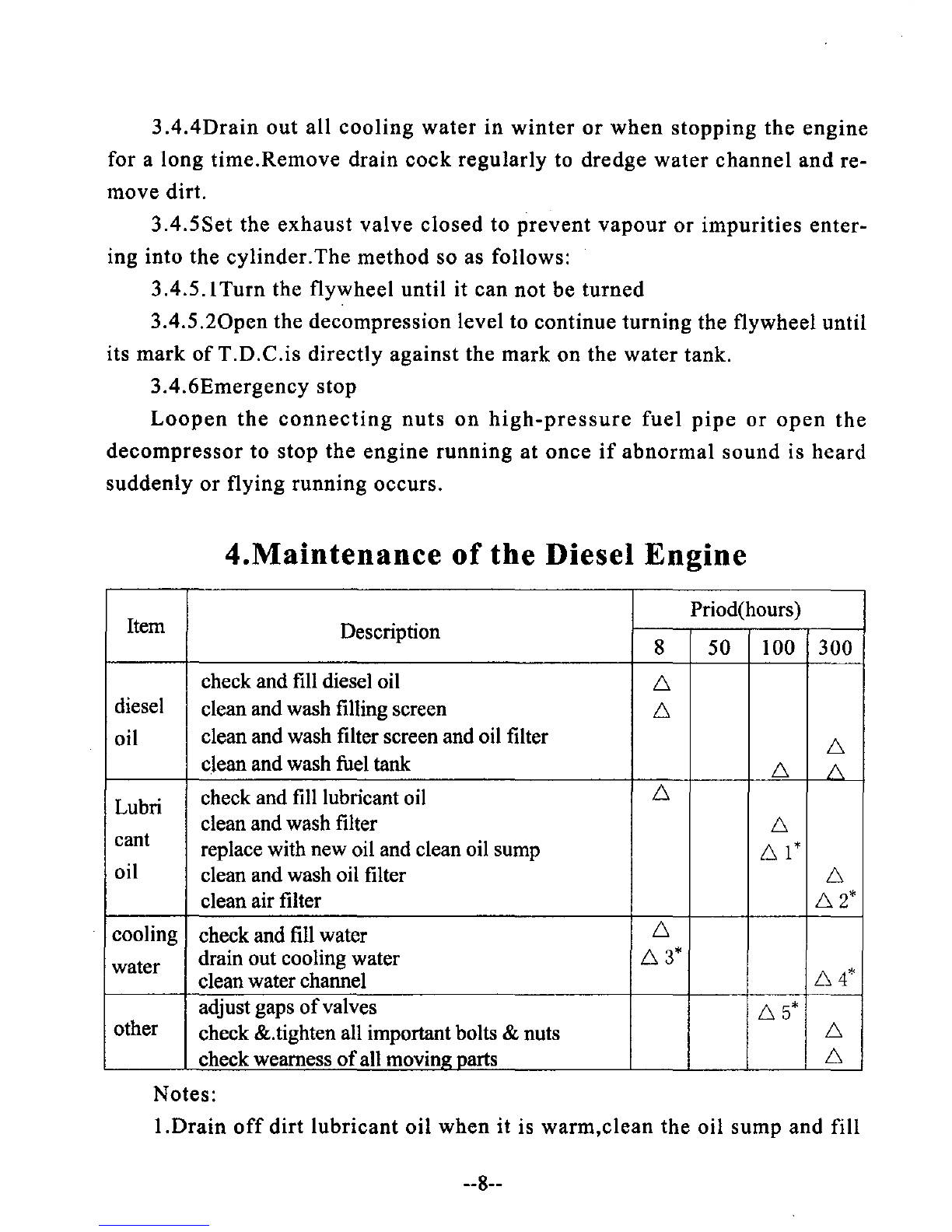

4.Maintenance

of

the

Diesel

Engine

Item Priod(hours)

Description 850 100 300

check and fill diesel oil 6

diesel clean and wash filling screen 6

oil clean and wash filter screen and oil filter 6

clean and wash fuel tank 6

/\

Lubri check and fill lubricant oil 6

clean and wash filter 6

cant replace with new oil and clean oil sump

61*

oil clean and wash oil filter 6

clean air filter

62*

cooling check and fill water 6

water drain out cooling water

63*

clean water channel

64*

adjust gaps

of

valves

65*

other check &.tighten all important bolts &nuts 6

check wearness

of

all

movinl!:

Darts

6

Notes:

I.Drain

off

dirt

lubricant

oil

when

it

is

warm,clean

the

oil

sump

and fill

--8--

new oil.

2.Aircleaner should be cleaned every 50 hours

if

more dust exists around the engine.

3.Drain

off

the cooling water at once after stopping the engine in winter to prevent

engine and cylinder cover being frozen.

4.Remove the watertank and fill hydrochloric acid with adensity

of25

per

cent into

water channel and keep it there for 20 minutes,then drain

off

it and clean channel with

water again and again.

5.Check the gaps

of

valves in cold state every day.It shouldbe 0.3-0.4mm for intake

valve and 0.4-0.5mm for exhaust valve.

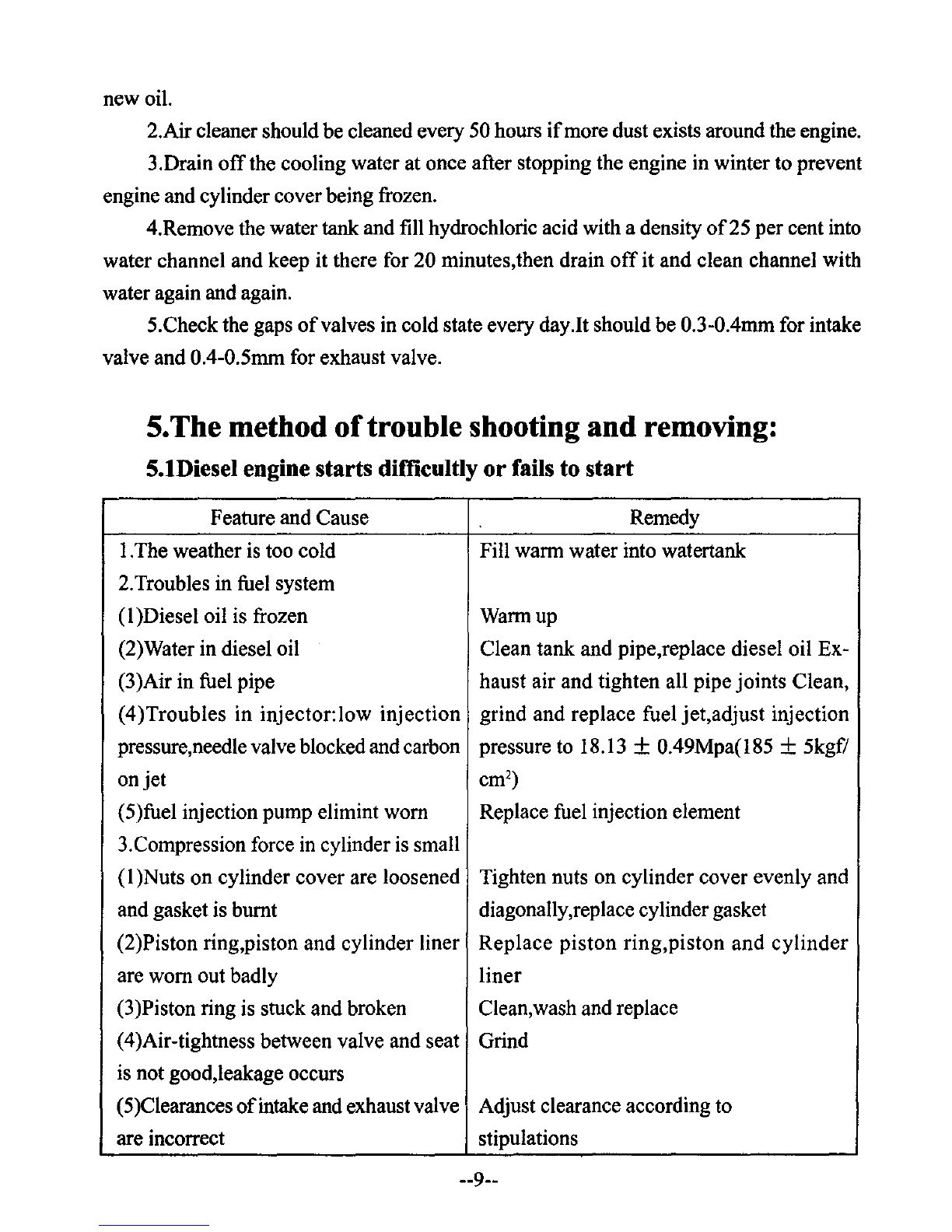

5.

The method

of

trouble shooting and removing:

5.1Diesel engine starts difficultly or fails to start

Feature and Cause Remedy

I.The weather is too cold Fill warm water into watertank

2.

Troubles in fuel system

(I

)Diesel oil is frozen Warmup

(2)Water in diesel oil Clean tank and pipe,replace diesel oil Ex-

(3)Air in fuel pipe haust air and tighten all pipe joints Clean,

(4)Troubles in injector:low injection grind and replace fuel jet,adjust injection

pressure,needle valve blockedand carbon pressure to 18.13 +0.49Mpa(185 +5kgf/

on

jet

cm2)

(5)fuel injection pump elimint worn Replace fuel injection element

3.Compression force

in

cylinder

is

small

(I

)Nuts on cylinder cover are loosened Tighten nuts on cylinder cover evenly and

and gasket is burnt diagonally,replace cylindergasket

(2)Piston ring,piston and cylinder liner

Replace

piston

ring,piston

and

cylinder

are worn out badly

liner

(3

)Piston ring is stuck and broken Clean,wash and replace

(4)Air-tightness between valve and seat Grind

is not good,leakage occurs

(5)Clearances

of

intake and exhaust valve Adjust clearance according to

are incorrect stipulations

--9--

5.Viscosity oflubricant oil is thicker,speed

could not be increased

by

hand

Check diesel oil cock,clean oil filter and

fuel pipe

Repair or replace damaged parts

of

pump

Refer to

iteml.2.(

4)of

5

Refer to item1.3.of5

Remove,clean or replace filter

Adjust according to stipulation

Feature and Cause Remedy

:---:-~--t-c::c------:---~-

.-,'-----;--;-:-------

(6)Valve stem is blocked in guide bushing Remove valve,wash valve and guide

(7)Compression ratio is decreased due to bushing with diesel oil

more repairs Replace valve seat

4.Advance angle

of

delivery is incorrect Adjust it at 220+I0before T.D.C.

according to stipulation

Replace lubricant oil with specific brand

5.2 Power is insufficient

Feature and cause Remedy

-----.----.-----.--.-.--f--.-.-----.---=--------

1.Troubles in fuel system

(I

)Diesel oil filter and fuel pipe blocked,

fuel delivery is not smooth

(2)Fuel delivery

of

pump is bad

(3)Troubles in injector

2.Compression force in cylinder is small

3.Air filter clogged

4.Advance angle

offuel

delivery is wrong I

'--

..L...

~

J

5.3 Diesel engine stall

Feature and cause Remedy

..

_---

-----

._---

----.--._.--.----

-_._------1

I.Troubles

in

fuel system

(I)Air in fuel system Remove air

(2)Quality

of

diesel oil

is

bad or there is Refer to item 1.2(2)

of

5

water

in

it

(3)Needle valve

injet

is blocked or injee- Refer to itim 1.2(4)

of

5

tion pressure

is

much higer

(4)Jet coupler,injection pump coupler and Replace damaged parts

fuel out let valve damaged

2.Speed system blocked

or

adjust bolt on Check or adjust the extension

of

bolt

speed level worn out

--10--

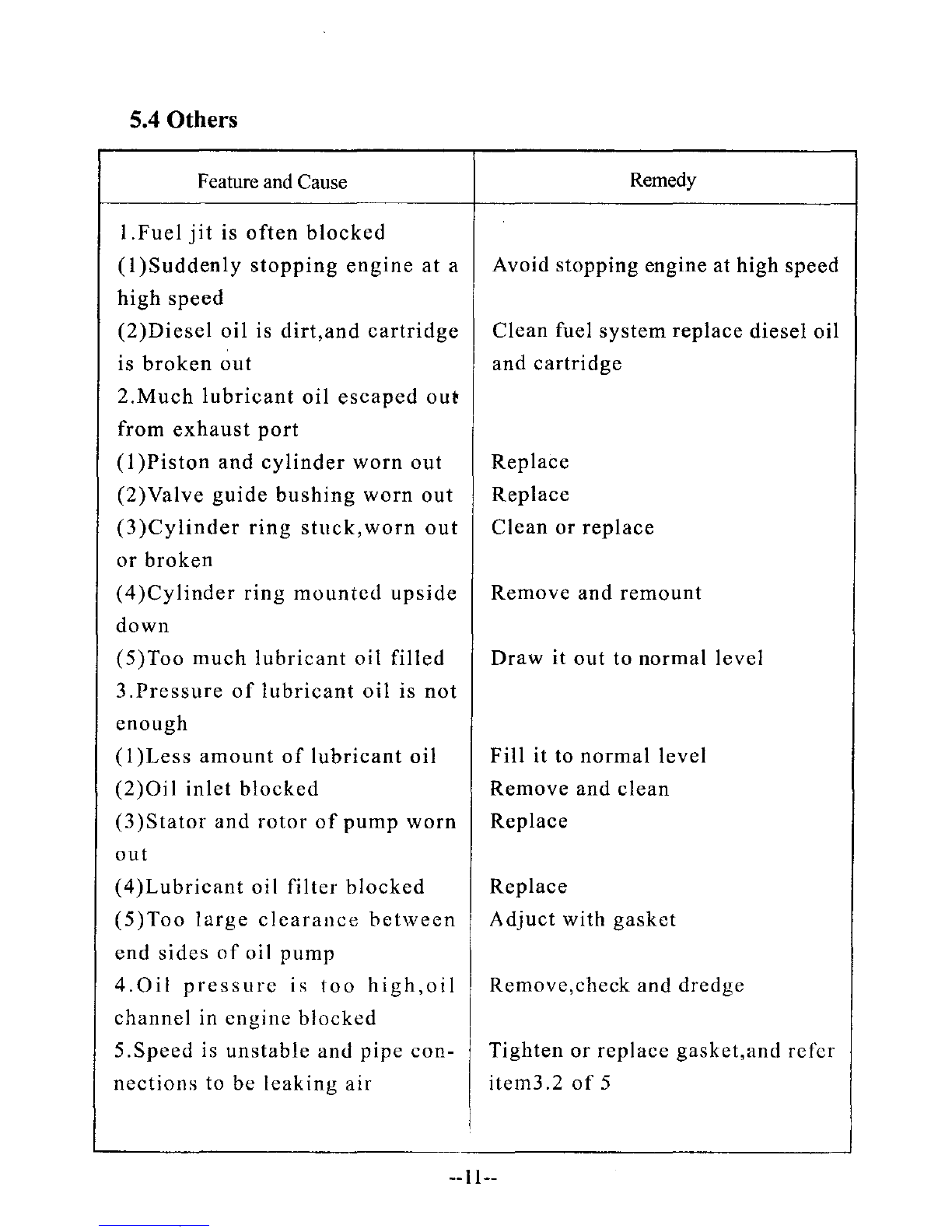

5.4 Others

Feature

and

Cause

Remedy

I.Fuel

jit

is

often

blocked

(I

)Suddenly

stopping

engine

at

aAvoid

stopping

engine at high speed

high

speed

(2)Diesel

oil

is

dirt,

and

cartridge

Clean

fuel

system

replace

diesel

oil

is

broken

out

and

cartridge

2.Much

lubricant

oil

escaped

out

from

exhaust

port

(I

)Piston

and

cylinder

worn

out

Replace

(2)Valve

guide

bushing

worn

out

Replace

(3)Cylinder

ring

stuck,worn

out

Clean

or

replace

or

broken

(4)Cylinder

ring

mounted

upside

Remove

and

remount

down

(5)Too

much

lubricant

oil

filled

Draw

it

out

to

normal

level

3.Pressure

of

lubricant

oil

is

not

enough

(1

)Less

amount

of

lubricant

oil

Fill

it to

normal

level

(2)Oil

inlet

blocked

Remove

and

clean

(3

)Stator

and

rotor

of

pump

worn

Replace

out

(4)Lubricant

oil

filter

blocked

Replace

(5)Too

large

clearance

between

Adjuct

with

gasket

end

sides

of

oi1

pump

4.0il

pressure

is

too

high,oil

Remove,check

and

dredge

channel

in

engine

blocked

5.Speed

is

unstable

and

pipe

con-

Tighten

or

replace

gasket,and

refcr

nections

to be

leaking

air

item3.2

of

5

--11--

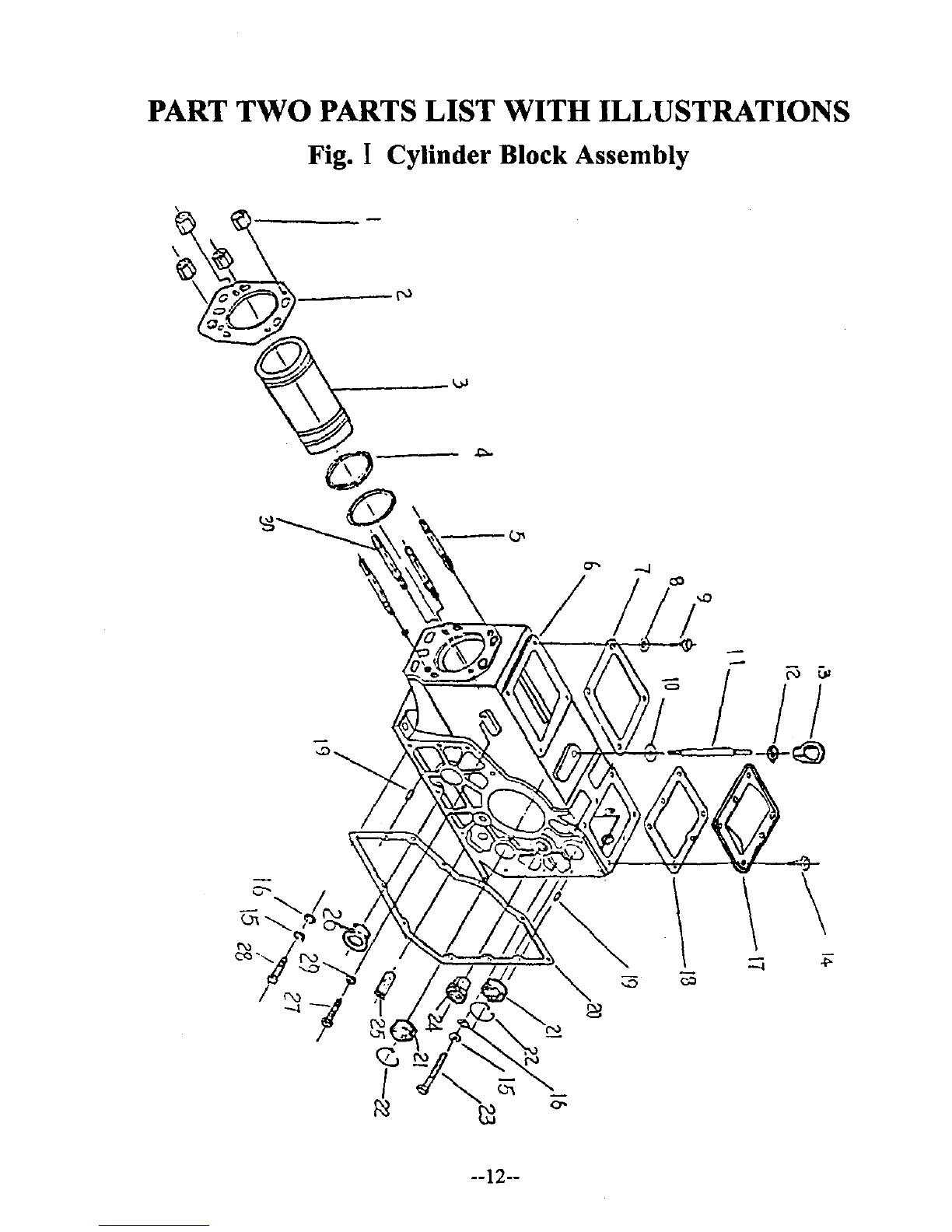

PART

TWO

PARTS LIST

WITH

ILLUSTRATIONS

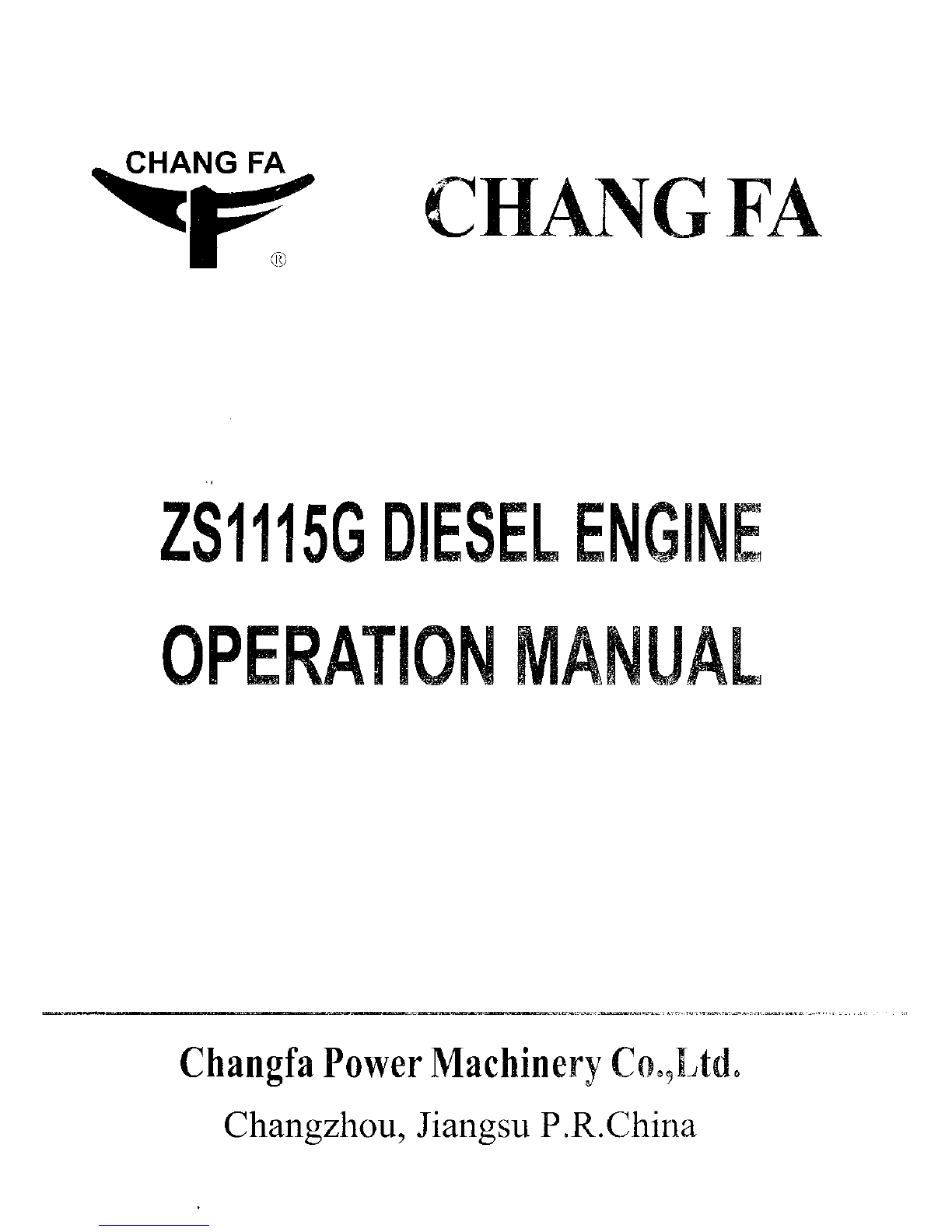

Fig. ICylinder Block Assembly

~_-['l

\----"-"

__

.l'>o

--12--

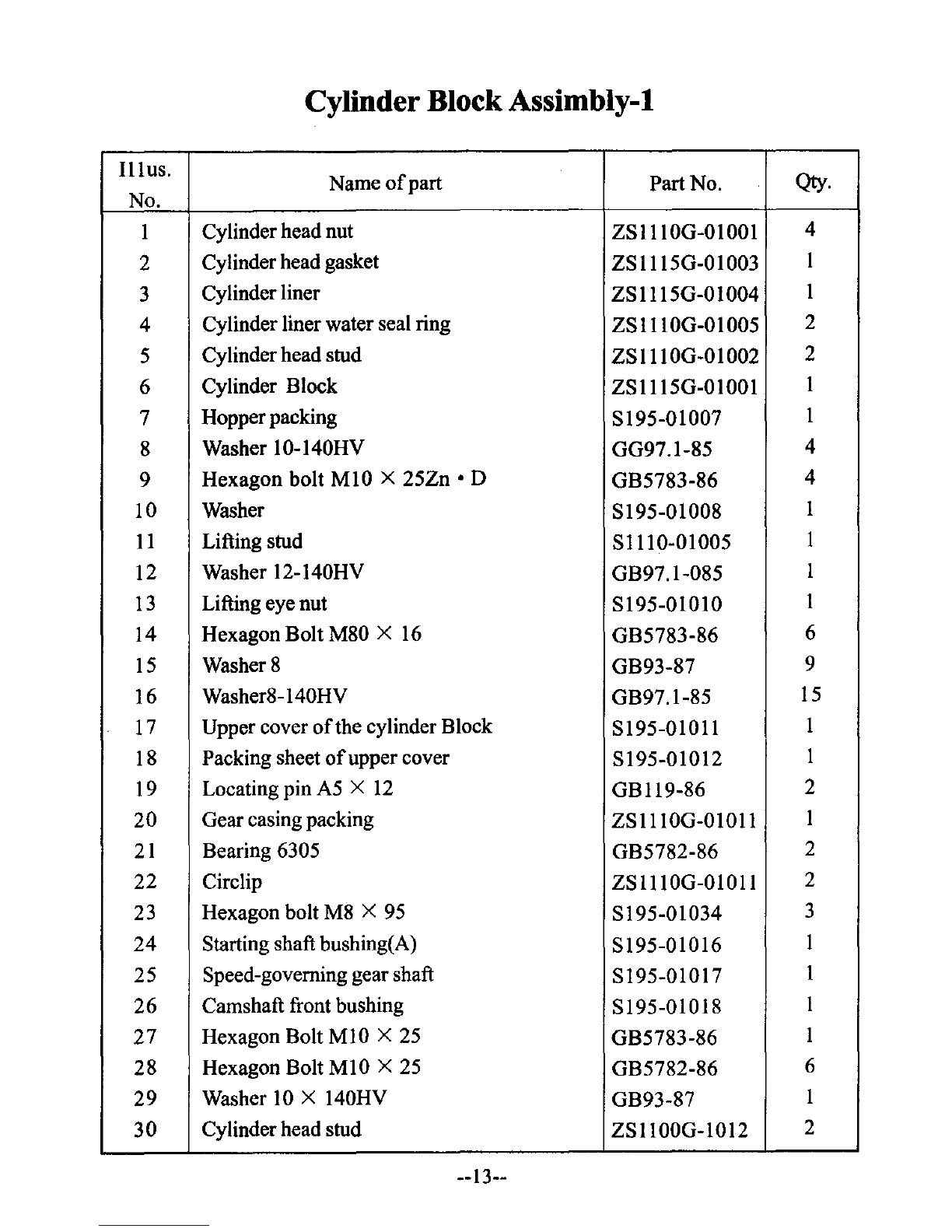

Cylinder BlockAssimbly-l

Illus.

Name

of

part Part No.

Qty.

No.

ICylinderhead nut ZSl1IOG-OIOOI 4

2Cylinder head gasket ZS1115G-01003 I

3Cylinderliner ZSII15G-OI004 I

4Cylinder liner water seal ring ZSIIIOG-OI005 2

5Cylinderhead stud ZS

III

OG-O

I002 2

6Cylinder Block ZS1115G-01001 I

7Hopperpacking S195-01007 I

8Washer 10-140HV GG97.1-85 4

9Hexagon bolt MIO X25Zn • D GB5783-86 4

10 Washer S195-01008 I

11

Lifting stud Sl110-01005 I

12 Washer 12-140HV GB97.1-085 I

13

Lifting eye nut S195-0101O I

14 Hexagon Bolt M80 X

16

GB5783-86 6

15

Washer 8GB93-87 9

16 Washer8-140HV GB97.1-85 15

17 Upper cover

of

the cylinder Block SI95-01011 I

18 Packing sheet

of

upper cover S195-01012 I

19 Locating pin

A5

X

12

GB119-86 2

20 Gear casing packing ZSl1IOG-OI011 I

21

Bearing 6305 GB5782-86 2

22 Circlip ZSl1IOG-OI011 2

23 Hexagon bolt M8 X

95

S195-01034 3

24

Starting shaft bushing(A) S195-01016 I

25 Speed-governing gear shaft S195-01017 I

26 Camshaft front bushing S195-0I0

18

I

27

Hexagon Bolt MIO X

25

GB5783-86 I

28 Hexagon Bolt MI0 X

25

GB5782-86 6

29 Washer

10

X140HV GB93-87 I

30

Cylinderhead stud ZSl1OOG-IOI2 2

--13--

Fig.

11

Cylinder Block Assembly

,•

000

•00

•

__

14--

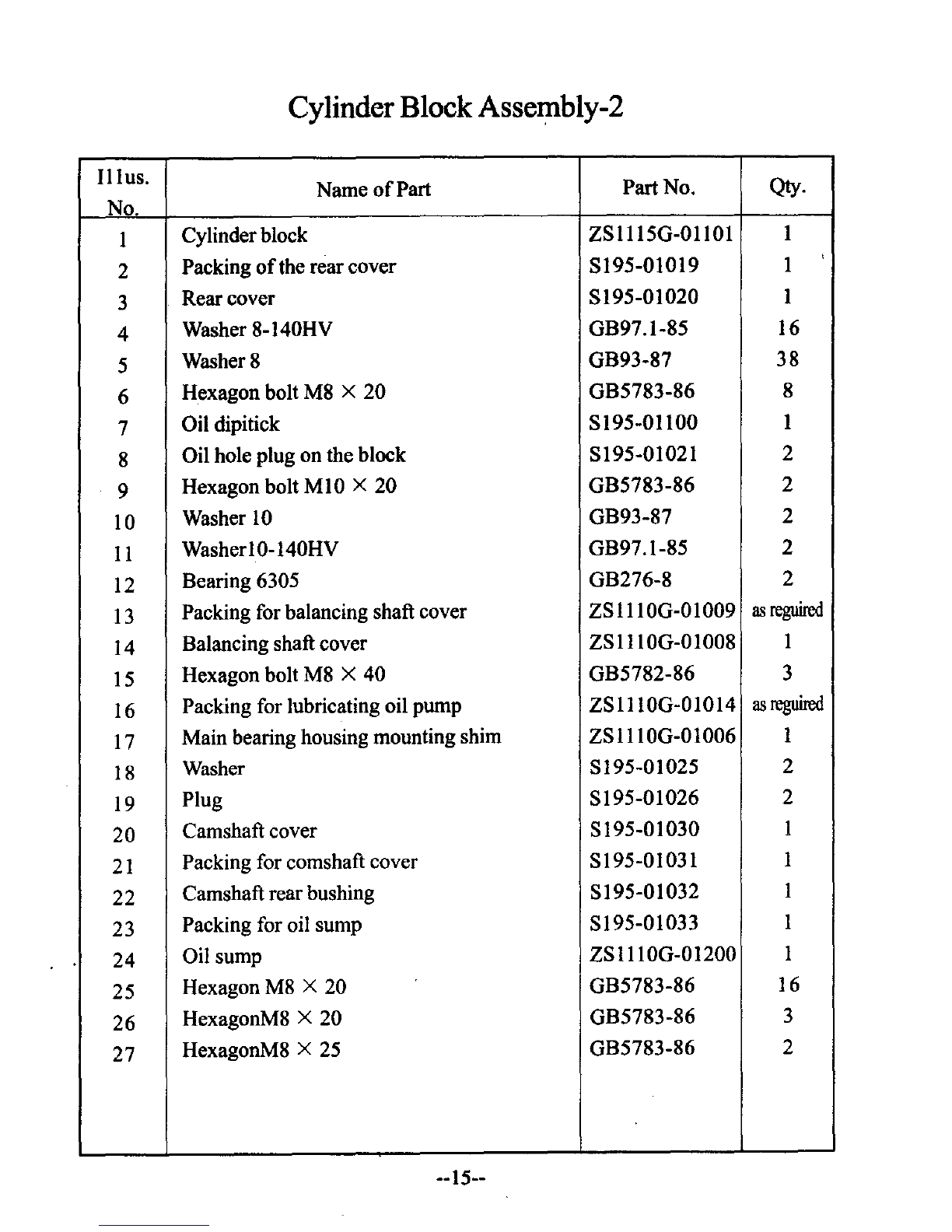

Cylinder

Block

Assembly-2

Hlus.

Name

of

Part Part No. Qty.

No.

ICylinderblock ZS11I5G-01I01 1

2Packing

of

the rear cover S195-01019 I,

3Rear cover S195-01020 I

4Washer 8-140HV GB97.1-85 16

5Washer 8GB93-87

38

6Hexagon bolt M8 X

20

GB5783-86 8

7Oil dipitick

S195-01l00

1

8Oil hole plug on the block S195-01021 2

9Hexagon bolt MIO X

20

GB5783-86 2

10 Washer

IO

GB93-87 2

II

WasherI0-140HV GB97.1-85 2

12 Bearing 6305 GB276-8 2

13

Packing for balancing shaft cover ZS

III

OG-O

I009

as

reguired

14 Balancing shaft cover ZS

III

OG-O

I008 I

15 Hexagon bolt M8 X40 GB5782-86 3

16 Packing for lubricating oil pump ZS

III

OG-O

1014

as

reguired

17 Main bearing housing mounting shim

ZSIIIOG-01006

I

18 Washer 8195-01025 2

19 Plug S195-01026 2

20

Camshaft cover S195-01030 I

21 Packing for comshaft cover 8195-01031 I

22

Camshaft rear bushing S195-01032 I

23 Packing for oil sump 8195-01033 I

24

Oil sump Z81110G-01200 I

25 Hexagon M8 X20 GB5783-86 16

26

HexagonM8 X20 GB5783-86 3

27

HexagonM8 X25 GB5783-86 2

--15--

Fig.

III

Camshaft Assembly

--16--

Table of contents

Other Chang Fa Engine manuals