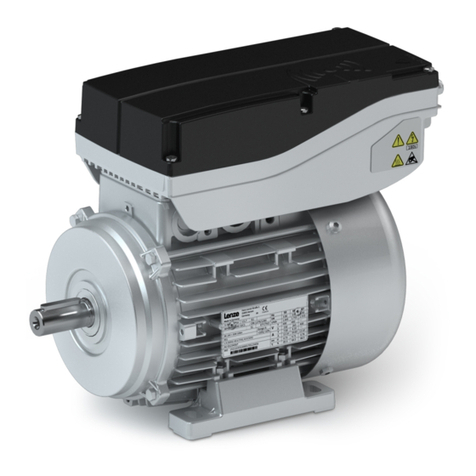

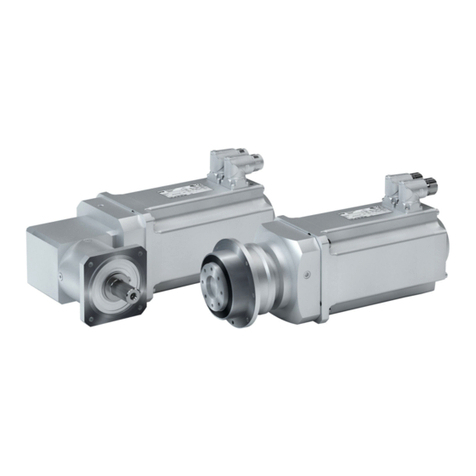

The modular system

Values printed in bold are standard designs. Values that are not printed in bold

are potenal extensions, some of them including a surcharge.

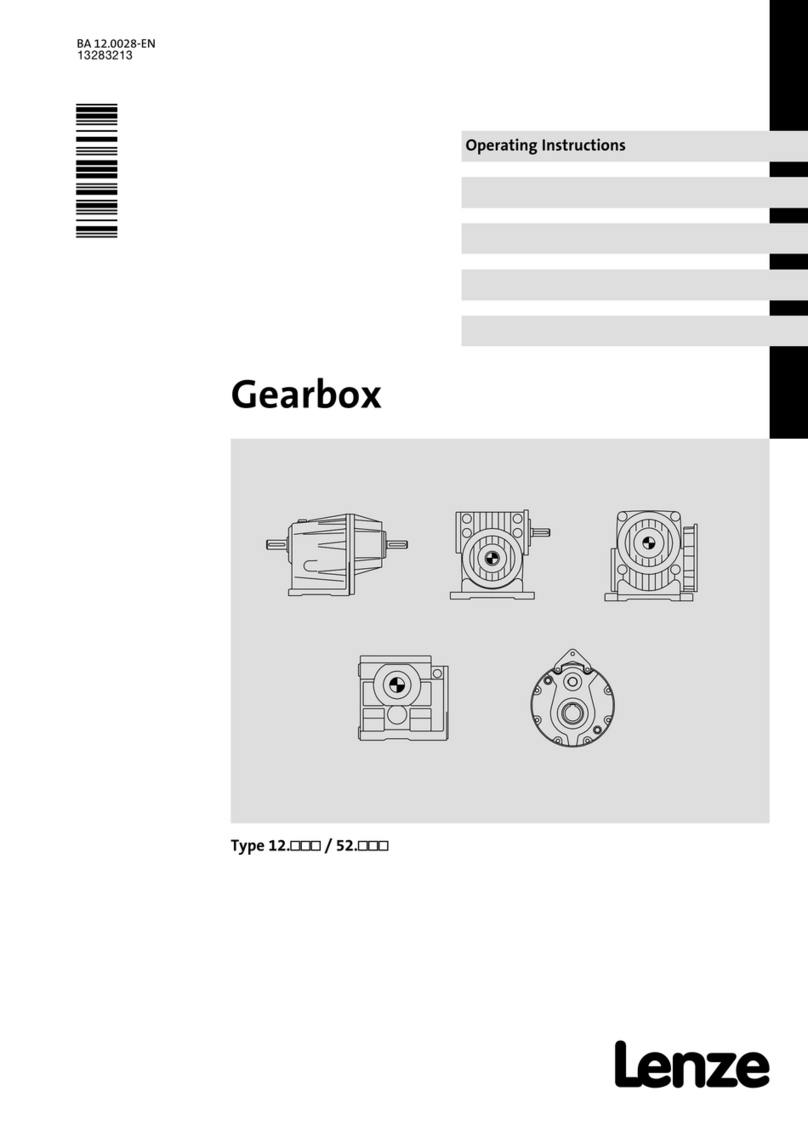

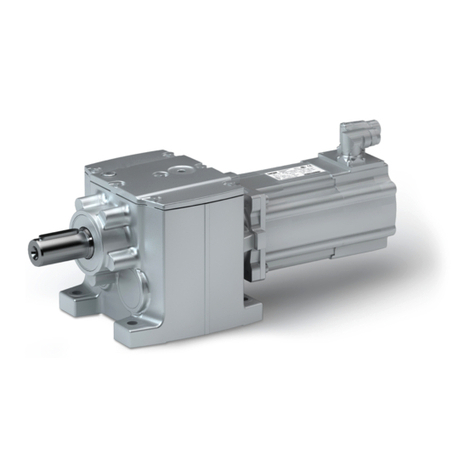

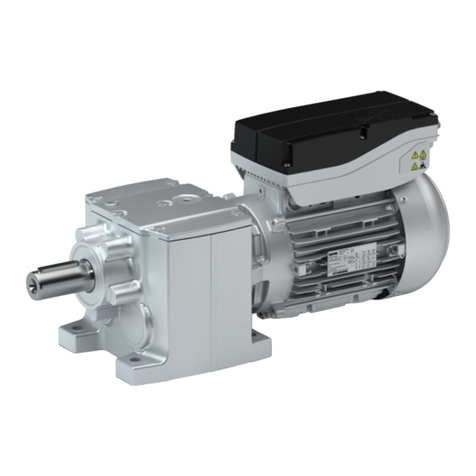

Geared motors up to 450 Nm

Gearboxes g500-B110 g500-B240 g500-B450

Min. motor assignment m850-S120 m850-S120 m850-S120

Max. motor assignment m850-S120 m850-S140 m850-S140

Technical data

Max. output torque Nm 100 140 210

Min. drive torque Nm 4.8 4.8 4.8

Max. drive torque Nm 7.4 14.0 17.4

Mounng posion

Standard A/B/C/D/E/F

Combined AEF

Colour Primed

Painted in RAL colours

Surface and corrosion protecon OKS-G

Dierent types of OKS

Output sha

Solid sha with featherkey (V) mm 20 x 40 30 x 60 30 x 60

Hollow sha with keyway (H) mm 20/25 30/35 35/40

Hollow sha with shrink disc (S) mm 20 30/35 35

Sha material Steel

Stainless steel

Sha sealing ring material NBR

FKM (Viton)

Output sha bearing Normal

Reinforced

Gearbox design With foot (HBR)/(VBR/SBR)

With foot and centring (HAR/VAR/SAR)

With foot and output ange (HAK/VAK/SAK)

Output ange (K) mm 120/160 160/200 200

Lubricant Synthec oil

Food-grade oil

Cooling Self-venlated

Torque support At threaded pitch circle

On the housing foot

Sha cover Hollow sha cover, hoseproof

Shrink disc cover

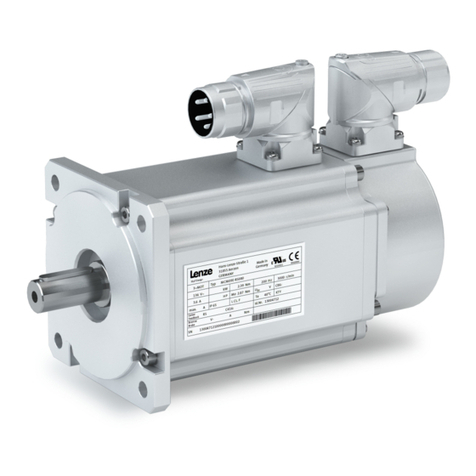

Motor connecon Connectors

Hybrid connector ICN for one-cable technology

Permanent magnet holding brake Without

With

Feedback Resolver

Absolute value encoder

Digital absolute value encoder for one-cable technology

Temperature monitoring Thermal detectors PT1000

Product informaon

The modular system

10