Channell Green Hornet G5N User manual

INSTALLATION INSTRUCTIONS

G5N

channell.com

100%

Made in

USA

Table of Contents

I. Product Introduction ................................................3

II. Tools Recommended .................................................4

III. Installation Kit .........................................................5

IV. Cable Preparation.....................................................5

A. For mid-span access .............................................5

B. For cable ends......................................................6

V. Shield Bond Connector Installation...........................7

VI. Cable Lubrication.....................................................8

VII. Installation of Main Grommet ..................................9

VIII. Branch Cable Grommet Installation ........................10

IX. Bonding and Grounding of Installed Cable ...............1 1

X. Strength Member Tiedowns .....................................12

XI. Splice Tray Preparation............................................12

XII. Slack Storage...........................................................13

XIII. Drop Cable Installation ......................................14-15

XIV. Closing the G5N Enclosure.....................................16

channell.com

I. Product Introduction

The Next Generation Green Hornet has been updated and advanced to

simplify installation and increase capacity. The new design implements

a bottom slack basket and splice trays that can be customized to the

needs of the architecture. The G5N uses Channell’s Universal Splice

Tray to accommodate single fiber splicing, ribbon splicing, Engineered

Tap/PLC splitters, and a 16-port bulkhead. Fully loaded with splice

holders on each of the Universal Splice Trays 144 fibers can be single

spliced inside this closure and 192 fibers if ribbon splicing is performed.

3

All specifications subject to change without notice.

36 Fiber Tray

Ribbon Splice Tray Splitter Tray

24 Fiber Tray

4

All specifications subject to change without notice.

II. Tools Recommended

• Safety glasses

• Gloves

• Other Personal Protective Equipment as required

• Electrician scissors

• Side-angle cutters

• 216 Tool (can wrench)

• Cable knife

• Tape measure

• Rotary Buffer Tube Ringer

• Mid-Span Access Tool

• Cleaning solvent/degreaser

• Splicing equipment

The Next Generation Green Hornet G5 closure is available in two

different base styles.

Option One is the Branch

Base option that has a

Figure-8 hole for main feeder

cables, a single Branch Port

for lateral cables up to .8”

OD and eight Drop Ports for

cables up to .45” OD.

Option Two is the Terminal

base that has a Figure-8 hole

for main feeder cables and

twelve Drop Ports for cables

up to .45” OD.

5

All specifications subject to change without notice.

III. Installation Kit

• 2 – 9”x 5mm transition tubes

• 2 – 99% alcohol wipes

• 8 – 4” black zip ties for trays

• Blue felt for buffer tubes

• ¼”- 20 bolt and washer for bracket installation when needed

• 12 fiber single splice holder

• Three position splitter holder

• Bonding and grounding kit (optional)

IV. Cable Preparation

A. For mid-span access

1. Create a loop in the cable that will allow for ring cuts on both

sides of the loop. The opening of the cable should be 96” total.

2. At the center of the loop remove 4” of sheath from the cable

exposing the buffer tubes and locate the pull strings used to rip

the sheath.

3. If possible, try to locate and center the RO, reverse oscillation,

point of the cable and make this the center of the loop. This will

allow for easier unwrapping of the buffer tubes.

4. Make a ring cut on both sides of the loop 48” from the center of

your loop.

6

All specifications subject to change without notice.

5. Notch the sheath with a pair of electrician scissors where the pull

string is located to help start the cutting of the sheath with the

pull string.

6. Cut the pull strings in half and use each pull string to cut through

the sheath on both sides down to the ring cut made in step 4 and

cut the pull strings cleanly away from the cable.

7. Remove the sheath and any binder cords, aramid yarn, or water-

swellable tape that may be on the buffer tubes.

8. Based on Engineering design, identify which buffer tube will be

used at this time as the feeder and carefully unwrap from the

group using the Reverse-Oscillation Point to assist with counter-

wraps. Separate this buffer tube or ribbon all the way back to the

sheath opening.

9. Utilizing the Reverse-Oscillation Point (or counter-wrap) unwrap

the central strength member, if present, keeping all other buffer

tubes wrapped up neatly.

10. Cut both sides of the central strength member 5” from the

sheath opening. These will be trimmed down during cable

installation.

B. For Cable Ends

1. Measure the cable end to be opened with at least 48” of buffer

tube remaining.

2. Make a ring cut where the sheath will be removed, and the buffer

tubes will be exposed.

3. Remove two inches of sheath from the end of the cable.

4. Notch the sheath where the pull strings are located to assist with

the sheath opening.

5. Pull both pull strings from the end of the cable down to where

the ring cut was made and cleanly cut away the strings at the

sheath opening.

6. Remove the sheath and any binder cords, aramid yarn, or water-

swellable tape that may be present in the cable.

7. If present, unwrap the central strength member from the end

of the cable back to the sheath opening keeping all buffer tubes

cleanly wrapped together.

8. Cut the central strength member 5” from the sheath opening.

This will be trimmed down during cable installation.

7

All specifications subject to change without notice.

V. Shield Bond Connector Installation

The Shield Bond Connectors are designed to make a stable and low

resistance electrical connection between communications cables of

.80” diameter or less and a conductor such as a strap, wire, or braid.

1. At your ring point, remove outer sheath and cut the armor shield

flush with the cable opening.

2. Using the pull strings or tabbing shears create a 1” (25 mm) slit on

both sides of the sheath, to ease insertion and to avoid buffer tube

damage.

3. When using the Shield Bond Connectors on single-sheath cable,

insert the Pair Saver insulating shoe between the core wrap and the

shield.

4. Insert connector base between shield and buffer tubes until

“connector stops” meet outer sheath. Tap sheath above connector

base to set teeth.

5. Install the top of the shield connector and secure it with one of the

nuts provided. Torque the nut to 35-45 inch-lbs. (4.0-5.2 kgm)

with a company-approved tool

6. The bond braid or other grounding or bonding hardware should be

installed above the first nut and secure it with the additional nut.

Note: Use a company approved tool to achieve the torque requirement specified.

8

All specifications subject to change without notice.

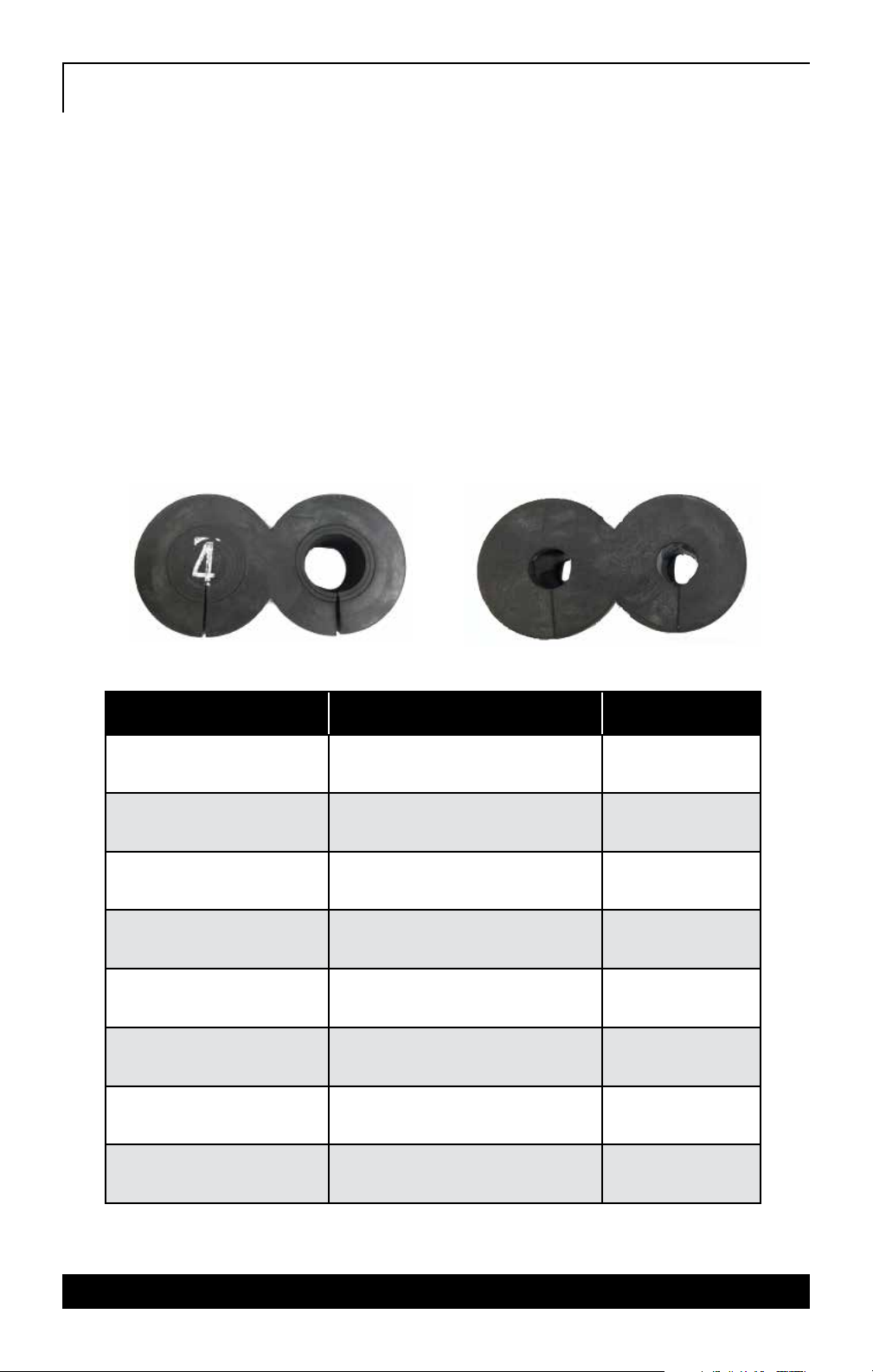

VI. Main Cable/Figure-8 Grommet Selection

If Mid-Span Access, carefully feed the buffer tube(s), with sheath

removed, through the figure-8 shaped port of the enclosure and

assure that no tube is excessively bent. If cable ends, feed the buffer

tube(s) through the appropriate port of the enclosure.

There are two types of Figure-8 grommets that may be included

with the enclosure pinned and serrated. See your local Channell

Salesperson to determine which grommet is best for your application.

Determine the appropriate Figure-8 grommet to install based on cable

diameter. The cable diameter should be within the parameters of the

hole size for the correct grommet.

PART # CABLE SIZE QUANTITY

GR06106407-34 Cable Size .188-.250” 12 per kit

GR06106407-45 Cable Size .250-.313” 12 per kit

GR06106407-56 Cable Size .313-.375” 12 per kit

GR06106407-67 Cable Size .375-.438” 12 per kit

GR06106407-78 Cable Size .438-.500” 12 per kit

GR06106407-89 Cable Size .500-.562” 12 per kit

GR03106407-49 Serrated Grommet, Cable Size .4-.9” 12 per kit

GR03106407-47 Serrated Grommet, Cable Size .4-.7” 12 per kit

9

All specifications subject to change without notice.

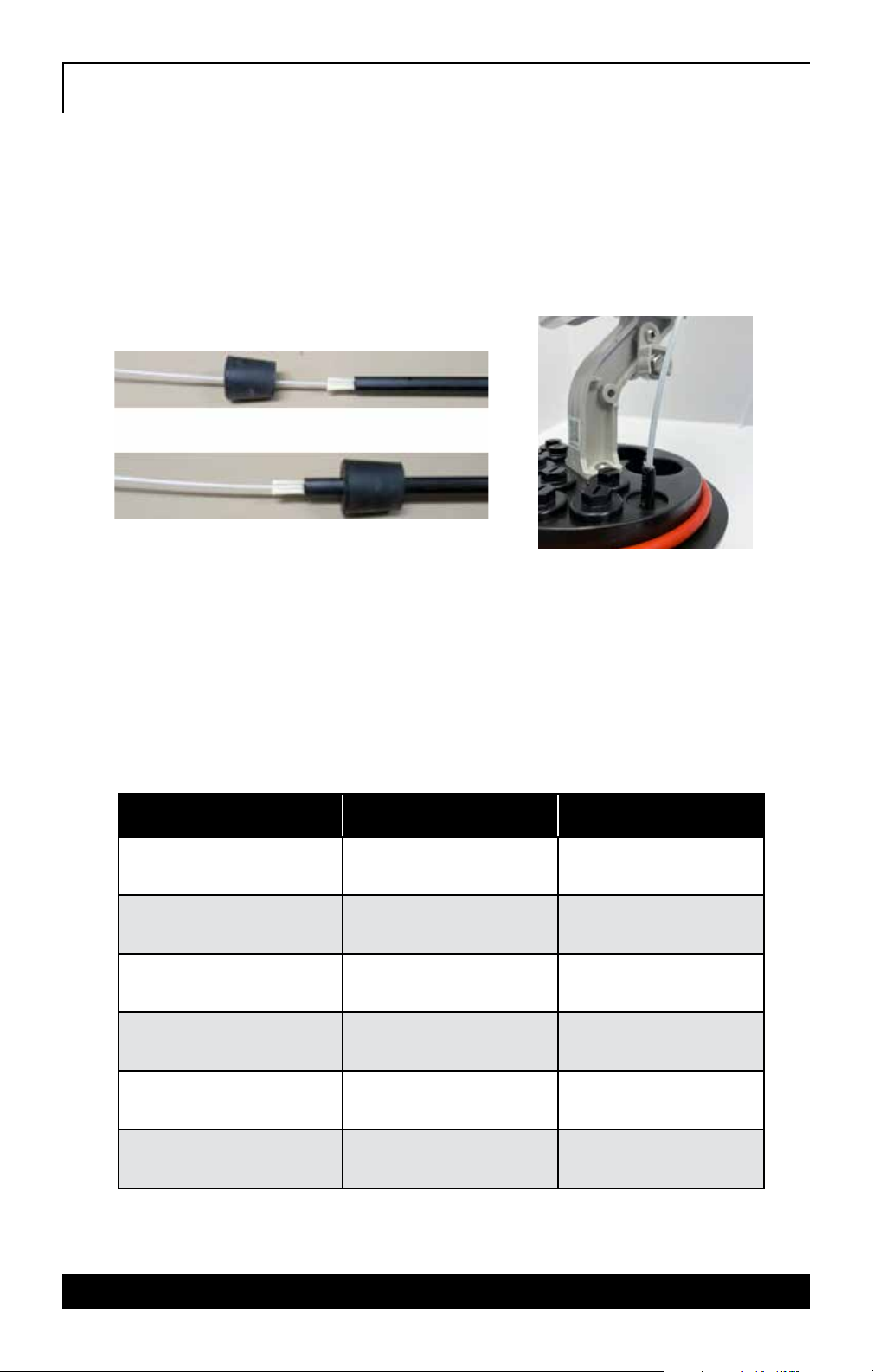

Example of Using Correct Amount of Channell Lubrication

*Note-Only Channell provided lubricant in conjunction with the correct

grommet will create an air/watertight seal. Use of any other lubricant will

nullify the sealing integrity of the enclosure and product warranty.

VII. Installation of Main Grommet

**Serrated grommet has rings that will need to be CUT OUT based on the cable

diameter. This is determined with the measuring tape included with this type of

grommet.

1. No electrical tape or other material should be placed on the cable

where it will contact the grommet. Doing so will create a leak.

2. Apply a small amount of Channell lubricant to the entire outside and

vertical slit of the grommet. The surface should appear wet but not

excessively so. The amount of lubricant used directly relates to the

amount of time it will take to create a permanent seal. With the right

amount, the grommet will seal within 10-15 minutes. More time will be

needed if excessive lubricant is used.

3. If armored cable is used and a ground bond is required, it should be

installed after the cable is through the base of the closure but before

the grommet is installed.

4. Place grommet around cable, leaving about 1/2” of sheath above the

grommet if dielectric cable is used. 1 1/2” if armored cable requiring

grounding.

NONE CORRECT AMOUNT TOO MUCH

5. Use steady downward pressure to sink the grommet into the

Figure-8 port. Continue pressure until grommet hits the bottom

stop of the port. The grommet will sit below the surface if seated

properly.

6. Verify that the entire surface of the grommet is level and neither

side of the vertical slit is higher than the other.

7. Wipe off any excess lubricant from the base surface using isopropyl

alcohol wipes included.

8. Attach the central strength member to the CTM and trim off any

excess strength member flush with the top of the clip.

9. Allow to dry before tension is placed on the cable.

VIII. Branch Cable Grommet Installation

GR03106161 Serrated Grommet, Hole Size .4-.8”

**Serrated grommet has rings that will need to be CUT OUT

based on the cable diameter. This is determined with the

measuring tape included with this type of grommet. Same

step as the main grommet

1. No electrical tape or other material should be placed on the cable

where it will contact the grommet. Doing so will create a leak.

2. Apply a small amount of Channell lubricant to the entire outside

and vertical slit of the grommet. The surface should appear wet but

not excessively so. The amount of lubricant used directly relates

to the amount of time it will take to create a permanent seal. With

the right amount, the grommet will seal within 10-15 minutes.

More time will be needed if excessive lubricant is used.

3. Face vertical slit towards the outside of the enclosure.

4. If armored cable is used and a ground bond is required, it should

be installed after the cable is through the base of the closure but

before the grommet is installed.

10

All specifications subject to change without notice.

11

All specifications subject to change without notice.

5. Place grommet around cable, leaving about 1/2” of sheath above

the grommet if dielectric cable is used. 1½” if armored cable

requiring grounding.

6. Use steady downward pressure to sink the grommet into the

Branch port. Continue pressure until grommet hits the bottom

stop of the port. The grommet will sit below the surface if seated

properly.

7. Verify that the entire surface of the grommet is level and neither

side of the vertical slit is higher than the other.

8. Wipe off any excess lubricant from the base surface using

isopropyl alcohol wipes included.

9. Attach the central strength member to the CTM and trim off any

excess strength member flush with the top of the clip.

10. Allow to dry before tension is placed on the cable.

IX. Bonding and Grounding of Installed Cable

1. When armored cable is used and the bond device has been

installed on each cable the cables will need to be strapped to the

Ground Post that is embedded in the base of the G5N.

2. Starting with the cable that is furthest from Ground Post install

the braided ground strap (using an eyelet) to the post of the

ground bond on the cable and secure with the nut provided with

the ground bond.

3. Use one eyelet for each of the cables that are bonded securing

them with the nuts from the ground bond kit.

4. With the last eyelet of the braided strap attach the strap under

the washer and nut of the ground post that is embedded into the

base of the closure.

5. Tighten and secure each nut on every connection to the specific

torque described in the bonding and ground section.

12

All specifications subject to change without notice.

X. Strength Member Tie Down for Main Cable

and Branch Cable

The strength member should be tied down for any cable installed into either the

main, Figure-8 grommet or Branch grommet.

1. In the previous step there was about 5” of strength member

left. At this point, line up the strength member with the top,

inside edge of the strength member holder and cut the strength

member to that length.

2. With a 7/16” nut driver loosen or remove the bolt and washer of

the strength member holder and slide the strength member of

the cable under the washer.

3. Re-tighten the bolt and washer.

XI. Splice Tray Preparation

1. For mid-span access of buffer tube, separate the intended buffer

tube used at this location according to engineering.

2. Secure the buffer tube(s) to the slack basket under the splice

trays with a zip tie.

3. Take the buffer tube(s) needed and route them around the slack

basket and exit out the opposite side from where they came in.

4. Route that tube up to the appropriate splice tray going around

the tray stalk.

5. Using a felt tip marker, make a mark on the buffer tube(s) at the

point of the splice tray before reaching the storage area of the

tray. (About ½” in)

6. Using preferred mid-span access tool, remove all buffer tube

material between marks to expose the fiber.

7. If a tail is being installed, mark the buffer tube at the same point

as would be done for a mid-span access. Use a ringing tool to

remove buffer tube at your mark.

13

All specifications subject to change without notice.

8. Clean and dry all fiber thoroughly before applying the blue felt

padding.

9. Using felt padding provided, wrap a single layer around the buffer

tube just below the point of tube removal. This will prevent the

buffer tube from sliding into or out of the splice tray.

10. With two cable ties (provided) secure the felt wrapped buffer

tube(s) into the tray on both sides.

11. Splice according to engineering design.

12. Wrap all spliced fiber up first and then pass-through fibers from

expressed tubes and then wrap any cut fiber that was not spliced.

13. Place plastic cover on splice tray to protect any fibers that are in

the tray.

XII. Slack Storage

All buffer tubes that are not being used at this location should be

wrapped up neatly in the slack basket below the splice trays. Secure the

wraps of buffer tubes with cable ties.

XIII. Drop Cable Installation

Measure the outside diameter of utilized drop to determine the

correct grommet size.

Note: For flat drop cables, the sealing grommet labeled 3-4

(smallest available) is to be used.

Channell Drop grommets to seal one cable each

Note-Only Channell provided lubricant in conjunction with the

correct grommet will create an air/watertight seal. Use of any other

lubricant will nullify the sealing integrity of the enclosure and

product warranty.

14

All specifications subject to change without notice.

PART # CABLE SIZE QUANTITY

GR06116101-02 Cable Size .062-.125” 12 Cards, 6 grommets per card

GR06116101-34 Cable Size .188-.250” 12 Cards, 6 grommets per card

GR06116101-45 Cable Size .250-.313” 12 Cards, 6 grommets per card

GR06116101-56 Cable Size .313-.375” 12 Cards, 6 grommets per card

GR06116101-67 Cable Size .375-.438” 12 Cards, 6 grommets per card

GR06116101-78 Cable Size .438-.500” 12 Cards, 6 grommets per card

15

All specifications subject to change without notice.

1. Remove the reusable plug from the base in the port where the cable

is to be installed.

2. No electrical tape or other material should be placed on the cable

where it will contact the grommet. Doing so will create a leak.

3. If the drop cable being installed has a tracer wire, this wire must be

stripped back so that it is completely outside of the closure after

grommet installation.

4. Sand the excess material left after removing tracer wire.

5. Insert the cable through the base from the outside. Place the sealing

grommet over the end of the cable and slide along the length of the

cable until ½” of sheath is sticking out of the top of the grommet.

6. Lubricate the outside of the sealing grommet with the lubricant

provided and wipe a small amount of the lubricant inside of the drop

port you are installing into to assist with insertion.

7. Insert the drop grommet into the terminal base, as shown.

8. Press firmly down on the top of the grommet until the grommet is

sitting just below the surface of the base. If necessary, use a blunt

tool like a screwdriver to go around the top surface of the grommet

and compress the grommet until it is fully seated.

16

All specifications subject to change without notice.

9. The sealing grommet is properly installed when the top surface of

sealing grommet is sitting slightly below top surface of terminal base.

10. Make sure to remove any excess lubricant from around the base using

an alcohol wipe.

11. Once the drop cable has been installed correctly into the base of the

G5N the fiber or buffer tube can be routed to the appropriate splice

tray or adapter.

12. Remove the clear cover of the splice tray the fiber will be installed

into.

13. Secure the buffer tube or fiber to the splice tray and route around

the tray to the correct length for splicing. If a connector is installed

on the end of the drop cable leave a couple of inches of slack in the

fiber before plugging into the adapter to prevent tension on the

connector and fiber.

14. If splicing a pigtail on the end of the drop utilize one of the splice

trays below the adapter tray.

15. First, clean the connector of the pigtail and plug it into the port

assigned by engineering.

16. Route the pigtail down to the splice tray using one of the 5mm tubes

provided in the set-up kit and splice according to engineering.

17. Install clear cover back on the splice tray to protect all the fibers and

splices.

XIV. Closing the G5N Enclosure

1. Using the orange, Fiber Optic Sticker adhered to the outside of the

dome line up the ¼” hole in the side wall of the base with the sticker

and slide the dome down over the trays and slack basket being careful

not to snag or smash any fiber or buffer tubes inside.

2. Wrap the dome clamp around the edge of where the dome and base

meet.

3. Latch the lock of the clamp and press closed until the clamp is fully

sealed and secure around the dome and base.

WORLDWIDE HEADQUARTERS: Channell Commercial Corporation, Rockwall, TX, United States • Tel 800.423.1863 • Fax 951.296.2322

CANADA: Channell Canada, Inc., Mississauga, ON, Canada • Tel 905.565.1700 • Fax 905.565.8282

EUROPE, MIDDLE EAST, AFRICA: Channell Ltd., Dartford, United Kingdom • Tel 44.1322.312590 • Fax 44.1322.508490

AUSTRALIA, ASIA, PACIFIC RIM: Channell Pty. Ltd., Seven Hills, NSW, Australia • Tel 61.2.8884.4111 • Fax 61.2.8814.8841

www.channell.com

All specifications subject to change without notice. © 2021 Channell Commercial Corporation. All rights reserved.

092821PART NUMBER 0000-00000-00

Table of contents

Popular Enclosure manuals by other brands

Thermaltake

Thermaltake View 91 TG user manual

StarTech.com

StarTech.com RK1219WALHM instruction manual

Hubbell

Hubbell GAI-TRONICS 733-006 manual

Western Digital

Western Digital WDBABV0010ABK - Elements SE Portable Specifications

Salsbury Industries

Salsbury Industries S-61000 Series installation instructions

Icy Box

Icy Box IB-RD3621-C31 manual