Chapman TH200 User manual

Page 2

Contents

Contents............................................................................................................................................................. 2

HSE Information................................................................................................................................................. 3

Important Safety Information ........................................................................................................................... 4

DEFINITIONS .................................................................................................................................................. 4

Safety Information......................................................................................................................................... 4

Transportation Safety.................................................................................................................................... 4

Operating Safety............................................................................................................................................ 4

Description......................................................................................................................................................... 5

Identification.................................................................................................................................................. 5

Implement Decals.......................................................................................................................................... 5

Attachment........................................................................................................................................................ 7

Before Attaching the Machine ...................................................................................................................... 7

Attaching the Machine .................................................................................................................................. 7

Initial Set-up....................................................................................................................................................... 7

Height ............................................................................................................................................................ 7

Initial Test Operation..................................................................................................................................... 8

Operation........................................................................................................................................................... 8

Operation....................................................................................................................................................... 8

Forward Speed............................................................................................................................................... 8

Operating Limits ............................................................................................................................................ 8

Storage........................................................................................................................................................... 9

Troubleshooting................................................................................................................................................. 9

Warranty.......................................................................................................................................................... 10

The Chapman Warranty .............................................................................................................................. 10

Warranty Conditions ................................................................................................................................... 10

Transfer of Warranty................................................................................................................................... 10

THIS MANUAL MUST BE HANDED TO THE OPERATOR BEFORE USE. THE OPERATOR MUST UNDERSTAND FULLY THE

CONTENT OF THIS HANDBOOK BEFORE USING THE MACHINE FOR THE FIRST TIME. OF THE IMPLEMENT IS

RESOLD, THIS MANUAL MUST ACCOMPANY THE MACHINE.

NOTE:

The information contained in this manual is correct at the time of going to press. However, in the course of

development, changes in specification are inevitable. Should you find the information given differs from your

machine, please contact Chapman Machinery Ltd direct for advice. Use only Chapman Genuine Service Parts on

Chapman Machinery and Machines.

Page 3

HSE Information

Safe use of all-terrain vehicles (ATVs) in agriculture and forestry –AIS Sheet 33

Introduction

This information sheet gives advice on the safe use of ATVs. It covers

the two main types used in off-road working in agriculture and

forestry, which are:

•sit-astride ATV / sit-in machines

•side-by-side mini-utility vehicles,

The Full HSE information sheet can be found here or using the QR

Code at the bottom of the article:

https://www.hse.gov.uk/pubns/ais33.pdf and must be read prior to

any ATV/UTV use. Below are related extracts to trailed machinery.

REMEMBER - GET PROPERLY TRAINED AND ALWAYS WEAR

HEAD PROTECTION

Training

Under the Provision and Use of Work Equipment Regulations 1998

(PUWER), there is a legal requirement for employers to provide

adequate training, and to ensure that only employees who have

received appropriate training in their safe use, including the use of

any towed equipment or attachments, are permitted to ride ATVs.

The same requirements apply to the self- employed. HSE regards

training provided by recognised training providers as being

adequate for the purposes of PUWER.

Protective clothing

More than half of all ATV riders have been thrown off at some time.

As these machines are not fitted with either a cab or roll bar, your

only protection is what you wear.

●

Head protection is vital. The majority of ATV fatalities in the

UK in the last ten years have been caused by head injuries.

Nobody who died from head injuries was wearing a helmet.

Helmets would certainly have prevented most, if not all, the

deaths. You should always wear a helmet when riding an

ATV. All helmets should have a chinstrap and be capable of

being used with suitable eye protection. The type of helmet

chosen should be based on an assessment of the

circumstances in which the ATV will be used, eg the types of

surface travelled over and anticipated speeds. The harder the

surface and higher the speed the greater the degree of

protection needed. NB: Forestry helmets and industrial hard

hats are not acceptable for any ATVoperations.

●

Wear clothing that is strong and covers your arms and legs.

Gloves are useful for protection and to keep hands warm in

cold weather for good control of the ATV.Wear sturdy, ankle-

covering footwear, eg boots or wellingtons that are strong,

supportive and have good wet grip.

●

Protect your eyes from insects and branches with either a

visor or goggles.

Trailed equipment and loads

Ensure all riders know the manufacturers recommended

towing capacity and drawbar loading limit. Always operate

within these requirements.

Remember that your ability to control the ATV by your body

movements will be considerably reduced when carrying a load or

towing a trailer.

●

When selecting trailed equipment look for:

-

over-run brakes;

-

a swivel hitch drawbar;

-

bead lock rims on wheels;

-

a low centre of gravity and a wide wheel track;

-

a long drawbar; and

-

attachment points for securing a load.

●

Check the weight ratio between your ATV and its trailed load.

This needs to be assessed for each operation. As a general

guide, on level ground, braked trailed equipment can be a

maximum of four times the unladen weight of the ATV.For

unbraked trailed equipment the maximum should be twice

the unladen weight. These loads should be reduced when

working on slopes, uneven ground or poor surface

conditions. Follow the manufacturers advice for your

particular machine.

●

Weight transfer is also important. Stability and resistance to

jack-knifing is improved if some load is transferred onto the

ATVʼs drawbar. Approximately 10% of the gross weight of the

loaded trailer is recommended, but this should not exceed

the manufacturers drawbar loading limit. Remember that

weight transfer can change dramatically when you start going

up or down hill.

●

When selecting mounted equipment, make sure it is within

the manufacturers approved weight limit, with a low centre

of gravity, and controls which are easy to operate but do not

create a hazard. Where equipment is added to one end of the

machine, add ballast at the other end to maintain stability.

●

Loads carried on racks must be well secured, e.g. with ratchet

straps, and be evenly balanced between the front and rear,

except where they are deliberately altered to aid stability

when going up or down a slope.

●

Only tow a load from the hitch point. Loads towed from other

points such as the rear rack have caused sudden rear

overturning even on slight slopes or with slight acceleration.

Ropes or chains should not be used to drag a load where they

can become caught on a wheel. This may lead to

entanglement with the brake cable, causing unexpected

braking.

Further information

For information about health and safety go to

https://www.hse.gov.uk/

© Crown copyright This publication

may be freely reproduced, except for

advertising, endorsement or

commercial purposes. First published

05/99. Please acknowledge the source

as HSE.

Page 4

Important Safety Information

Always read this manual before fitting or operating the machine –whenever any doubt exists contact your

dealer or the Chapman Machinery Service Department for advice and assistance.

DEFINITIONS

The following definitions apply throughout this manual:

WARNING - An operating procedure, technique etc., which can result in personal injury or loss of life if not observed

carefully.

CAUTION - An operating procedure, technique etc., which can result in damage to either machine or equipment if

not observed carefully.

NOTE - An operating procedure, technique etc, which is considered essential to emphasis.

LEFT & RIGHT HAND - This term is applicable to the machine when attached to the towing vehicle and is viewed

from the rear –this also applies to tractor references.

Safety Information

•Do not operate this equipment unless you have studied this manual in full

•Only use this machine for its designated task - improper use is both highly dangerous and damaging to

machine components

•Both operators & maintenance fitters should be familiar with the machine and fully aware of dangers

surrounding improper use or incorrect repairs

•Before starting, carry out a visual check on both machine & towing vehicle as regards functionality,road

safety & accident prevention rules

•Even when using the machine correctly, accidents can occur. It is imperative that nobody stand withinthe

danger area. If working near roads, buildings or animals, special attention must be taken to ensure safety.

•Never wear loose clothing which could get caught in rotatingequipment

•Never carry passengers on the towing vehicle

•Do not stand near the machine when operating

•Damaged or missing safety decals must be replaced immediately

Transportation Safety

•When transporting, especially over rough ground, reduce speed to prevent damage to machine.

•This machine is not road legal in its standard form. DO NOT tow on public highways unless you have

specified the road-legal model, and checked that this and the towing vehicle comply with local highway

regulations in place.

Operating Safety

•Pay special attention when working not to harm livestock if crowding around the machine occurs.

•If anything should become entangled in the mechanism, or blocked in the chute, stop the machine and

disconnect the power before attempting to clear the blockage.

Page 5

Description

The TH200 Tine Harrow is a 2m wide (approx) unit, designed for quick and easy maintenance of grassland

and pasture.

The TH200 Tine Harrow is a trailed attachment, with 4 rows of spring tines. The angle of attack of the

spring tines can be adjusted in 3 increments from soft to aggressive. The height of the unit can also be

adjusted using the electric actuator, to change between working and transport modes.

These machines should however only be used to perform tasks for which they were designed - use of the

machine for any other function may be both dangerous to persons, and potentially damaging to

components. Use of the machine beyond the stated usage may invalidate any applicable warranty, as well

as being potential in breach of applicable safety regulations.

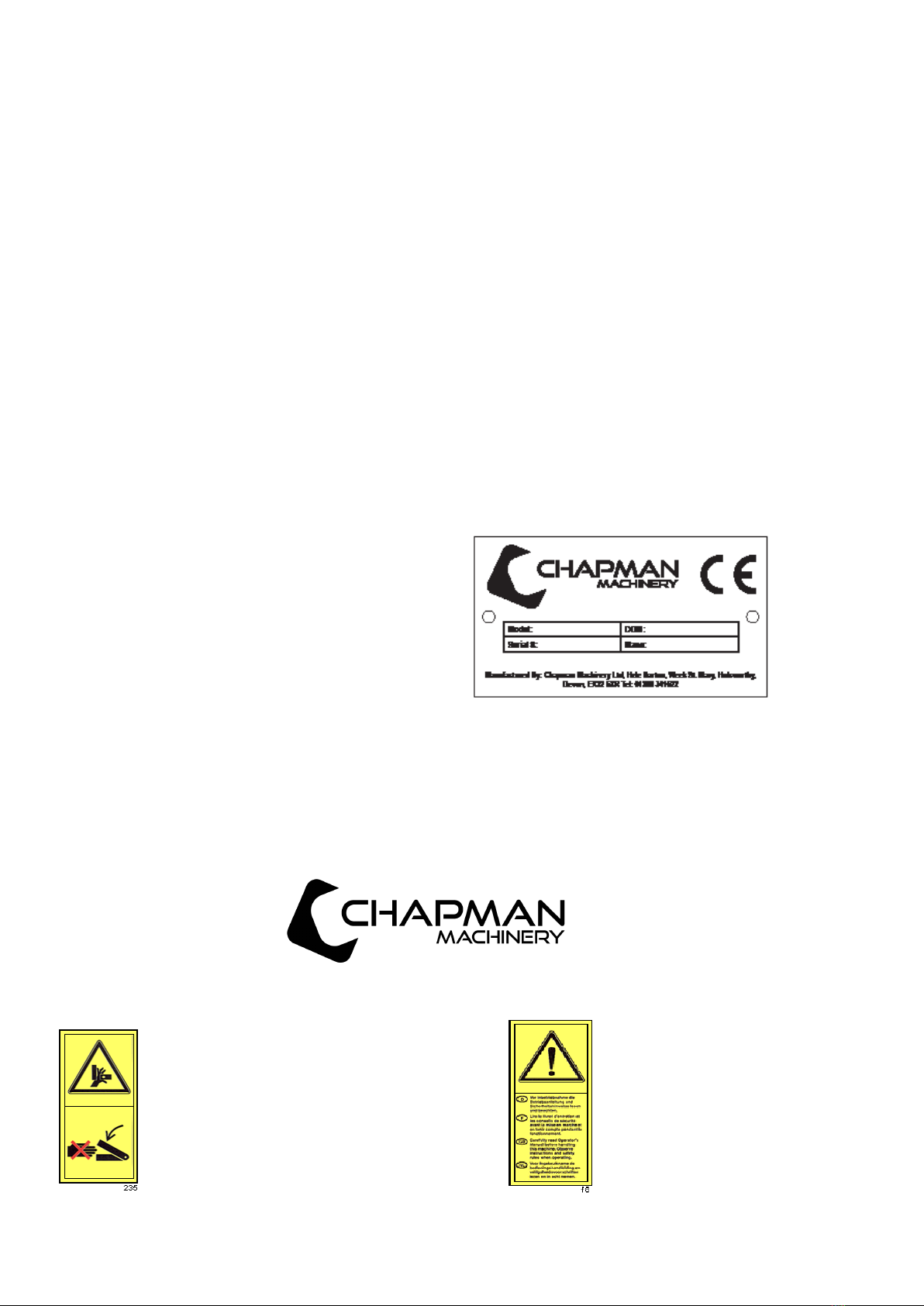

Identification

Each machine is fitted with a serial plate (shown below) which details the following:

1. Model

2. Date of Manufacture (DOM)

3. Serial Number

4. Mass

When enquiring regarding spares or additional

equipment, ensure you have this information to hand.

Implement Decals

If your implement does not contain all of the decals shown below, please contact Chapman Machinery for

replacement decals before use. Note: All decals must be present and visible. It is imperative that these are replaced

if damaged to prevent potential harm to users.

* Caution, crush hazard –never reach

into crush area as parts may move

trapping appendages

* Carefully read operators manual

before handling this machine. Observe

instructions and safety rules when

operating.

Page 6

Component Identification

Page 7

Attachment

Before Attaching the Machine

Before attachment, ALWAYS ensure the following:

- All safety guards & decals are in good working order and correctly fitted

- Lubrication points have been lubricated as per scheduled maintenance period

- The tyres are free of damage and inflated to the correct pressure

- Electrical connections are free of dirt and moisture

Attaching the Machine

NOTE: This machine is designed to attach to the towing vehicle through a 50mm diameter ball hitch.

1. Reverse the towing vehicle up to the machine.

2. Attach the machine onto the towing vehicle’scoupling. Adjust drawbar angle is necessary to ensure main frame of

machine is parallel with ground when in working height, this ensures even tine contact across the 4 rows of tines.

3. Attach the control cable to the control socket fitted on the towing machine, ensuring a secure connection.

4. If required, adjust tine angle setting before lowering machine into work mode.

WARNING: ENSURE CONTROL EQUIPMENT IS SECURELY ATTACHED TO THE TOWING VEHICLE BEFORE USE,

REPLACEMENT CONTROL BOX ASSEMBLIES ARE EXPENSIVE!

Initial Set-up

Tine Angle

The tines on the TH200 can be set to three settings of aggressiveness, using the black tine bar adjuster

located just behind the machine drawbar. Pulling the adjuster forwards (towards the towing vehicle) will

make the tines less aggressive and pushing the adjuster rearwards will make the tines more aggressive. The

adjuster s fixed in place once set using a pin and retaining clip. *We recommend you begin operation with

the tines in the middle setting and adjust as required thereafter*

Height

The working height of the machine is set using the electronic actuator and control box. Pressing the

relevant up / down arrow will raise or lower the main frame accordingly. The TH200 should only be

transported across fields with the height at it’s maximum, and then lowered into use as required. The

TH200 should be lowered to allow weight onto the tines, such that consistent ground contact is achieved

by the tines. The wheels will always carry some weight, to ensure the unit tows easily and travels over

rough terrain smoothly.

Page 8

Initial Test Operation

In order to familiarise the operator(s) with the machine, first adjust the tines and machine height in the

yard, before going out to the pasture to commence work. This will ensure the operator is fully familiar with

the operation of the machine. During this period the angle of the drawbar should be adjusted to suit the

towing vehicle, such that the main frame of the TH200 runs level with the ground when the unit is in a

working height.

Once the operator(s) are familiar with the machine and operation, the tank can be drained and refilled with

water / herbicide as per the herbicide manufacturers recommendations.

Operation

Ensure that the operator is suitably qualified to use a machine of this nature and that they have fully read

and

understood this manual - they should be aware of all safety aspects relating to the safe use of the machine.

AFTER APPROXIMATELY ONE HOUR OF WORK WITH A NEW MACHINE, ALL NUTS, BOLTS AND DRIVE BELTS

SHOULD BE CHECKED FOR TIGHTNESS AND ADJUSTED AS NECESSARY!

Operation

1. Set desired tine angle with machine in transport position (ie. height at maximum). Recommended

start position is middle hole on tine adjustment.

2. Drive into paddock and using control box, lower tines onto ground until all tines are in contact with

the ground. Ensure main frame is roughly parallel with ground and adjust drawbar angle if necessary.

3. The TH200 is quite heavy and the weight of the machine can be used to increase the pressure on the

tines –more pressure = more tine penetration through the sward. Heavy harrowing in the spring will

usually need more tine pressure and lighter de-thatching in the summer will need less pressure.

4. Harrow the field by first running around the edge a few times to allow turning room, and then

traversing the field in straight lines. For some pastures a second pass at 90° to the first pass will be

required.

5. Once finished harrowing raise to transport position (maximum height) for transport.

Forward Speed

A forward speed of around 5mph will typically produce the best results, however this may need to be

increased or reduced depending on the ground conditions and depth of grass sward.

Operating Limits

WARNING: DO NOT OPERATE BEYOND OPERATING LIMITS, DAMAGE TO MACHINERY OR INJURY TO

OPERATOR MAY OCCUR.

Minimum / Maximum Temperature: 5°C / +40°C

Page 9

Storage

For extended periods of storage, it is advisable that the machine be kept in a clean dry environment

protected from the elements to avoid risk of corrosion.

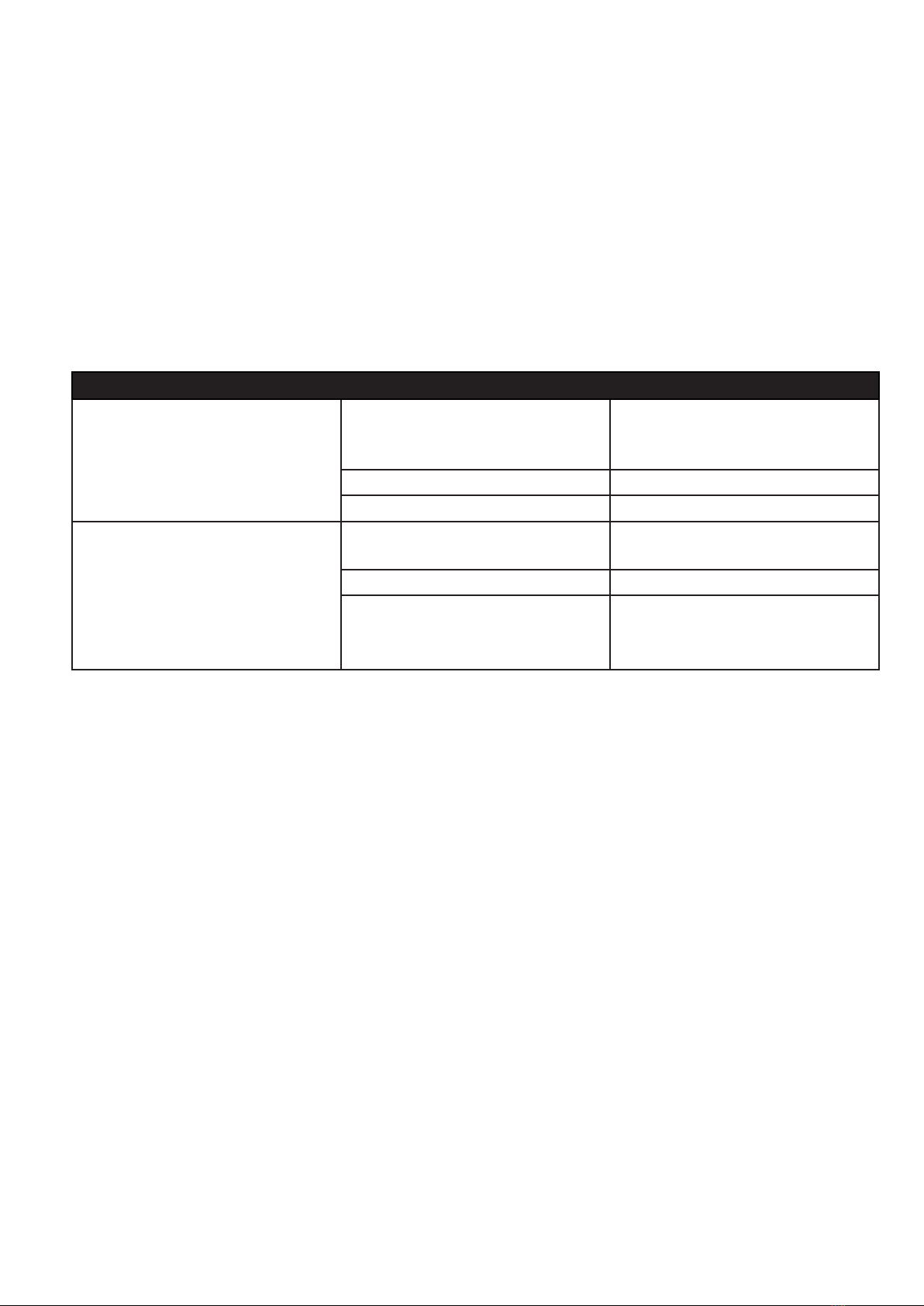

Troubleshooting

Problem

Possible Causes

Remedies

Unit will not raise or lower

Shortage in wiring (may be

indicated by unit losing powerwhen

run button pressed)

Check plug and battery connection

are free from dirt and making good

contact

Actuator Fault

Replace motor, contact distributor

Switch Fault

Replace switch, contact distributor

Poor tine contact with ground

Working height too high

Lower unit

Tines worn

Inspect tines, replace if worn

Drawbar angle incorrect

Adjust drawbar adjuster so that

main frame is parallel with ground

when at working height

Page 10

Warranty

The Chapman Warranty

Chapman Machinery Ltd (herein ‘Chapman’ or ‘Chapman Machinery’) warrants that the machine referred to in the Warranty Registration Form will be free

from manufacturing defects for a period of 24 months from the date of sale. This warranty does not affect your statutory rights, but merely adds to them.

Should you have a problem within 24 months from the date of sale please contact your original dealer, or Chapman Machinery’s Service Department.

Any part found to be defective during this period will be replaced or repaired, at our discretion, by the dealer or a authorised Service Engineer.

Warranty Conditions

1. The Warranty Registration Form must be completed and returned to Chapman Machinery Ltd within 30 days of the date of sale

2. This warranty does not cover defects arising from fair wear and tear, wilful damage, negligence, misuse, abnormal working conditions, use in competition,

failure to follow Chapman Machinery’s instructions (oral or written, including all instructions and recommendation made in the Operator’s Manual) or

alteration or repair of the

machinery without prior approval.

3. The machinery must have been serviced in accordance with the Operator’s Manual and the Service Log must have been

kept up to date and made available tothe

dealer should service, repair or warranty work be undertaken.

4. This warranty does not cover claims in respect of wearing parts such as blades, flails, paintwork, tyres, belts, hydraulic hoses, bearings, bushes, linkage pins,

top links, ball ends unless there is a manufacturing or material defect or the cost of normal servicing items such as oils and lubricants.

5. This warranty does not cover any expenses or losses incurred whilst the machinery is out of use for warranty repairs or parts replacement.

6. This warranty does not extend to parts, materials or equipment not manufactured by Chapman Machinery, for which the Buyer shall only be entitled to the

benefit of any such warranty or guarantee given by themanufacturer to Chapman Machinery. Only genuine replacement parts will be allowable for warranty

claims.

7. All parts replaced by Chapman Machinery under warranty become the property of Chapman Machinery and must be returned to Chapman Machinery if

so requested. Such parts may only be disposed of after a warranty claim has been accepted and processed by Chapman Machinery.

8. Chapman Machinery is not liable under this warranty for any repairs carried out without Chapman Machinery’s written consent or without Chapman

Machinery being afforded a reasonable opportunity toinspect the machinery the subject of the warranty claim. Chapman Machinery’s written consent must,

therefore, be obtained before any repairs are carried out or parts replaced. Use of non- Chapman Machinery parts automatically invalidates the Chapman

Warranty. Failed components must not be dismantled except as specifically authorised by Chapman Machinery and dismantling of any components without

authorisation from Chapman Machinery will invalidate this warranty.

9. All warranty claims must be submitted to Chapman Machinery on Chapman Machinery Warranty Claim Forms within 30 days of completion of warranty

work.

Using the machine implies the knowledge and acceptance of these instructions and the limitations contained in this

Manual.

Transfer of Warranty

The Chapman warranty be transferred to a subsequent owner of the machinery (for use within the UK only) for the balance of the warranty period subject to

all of the stated warranty conditions and provided that the Change of Owner form is completed and sent to Chapman Machinery within 14 days of change of

owner- ship.

Chapman Machinery Ltd retain the right to refuse transfer of warranty.

Chapman Machinery reserves the right to make alterations and improvements to any machinery

without notification and without obligation to do so.

Page 11

EC DECLARATION OF CONFORMITY

Machinery Directive 2006/42/EC

Chapman Machinery Ltd

Hele Barton

Week St. Mary

Holsworthy

Devon

EX22 6XR

The Products Covered by this Declaration

Product: TH200 Tine Harrow

Standards and Regulations used: Machinery Directive 2006/42/EC

Place of Issue: United Kingdom

Name of Representative: James Chapman

Position of representative: Director

The Basis on which Conformity is being Declared

I declare that as the authorised representative, the above information in relation to the supply /

manufacture of this product, is in conformity with the stated standards and other related documents

following the provisions of Machinery Directive 2006/42/EC directives

The products described above comply with the essential requirements of the directives specified.

Signed:

Date: ......21/01/2014..................

Table of contents