I.C.P. Srl Savannah™VG FLIGHT MANUAL Pag. 8

Issue 1/Revision 03 ICP Srl – S.P.16 km 15,150 14022 Castelnuovo Don Bosco (AT)

Jan.2012 Tel. 011.9927503 Fax 011.9927266

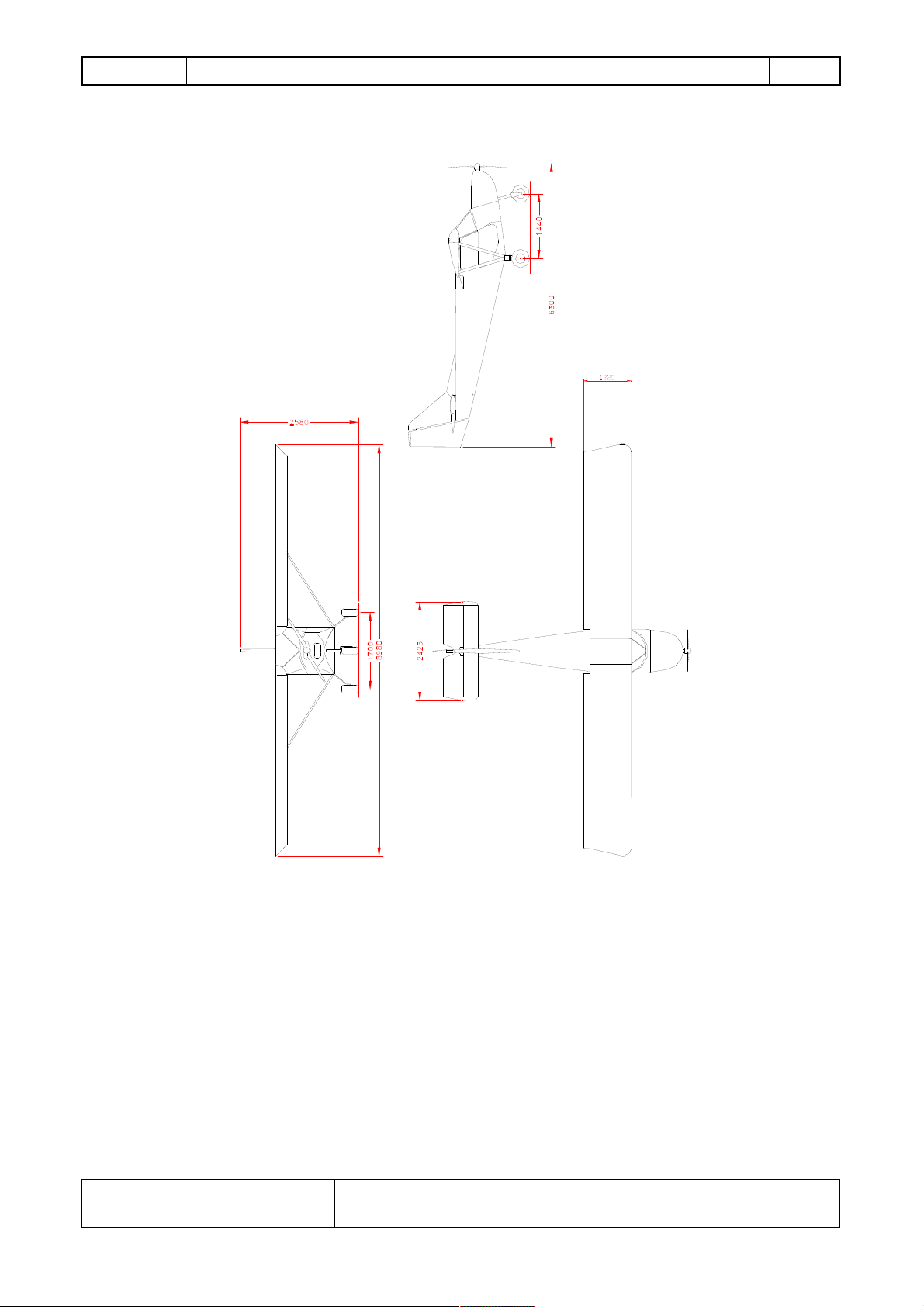

1.3 LANDING GEAR

The aircraft has a tri-cycle type landing gear. The main landing gear is made by a single-piece

aluminium alloy single-leaf leg. The nose landing gear has a telescopic, elastic chord shock absorber

and is steerable in order to ease the taxiing.

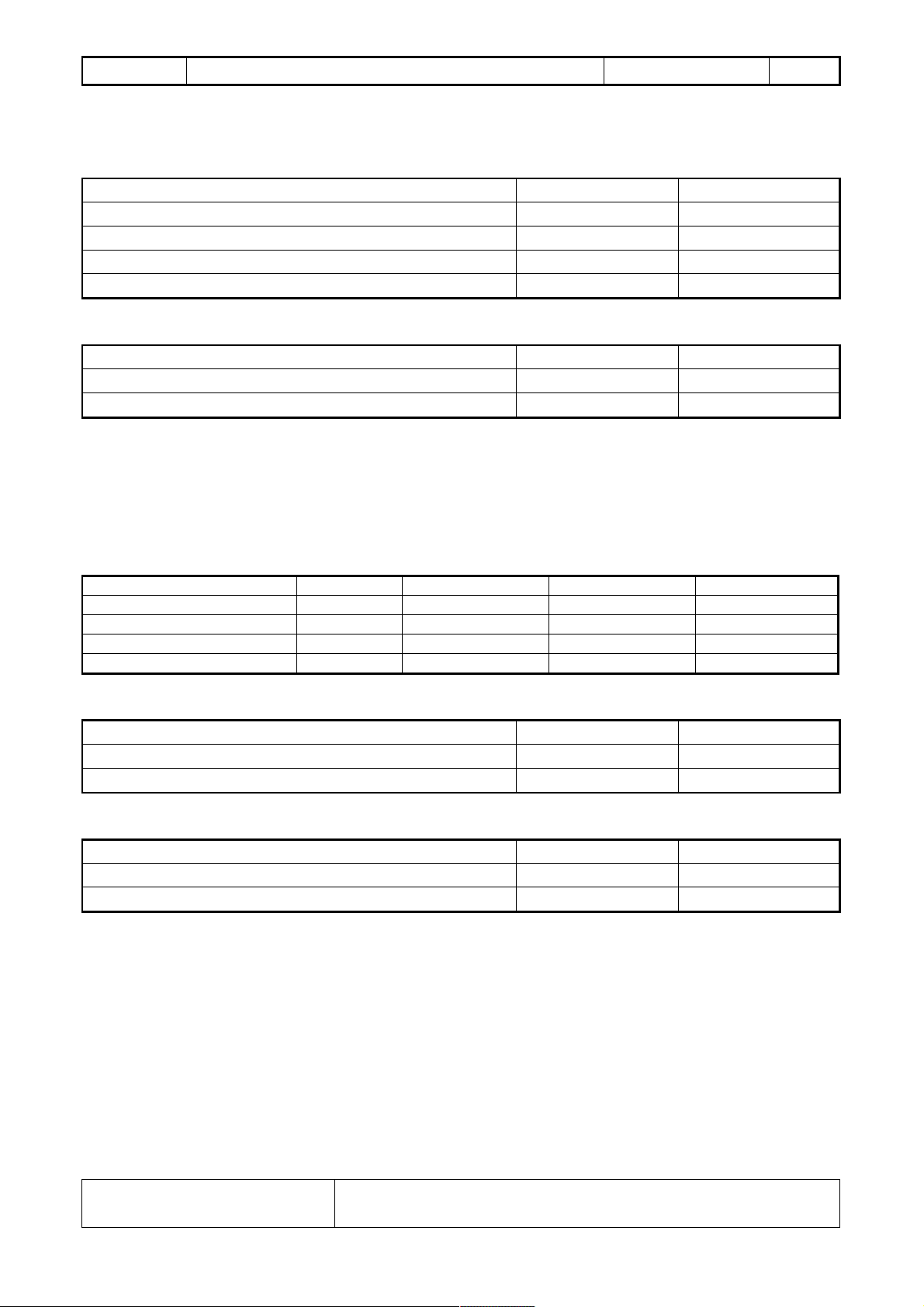

1.4 ENGINE

This aircrft has two engine installation options: the ROTAX 912 ULS/ROTAX 912 UL or

Jabiru2200. Please refer to Engine manual for any data and specifications.

WARNING: Rotax and Jabiru manufacturers issue several service and information bulletins.

It is the owner’s responsibility to acquire these documents available at www.rotax-aircraft-

engines.com or www.jabiru.net.au.

WARNING: All engines are subject to sudden stoppage. Engine stoppage can result in crash

landings, forced landings or no power landings. Such crash landings can lead to serious bodily

injury or death. Never fly the aircrafts at locations, airspeeds, altitudes, or other circumstances

from which a successful no power landing cannot be made.

These engines are not certificated aircraft engines. They have not received any safety or

durability testing and may not conform to aircraft standards.

User assumes all risks of use and fully acknowledges by his use that he knows this engine is

subject to sudden stoppage.

Note: check your country’s regulations to establish the approved condition in which the

airplane can be flown (VFR/IFR, Night/Day) and the type of airworthiness certificate that can

be issued.

1.5 ENGINE CONTROLS

There are two push-pull throttle controls with a friction adjusting knob. In the Jabiru

installation the mixture control is located near the pilot’s side throttle control. In the Rotax

installation the choke is in that position. The air-box control (Rotax 912 ULS) is located near the

throttle control: pull for hot air to carburetors, push for cold air to carburetors (for values of

temperature to maintain see chapter 2.3).

The key-operated master switch connects the electrical system to the 12V battery. The whole

electrical system is protected by thermal type re-settable breakers.

The engine can be operating with the master switch OFF and the breakers OFF since the

ignition system is independent. It can only be turned off by switching OFF the two magnetos

switches. All of the electrical instruments and devices, including the engine starter will not operate

when the master switch is OFF.

WARNING: The engine may start with the master switch OFF, if the magnetos switch (even

only one) is ON and the propeller is hand rotating or windmilling. For safety, it is strongly

recommended to pull-out the master switch key when exiting the cabin.