riddle,andopentheaircontrolsto

maximum.Whenthefireisburning

wellloadonmorefuelasnecessary

andmovetheaircontrolstothe

desiredsetting.

Whenburningwooduselargelogs

ratherthansmallones.Proceedas

above,butdonotriddlethefireeither

whenshuttingdownorreviving.

Thestoveisfinishedwithahigh

temperaturepaintwhichwill

withstandthetemperatures

encounteredinnormaluse.Thismay

becleanedwithadamplint-freecloth

whenthestoveiscold.Shouldre-

paintingbecomenecessary,high

temperaturepaintsareavailablefrom

yoursupplierorfromstoveshops.

Theglassinthedoorsisazero

expansionceramicglass,capableof

withstandingtheheatofthefire.

Beforecleaningtheglassopenthe

doorsandallowthemtocool.Clean

theglassusingadampclothandthen

wipingoverwithadrycloth.Any

stubborndepositsontheglassmaybe

removedwithaproprietarystoveglass

cleanerorceramichobcleaner.Some

depositsontheglassmaybeburntoff

simplybyrunningthefireatafastrate

forafewminutes.Donotuseabrasive

cleanersorpadsasthesescanscratch

thesurfacewhichwillweakenthe

glassandcauseprematurefailure.

Itisimportantthatthe throatplateand

allthestovefluewaysarekeptclean.

Whenburningsmokelessfuelsthey

shouldbecleanedmonthly.When

burningotherfuelstheyshouldbe

cleanedatleastonceaweek,andmore

frequentlyifnecessary.Itisnot

necessarytoletthefireoutcompletely

tocarryouttheseoperations.

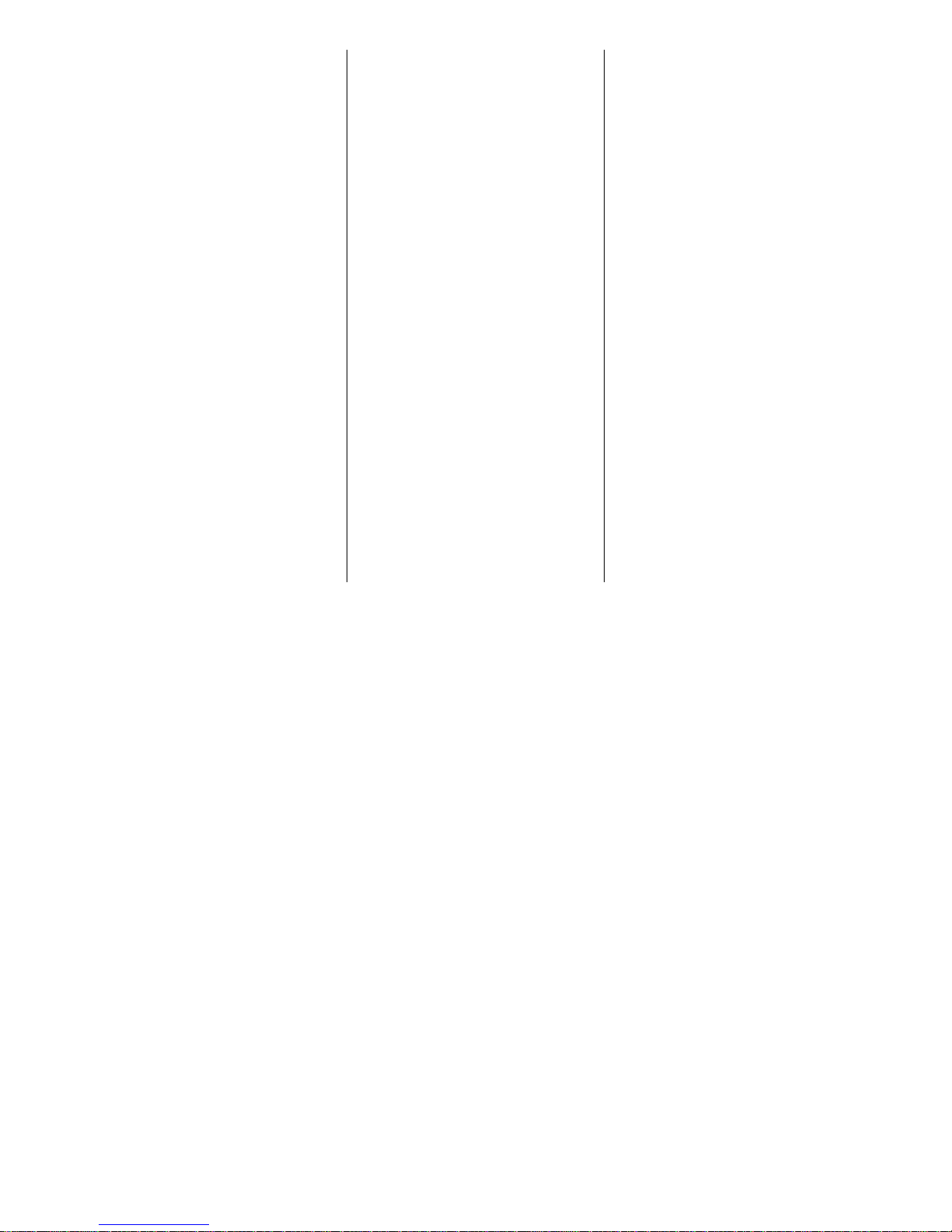

Thethroatplateisloweredusingthe

dooropeningtool.Slidethetoolinto

thebracketfromtheside,pullthe

throatplateforward,andthenlowerit

asshowninFig.3.Anysootydeposits

shouldthenbesweptfromtheplate

andintothefire.

Whilethethroatplateisloweredclean

anysootydeposits fromtheboiler

facesandtheairwashtubes.

Returnthethroatplatetoitscorrect

position-raisethefrontoftheplate,

pushitbackandthenloweritontothe

CLEANINGAND

MAINTENANCE

THROATPLATEAND

FLUEWAYCLEANING

retaininglugs.

Thechimneyshouldbesweptatleast

twiceayear.Whereatopoutletis

useditwillgenerallybepossibleto

sweepthechimneythroughthe

appliance.

Firstremovethesidefireplates,front

firebarsandthethroatplate.Then

sweepthechimneyensuringthatsoot

isremovedfromallhorizontal

surfacesaftersweeping.

Insituationswhereitisnotpossibleto

sweepthroughtheappliancethe

installerwillhaveprovidedalternative

means,suchasasootdoor.After

sweepingthechimneytheappliance

flueoutletandthefluepipe

connectingthestovetothechimney

mustbecleanedwithafluebrush.

Afterclearinganysootfromwithin

thestove,replacethethroatplate(see

Fig.3),thefrontfirebars,andside

fireplates.

Differenttypesofsweep'sbrushesare

availabletosuitdifferentflueways.

Forstandardbrickchimneysawire

centresweep'sbrushfittedwitha

guidewheelisrecommended.For

prefabricatedinsulatedchimneysthe

manufacturersinstructionswithregard

tosweepingshouldbeconsulted.

Checkthat:

a)theairinletisnotobstructedinany

way,

b)chimneysandfluewaysareclear,c)

CHIMNEYSWEEPING

TROUBLESHOOTING

FireWillNotBurn.

thatasuitablefuelisbeingused,d)

thatthereisanadequateairsupply

intotheroom,

e)thatanextractorfanisnotfittedin

thesameroomasthestove.

f)thereissufficientdrawinthe

chimney,(oncethechimneyiswarma

draughtreadingofatleast0.10inches

watergaugeshouldbeobtained).

Keepingtheglasscleanrequiresa

certainamountofexperimentationdue

tothedifferencesinthedrawof

differentchimneys.Thefollowing

pointsshouldbenotedandwithalittle

careshouldenabletheglasstobekept

cleaninmostsituations:

a)Theairwashreliesonasupplyof

heatedairtokeepthe glassclean,

therefore,whenlightingthestove

allowthefirebedtobecomewell

establishedbeforeclosingtheair

controls.Thismayalsobenecessary

whenre-fuellingthestove.

b)Whenre-fuellingkeepthefuelas

farbackfromthefrontfirebarsas

possible,donottrytofittoomuch

fuelintothefirebox.

c)Nevercompletelyclosetheairwash

control-asaguideitshouldbeat

leastaquarteropen.

d)Wetwoodorlogsoverhangingthe

frontfirebarswillcausetheglassto

blacken.

Itisalwaysmoredifficulttokeepthe

glasscleanwhenrunningthestove

veryslowlyforlongperiods.

Ifblackeningoftheglassstilloccurs

checkthatallflueconnectionsandthe

blankingplatearewellsealed.Itis

alsoimportantthatthechimneydraw

issufficient,(whenthechimneyis

warmadraughtreadingofatleast

2.54mm,or0.10inches,watergauge

shouldbeobtained),andthatitisnot

affectedbydown-draught.

Whenburningcoalsomeblackening

oftheglassmayoccurbelowthelevel

ofthefrontfirebars.Thiswillnot

obscuretheviewofthefireoraffect

itsperformance.

DoorGlassBlacksUp

FumeEmission.

WarningNote:Properlyinstalled

andoperatedthisappliancewillnot

emitfumes.Occasionalfumefrom

de-ashingandre-fuellingmayoccur.

Persistentfumeemissionis

potentiallydangerousandmustnot

betolerated.Iffumeemissiondoes

persist,thenthefollowing

Page3

Country14B09/03

Fig.3ThroatPlateLocation

Tool

PullForward

SwingDown