Chassis Plans CPX-15 Use and care manual

CPX-15

CPX-17

CPX-19

Rugged Military Grade

8U Rack Mount

LCD Display

15” XGA TRANSFLECTIVE LCD

17” or 19” SXGA LCD

Technical Reference

22010100B

Revision B

October 8, 2014

Warranty The product is warranted against material and manufacturing defects for two years from

date of delivery. Buyer agrees that if this product proves defective Chassis Plans’ is only

obligated to repair, replace or refund the purchase price of this product at Chassis Plans’

discretion. The warranty is void if the product has been subjected to alteration, neglect,

misuse or abuse; if any repairs have been attempted by anyone other than Chassis Plans;

or if failure is caused by accident, acts of God, or her causes beyond the control of Chassis

Plans. Chassis Plans reserves the right to make changes or improvements in any product

without incurring any obligation to similarly alter products previously purchased.

In no event shall Chassis Plans be liable for any defect in hardware or software or loss or

inadequacy of data of any kind, or for any direct, indirect, incidental or consequential

damages arising out of or in connection with the performance or use of the product or

information provided. Chassis Plans’ liability shall in no event exceed the purchase price

of the product purchased hereunder. The foregoing limitation of liability shall be equally

applicable to any service provided by Chassis Plans.

Return Policy Products returned for repair must be accompanied by a Return Material Authorization

(RMA) number, obtained from Chassis Plans prior to return. Freight on all returned items

must be prepaid by the customer, and the customer is responsible for any loss or damage

caused by common carrier in transit. Items will be returned from Chassis Plans via

Ground, unless prior arrangements are made by the customer for an alternative shipping

method

To obtain an RMA number, call us at 858-571-4330. We will need the following

information:

Return company address and contact

Model name and model # from the label on the back of the display

Serial number from the label on the back of the display

Description of the failure

An RMA number will be issued. Mark the RMA number clearly on the outside of each box,

include a failure report for each board and return the product(s) to our San Diego, CA

facility:

Chassis Plans.

10123 Carroll Canyon Road

San Diego, CA 92131

Attn: Repair Department

Trademarks “The Original Industrial Computer Source”, “Systems Engineered to Perform” and Chassis

Plans are registered trademarks of Chassis Plans, LLC.

IBM, PC/AT, VGA, EGA, OS/2 and PS/2 are trademarks or registered trademarks of

International Business Machines Corp.

Intel is a registered trademark of Intel Corporation.

MS-DOS and Microsoft are registered trademarks of Microsoft Corp.

All other brand and product names may be trademarks or registered trademarks of their

respective companies.

Liability

Disclaimer This manual is as complete and factual as possible at the time of printing; however, the

information in this manual may have been updated since that time. Chassis Plans

reserves the right to change the functions, features or specifications of their products at

any time, without notice.

Copyright © 2014 by Chassis Plans. All rights reserved.

E-mail: Support@chassisplans.com

Web: www.chassisplans.com

Chassis Plans

10123 Carroll Canyon Road • San Diego, CA 92131

Phone: (858) 571-4330 • Fax: (858) 571-6146 • Email: Saleseng@chassisplans.com

CAUT

is inte

n

which

WAR

N

alert t

h

the lit

e

WAR

N

move

WAR

N

the s

u

NOT

E

milita

WA

R

will v

o

WAR

N

groun

d

such

a

nation

by re

m

must

b

ION: The lig

h

n

ded to alert

t

may be of su

N

ING: The e

x

h

e user to th

e

e

rature acco

m

N

ING: If you

a

it without hel

N

ING: Befor

e

u

pplied safet

y

E

: This equip

m

ry environme

R

NING: Chan

g

o

id the syste

m

N

ING: For yo

u

d

ed wall outl

e

a

s the one pr

o

al safety sta

n

m

oving the p

o

b

e located cl

o

h

ting flash wit

h

t

he user to th

f

ficient magn

x

clamation p

o

e

presence o

f

m

panying the

a

re unsure th

p.

e

you connec

t

y

and installat

m

ent is desi

g

nts as per MI

g

es or modifi

c

m

warranty a

n

u

r safety, al

w

e

t. Always u

s

o

vided with t

h

n

dards. This

o

wer cord fro

m

o

se to an eas

h

arrowhead

e presence

o

itude to cons

t

o

int within an

e

f

important o

p

appliance.

at you can lif

t

t

any cables

o

ion instructio

n

g

ned to meet

h

L-STD-810G

c

ations not e

x

n

d could pos

s

w

ays connect

s

e a power c

o

h

e equipment

equipment c

a

m

the power

o

ily accessibl

e

symbol insid

e

o

f uninsulated

t

itute a risk o

f

equilateral tri

p

erating and

s

f

t the equipm

e

o

r install the

C

n

s.

harsh enviro

n

G

, MIL STD-4

6

x

pressly app

r

s

ibly damage

equipment t

o

o

rd with a pro

t

, or one in c

o

a

n be discon

n

o

utlet. This

m

e

power outle

t

e

an equilate

r

, dangerous

v

f

electric sho

c

angle is inte

n

s

ervicing inst

r

e

nt safely, no

C

PX monitor,

n

mental cond

6

1F and DO-

1

r

oved by Cha

s

the equipme

o

a three-pro

n

perly ground

e

o

mpliance wit

h

n

ected from t

h

m

eans the eq

u

t

r

al triangle

v

oltage

c

k

n

ded to

r

uctions in

not try to

refer to

itions of

1

60F

s

sis Plans

nt.

n

g,

e

d plug,

h

your

h

e power

u

ipment

Chassis Plans CPX-15, -17, -19 Technical Reference Index

Table of Contents

Chapter1‐Introduction_______________________________________________________________1

Description_______________________________________________________________________________1

Table1–DisplaySpecifications____________________________________________________________________1

CPXPartNumberMatrix_____________________________________________________________________2

Table2–CPXPartNumberMatrix_________________________________________________________________2

LCDEnhancements_________________________________________________________________________3

Figure1–EMIShieldingEffectivenessofITOCoating__________________________________________________3

Figure2–OpticalStackonLCD____________________________________________________________________3

Figure3–ComparisonofReflectionswithandwithoutOpticalBonding___________________________________4

Figure4–ComparisonwithandwithoutOpticalBonding_______________________________________________4

GenesisBasedLCDControllers________________________________________________________________5

Photos___________________________________________________________________________________5

FrontView____________________________________________________________________________________5

RearPanelI/O–StandardController_______________________________________________________________5

RearPanelI/O–AdvancedController_______________________________________________________________5

Specifications______________________________________________________________________________6

Enclosure________________________________________________________________________________________6

15”Display______________________________________________________________________________________6

17”Display______________________________________________________________________________________6

19”Display______________________________________________________________________________________6

PowerSupplyOptions______________________________________________________________________________6

DisplayEnhancementOptions_______________________________________________________________________6

Table3–Specifications__________________________________________________________________________6

Environmental____________________________________________________________________________________7

Table4–EnvironmentalSpecifications______________________________________________________________7

StandardControllerDVI‐D/VGAInputFeatures:_________________________________________________________8

AdvancedControllerMulti‐InputFeatures:_____________________________________________________________8

Table5–LCDControllersSpecifications_____________________________________________________________8

Figure5‐CPXOutlineDrawing____________________________________________________________________9

Chapter2–PowerSupplyOptions______________________________________________________10

ACInputPowerSupply_____________________________________________________________________10

Table6‐ACInputSupplySpecifications____________________________________________________________10

Photo1‐ACPowerSupply______________________________________________________________________10

12VDCInputTransientFilter________________________________________________________________11

Connectors_____________________________________________________________________________________11

MIL‐STD‐704/1275DCInputConverter________________________________________________________12

OperatingSpecifications___________________________________________________________________________12

Connectors_____________________________________________________________________________________12

EnvironmentalSpecifications_______________________________________________________________________12

Table7‐MIL‐STD‐704PowerSupplySpecifications___________________________________________________12

+/‐48VDCPowerSupply____________________________________________________________________13

OperatingSpecifications___________________________________________________________________________13

Connectors_____________________________________________________________________________________13

ElectricalSpecifications____________________________________________________________________________13

Table8‐48VDCPowerSupplySpecifications________________________________________________________13

Chassis Plans CPX-15, -17, -19 Technical Reference Index

Chapter3–Installation_______________________________________________________________14

ProductContents__________________________________________________________________________14

RackInstallation__________________________________________________________________________14

Figure6‐RackMountingHoleSpacing_____________________________________________________________14

ConnectingtheDisplay_____________________________________________________________________15

StandardControllerRearPanelConnections___________________________________________________15

Figure7‐StandardControllerRearPanelI/O________________________________________________________15

Table9‐RearPanelConnections–StandardController_______________________________________________15

AdvancedControllerRearPanelConnections___________________________________________________16

Figure8‐AdvancedControllerRearPanelI/O_______________________________________________________17

Table10‐RearPanelConnections–AdvancedController______________________________________________17

Chapter4–Operation________________________________________________________________18

LCDFrontPanelControls___________________________________________________________________18

Table11‐FrontPanelControls___________________________________________________________________18

StandardControllerOSDMenus_____________________________________________________________19

Table12‐StandardControllerOSDMenus__________________________________________________________20

AdvancedControllerOSDMenus_____________________________________________________________21

AppendixA–DisplaySerialControlProgramming_______________________________________25

RS‐232Serialcontrol_______________________________________________________________________25

StandardControllerSerialControlFunctions___________________________________________________25

Table13‐StandardControllerCommandstoImplementSwitchMountControlButtons_____________________25

Table14‐StandardControllerParameterSetting‐Immediate,Relative,ResetandQuery____________________26

Table15‐StandardControllerOtherControl________________________________________________________28

AdvancedControllerSerialControlFunctions___________________________________________________29

Table16‐AdvancedControllerCommandstoImplementSwitchMountControlButtons____________________29

Table17‐AdvancedControllerParameterSetting‐Immediate,Relative,ResetandQuery___________________29

Table18‐AdvancedControllerOtherControl_______________________________________________________38

Table19‐HextoASCIIConversionTable___________________________________________________________40

AppendixB–AutoColorGain__________________________________________________________41

ImageB‐1–AutoColorGainExample______________________________________________________________41

AppendixC–DVI‐DversusDVI‐IConnectors______________________________________________42

Overview________________________________________________________________________________42

Connectors_______________________________________________________________________________42

AppendixD–EthernetNetworkConnection______________________________________________43

ConnectinganetworkporttoCPXFamily______________________________________________________43

GettheIPaddressusingDHCP_______________________________________________________________44

WebConsole_____________________________________________________________________________44

IPLocator________________________________________________________________________________44

ImageD‐1–IPLocatorScreenShot________________________________________________________________44

Chassis Plans CPX-15, -17, -19 Technical Reference Index

Networkconfiguration_____________________________________________________________________44

ImageD‐2–NetworkDropDown_________________________________________________________________44

ImageD‐3–NetworkConfigureSettings___________________________________________________________45

ConnecttoasingleCPXFamily_______________________________________________________________45

TableD‐1–RemoteControl______________________________________________________________________45

ImageD‐4–IPAddressLocator___________________________________________________________________46

ImageD‐5–IPAddressSettingandEnable__________________________________________________________46

ConnecttomultipleCPXFamily______________________________________________________________46

TableD‐2–RemoteControl______________________________________________________________________46

ImageD‐6–DHCPTableScreenshot_______________________________________________________________47

ImageD‐7–NATFowardingScreenshot____________________________________________________________47

Chassis Plans CPX-15, -17, -19 Technical Reference Index

This Page Intentionally Blank

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 1

Chapter 1 - Introduction

Description

The military grade CPX family – comprised of 8U TFT LCD’s, offer rugged military rack mount or panel mount

LCD displays. Whether seeking a 15”, 17” or 19” display, these military touch screen monitors are designed to

perform and engineered to last. Meeting military standards 901D and 810G, the CPX family’s 5052-H32

aluminum construction and locking stainless steel hardware are inherently rugged and reliable. All electrical

components are selected for strength, integrity, and reliable operation. Rack mount ears are securely screwed to

the sides of the display body and can be removed, allowing the monitor to be used with a VESA mount, panel

mount or bulkhead mount.

The 17” and 19” displays are high performance, long life TFT LCD’s offering a maximum native resolution of

1280x1024. The displays offer optional optically bonded 3mm Dura Block 90 anti-reflective overlay glass. In

addition, an optional laminated 1.1mm soda lime glass with an ITO conductive EMI filter and an additional

1.1mm soda lime glass overlay with Dura Block 90 anti-reflective (AR) coating. Both glass components are

optically bonded to each other, and to the front of the display, for superior viewing clarity and overall

ruggedness. A 3mm copper bus bar surrounds the entire glass stack-up and provides consistent grounding. A

contrast ratio of approximately 1300:1 is delivered with this ITO/Anti-Reflective glass stack-up.

The 15-inch display offers 1024x768 resolution, transflective TFT technology and an LED backlight and is

intended for high bright installations such as outdoors. The other two models offer either 17-inch or 19-inch

LCDs with LED backlights. All other features of the systems are identical including dimensions, input signal

options and LCD controllers.

CPX-15 15” LCD CPX-17 17” LCD CPX-19 19” LCD

Contrast Ratio 1000:1 1000:1 1000:1

Viewing Angle (L/R/U/D) 80º 80º 80º

Response Time 17ms 30ms 5ms

Brightness 950 cd/m

2

350 cd/m

2

350 cd/m

2

Backlight LED LED LED

Native Resolution 1024 x 768 1280 x 1024 1280 x 1024

Aspect Ratio 4:3 5:4 5:4

Table 1 – Display Specifications

Dura Block 90 is a two surface treatment. The front surface is an oleophobic anti-reflective coating resistant to

fingerprints. The inner surface is treated with an infrared resistant coating to reduce heat loading on the LCD

display from exposure to sunlight.

The displays offer 16.7 million colors (True Color). The displays provide multiple signal input options including

aRGB, DVI-D, DVI-I, NTSC, S-Video and Composite Video, depending on the controller.

The displays offer a choice of high quality advanced scaling controllers with a Genesis chipset. The Standard

Controller offers DVI-D and VGA (aRGB) inputs. The Advanced Controller offers DVI-D, VGA (aRGB), HDMI,

NTSC, S-Video and CVS with an option for Component (YCbCr) input. In addition, the Advanced Controller

supports Picture-In-Picture (PIP) and Picture-By-Picture. These are specifically ruggedized controllers offering

as standard conformal coating with high shock/vibration and temperature extreme tolerances as well as long life

product availability for assured delivery throughout multi-year programs.

As with all Chassis Plans products, a wide variety of custom options can be configured per customer or

application specific requirements. Contact your Sales Engineer to discuss your particular requirements.

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 2

CPX Part Number Matrix

Product Family Head Unit Controller Option Power Input

CPX1 = CP Panel Extreme

151A = 15” LCD with EMI Shield A1 = Advanced

Controller

A = AC 110V

151B = 15” LCD C1 = Standard

Controller

B = 12VDC

151C = 15” LCD with 3mm cover

glass

C = 28VDC

151E = 15” LDC with USB Rhino

Touch, Touch Screen

D = 48VDC

171A = 17” LCD with EMI Shield

171B = 17” LCD

171C = 17” LCD with 3mm cover

glass

171E = 17” LDC with USB Rhino

Touch, Touch Screen

191A = 19” LCD with EMI Shield

191B = 19” LCD

191C = 19” LCD with 3mm cover

glass

191E = 19” LDC with USB Rhino

Touch, Touch Screen

Table 2 – CPX Part Number Matrix

Part Number Scheme CPX1-XXXXXX-A

Example: CPX1 -171CA1-A

CPX1 = CP Panel Extreme

171C = 17” LCD with 3mm cover glass

A1 = Advanced Controller

A = AC 110V

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 3

LCD Enhancements

Chassis Plans starts with Grade A Industrial Quality LCD panels selected for optical performance, high reliability

and long product life cycle. In order to not only ruggedize the LCD, but to also enhance the mechanical, optical

and EMI properties of the finished unit, as an option, Chassis Plans optically bonds one 3mm AR or two layers

of coated 1.1 mm soda-lime float glass to the front of the LCD panel. The first layer is coated with an Indium Tin

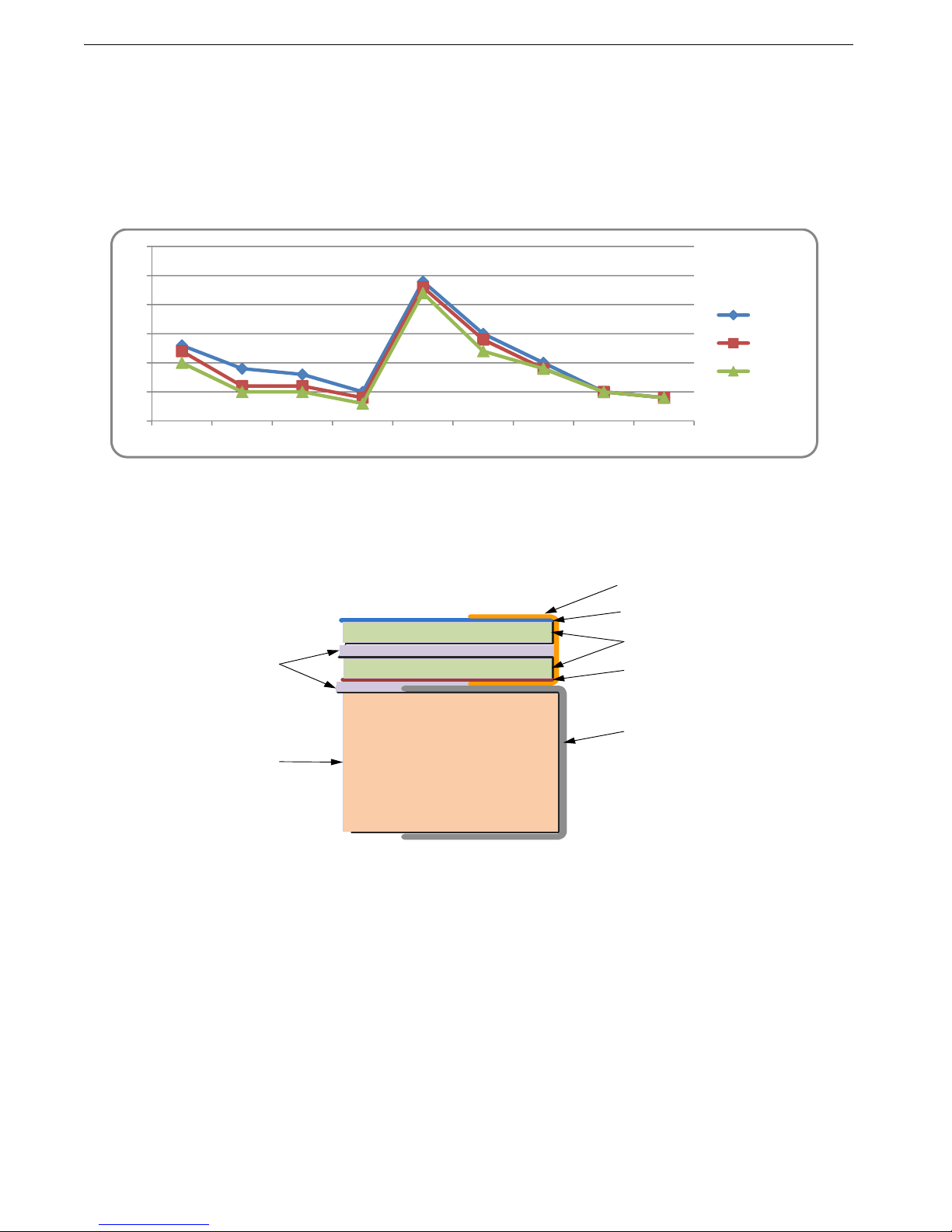

Oxide (ITO) coating with a surface resistivity of <13.5 ohms/sq. See Figure 1 for attenuation values.

Figure 1 – EMI Shielding Effectiveness of ITO Coating

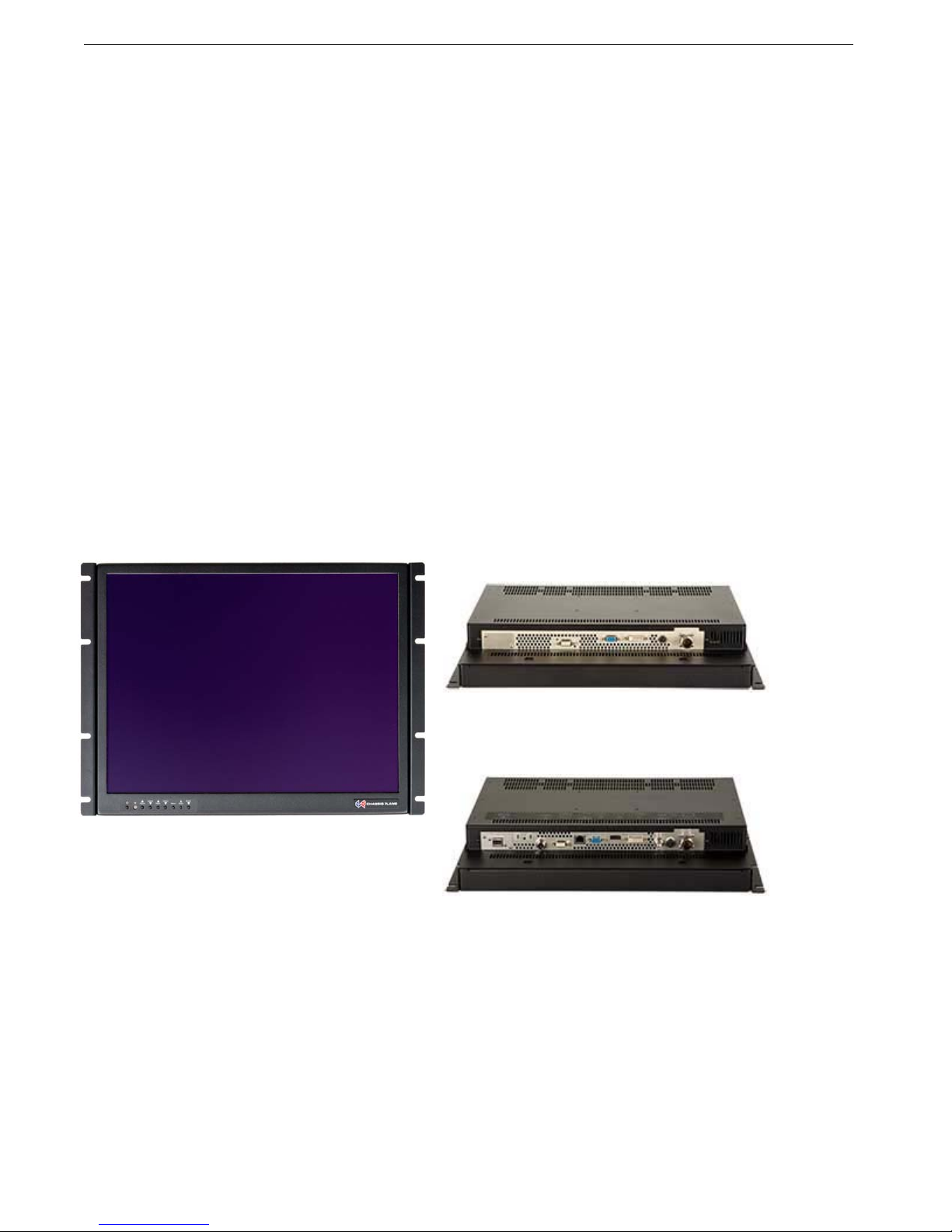

There is a Copper conductive buss bar that wraps around the edge of the glass to facilitate conduction from the

ITO coating to the front surface of the laminated structure to make a complete electrical shield around the face of

the LCD. See Figure 2 for details.

Figure 2 – Optical Stack on LCD

The second layer of glass is coated with a Dura Block 90 Oleophobic Anti-Reflective (AR) coating which

matches the index of refraction of air to eliminate surface reflections. These layers of coated glass are bonded

together with an index matching optical adhesive to eliminate internal reflections caused by the index of

refraction mismatch between the soda lime glass and air. This eliminates over 95% of unwanted glare from the

screen. Please see Figure 3 below for more details.

20

25

30

35

40

45

50

30MHz 75MHz 100MHz 150MHz 200MHz 300MHz 500MHz 700MHz 1000MHz

15"LCD

17"LCD

19"LCD

AR Coating

ITO Coating

Soda Lime Float Glass

Copper Buss Bar

LCD Frame

O ptical Index

Matching

Adhesive

LCD Panel

And

Backlight

C

T

a

d

r

e

a

d

a

c

p

r

f

o

c

o

B

h

i

t

h

b

y

P

h

G

D

C

hassis Plan

s

he resulting

s

d

hesive used

e

mains pliabl

e

d

ditional laye

c

tually occur

r

events any

c

o

gging of the

d

o

nduction pa

t

y eliminating

i

gh bright sit

u

h

e reflected li

g

y

the backlig

h

h

oto Courtesy of

D

S Clearview

4.5

%

4.5

%

4.5

%

4.5

%

4.5

%

Witho

O

s

CPX-15, -1

7

Figure 3

s

tructure has

is a silicone

e

and therefo

rs of glass p

r

the shards o

f

c

ondensation

d

isplay. Fin

a

t

h to help dis

s

the majority

o

u

ations. An al

t

g

ht. The dow

n

h

ts.

F

i

Refle

Lig

To

t

22.

5

%

%

%

%

%

ut Optical Bond

i

O

r AR Coating

7

, -19 Techni

c

– Comparis

o

greatly enha

n

RTV and off

e

r

e acts as a

s

r

ovides a ver

y

f

glass will be

from buildin

g

a

lly, the adde

d

s

ipate the he

a

o

f reflected li

g

t

ernative to i

m

n

side to this

a

i

gure 4 – Co

m

cted

ht

t

al

5

%

i

ng

c

al Referenc

e

P

o

n of Reflec

t

n

ced optical

c

e

rs other ben

e

s

hock absorb

i

y

rugged com

retained tog

e

g

up in the air

d

mass bond

e

a

t generated

g

ht, the appa

r

m

proving the

c

a

pproach is t

h

m

parison wi

e

P

age 4

t

ions with a

n

c

haracteristic

s

e

fits mechani

i

ng medium f

o

posite struct

u

e

ther to prev

e

gap betwee

n

e

d to the fron

t

in the backlig

r

ent contrast

c

ontrast is to

h

e higher po

w

th and with

o

n

d without O

s

in high am

b

cally to the L

C

o

r the front o

f

u

re. Another

e

nt injury to

p

n

the layers o

f

t

of the LCD

d

g

hts themselv

improves m

a

increase the

w

er requirem

e

o

ut Optical

B

0.3%

With

An

0.1%

0.1%

0.1%

0.1%

Ch

ptical Bondi

b

ient light con

CD as well.

T

f

the LCD. T

o

benefit is tha

p

ersonnel. T

h

f

glass which

d

isplay adds

v

es.

a

king the disp

back light le

v

e

nts and hig

h

B

onding

Reflected

Light

Total

0.7%

Optical Bondin

g

d AR Coatin

g

apter 1 - Intr

o

ng

ditions. The

T

he adhesiv

e

o

gether with

t

t should bre

a

h

e adhesive

a

would caus

e

a thermal

lay more rea

d

v

els to overp

o

h

er heat gene

g

o

duction

optical

e

t

he

a

kage

a

lso

e

d

able in

o

wer

rated

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 5

Genesis Based LCD Controllers

The LCD Controller is a key component in any display system and no expense has been spared in specifying

the Standard Controller and Advanced Controller Genesis controllers. These are long life revision controlled

military grade components. The Genesis chip set is the current gold standard for LCD controllers. The

controllers support 3x8-bit 16.7 million colors at up to 1600x1200 (Advanced Controller) scaled to 1280x1024

native panel resolution. Refresh rates of 60Hz for UXGA and SXGA with higher refresh rates for lower

resolutions available. Computer input signals of VGA, SVGA, XGA, SXGA, WXGA and UXGA are supported.

Video inputs of NTSC, PAL and SECAM are optionally available. DVI inputs supports up to 1600x1200 60Hz

signals. These ruggedized military grade controllers are rated for operating at -40 to +80 deg C, use low mass

tantalum capacitors for maximum vibration and shock tolerance and are conformal coated for extreme

ruggedness. The coating is silicone resin conformal coating.(MOD) DEF-STAN 59/47 Issue 4 &UL QMJU2

compliant

MTBF for the controllers is in excess of 150,000 to 200,000 hours.

The Standard Controller provides up scaling while the Advanced Controller provides up and down scaling. This

allows input scaling of virtually any input signal to scale the image to the 1280x1024 native LCD panel

resolution. They provide for PC, Apple and Sun input resolutions.

The Standard Controller and Advanced Controller provide DVI-D inputs.

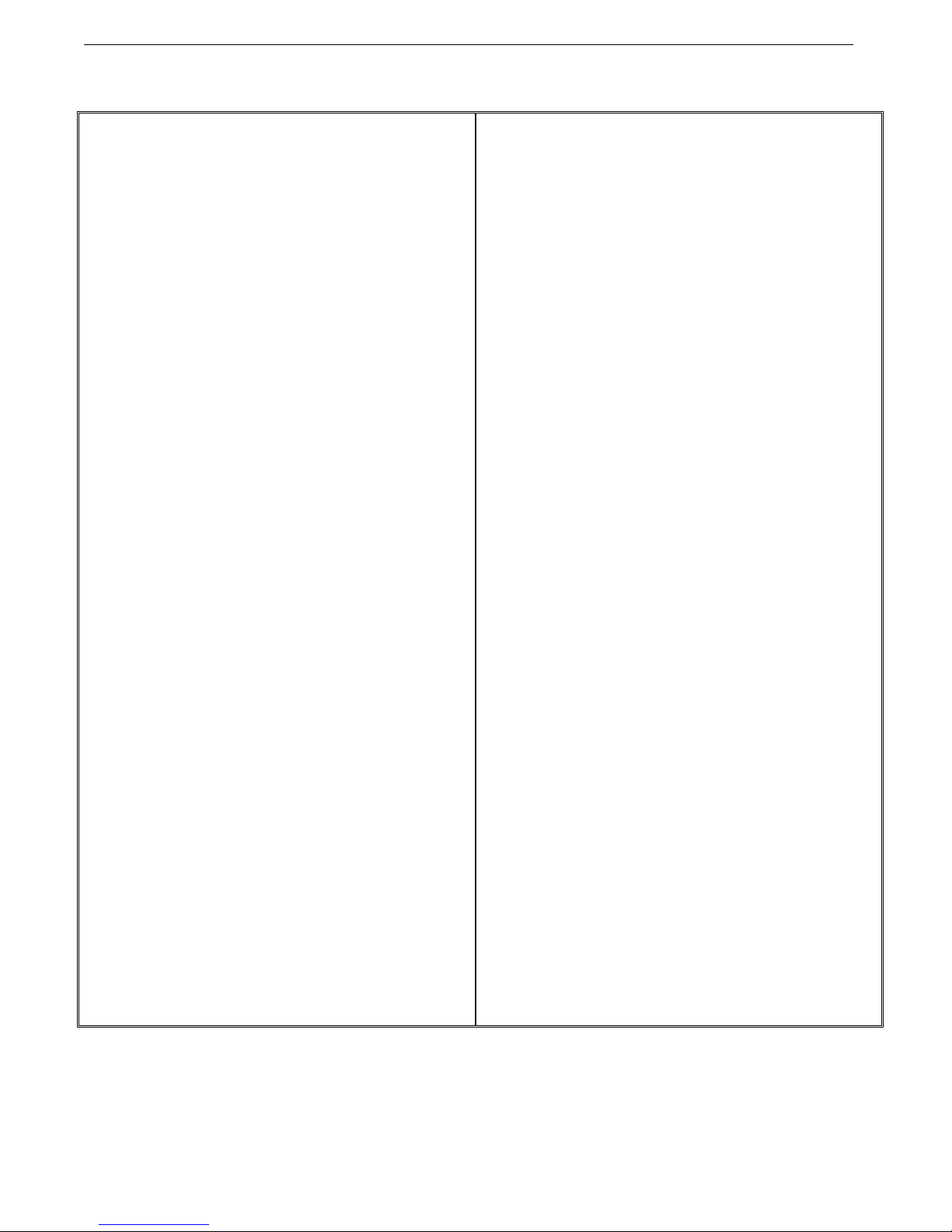

Photos

Front View

Rear Panel I/O – Standard Controller

Rear Panel I/O – Advanced Controller

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 6

Specifications

Enclosure

8U (13.97”) x 3.2” deep

Construction: 5052 aluminum alloy

All stainless steel hardware

All self-locking pressed in fasteners where

appropriate

Powder coat black, medium texture, for ruggedness

Other colors optionally available

Designed to Mil-Spec Standards to Satisfy Military,

Industrial and Commercial Requirements

Compact Enclosure for Limited Depth Installation

Weight: 19.5-20.5lbs (depending on model &

features)

15” Display

17" TFT LCD 1024x768

Display Colors: 16.7 Million

Response Time: 17ms Typical

Viewing Angle: 80 deg

Contrast Ratio: 1000:1 typical native

Brightness: 950cd/m2 typical

Pixel Pitch: 0.264mm x 0.264mm

Pixel Arrangement: R.G.B Stripe

Operating Temperature: -30 to + 70 Deg C

Storage Temperature: -40 to +80 Deg C

17” Display

17" TFT LCD 1280x1024

Display Colors: 16.7 Million

Response Time: 30ms Typical

Viewing Angle: 80 deg

Contrast Ratio: 1000:1 typical native

Brightness: 350cd/m2 typical

Pixel Pitch: 0.264mm x 0.264mm

Pixel Arrangement: R.G.B Stripe

Operating Temperature: -20 to + 70 Deg C

Storage Temperature: -30 to +80 Deg C

19” Display

19" TFT LCD 1280x1024

Display Colors: 16.7 Million

Response Time: 5ms

Viewing Angle: 80 deg

Contrast Ratio: 1000:1 typical native

Brightness: 350cd/m2 typical

Pixel Pitch: 0.297mm x 0.297mm

Pixel Arrangement: R.G.B. Stripe

Operating Temperature: 0 to + 50 Deg C

Storage Temperature: -20 to +60 Deg C

Power Supply Options

AC Input

100 to 260VAC, auto selecting

47-66 HZ

12VDC Input Transient Filter

Line transient protection for 12VDC vehicular

applications

Mil-Std-1275A DC/DC Converter

True 1275 compliance for military 28VDC

nominal vehicle inputs

18 to 36VDC input

48VDC DC/DC Converter

36 to 75VDC Input

Isolated Inputs for +/- input levels

See the appropriate power supply section for complete

power supply specifications.

Display Enhancement Options

Using 3mm smudge-resistant AR coated soda lime

float glass, bonded to the LCD panel with optical

index matched adhesive

Using a laminate of 1.1mm smudge-resistant AR

coated soda lime float glass panel and a 1.1 mm

ITO coated glass panel(<12.5Ω/sq) grounded via a

copper buss bar, bonded to the LCD panel with

optical index matched adhesive

Table 3 – Specifications

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 7

Environmental

Designed to meet or exceed MIL-STD-810G to the below specifications.

ALTITUDE

10,000 ft. Operational,

30,000 ft. Storage

MIL-STD-810, Method 500.5

HIGH TEMPERATURE

70°C Operational, 80°C Storage

MIL-STD-810, Method 501.5

LOW TEMPERATURE

-20°C Operational, -30°C Storage

MIL-STD-810, Method 502.5

HUMIDITY

5-95%, Non-condensing

MIL-STD-810, Method 507.5

BLOWING SAND AND DUST

Procedures I and II

MIL-STD-810, Method 510.5

TRANSPORT VIBRATION

US Highway Truck and Air Transport

MIL-STD-810, Method 514.6

BENCH HANDLING SHOCK

Procedure VI, 20G @ 11ms

MIL-STD-810, Method 516.6

Table 4 – Environmental Specifications

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 8

Standard Controller DVI-D/VGA Input Features:

Inputs:

Analog RGB: 60Hz at SXGA, WXGA, XGA,

SVGA, VGA

With auto detect of Digital

Separate Sync, Sync-On-Green &

Composite Sync. Auto detects

VGA ~SXGA interlaced &

noninterlaced.

DVI-D: 60Hz at SXGA, WXGA, XGA,

SVGA, VGA

Image Scaling: Up scaling to fit input to panel

resolution.

Image Control: Brightness, Contrast, Saturation,

Hue, Frequency, Phase, Color

temperature, Image position, Hue,

Gamma.

Other Features: Auto picture setup, Auto RGB cali-

bration, Auto source seek, OSD

timeout, OSD position, Input

source select, OSD menu lock,

Direct key for brightness level

adjustment.

Advanced Controller Multi- Input Features:

Inputs:

Analog RGB: 60Hz @ UXGA

75Hz @ SXGA, WXGA, SVGA, VGA

1152 x 900 @ 66Hz (SUN)

1152 x 900 @ 76Hz (SUN)

1280 x 1024 @ 76Hz (SUN)

With auto detect of Digital Separate

Sync, Sync-On-Green & Composite

Sync. Auto detects VGA ~UXGA

interlaced & non-interlaced.

DVI-D: 60Hz @ WUXGA

60Hz @ UXGA

75Hz @ SXGA, WXGA, XGA,

SVGA, VGA

HDMI: 60Hz @ WUXGA

60Hz @ UXGA

75Hz @ SXGA, WXGA, XGA,

SVGA, VGA

Video: NTSC / PAL / SECAM (Interlaced)

Composite Video

HD Component YPbPr

SD Component YCbCr

RGB Video SD Component (YCbCr)

(Optional)

Features: Image Up-Scaling

Image Down-Scaling

Picture In Picture

Picture By Picture

Memory Buffer

Sync On Green/Composite

DV RS-232 Serial Protocol

Ethernet Command Protocol

Text Overlay Function

Variable Aspect

Freeze & Zoom Function

Programmable Hot Keys

Image Control: Auto configuration, Brightness,

Contrast, Clock, Phase, Color

temperature, Image position,

Saturation, Hue, Gamma.

Other Features: System Information, OSD position,

Scaling to fill screen and fill to aspect

ratio, OSD timeout, Factory reset,

OSD menu transparency, Horizontal

& Vertical image inversion, Picture in

Picture.

Table 5 – LCD Controllers Specifications

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 1 - Introduction

Page 9

Figure 5 - CPX Outline Drawing

C

A

T

ci

p

r

A

I

O

S

Chassis Pla

n

C

hapter

A

C Input

P

he AC Input

P

rcular mil co

n

r

ovided to se

c

A

lternate AC

s

I

NPUT

Voltage

Current

Frequency

Input Conn

e

O

UTPUT

Total Regul

Set Point A

c

Hold-up Ti

m

Over Volta

g

Over Curre

n

Short Circu

S

IZE

L X W X H

Weight

n

s CPX-15, -1

2 – Po

w

P

ower S

u

P

ower Suppl

y

n

nector for c

o

c

urely mount

s

upplies are

a

e

ctor

ation

c

curacy

m

e

g

e Protection

n

t Protection

it Protection

7, -19 Techn

w

er Sup

p

u

pply

y

is a 65W M

e

o

nnecting to t

h

the supply in

a

vailable as r

e

100-240VA

C

2.0A @ 10

0

50-60Hz

3-Pin IEC 3

2

< +/- 5%

< +/- 3% @

>12mS @

F

115VAC

Built-in

Built-in

Pulsing mo

d

recovery

5.07” X 3.0

6

1.2 lbs

Tabl

e

ical Referen

c

P

p

ly Opti

o

e

dical Grade

h

e CPX. Th

e

a rack.

e

quired by th

e

C

0

VAC

2

0 Receptacl

60% Load

F

ull Load,

d

e, auto

6

” X 1.35”

e

6 -

A

C Inpu

t

Photo 1 -

A

c

e

P

age 10

o

ns

“Brick” style

p

e

input accep

t

e

application

o

e

ENVI

R

Op

e

Sto

r

SAF

E

c

T

UL

6

CS

A

CB

p

CE

m

Cla

s

EMI/

E

Emi

s

Im

m

t

Supply Sp

e

A

C Power Su

C

p

ower supply

t

s a standard

o

r environm

e

R

ONMENTA

L

e

rating Temp

e

r

age Temper

a

E

TY

T

UVus

6

0601-1

A

C22.2 No.

6

p

er IEC 6060

m

arked to L

V

s

s I

E

MC

s

sions

m

unity

e

cifications

u

pply

C

hapter 2 – P

o

. The output

IEC 320 plu

g

e

ntal require

m

L

e

rature

a

ture

6

01.1-M90

0

1-1

V

D

CISPR11 an

EN61000-3-

2

EN61000-4-

2

o

wer Supply

is provided

w

g

.

A

bracket

i

m

ents.

0 to

5

-40 t

o

d FCC Part 1

2

, -3

2

, -3, -4, -5, -

6

Options

w

ith a

i

s

5

0°C

o

+85°C

5, Class B

6

, -9, -11

Chassis Plans CPX-15, -17, -19 Technical Reference Chapter 2 – Power Supply Options

Page 11

12VDC Input Transient Filter

The CPX family display consoles require nominal +12VDC at 40W for operation. An EMI line filter is provided to

limit EMI emissions and to provide a small measure of input filtering.

For operation from unregulated 12VDC (+/-10%) such as in a vehicular or marine environment, front end

transient filtering is required to suppress potentially damaging spikes from large inductive loads in the DC circuit

(starters, etc.).

The xxx 12VDC Input Transient Filter provides an input Transient Protection as well as inductive and capacitive

filtering to suppress large input transients. A bridge rectifier provides reverse connection protection. A circuit

breaker provides for failure protection and allows the power to be disconnected.

Connectors

Input Connector MS3102A-10SL-3P (MIL-C-5015)

Mating Input Connector MS3106A-10SL-3S (Straight)

MS3108A-10SL-3S (Right Angle)

Pinouts Pin A – Positive

Pin B – Negative Input

Pin C – N/C

Output Connector MS3102A-10SL-3S (MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S (Straight)

MS3108A-10SL-3S (Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C – N/C

This manual suits for next models

2

Table of contents

Other Chassis Plans Monitor manuals