Chassis Plans CPX2-173 Use and care manual

CPX2-173

Rugged Military Grade

6U Rack Mount

17.3-Inch Wide-Screen LCD Display

Technical Reference

22009400A

Revision Preliminary X1

April 11, 2014

Warranty The product is warranted against material and manufacturing defects for two years from

date of delivery. Buyer agrees that if this product proves defective Chassis Plans’ is only

obligated to repair, replace or refund the purchase price of this product at Chassis Plans’

discretion. The warranty is void if the product has been subjected to alteration, neglect,

misuse or abuse; if any repairs have been attempted by anyone other than Chassis Plans;

or if failure is caused by accident, acts of God, or her causes beyond the control of Chassis

Plans. Chassis Plans reserves the right to make changes or improvements in any product

without incurring any obligation to similarly alter products previously purchased.

In no event shall Chassis Plans be liable for any defect in hardware or software or loss or

inadequacy of data of any kind, or for any direct, indirect, incidental or consequential

damages arising out of or in connection with the performance or use of the product or

information provided. Chassis Plans’ liability shall in no event exceed the purchase price

of the product purchased hereunder. The foregoing limitation of liability shall be equally

applicable to any service provided by Chassis Plans.

Return Policy Products returned for repair must be accompanied by a Return Material Authorization

(RMA) number, obtained from Chassis Plans prior to return. Freight on all returned items

must be prepaid by the customer, and the customer is responsible for any loss or damage

caused by common carrier in transit. Items will be returned from Chassis Plans via

Ground, unless prior arrangements are made by the customer for an alternative shipping

method

To obtain an RMA number, call us at 858-571-4330. We will need the following

information:

Return company address and contact

Model name and model # from the label on the back of the display

Serial number from the label on the back of the display

Description of the failure

An RMA number will be issued. Mark the RMA number clearly on the outside of each box,

include a failure report for each board and return the product(s) to our San Diego, CA

facility:

Chassis Plans.

10123 Carroll Canyon Road

San Diego, CA 92131

Attn: Repair Department

Trademarks “The Original Industrial Computer Source”, “Systems Engineered to Perform” and Chassis

Plans are registered trademarks of Chassis Plans, LLC.

IBM, PC/AT, VGA, EGA, OS/2 and PS/2 are trademarks or registered trademarks of

International Business Machines Corp.

Intel is a registered trademark of Intel Corporation.

MS-DOS and Microsoft are registered trademarks of Microsoft Corp.

All other brand and product names may be trademarks or registered trademarks of their

respective companies.

Liability

Disclaimer This manual is as complete and factual as possible at the time of printing; however, the

information in this manual may have been updated since that time. Chassis Plans

reserves the right to change the functions, features or specifications of their products at

any time, without notice.

Copyright © 2014 by Chassis Plans. All rights reserved.

E-mail: Support@chassisplans.com

Web: www.chassis-plans.com

Chassis Plans

10123 Carroll Canyon Road • San Diego, CA 92131

This Page Intentionally Blank

Chassis Plans CPX2-173 Technical Reference Index

Table of Contents

Chapter1‐Introduction_______________________________________________________________1

Description_______________________________________________________________________________1

Table1–DisplaySpecifications____________________________________________________________________1

LCDEnhancements_________________________________________________________________________2

Figure1–EMIShieldingEffectivenessofITOCoating__________________________________________________2

Figure2–OpticalStackonLCD____________________________________________________________________2

Figure3–ComparisonofReflectionswithandwithoutOpticalBonding___________________________________3

Figure4–ComparisonwithandwithoutOpticalBonding_______________________________________________3

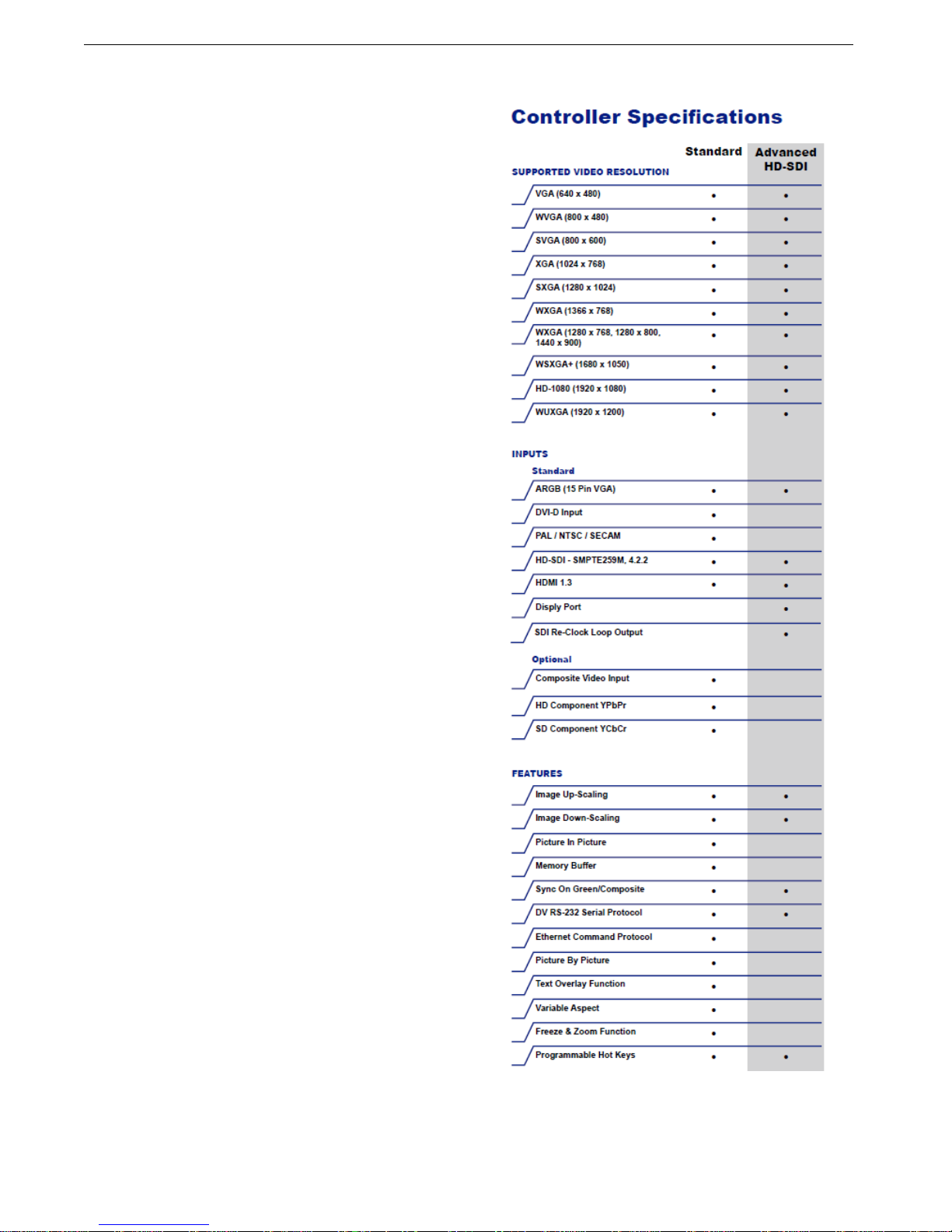

GenesisBasedLCDControllers________________________________________________________________4

Figure5–ControllerSpecifications_________________________________________________________________4

Photos___________________________________________________________________________________5

Specifications______________________________________________________________________________6

Enclosure________________________________________________________________________________________6

Display__________________________________________________________________________________________6

DisplayEnhancementOptions_______________________________________________________________________6

PowerSupplyOptions______________________________________________________________________________6

Environmental____________________________________________________________________________________6

Table2–Specifications__________________________________________________________________________6

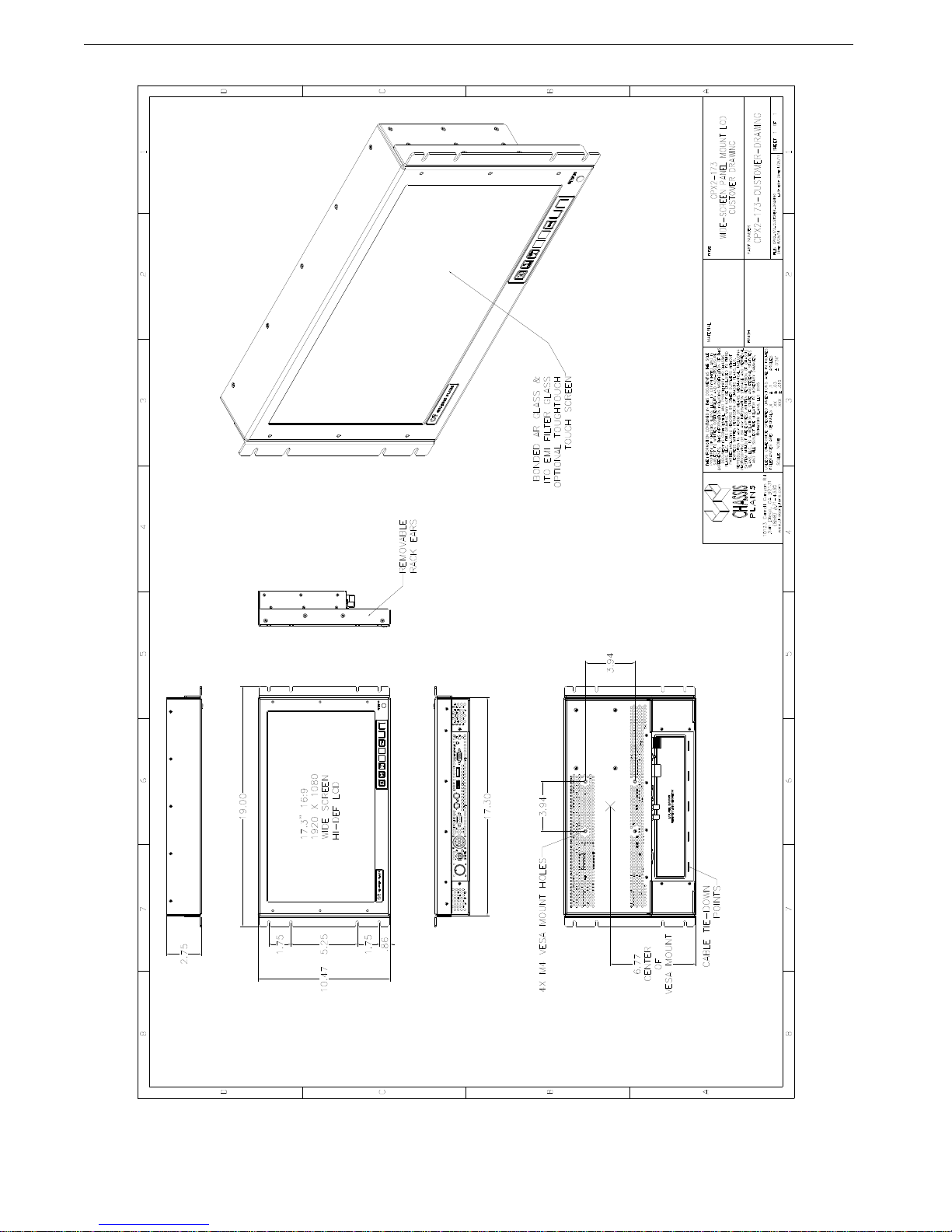

Figure6‐CCXOutlineDrawing____________________________________________________________________7

Chapter2–PowerSupplyOptions_______________________________________________________9

ACInputPowerSupply______________________________________________________________________9

Table3‐ACInputSupplySpecifications_____________________________________________________________9

Photo1‐ACPowerSupply_______________________________________________________________________9

12VDCInputTransientFilter________________________________________________________________10

Connectors_____________________________________________________________________________________10

Photo2‐12VDCInputFrontEndFilter_____________________________________________________________10

MIL‐STD‐704/127528VDCDCInput___________________________________________________________11

OperatingSpecifications___________________________________________________________________________11

Connectors_____________________________________________________________________________________11

EnvironmentalSpecifications_______________________________________________________________________11

Table4‐MIL‐STD‐704PowerSupplySpecifications___________________________________________________11

+/‐48VDCPowerSupply____________________________________________________________________12

OperatingSpecifications___________________________________________________________________________12

Connectors_____________________________________________________________________________________12

ElectricalSpecifications____________________________________________________________________________12

Table5‐48VDCPowerSupplySpecifications________________________________________________________12

Photo3‐48VDCPowerSupply____________________________________________________________________12

Chapter3–OrderingInformation______________________________________________________13

PartNumberMatrix______________________________________________________________________________13

ExamplePartNumbers____________________________________________________________________________13

Chapter4‐Installation_______________________________________________________________15

PackageContents________________________________________________________________________________15

Table6‐PackageContents______________________________________________________________________15

RackInstallation__________________________________________________________________________16

Chassis Plans CPX2-173 Technical Reference Index

Figure7‐RackMountingHoleSpacing_____________________________________________________________16

ConnectingtheDisplay_____________________________________________________________________17

StandardControllerRearPanelConnections___________________________________________________17

Photo4–StandardControllerRearPanelI/O________________________________________________________17

Table7‐RearPanelConnections–StandardController_______________________________________________17

AdvancedControllerRearPanelConnections___________________________________________________18

Photo5‐AdvancedHD/SDIControllerRearPanelI/O_________________________________________________18

Table8‐RearPanelConnections–AdvancedHD/SDIController________________________________________18

Chapter5‐Operation________________________________________________________________19

LCDFrontPanelControls___________________________________________________________________19

Table9‐FrontPanelControls____________________________________________________________________19

StandardControllerOSDMenus_____________________________________________________________20

AdvancedHD/SDIControllerOSDMenus______________________________________________________25

AppendixA–DisplaySerialControlProgramming_______________________________________27

RS‐232Serialcontrol_______________________________________________________________________27

ControllerSerialControlFunctions___________________________________________________________27

Table10‐StandardControllerCommandstoImplementSwitchMountControlButtons_____________________27

Table11‐StandardControllerParameterSetting‐Immediate,Relative,ResetandQuery____________________28

Table12‐StandardControllerOtherControl________________________________________________________38

Table13‐HextoASCIIConversionTable___________________________________________________________40

AppendixB–AutoColorGain__________________________________________________________41

ImageB‐1–AutoColorGainExample______________________________________________________________41

AppendixC–DVI‐DversusDVI‐IConnectors______________________________________________42

Overview________________________________________________________________________________42

Connectors_______________________________________________________________________________42

AppendixD–EthernetNetworkConnection______________________________________________43

ConnectinganetworkporttoCPX2‐173_______________________________________________________43

GettheIPaddressusingDHCP_______________________________________________________________44

WebConsole_____________________________________________________________________________44

IPLocator________________________________________________________________________________44

ImageD‐1–IPLocatorScreenShow_______________________________________________________________44

Networkconfiguration_____________________________________________________________________44

ImageD‐2–NetworkDropDown_________________________________________________________________44

ImageD‐3–NetworkConfigureSettings___________________________________________________________45

ConnecttoasingleCPX2‐173________________________________________________________________45

TableD‐1–RemoteControl______________________________________________________________________45

ImageD‐4–IPAddressLocator___________________________________________________________________46

ImageD‐5–IPAddressSettingandEnable__________________________________________________________46

ConnecttomultipleCPX2‐173_______________________________________________________________46

TableD‐2–RemoteControl______________________________________________________________________46

ImageD‐6–DHCPTableScreenshot_______________________________________________________________47

ImageD‐7–NATFowardingScreenshot____________________________________________________________47

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 1

Chapter 1 - Introduction

Description

The CPX2-173 is a military-grade high-performance 6U rack mount or panel mount LCD display offering 1920 x

1080 wide-screen high-definition resolution. The CPX2-173 is designed to meet Mil-Std 901D and MIL-STD-

810G and includes a solid milled aluminum front panel, lightweight 5052-H32 aluminum construction and locking

stainless hardware throughout. The CPX2-173 is ideal for mounting in a transit case for adverse environments

that would destroy lesser displays.

Two versions offer standard brightness or hi-bright for sunlight visibility.

CPX2-1731

Standard

CPX2-1732

Hi-Bright

Contrast Ratio 600:1 600:1

Viewing Angle (L/R/U/D) 80º 80º

Response Time 40ms 40ms

Brightness 400 cd/m

2

1000 cd/m

2

Backlight LED LED

Native Resolution 1920 x 1080 1920 x 1080

Aspect Ratio 16:9 16:9

Table 1 – Display Specifications

The displays are high-performance, long life TFT LCD’s offering a maximum native wide-screen resolution of

1920 x 1080. The displays offer optional optically bonded anti-reflective overlay glass. In addition, an optional

laminated 1.1mm soda lime glass with an ITO conductive EMI filter and an additional 1.1mm soda lime glass

overlay with anti-reflective (AR) coating. Both glass components are optically bonded to each other, and to the

front of the display, for superior viewing clarity and overall ruggedness. A 6mm copper bus bar surrounds the

entire glass stack-up and provides consistent grounding. A contrast ratio of approximately 1300:1 is delivered

with this ITO/Anti-Reflective glass stack-up. The front surface is an oleophobic anti-reflective coating resistant to

fingerprints.

The displays offer 16.7 million colors (True Color). The displays provide multiple signal input options including

aRGB, DVI-D, HDMI, Display Port, HD-SDI, NTSC, S-Video and Composite Video, depending on the controller.

The displays offer a choice of high quality advanced scaling controllers with a Genesis chipset. These are

specifically ruggedized controllers offering as standard conformal coating with high shock/vibration and

temperature extreme tolerances as well as long life product availability for assured delivery throughout multi-year

programs.

The Standard Controller offers DVI-D, VGA (aRGB), HDMI, NTSC, S-Video and CVS with an option for

Component (YCbCr) input. In addition, the Standard Controller supports Picture-In-Picture (PIP) and Picture-By-

Picture.

The Advanced HD-SDI Controller offers VGA (aRGB), HDMI, Display Port, HD-SDI and 3G HD-SDI.

The display is only 6U (10.47-inches) high offering significant rack space savings. It can be rack mounted, panel

mounted, or mounted using a VESA adapter via the included VESA hole pattern on the rear of the unit. It is only

3.2-inches deep and power and signal cables exit down so as to not increase depth requirements.

As with all Chassis Plans products, a wide variety of custom options can be configured per customer or

application specific requirements. Contact your Sales Engineer to discuss your particular requirements.

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 2

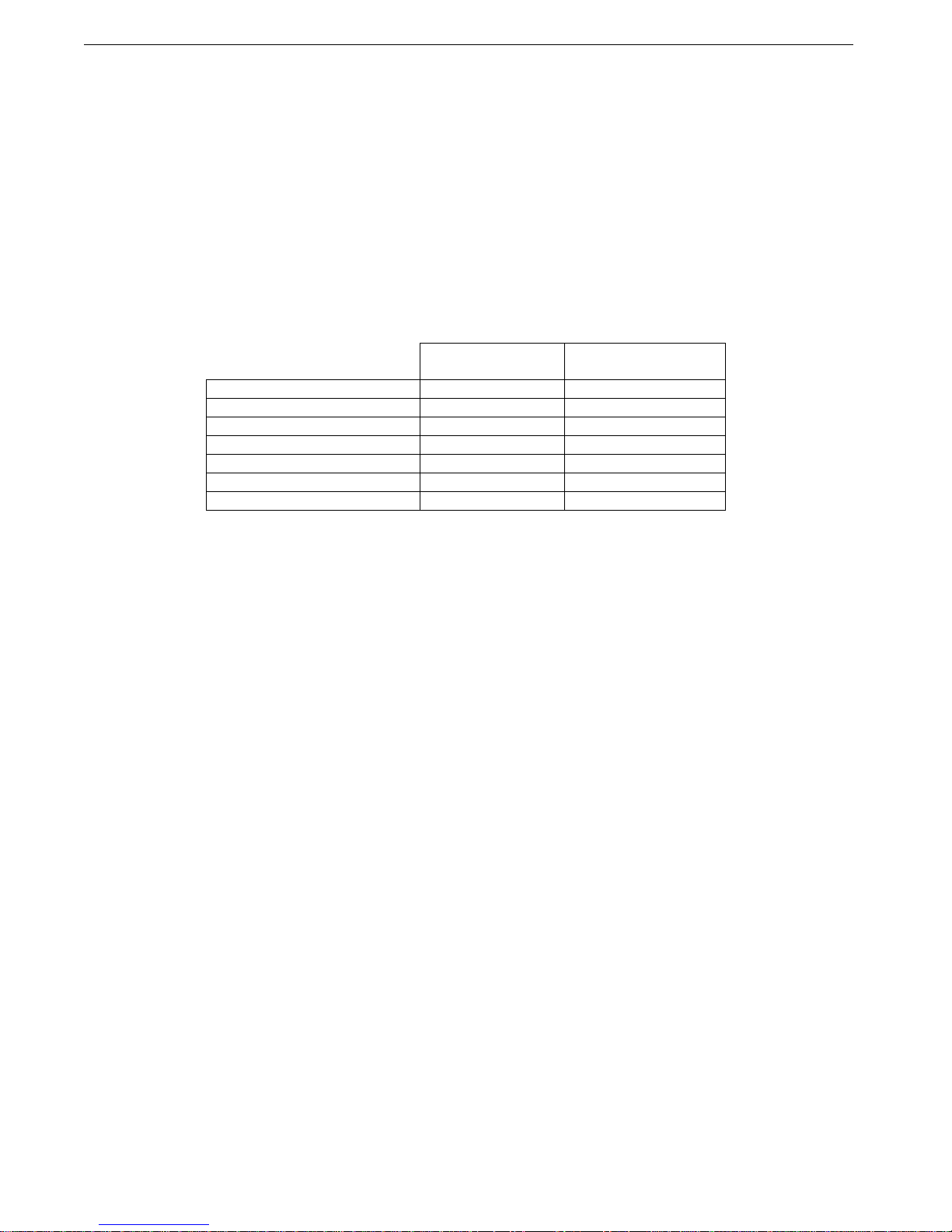

LCD Enhancements

Chassis Plans starts with Grade A Industrial Quality LCD panels selected for optical performance, high reliability

and long product life cycle. In order to not only ruggedize the LCD, but to also enhance the mechanical, optical

and EMI properties of the finished unit, as an option, Chassis Plans optically bonds one 3mm anti-reflective or

two layers of coated 1.1 mm soda-lime float glass to the front of the LCD panel. The first layer is coated with an

Indium Tin Oxide (ITO) coating with a surface resistivity of <13.5 ohms/sq. See Figure 1 for attenuation values.

Figure 1 – EMI Shielding Effectiveness of ITO Coating

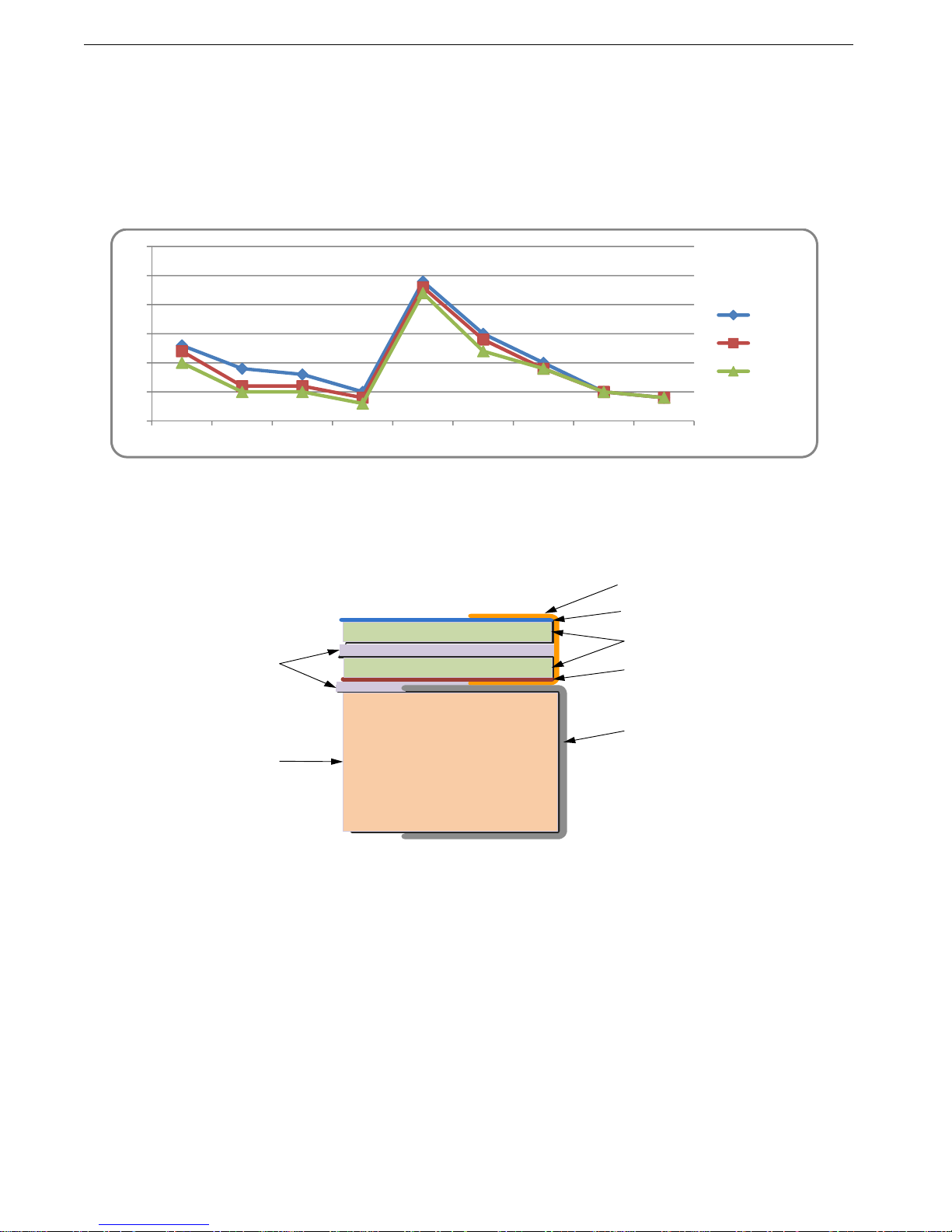

There is a Copper conductive buss bar that wraps around the edge of the glass to facilitate conduction from the

ITO coating to the front surface of the laminated structure to make a complete electrical shield around the face of

the LCD. See Figure 2 for details.

Figure 2 – Optical Stack on LCD

The second layer of glass is coated with an Oleophobic Anti-Reflective (AR) coating which matches the index of

refraction of air to eliminate surface reflections. These layers of coated glass are bonded together with an index

matching optical adhesive to eliminate internal reflections caused by the index of refraction mismatch between

the soda lime glass and air. This eliminates over 95% of unwanted glare from the screen. Please see Figure 3

below for more details.

20

25

30

35

40

45

50

30MHz 75MHz 100MHz 150MHz 200MHz 300MHz 500MHz 700MHz 1000MHz

15"LCD

17"LCD

19"LCD

AR Coating

ITO Coating

Soda Lime Float Glass

Copper Buss Bar

LCD Frame

O ptical Ind ex

Matching

Adhesive

LCD Panel

And

Backlight

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 3

Figure 3 – Comparison of Reflections with and without Optical Bonding

The resulting structure in conjunction with the CPX2-1732 Hi-Bright 1000nit panel has greatly enhanced optical

characteristics in high ambient light conditions. The optical adhesive used is a silicone RTV and offers other

benefits mechanically to the LCD as well. The adhesive remains pliable and therefore acts as a shock

absorbing medium for the front of the LCD. Together with the additional layers of glass provides a very rugged

composite structure. Another benefit is that should breakage actually occur the shards of glass will be retained

together to prevent injury to personnel. The adhesive also prevents any condensation from building up in the air

gap between the layers of glass which would cause fogging of the display. Finally, the added mass bonded to

the front of the LCD display adds a thermal conduction path to help dissipate the heat generated in the

backlights themselves.

By eliminating the majority of reflected light, the apparent contrast improves making the display more readable in

high bright situations. An alternative to improving the contrast is to increase the back light levels to overpower

the reflected light. The downside to this approach is the higher power requirements and higher heat generated

by the backlights.

Photo Courtesy of

GDS Clearview

Figure 4 – Comparison with and without Optical Bonding

Reflected

Light

Total

22.5%

4.5%

4.5%

4.5%

4.5%

4.5%

Without Optical Bonding

Or AR Coating

Reflected

Light

Total

0.7%

0.3%

With Optical Bonding

And AR Coating

0.1%

0.1%

0.1%

0.1%

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 4

Genesis Based LCD Controllers

The LCD Controller is a key component in any display

system and no expense has been spared in specifying the

Standard Controller and Advanced HD-SDI Controller

Genesis controllers. These are long life revision

controlled military grade components. The Genesis chip

set is the current gold standard for LCD controllers.

The controllers support 3x8-bit 16.7 million colors at up to

1920 x 1200. Refresh rates of 60Hz for WUXGA and

UXGA with higher refresh rates for lower resolutions

available. Computer input signals of VGA, SVGA, XGA,

SXGA, WXGA, UXGA and WUXGA are supported.

Video inputs of NTSC, PAL and SECAM are optionally

available. DVI inputs supports up to 1920 x 1080

WUXGA 60Hz signals.

These ruggedized military grade controllers are rated for

operating at -40 to +80 deg C, use low mass tantalum

capacitors for maximum vibration and shock tolerance

and are conformal coated for extreme ruggedness. The

coating is silicone resin conformal coating.(MOD) DEF-

STAN 59/47 Issue 4 &UL QMJU2 compliant

MTBF for the controllers is in excess of 150,000 to

200,000 hours.

Figure 5 – Controller Specifications

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 5

Photos

Connector details dependent on installed controller

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 6

Specifications

Enclosure

6U (10.47”) x 3.2” deep

Front Panel milled 5052 aluminum alloy

Body made of 5052-H32 aluminum alloy

All stainless steel hardware

All self-locking pressed in fasteners where

appropriate

Powder coat black, medium texture, for ruggedness

Other colors optionally available

Designed to Mil-Spec Standards to Satisfy Military,

Industrial and Commercial Requirements

Compact Enclosure for Limited Depth Installation

Weight: 9.7lbs (depending on model & features)

Display

17.3" Wide-Screen TFT LCD 1920 x 1080

Display Colors: 16.7 Million

Response Time: 40ms Typical

Viewing Angle: 80 deg

Contrast Ratio: 600:1 typical native

Brightness: 400cd/m2 standard (CPX2-1731),

1000cd/m2 enhanced daylight visibility (CPX2-

1732)

Pixel Pitch: 0.1989mm x 0.1989mm

Pixel Arrangement: R.G.B Stripe

Display Enhancement Options

3mm smudge-resistant anti-reflective coated soda

lime float glass,bonded to the LCD panel with

optical index matched adhesive

Laminate of 1.1mm smudge-resistant anti-reflective

coated soda lime float glass panel and a 1.1 mm

ITO coated glass panel(<12.5Ω/sq) grounded via

a copper buss bar, bonded to the LCD panel with

optical index matched adhesive

Power Supply Options

AC Input

100 to 260VAC, auto selecting

47-66 HZ

12VDC Input Transient Filter

Line transient protection for 12VDC vehicular

applications

Mil-Std-1275A DC/DC Converter

True 1275 compliance for military 28VDC

nominal vehicle inputs

18 to 36VDC input

48VDC DC/DC Converter

36 to 75VDC Input

Isolated Inputs for +/- input levels

See the appropriate power supply section for complete

power suppl

y

specifications.

Environmental

(Designed to meet or exceed)

Altitude

10,000 ft. Operational,

30,000 ft. Storage

MIL-STD-810, Method 500.5

High Temperature

70°C Operational, 70°C Storage

MIL-STD-810, Method 501.5

Low Temperature

0°C Operational, -20°C Storage

MIL-STD-810, Method 502.5

Humidity

5-95%, Non-condensing

MIL-STD-810, Method 507.5

Blowing Sand and Dust

Procedures I and II

MIL-STD-810, Method 510.5

Transport Vibration

US Highway Truck and Air Transport

MIL-STD-810, Method 514.6

Bench Handling Shock

Procedure VI, 20G @ 11ms

MIL-STD-810, Method 516.6

Table 2 – Specifications

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 7

Figure 6 - CCX Outline Drawing

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Page 8

This Page Intentionally Blank

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

Page 9

Chapter 2 – Power Supply Options

AC Input Power Supply

The AC Input Power Supply is a 65W Medical Grade “Brick” style power supply. The output is provided with a

circular mil connector for connecting to the LCD Keyboard Drawer. The input accepts a standard IEC 320 plug.

A bracket is provided to securely mount the supply in a rack.

Alternate AC supplies are available as required by the application or environmental requirements.

INPUT

Voltage 100-240VAC

Current 2.0A @ 100VAC

Frequency 50-60Hz

Input Connector 3-Pin IEC 320 Receptacle

OUTPUT

Total Regulation < +/- 5%

Set Point Accuracy < +/- 3% @ 60% Load

Hold-up Time >12mS @ Full Load,

115VAC

Over Voltage Protection Built-in

Over Current Protection Built-in

Short Circuit Protection Pulsing mode, auto

recovery

SIZE

L X W X H 5.07” X 3.06” X 1.35”

Weight 1.2 lbs

ENVIRONMENTAL

Operating Temperature 0 to 50°C

Storage Temperature -40 to +85°C

SAFETY

cTUVus

UL 60601-1

CSA C22.2 No. 601.1-M90

CB per IEC 60601-1

CE marked to LVD

Class I

EMI/EMC

Emissions CISPR11 and FCC Part 15, Class B

EN61000-3-2, -3

Immunity EN61000-4-2, -3, -4, -5, -6, -9, -11

Table 3 - AC Input Supply Specifications

Photo 1 - AC Power Supply

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

Page 10

12VDC Input Transient Filter

The CPX2-173 display consoles require nominal +12VDC at 40W for operation. An EMI line filter is provided to

limit EMI emissions and to provide a small measure of input filtering.

For operation from unregulated 12VDC (+/-10%) such as in a vehicular or marine environment, front end

transient filtering is required to suppress potentially damaging spikes from large inductive loads in the DC circuit

(starters, etc.).

The xxx 12VDC Input Transient Filter provides an input Transient Protection as well as inductive and capacitive

filtering to suppress large input transients. A bridge rectifier provides reverse connection protection. A circuit

breaker provides for failure protection and allows the power to be disconnected.

Connectors

Input Connector MS3102A-10SL-3P (MIL-C-5015)

Mating Input Connector MS3106A-10SL-3S (Straight)

MS3108A-10SL-3S (Right Angle)

Pinouts Pin A – Positive

Pin B – Negative Input

Pin C – N/C

Output Connector MS3102A-10SL-3S (MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S (Straight)

MS3108A-10SL-3S (Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C – N/C

Photo 2 - 12VDC Input Front End Filter

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

Page 11

MIL-STD-704/1275 28VDC DC Input

The ‘C’ option 28VDC Mil-Std-704/1275 DC Input is an internal power supply providing true 704/1275 input

specifications allowing reliable operation from nominal 28VDC input mains in a military environment. This supply

meets Mil-Std-704A and Mil-Std-1275A (100V for 50mS).

Operating Specifications

Input Voltage 18-36VDC

Output Voltage 12.0VDC

Output Current 5A

Output Power 75W

Electrical Specifications

Efficiency 81%

Isolation 200VDC, Input to

Output and Input to Case

EMI Filtering Mil-Std-461E,

CD101 and CE102 on the input

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +100°C

Connectors

Input Connector MS3102A-10SL-4P

(MIL-C-5015)

Mating Input Connector MS3106A-10SL-4S

(Straight)

MS3108A-10SL-4S

(Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C –N/C

Output Connector MS3102A-10SL-3S

(MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S

(Straight)

MS3108A-10SL-3S

(Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C– N/C

Environmental Specifications

Pressure-Altitude Per MIL-STD-810F,

Method 500.4, Procedure I

and II

High Temperature Per MIL-STD-810F,

Method 501.4, Procedure I

and II

Low Temperature Per MIL-STD-810F,

Method 502.4, Procedure I

Humidity Per MIL-STD-810F,

Method 507.4, Procedure I

Fungus Per Mil-Std-810F, Method

508.5, Procedure I

Salt Fog Per Mil-Std-810F, Method

509.4, Procedure I

Sand and Dust Per Mil-Std-810F, Method

510.4, Procedure I and II

Explosive Atmosphere Per Mil-Std-810F, Method

511.4, Procedure I

Acceleration Per MIL-STD-810F,

Method 513.5, Procedure I

and II

Vibration Per MIL-STD-810F,

Method 514.5, Procedure

I, Category 1, 4, 7 thru 14

and 16 thru 21

Shock Per MIL-STD-810F,

Method 516.5, Procedure

I, IV

Table 4 - MIL-STD-704 Power Supply Specifications

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

Page 12

+/-48VDC Power Supply

The xx 48VDC Input Converter provides universal isolated 48VDC input, either positive or negative input. Thus

it can be used in a data center with centralized power of +48VDC as well as a central office with -48VDC mains.

The system is provided in a rack mountable case with military grade circular connectors.

Operating Specifications

Input Voltage 36-75VDC

Output Voltage 12.0VDC

Output Current 10A

Output Power 120W

Connectors

Input Connector MS3102A-14SL-7P

(MIL-C-5015)

Mating Input Connector MS3106A-14S-7S

(Straight)

MS3108A-14S-7S

(Right Angle)

Pinouts Pin A - Positive

Pin B – Negative

Output Connector MS3102A-10SL-3S

(MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S

(Straight)

MS3108A-10SL-3S

(Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C– N/C

Electrical Specifications

Efficiency 92%

Isolation 1500VDC, Input to

Output and Input to

Case

EMI Filtering Mil-Std-461E,

CD101 and CE102 on

the input

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +125°C

Table 5- 48VDC Power Supply Specifications

Photo 3- 48VDC Power Supply

Chassis Plans CPX2-173 Technical Reference Chapter 3 – Ordering Information

Page 13

Chapter 3 – Ordering Information

Part Number Matrix

CPX2-173[M][ME][S][P])

(M) Standard or Hi-Bright Monitor

1 – Standard 600 cd/m2

2 – Hi-Bright 1,000 cd/m2

(ME) LCD Surface Enhancements

A – Bonded EMI Filter and AR cover glass

B – Standard w/ no screen enhancements

C - Bonded 3mm AR coated cover glass

E - Bonded USB Resistive touch screen

(S) Video Signal Inputs

D4 – Includes VGA, DVI-D, HDMI, Component, Composite

G1 - VGA, Dispay Port, HDMI, Component, Composite, HD-SDI

(P) Power Supply Option

N – No supply provided. Operates from nominal 12VDC +/-5%

A – AC input, universal 100-260VAC, 50/60Hz

B – 12VDC Front End Transient Filter

C – 28VDC Mil-Std-704 Military Grade

D – 12VDC for connection to Chassis Plans Chassis Power Plug

E – +/-48VDC, Vicor Module Military Grade

F – AC input, universal 100-260VAC, 400Hz

Example Part Numbers

CPX2-1731BD4A – Standard brightness. No LCD enhancements. VGA/DVI/HDMI input. AC Power.

CPX2-1732CG1C – Hi-Bright display brightness. Anti-reflective LCD enhancement. Enhanced HD/SDI

controller. 28VDC input power.

Chassis Plans CPX2-173 Technical Reference Chapter 3 – Ordering Information

Page 14

This Page Intentionally Blank

Table of contents

Other Chassis Plans Monitor manuals