CHD P6-M User manual

P6

P6P6

P6-

--

-M

MM

M

MIDI Interface for

MIDI Interface forMIDI Interface for

MIDI Interface for

Korg Polysix Synthesizer

Korg Polysix SynthesizerKorg Polysix Synthesizer

Korg Polysix Synthesizer

Model 8

Model 8Model 8

Model 8-

--

-427

427427

427

Version 1.0

Version 1.0Version 1.0

Version 1.0

Installation Manual

Installation ManualInstallation Manual

Installation Manual

© 2021 CHD Elektroservis

© 2021 CHD Elektroservis© 2021 CHD Elektroservis

© 2021 CHD Elektroservis

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

2

2

2

2

Contents Page

1

11

1

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................

..........................

............. 3

33

3

1.1

MIDI INTERFACE KIT PARTS............................................................................................................................. 3

1.2

GENERAL INFORMATION................................................................................................................................ 3

1.3

INTERFACE CONNECTION............................................................................................................................... 4

2

22

2

INSTALLATION PROCEDURE

INSTALLATION PROCEDUREINSTALLATION PROCEDURE

INSTALLATION PROCEDURE................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................................

..........................................................

............................. 5

55

5

2.1

THE INSTRUMENT OPENING........................................................................................................................... 5

2.2

MIDI DIN SOCKETS INSTALLATION ................................................................................................................... 5

2.2.1

HOLES FOR MIDI SOCKETS DRILLING ................................................................................................................ 6

2.2.2

MIDI SOCKETS MOUNTING ............................................................................................................................. 6

2.3

RESET BUTTON AND INDICATION LED INSTALLATION......................................................................................... 7

2.3.1

HOLES FOR RESET BUTTON AND INDICATION LED DRILLING................................................................................ 7

2.3.2

RESET BUTTON AND INDICATION LED MOUNTING............................................................................................. 8

2.4

20-CORE RIBBON CABLE MOUNTING ............................................................................................................... 8

2.5

16-CORE RIBBON CABLE MOUNTING ............................................................................................................. 10

2.6

INTERFACE BOARD INSTALLATION................................................................................................................. 12

2.7

INSTRUMENT RE-ASSEMBLY ......................................................................................................................... 14

3

33

3

INSTALLATION TIPS

INSTALLATION TIPSINSTALLATION TIPS

INSTALLATION TIPS ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................

............

...... 15

1515

15

3.1

MIDI INPUT AND OUTPUT ............................................................................................................................ 15

3.2

RESET BUTTON AND INDICATION LED ............................................................................................................ 15

3.3

MEMORY PROTECTION................................................................................................................................ 16

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

3

3

3

3

1

11

1

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

1.1

1.11.1

1.1

MIDI INTERFACE KIT PARTS

MIDI INTERFACE KIT PARTSMIDI INTERFACE KIT PARTS

MIDI INTERFACE KIT PARTS

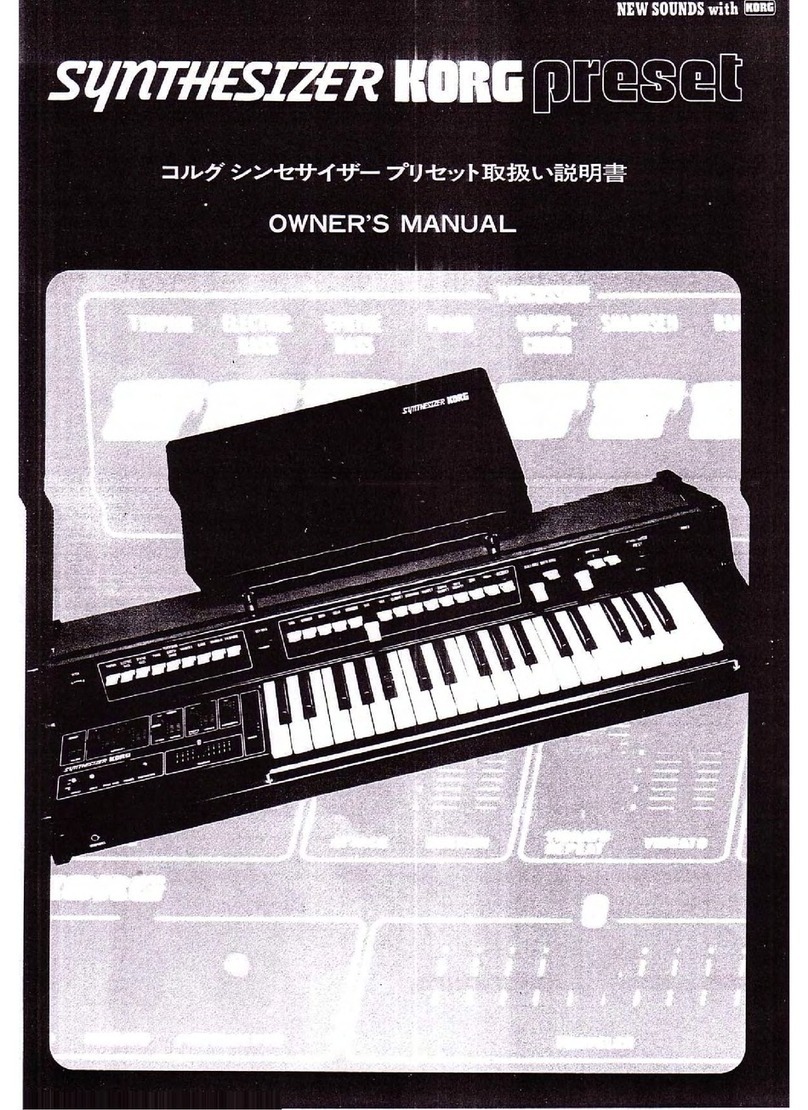

Fig. 1.1.1

Fig. 1.1.1 Fig. 1.1.1

Fig. 1.1.1 -

--

- Parts of P6

Parts of P6 Parts of P6

Parts of P6-

--

-M interface kit

M interface kitM interface kit

M interface kit

The MIDI interface kit contents all

necessary parts for installation incl. all

support and coupling elements. The

delivery also includes both installation

and operation manuals in printed

form. Please check if the delivery is

complete before the installation (see

fig. 1.1.1):

(1) MIDI Interface board

(2) 2x DIN-5 socket with cable

(3) Bunched cables with button and

LED

(4) 16-core ribbon cable with

connector

(5) 20-core ribbon cable with

connector

(6) Coupling elements (LED holder,

jumper, self-tapping screws,

insulation tubes and tightening strips)

(7) Owner’s and Installation manuals in printed form

1.2

1.21.2

1.2

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

Mounting the interface in the Korg Polysix synthesizer is very easy. If you follow the instructions from this

manual, there should be no major problems during the installation. The interface installation procedure is

thoroughly described in the following chapters. Please follow these instructions accurately to avoid any damage

of the instrument.

Attention! Disconnect the instrument form the mains prior to the installation. There is a risk of the

Attention! Disconnect the instrument form the mains prior to the installation. There is a risk of the Attention! Disconnect the instrument form the mains prior to the installation. There is a risk of the

Attention! Disconnect the instrument form the mains prior to the installation. There is a risk of the

electric shock!

electric shock!electric shock!

electric shock!

Attention! Observe precautions for handling electrosta

Attention! Observe precautions for handling electrostaAttention! Observe precautions for handling electrosta

Attention! Observe precautions for handling electrostatic discharge sensitive devices!

tic discharge sensitive devices!tic discharge sensitive devices!

tic discharge sensitive devices!

The producer is not responsible for any eventual mechanical or electrical damage of the Korg

The producer is not responsible for any eventual mechanical or electrical damage of the Korg The producer is not responsible for any eventual mechanical or electrical damage of the Korg

The producer is not responsible for any eventual mechanical or electrical damage of the Korg

instrument caused by the infringement of the described installation procedure or by careless

instrument caused by the infringement of the described installation procedure or by careless instrument caused by the infringement of the described installation procedure or by careless

instrument caused by the infringement of the described installation procedure or by careless

manipulation during the installatio

manipulation during the installatiomanipulation during the installatio

manipulation during the installation of the MIDI interface!

n of the MIDI interface!n of the MIDI interface!

n of the MIDI interface!

It is recommended to calibrate the instrument accordingly to the instructions in service manual of the

It is recommended to calibrate the instrument accordingly to the instructions in service manual of the It is recommended to calibrate the instrument accordingly to the instructions in service manual of the

It is recommended to calibrate the instrument accordingly to the instructions in service manual of the

instrument prior the interface installation. This ensures trouble

instrument prior the interface installation. This ensures troubleinstrument prior the interface installation. This ensures trouble

instrument prior the interface installation. This ensures trouble-

--

-free operation of the interface.

free operation of the interface.free operation of the interface.

free operation of the interface.

The cover of the instrument will not be markedly damaged during the installation. The physical appearance of

the vintage instrument remains nearly the same as before the installation. If necessary, the interface can be

simply removed and the instrument restored back to original appearance.

All original circuits of the Korg Polysix remain without any modification. The instrument can be used the same

way as before the retrofitting.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

4

44

4

1.3

1.31.3

1.3

INTERFACE CONNECTION

INTERFACE CONNECTIONINTERFACE CONNECTION

INTERFACE CONNECTION

The interface is connected to the KLM-366 and KLM-371 boards of the instrument. The following diagrams (figs.

1.3.1, 1.3.2) explain the electrical connection of the interface in the instrument.

Fig. 1.3.1

Fig. 1.3.1 Fig. 1.3.1

Fig. 1.3.1 –

––

– Connection to the instrument

Connection to the instrument Connection to the instrument

Connection to the instrument

Fig. 1.3.2

Fig. 1.3.2 Fig. 1.3.2

Fig. 1.3.2 –

––

– Block diagram of the interface function

Block diagram of the interface function Block diagram of the interface function

Block diagram of the interface function

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

5

5

5

5

2

22

2

INSTALLATION PROCEDURE

INSTALLATION PROCEDUREINSTALLATION PROCEDURE

INSTALLATION PROCEDURE

2.1

2.12.1

2.1

THE INSTRUMENT D

THE INSTRUMENT DTHE INSTRUMENT D

THE INSTRUMENT DISASSEMBLY

ISASSEMBLYISASSEMBLY

ISASSEMBLY

a) Unscrew the four screws on the bottom side of the instrument (fig. 2.1.1) and four screws on the top panel

(fig. 2.1.2). Keep the screws. They will be used again after the MIDI kit installation is finished.

Fig. 2.1.1

Fig. 2.1.1Fig. 2.1.1

Fig. 2.1.1

Fig. 2.1.2

Fig. 2.1.2Fig. 2.1.2

Fig. 2.1.2

b) Carefully lift up the instrument top panel and turn it back (fig. 2.1.3). All instrument’s parts and boards

needed for the interface installation are now accessible (fig. 2.1.4).

Fig. 2.1.3

Fig. 2.1.3Fig. 2.1.3

Fig. 2.1.3

Fig. 2.1.4

Fig. 2.1.4Fig. 2.1.4

Fig. 2.1.4

2.2

2.22.2

2.2

MIDI DIN SOCKETS INSTALLATION

MIDI DIN SOCKETS INSTALLATIONMIDI DIN SOCKETS INSTALLATION

MIDI DIN SOCKETS INSTALLATION

The interface has both MIDI input and output. However, only MIDI input is necessary for basic operation of the

interface (i.e controlling the instrument by MIDI commands). MIDI THRU/OUT output connector need not to be

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

6

6

6

6

installed if you don’t require transfer of MIDI data to another MIDI devices (THRU function) or reverse

communication of the interface with host system (OUT function). Nevertheless, having both MIDI input and

output is more convenient for an easy integration in a more advanced MIDI system.

There are more possible ways to install the MIDI-IN socket(s) if you do not want to mechanically damage the

panels of the instrument by drilling (see chapter 3.1).

Recommended method of the MIDI socket(s) montage is described below.

2.2.1

2.2.12.2.1

2.2.1

HOLES

HOLESHOLES

HOLES FOR MIDI SOCKETS DRILLING

FOR MIDI SOCKETS DRILLING FOR MIDI SOCKETS DRILLING

FOR MIDI SOCKETS DRILLING

a) The best solution is to mount the MIDI sockets to the power cord sub-panel on the rear panel of the

instrument, where the serial number plate is originally fixed (fig. 2.2.1). This solution is recommended, since

you can revert the instrument to its original appearance if you decide to remove the interface in the future.

b) Unscrew the serial number plate from the power cord sub-panel (fig. 2.2.1). Safely store the serial number

plate and two self-tapping screws for future usage

1

11

1

.

c) Drill two holes with diameter 16 mm and two holes with diameter 2,2 mm to the sub-panel of the instrument

as shown on fig. 2.2.2. Use sharp drills and work carefully

work carefullywork carefully

work carefully so that the panel is not scratched and other parts of

the instrument are not damaged during the drilling!

Fig. 2.2.1

Fig. 2.2.1Fig. 2.2.1

Fig. 2.2.1

Fig. 2.2.2

Fig. 2.2.2Fig. 2.2.2

Fig. 2.2.2

d) Clean the edge of the holes with small rasp or tip of bigger drill from both sides of the panel after the holes

are drilled.

e) Clean all iron sawdust and raspings from the inside of the instru

Clean all iron sawdust and raspings from the inside of the instruClean all iron sawdust and raspings from the inside of the instru

Clean all iron sawdust and raspings from the inside of the instruments

mentsments

ments, they can cause short circuits or serious

electrical damage if they are left inside the instrument. Please clean the instrument carefully!

2.2.2

2.2.22.2.2

2.2.2

MIDI SOCKETS MOUNTING

MIDI SOCKETS MOUNTINGMIDI SOCKETS MOUNTING

MIDI SOCKETS MOUNTING

Fig. 2.2.3

Fig. 2.2.3Fig. 2.2.3

Fig. 2.2.3

a) Pull flat connectors of MIDI cables through the 16

mm holes in the panel from outer side and insert the

DIN sockets of the cables into the holes (fig. 2.2.3).

Both MIDI cables are identical and can be swapped.

b) Fix the DIN sockets to the panel using four self-

tapping screws from the interface accessory (fig.

2.2.4).

1

11

1

The plate can be placed back.to its original position to hide the drilled holes if the interface will be removed and the DIN sockets unmounted.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

7

7

7

7

c) It is recommended to label the DIN sockets ("MIDI IN", "MIDI THRU/OUT" for example) with self-adhesive foil

glued near the sockets (fig. 2.2.5).

Fig. 2.2.4

Fig. 2.2.4 Fig. 2.2.4

Fig. 2.2.4

Fig. 2.2.5

Fig. 2.2.5 Fig. 2.2.5

Fig. 2.2.5

2.3

2.32.3

2.3

RESET BUTTON AND INDICATION LED INSTALLATION

RESET BUTTON AND INDICATION LED INSTALLATIONRESET BUTTON AND INDICATION LED INSTALLATION

RESET BUTTON AND INDICATION LED INSTALLATION

There are two control elements on the interface – reset button and indication LED. There are more possible

ways to install the button and the LED. The button and the LED need not be installed if you prefer to maintain

the vintage status of the instrument (i.e. if you don’t want to damage the instrument’s panel by drilling). Or you

can install only the reset button or only the indication LED (see chapter 3.2). Nevertheless having both of them

installed is more convenient for easier device control.

2.3.1

2.3.12.3.1

2.3.1

HOLES FOR

HOLES FORHOLES FOR

HOLES FOR RESET BUTTON AND INDICATION LED DRILLING

RESET BUTTON AND INDICATION LED DRILLING RESET BUTTON AND INDICATION LED DRILLING

RESET BUTTON AND INDICATION LED DRILLING

a) If you decide to install the LED and the button, the suitable place for them is the right side of the front panel

of the instrument - above the highest keys (fig. 2.3.1).

b) Drill one hole with diameter 7 mm (for reset button) and one hole with diameter 6,5 mm (for indication LED)

to the panel – see fig. 2.3.2. Use sharp drills and work carefully

work carefullywork carefully

work carefully so that the panel is not scratched and other

parts of the instrument are not damaged during the drilling!

Fig. 2.3.1

Fig. 2.3.1Fig. 2.3.1

Fig. 2.3.1

Fig. 2.3.2

Fig. 2.3.2 Fig. 2.3.2

Fig. 2.3.2

c) Clean the edge of the holes with small rasp or tip of bigger drill from both sides of the panel after the holes

are drilled.

d) Clean all iron sawdust and raspings from the inside of the instruments

Clean all iron sawdust and raspings from the inside of the instrumentsClean all iron sawdust and raspings from the inside of the instruments

Clean all iron sawdust and raspings from the inside of the instruments, they can cause short circuits or serious

electrical damage if they are left inside the instrument. Please clean the instrument carefully!

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

8

8

8

8

2.3.2

2.3.22.3.2

2.3.2

RESET BUTTON AND INDICATION LED MOUNTING

RESET BUTTON AND INDICATION LED MOUNTINGRESET BUTTON AND INDICATION LED MOUNTING

RESET BUTTON AND INDICATION LED MOUNTING

a) Insert LED holder (from the interface accessory) into 6,5 mm hole in the instrument’s panel from the outer

side. Pull the lock ring of the LED holder over the supplied LED. Then insert the LED into the holder (from inner

side of the instrument’s panel) and fix it by the overthrust of the ring on the holder (fig. 2.3.3, 2.3.4).

b) Insert the reset button into 7 mm hole in the instrument’s panel from inner side. Fix the button to the panel

with the nut and spring washer (fig. 2.3.3, 2.3.4).

Fig. 2.3.3

Fig. 2.3.3 Fig. 2.3.3

Fig. 2.3.3

Fig. 2.3.4

Fig. 2.3.4Fig. 2.3.4

Fig. 2.3.4

2.4

2.42.4

2.4

20

2020

20-

--

-CORE RIBBON CABLE MOUNTING

CORE RIBBON CABLE MOUNTINGCORE RIBBON CABLE MOUNTING

CORE RIBBON CABLE MOUNTING

The delivered 20-core ribbon cable is fitted with 20-pin connector (fig. 2.4.1). It must be connected to several

pads at the KLM-371 board of the instrument (fig. 2.4.2). Note that the KLM-371 board is divided to three parts.

Fig. 2.4.1

Fig. 2.4.1Fig. 2.4.1

Fig. 2.4.1

Fig. 2.4.2

Fig. 2.4.2Fig. 2.4.2

Fig. 2.4.2

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

9

9

9

9

Split up free end of the cable (by ripping or cutting) to individual wires and adapt their lengths as necessary

during the cable installation. Stripe ends of all wires in length about 2 mm and tin them before they are

connected to the instrument. Individual control signal wires mu st be connected accordingly to the table 1 (also

see figs. 2.4.1 and 2.4.2). Wire Nr. 1 (terminal) is signed with red color.

Table 1

Table 1 Table 1

Table 1 –

––

– Connection of 20

Connection of 20 Connection of 20

Connection of 20-

--

-core ribbon cable to KLM

core ribbon cable to KLMcore ribbon cable to KLM

core ribbon cable to KLM-

--

-371 board

371 board371 board

371 board

Wire Nr.

Wire Nr.Wire Nr.

Wire Nr.

Signal

SignalSignal

Signal

Connector /

Connector / Connector /

Connector /

Pad Nr.

Pad Nr.Pad Nr.

Pad Nr.

Remark

RemarkRemark

Remark

Wire Nr.

Wire Nr.Wire Nr.

Wire Nr.

Signal

SignalSignal

Signal

Connector /

Connector / Connector /

Connector /

Pad Nr.

Pad Nr.Pad Nr.

Pad Nr.

Re

ReRe

Remark

markmark

mark

1 P17 CN12 / 6 Red signed wire 11 ACKI CN12 / 17 Unsolder the orig. wire

2 P16 CN12 / 7 12 ACKO (CN12 / 17) To the orig. freed wire

3 P15 CN12 / 8 13 PO13 CN10 / 5

4 P14 CN12 / 9 14 PO12 CN10 / 6

5 P13 CN12 / 10 15 PO11 CN10 / 7

6 P12 CN12 / 11 16 PO10 CN10 / 8

7 P11 CN12 / 12 17 DO4 CN10 / 9

8 P10 CN12 / 13 18 DO5 CN10 / 10

9 P20 CN12 / 14 19 DO6 CN10 / 11

10 ACKR CN12 / 16 20 DO7 CN10 / 12

a) Wires from Nr. 1

2

22

2

to Nr. 10 of the 20-core ribbon cable are solderd directly to pads 6 to 14 and 16 of CN12

connector

3

33

3

as shown on fig. 2.4.3. Solder the wires to these pads directly in parallel manner to original wires

leaded to the pads.

b) Unsolder the original wire from pad Nr. 17 of CN12. Solder wire Nr. 11 of the ribbon cable to the freed pad

(fig. 2.4.4).

Fig. 2.4.3

Fig. 2.4.3Fig. 2.4.3

Fig. 2.4.3

Fig. 2.4.4

Fig. 2.4.4Fig. 2.4.4

Fig. 2.4.4

Fig. 2.4.5

Fig. 2.4.5Fig. 2.4.5

Fig. 2.4.5

Fig. 2.4.6

Fig. 2.4.6Fig. 2.4.6

Fig. 2.4.6

2

22

2

Wire Nr. 1 is signed with red color.

3

33

3

There is no physical connector on the KLM-371 board. Only row of soldering pads is here. But these pads are labeled as CN12 connector in

technical documentation of the instrument.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

10

1010

10

c) Place heat-shrink insulation tube

φ

2 mm (from the interface accessory) on wire Nr. 12 of the ribbon cable

and solder the wire Nr. 12 of the ribbon cable to previously freed wire Nr. 17 of CN12 (fig. 2.4.5).

d) Isolate the connection with the insulation tube and heat it (with a hot-flue pistol for example) until it shrinks

tightly to the wires (fig. 2.4.6).

Fig. 2.4.7

Fig. 2.4.7Fig. 2.4.7

Fig. 2.4.7

e) Wires from Nr. 13 to Nr. 20 of the 20-core ribbon

cable are solderd directly to pads 5 to 12 of CN10

connector

4

44

4

as shown on fig. 2.4.7. Solder the wires to

these pads directly in parallel manner to original wires

leaded to the pads.

2.5

2.52.5

2.5

16

1616

16-

--

-CORE RIBBON CABLE MOUNTING

CORE RIBBON CABLE MOUNTINGCORE RIBBON CABLE MOUNTING

CORE RIBBON CABLE MOUNTING

The delivered 16-core ribbon cable is fitted with 16-pin

connector (fig. 2.5.1). It must be connected to several

pads at the KLM-366

5

55

5

board of the instrument (fig 2.5.2).

Fig. 2.5.1

Fig. 2.5.1Fig. 2.5.1

Fig. 2.5.1

Fig. 2.5.2

Fig. 2.5.2Fig. 2.5.2

Fig. 2.5.2

4

44

4

There is no physical connector on the KLM-371 board. There is only a row of soldering pads. But these pads are labeled as CN10 connector in

technical documentation of the instrument.

5

55

5

There are two a little different versions of the KLM-366 board. The installation process is the same for both old and new (KLM-366B) versions.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

11

1111

11

Fig. 2.5.3

Fig. 2.5.3Fig. 2.5.3

Fig. 2.5.3

Fig. 2.5.4

Fig. 2.5.4Fig. 2.5.4

Fig. 2.5.4

Split up free end of the cable (by ripping or cutting) to individual wires and adapt their lengths as necessary

during the cable installation. Stripe ends of all wires in length about 2 mm and tin them before they are

connected to the instrument. Individual control signals wires must be connected accordingly to the table 2 (also

see figs. 2.5.1, 2.5.2, 2.5.3 and 2.5.4). Wire Nr. 1 (terminal) is signed with red color.

Table 2

Table 2 Table 2

Table 2 –

––

– Connection of 16

Connection of 16 Connection of 16

Connection of 16-

--

-core ribbon cable to KLM

core ribbon cable to KLMcore ribbon cable to KLM

core ribbon cable to KLM-

--

-366 board

366 board366 board

366 board

Wire Nr.

Wire Nr.Wire Nr.

Wire Nr.

Signal

SignalSignal

Signal

Connector /

Connector / Connector /

Connector /

Pad Nr.

Pad Nr.Pad Nr.

Pad Nr.

Remark

RemarkRemark

Remark

Wire Nr.

Wire Nr.Wire Nr.

Wire Nr.

Signal

SignalSignal

Signal

Connector /

Connector / Connector /

Connector /

Pad Nr.

Pad Nr.Pad Nr.

Pad Nr.

Remark

RemarkRemark

Remark

1 DB0 CN04 / 9 Red signed wire 9 FCMO (CN17 /3) To lead of R51 resistor

2 DB1 CN04 / 10 10 FCMI CN17 / 3 To freed pad

3 DB2 CN04 / 11 11 +5V

4 DB3 CN04 / 12 12 +5V CN01 / 2 Both 11 and 12 wires

to the same pad

5 DB4 CN04 / 13 13 GND

6 DB5 CN04 / 14 14 GND CN01 / 3 Both 13 and 14 wires

to the same pad

7 DB6 CN04 / 15 15 -5V

8 DB7 CN04 / 16 16 -5V CN01 / 4 Both 15 and 16 wires

to the same pad

a) Wires from Nr. 1

6

66

6

to Nr. 8 of the 16-core ribbon cable are connected to pins 9 to 16 of CN04 connector as

shown in table 1. Since solder pads of the CN04 connector are not accessible directly (they are on bottom side

of the KLM-366 board), the wires are soldered to some via-pads on the board what conforms to the pins of the

CN04 connector (fig. 2.5.5).

b) Unsolder upper lead of R51 resistor from the KLM-366 board (fig. 2.5.6).

Fig. 2.5.5

Fig. 2.5.5Fig. 2.5.5

Fig. 2.5.5

Fig. 2.5.6

Fig. 2.5.6Fig. 2.5.6

Fig. 2.5.6

c) Solder wire Nr. 10 of the ribbon cable to the freed soldering pad (fig. 2.5.7)

d) Place heat-shrink insulation tube

φ

4 mm (from the interface accessory) on the wire Nr. 9 of the ribbon cable

and solder the wire Nr. 9 to freed lead of the R51 resistor (fig. 2.5.8).

6

66

6

Wire Nr. 1 is signed with red color.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

12

1212

12

Fig. 2.5.7

Fig. 2.5.7Fig. 2.5.7

Fig. 2.5.7

Fig. 2.5.8

Fig. 2.5.8Fig. 2.5.8

Fig. 2.5.8

e) Overlap the connection and R51 resistor with the insulation tube and heat it (with a hot-flue pistol for

example) until it shrinks tightly to the resistor and the wire (fig. 2.5.9).

f) Wires from Nr. 11 to Nr. 16 of the 16-core ribbon cable are connected to pins 2 to 4 of CN01 connector as

shown in table 1. Since solder pads of the CN01 connector are not accessible directly (they are on bottom side

of the KLM-366 board), the wires are soldered to some via-pads on the board what conforms to the pins of the

CN01 connector (fig. 2.5.10).

Fig. 2.5.9

Fig. 2.5.9Fig. 2.5.9

Fig. 2.5.9

Fig. 2.5.10

Fig. 2.5.10Fig. 2.5.10

Fig. 2.5.10

g) Solder both Nr. 11 and Nr. 12 wires of the 16-core ribbon cable to the “+5V” via-pad. It conforms to pin 2 of

the CN01 connector (fig. 2.5.10).

h) Solder both Nr. 13 and Nr. 14 wires of the 16-core ribbon cable to the “GND” via-pad. It conforms to pin 3 of

the CN01 connector (fig. 2.5.10).

i) Solder both Nr. 15 and Nr. 16 wires of the 16-core ribbon cable to the “-5V” via-pad. It conforms to pin 4 of

the CN01 connector (fig. 2.5.10).

2.6

2.62.6

2.6

INTERFACE BOARD INSTALLATION

INTERFACE BOARD INSTALLATIONINTERFACE BOARD INSTALLATION

INTERFACE BOARD INSTALLATION

Fig.. 2.6.1

Fig.. 2.6.1Fig.. 2.6.1

Fig.. 2.6.1

a) The interface board will be placed

on the rear panel of the instrument –

between the power supply board and

power cord sub-panel (fig. 2.6.1).

b) Cleanse the part of rear panel inside

of the instrument for the interface

board placement (fig. 2.6.1). It is

necessary to remove a paper label

usually glued in this area. Use a

chemical cleaner to remove all dirt and

grease.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

13

1313

13

c) Remove the protective foil form the self-adhesive supports of the interface board (fig. 2.6.2).

d) Attach the interface board to the instrument’s cover so that the board side with two ribbon cable connectors

X1 and X2 points to up as shown on the figure 2.6.3. Than fix the self-adhesive supports by pressing down to the

panel.

Fig. 2.6.2

Fig. 2.6.2Fig. 2.6.2

Fig. 2.6.2

Fig. 2.6.3

Fig. 2.6.3 Fig. 2.6.3

Fig. 2.6.3

Fig. 2.6.4

Fig. 2.6.4Fig. 2.6.4

Fig. 2.6.4

e) Plug two 3-pin connectors of the MIDI

cables to X3 (“IN”) and X4 (“OUT”) plug

heads on the interface board. Orientation

of the connectors is given by the

connector lock so they cannot be plugged

reversely but be sure that the connectors

are not exchanged: MIDI input must be

plugged to X3 head and MIDI output to X4

head (fig. 2.6.4).

f) Plug the 4-pin connector of the

bunched cables with button and LED to

X5 (“CTRL”) plug head on the interface

board. Orientation of the connector is

given by the connector lock again (fig.

2.6.4).

Fig. 2.6.5

Fig. 2.6.5Fig. 2.6.5

Fig. 2.6.5

g) Plug the 16-pin connector of the ribbon

cable leaded from the KLM-366 board to

X1 plug head on the interface board.

Orientation of the connector is given by

the lock slot again (fig. 2.6.5).

h) Plug the 20-pin connector of the ribbon

cable leaded from the KLM-371 board to

X2 plug head on the interface board.

Orientation of the connector is given by

the lock slot again (fig. 2.6.5).

i) Align newly installed cables and fix

them together to the original keyboard

bunched cables with four plastic stripes

from the interface accessory (fig. 2.6.6).

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

1

4

141

4

14

Fig. 2.6.6

Fig. 2.6.6Fig. 2.6.6

Fig. 2.6.6

2.7

2.72.7

2.7

INSTRUMENT RE

INSTRUMENT REINSTRUMENT RE

INSTRUMENT RE-

--

-ASSEMBLY

ASSEMBLYASSEMBLY

ASSEMBLY

a) Turn the top panel back to its original position on the instrument.

b) Fix the top panel to the side-boards of the instrument with four original screws (fig. 2.7.1) and to the bottom

plate of the instrument’s cover with four original screws (fig. 2.7.2). This is the reverse procedure of that

described in the chapter 2.1.

Fig. 2.7.1

Fig. 2.7.1Fig. 2.7.1

Fig. 2.7.1

Fig. 2.7.2

Fig. 2.7.2 Fig. 2.7.2

Fig. 2.7.2

The installation of the P6-M MIDI kit is now finished, the instrument is ready for use with MIDI control.

Please read the user’s manual carefully before the MIDI interface usage so you understand all interface functions.

Please read the user’s manual carefully before the MIDI interface usage so you understand all interface functions.Please read the user’s manual carefully before the MIDI interface usage so you understand all interface functions.

Please read the user’s manual carefully before the MIDI interface usage so you understand all interface functions.

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

15

1515

15

3

33

3

INSTALLATION TIPS

INSTALLATION TIPSINSTALLATION TIPS

INSTALLATION TIPS

3.1

3.13.1

3.1

MIDI INPUT AND OUTPUT

MIDI INPUT AND OUTPUTMIDI INPUT AND OUTPUT

MIDI INPUT AND OUTPUT

If you do not want to mechanically damage the panels of the instrument by drilling, you can use alternative

metod of the MIDI – IN / OUT sockets montage. You can lead out the MIDI cables through a slot on the

instrument cover (see fig. 3.1.1 for example). In that case, you will have to replace the delivered MIDI cables

with another ones equipped with cable type of the DIN sockets or plugs.

If you decide to install only MIDI-IN socket, the X4 connector (labeled “MIDI

MIDIMIDI

MIDI-

--

-OUT

OUTOUT

OUT”) on the interface board will

remain unused (see fig. 3.1.2).

Fig. 3.1.1

Fig. 3.1.1Fig. 3.1.1

Fig. 3.1.1

Fig. 3.1.2

Fig. 3.1.2Fig. 3.1.2

Fig. 3.1.2

X4 "MIDI-OUT"

3.2

3.23.2

3.2

RESET BUTTON AND INDICATION LED

RESET BUTTON AND INDICATION LEDRESET BUTTON AND INDICATION LED

RESET BUTTON AND INDICATION LED

Fig. 3.2.1

Fig. 3.2.1Fig. 3.2.1

Fig. 3.2.1

Installation of the reset button and indication LED isn’t

necessary as well. You don´t need to install this

bunched cables if you don’t want to damage the

instrument’s panel by drilling. In such case, the X5

connector (labeled “CTRL

CTRLCTRL

CTRL”) remains unused (see fig.

3.2.1). The interface operation is unaffected but you

have no optical info about the interface status and

reset of the interface must be executed by turning the

instrument off and on again or by MIDI commands

sent to the interface (see the Owner’s Manual of the

interface).

It is also possible to install only the indication LED or only the reset button on instrument’s panel:

For the indication LED only installation, cut-off black and both yellow wires of the bunched cables as shown on

fig. 3.2.2 and remove the reset button. Then connect the two free yellow wires together. If the reset button is

not installed, the interface operation is unaffected. The only limitation is that the reset of the interface can be

done only by turning the instrument off and on again or by MIDI commands sent to the interface (see the

Owner’s Manual of the interface).

X5 "CTRL"

Korg Polysix MIDI Interface

Korg Polysix MIDI InterfaceKorg Polysix MIDI Interface

Korg Polysix MIDI Interface

P6

P6 P6

P6-

--

-M

MM

M Installation

Installation Installation

Installation Manual

Manual Manual

Manual

8

88

8-

--

-427 / v. 1.00

427 / v. 1.00427 / v. 1.00

427 / v. 1.00

Copyright © 2021 CHD Elektroservis. All rights reserved.

No part of this publication may be reproduced in any form without the written permission of CHD Elektroservis.

16

1616

16

Fig. 3.2.2

Fig. 3.2.2Fig. 3.2.2

Fig. 3.2.2

For the reset button only installation, cut-off red, green and yellow wires of the bunched cables as shown on fig.

3.2.3 and remove the indication LED. If the indication LED is not installed, the interface operation is unaffected.

The only limitation is that you cannot see actual status of the interface (the “Indicator Mode” patch parameter

remains unsignificant - see user manual of the interface).

Fig. 3.2.3

Fig. 3.2.3Fig. 3.2.3

Fig. 3.2.3

3.3

3.33.3

3.3

MEMORY PROTECTION

MEMORY PROTECTIONMEMORY PROTECTION

MEMORY PROTECTION

Fig. 3.3.1

Fig. 3.3.1Fig. 3.3.1

Fig. 3.3.1

All user data stored in interface memory can be

protected against unwanted rewriting after the

memory is filled with your own data.

The jumper from interface accessory have to be

plugged on pin header (labeled “MEM

MEMMEM

MEM”) on the

interface board (see fig. 3.3.1) if you want to activate

the memory protection (see the Owner’s Manual of

the interface for details).

All documents and

All documents and All documents and

All documents and support software are available at manufacturer’s web pages.

support software are available at manufacturer’s web pages. support software are available at manufacturer’s web pages.

support software are available at manufacturer’s web pages.

Korg Polysix MIDI Interface

Model P6-M, Nr. 8-427, ver. 1.00

Document: 842710_instal, rev. 1

Manufacturer: CHD Elektroservis, Czech Republic

www.chd-el.cz info@chd-el.cz

Other manuals for P6-M

1

This manual suits for next models

1

Table of contents

Other CHD Synthesizer manuals