ChemInstruments PT-2000 User manual

PROBE TACK TESTER

MODEL PT-2000

OPERATING INSTRUCTIONS

CHEMINSTRUMENTS

510 COMMERCIAL DRIVE

FAIRFIELD, OHIO 45014

(513) 860-1598

www.cheminstruments.com

Revision 1.0

August 13, 2019

2 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

CONTENTS

PRODUCT DESCRIPTION ............................................................................................. 3

SPECIFICATIONS ................................................................................................ 3

UNPACKING ................................................................................................................... 4

ASSEMBLY ..................................................................................................................... 5

KEY COMPONENTS ...................................................................................................... 6

TOUCH SCREEN FORMAT ................................................................................. 8

THEORY OF OPERATION ........................................................................................... 11

POWER UP ........................................................................................................ 11

MACHINE SETUP .............................................................................................. 12

RUNNING A TEST ............................................................................................. 17

DWELL TIME MEASUREMENT ......................................................................... 18

EZ DATA SOFTWARE SYSTEM .................................................................................. 19

MAINTENANCE ............................................................................................................ 21

TROUBLESHOOTING ....................................................................................... 21

MAINTENANCE PROCEDURES ....................................................................... 21

CLEANING THE TOUCH SCREEN ................................................................... 22

LOAD CELL REMOVAL ..................................................................................... 23

3 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

PRODUCT DESCRIPTION

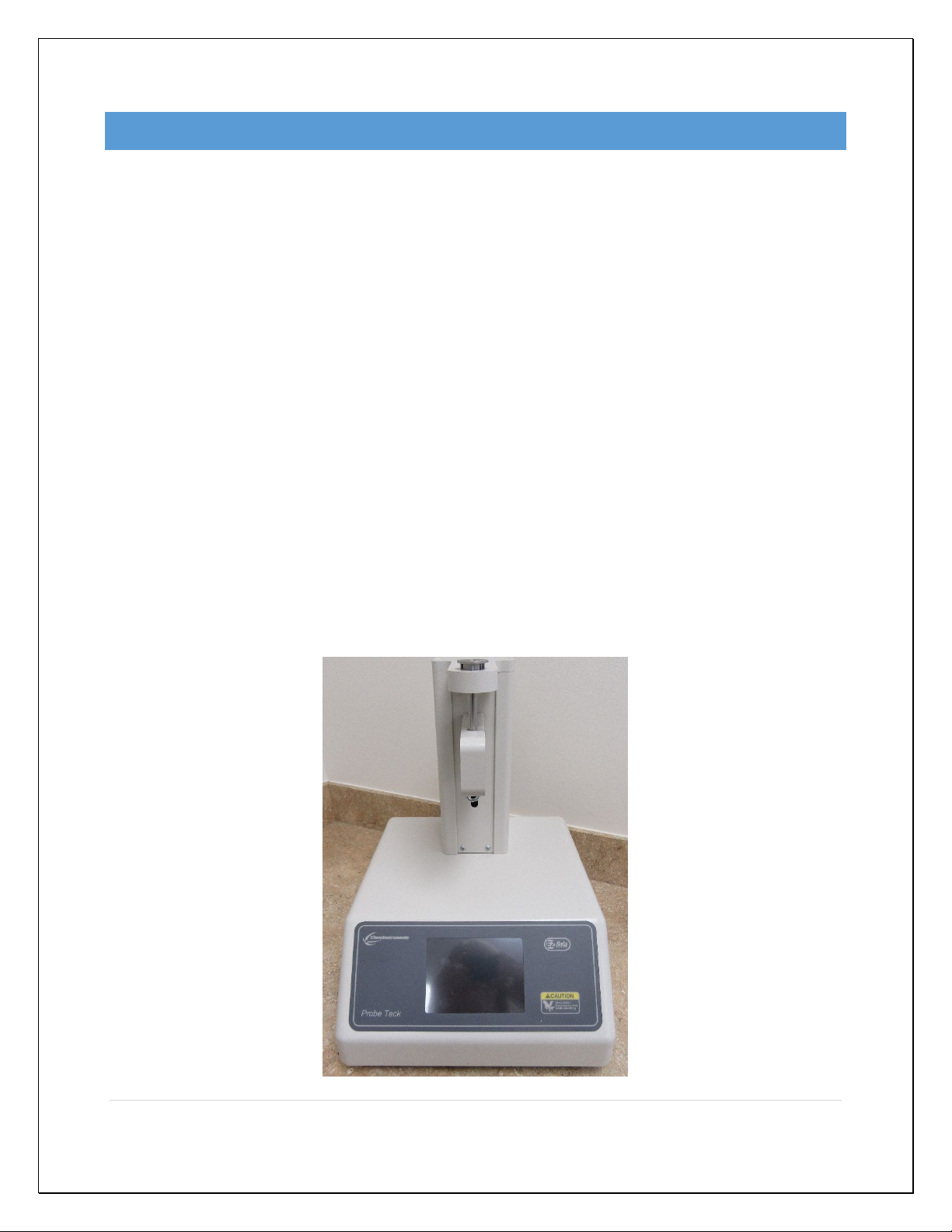

Congratulations on the purchase of your new ChemInstruments Probe Tack Tester.

This versatile, user-friendly, carefully designed instrument allows you to determine

probe tack values of adhesive laminates.

WARNING: This equipment can cause injury if not used properly. It is

the operator’s responsibility to observe all safety rules and warnings.

The unit has the following features:

Automated test sequence.

Collected test data can be exported via USB port.

Selectable units of measure: Kilograms, Grams, Newtons, Pounds, and Ounces.

Compatible with EZ Data System software. See www.cheminstruments.com for

details.

SPECIFICATIONS

Electrical 120/240 VAC, 50/60 Hz, 2 amps

Operating Temperature

32 – 122 degrees Fahrenheit (0 – 50 degrees Celsius)

Humidity 0 – 55% relative humidity

Speed 6 - 30 inches/minute, 1 IPM increments

2 - 12 millimeters/second, 1 mm/sec increments

Dwell Time 1 – 30 seconds, 1 second increments

Probe Diameter 5 millimeter

Annular Ring 19.6 grams

Physical Dimensions Width: 13 inches (33 centimeters)

Depth: 16 inches (41 centimeters)

Height: 18 inches (46 centimeters)

Weight: 25 pounds (12 kilograms)

4 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

UNPACKING

ChemInstruments has made every effort to ensure that the Probe Tack Tester arrives at

your location without damage. Carefully unpack the instrument and check for any

damage that may have occurred during shipment. If any damage did occur during

transit, notify the carrier immediately.

The ChemInstruments Probe Tack Tester consists of the following parts:

The test frame, which includes the motor/drive mechanism and the data

acquisition system.

Probe and annular ring

An envelope with this manual.

Power cord.

Make sure all of these components are present before discarding packaging material.

5 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

ASSEMBLY

Carefully remove the test frame/data acquisition assembly from the packaging and set it

on a sturdy bench top. Check the physical dimensions listed previously for the space

required for the instrument. As with any precision piece of laboratory equipment, it is

preferable to locate the Probe Tack Tester in an area where temperature and humidity

are controlled to standard conditions of 72 ± 2 degrees Fahrenheit and 50 ± 5% relative

humidity.

WARNING: Damage will occur if this unit is plugged into the incorrect

power supply. This is a dual voltage machine. Connect either 120 or 240

VAC.

Insert the annular ring in the test platform. Attach the probe to the threaded bolt on the

load cell.

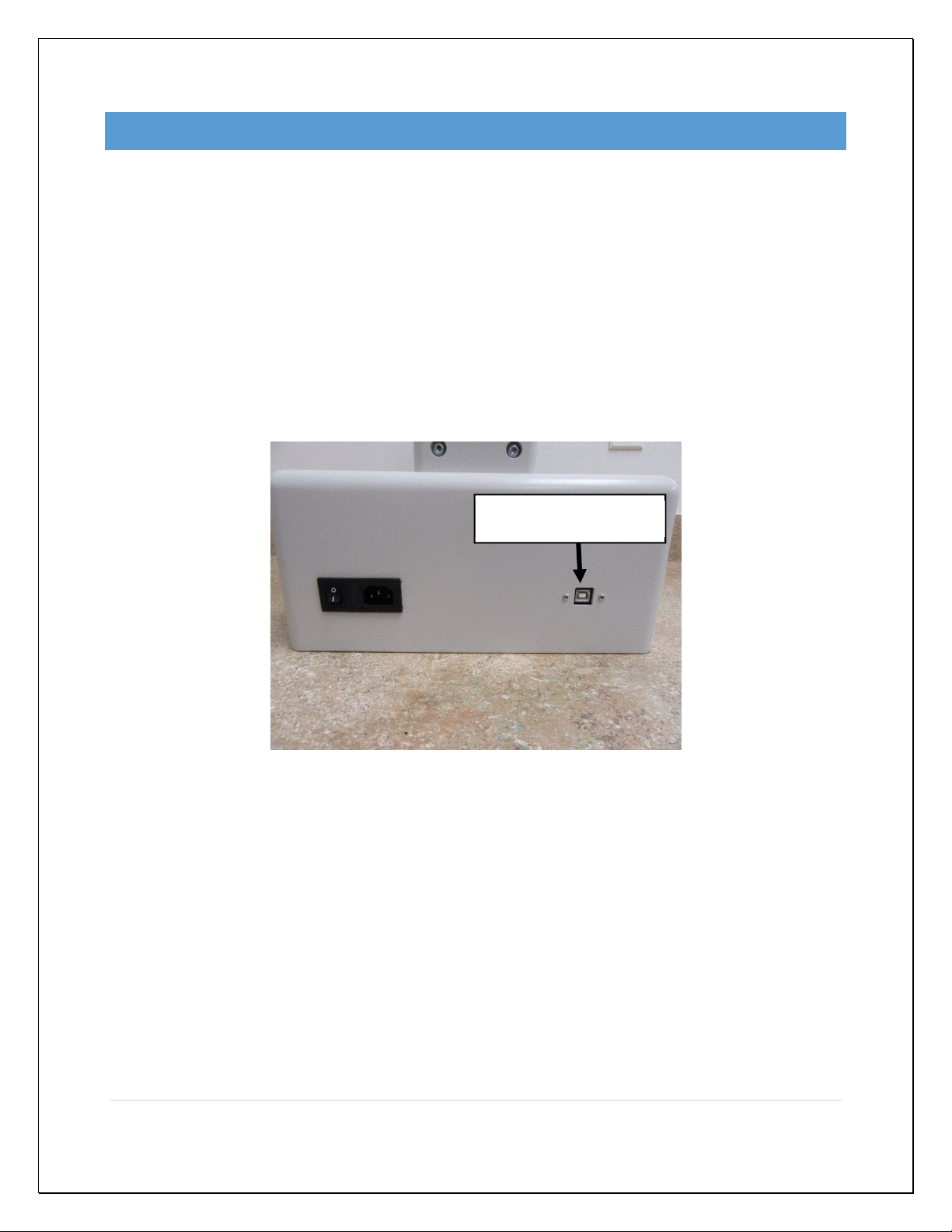

Connect the power cord to its receptacle on the backside of the control cabinet.

Complete the connection by inserting the male end of the power cord into an

appropriate AC outlet. Notice that the on/off power switch is located directly beside the

power cord receptacle on the backside of the test frame.

6 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

KEY COMPONENTS

POWER SWITCH is located on the back panel of the control cabinet directly

beside the power cord connection.

USB CONNECTION data output port for downloading test data.

ANNULAR RING holds test material

PROBE is used in measuring the force values of the test material

LOAD CELL ASSEMBLY consists of the mounting bracket for the load cell with

grip.

CALIBRATION HOOK is used to hang the weights during the calibration

procedure.

AC Power Input & Switch USB

Annular Ring

Probe

Calibration Hook

Load Cell Assembly

7 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

TOUCH SCREEN DISPLAY is the control center for the PT-2000.

8 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

TOUCH SCREEN FORMAT

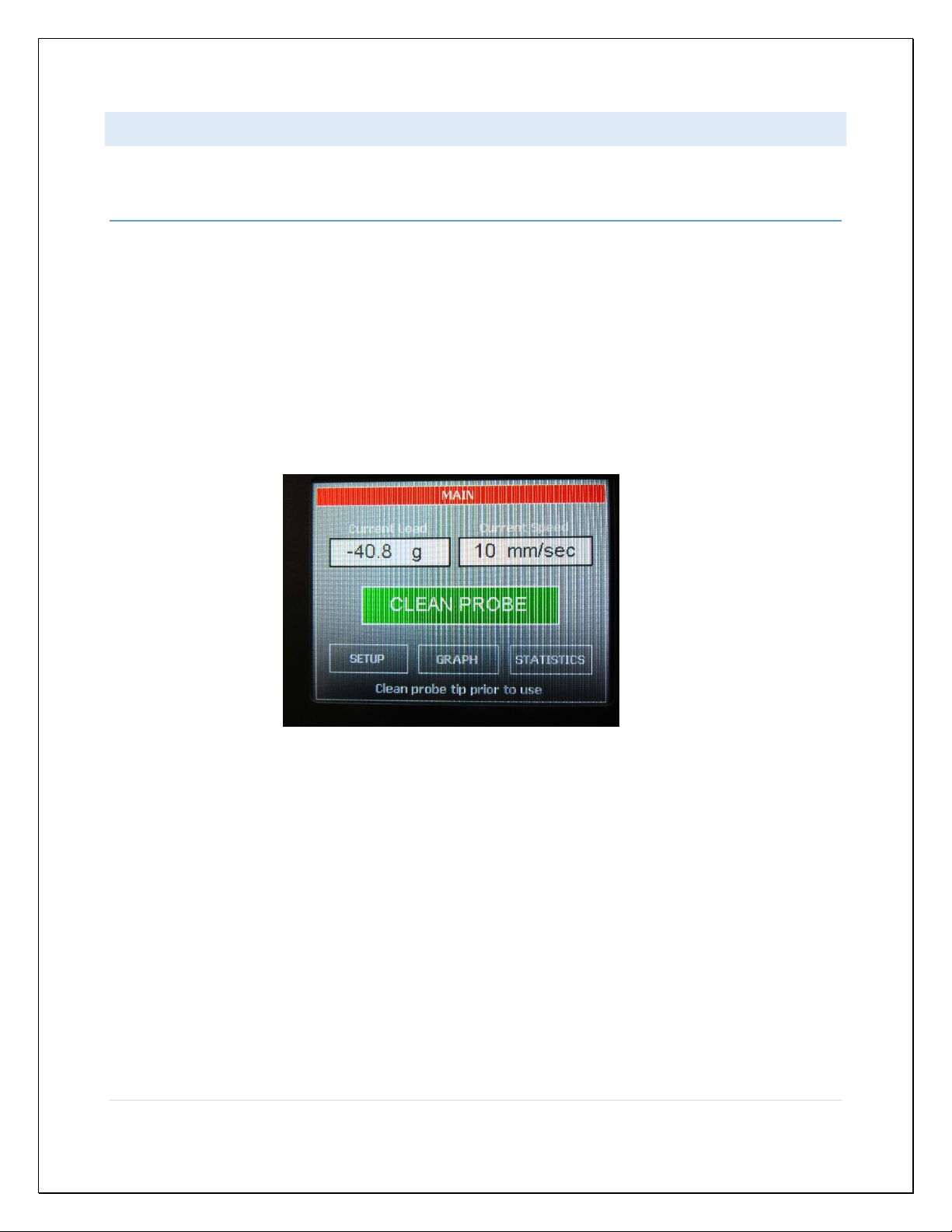

MAIN SCREEN

Current Load – displays the force currently measured by the load cell.

Current Speed – displays the set speed of the test.

Clean Probe – will move the probe to a position so that it may be cleaned prior

to running a test.

Setup – will display all setup options.

Graph – will display the graph, minimum, maximum, and average values of the

last test.

Statistics – will display the minimum, maximum, average, variance, standard

deviation, and work of the last test.

9 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

SETUP SCREEN

Calibrate Load Cell – allows the user to calibrate the load cell.

Units – change the force units and/or the speed units.

Speed – set the test platform’s test speed. If the mode is set to D 2979 then

speed is set to 24 in/min (or 10 mm/sec) and cannot be changed.

Dwell – is used to select the dwell time. If the mode is set to D 2979 then dwell

time is set to 1 second and cannot be changed.

Mode – sets the mode of test operation. D 2979 will set the speed and dwell

time specified in the test specification and will not allow the user to change these

two settings.

Qualify Operation – is used verify some of the hardware functions with the PT-

2000.

About – retrieve the machine’s software version and control board’s hardware

revision.

Exit – go back to the main screen.

If there are 30 seconds of no screen activity when in any of the setup screens except

the qualify operation screen, then the machine will exit the setup screen and return to

the main screen.

10 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

GRAPH SCREEN

The graph screen will display the graph, minimum, maximum, and average values of the

last test. Touch anywhere on the screen to exit the graph screen and return to the main

screen.

STATISTICS SCREEN

The statistics screen will display the minimum, maximum, average, variance, standard

deviation, and work of the last test.

11 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

THEORY OF OPERATION

A test sample is secured on the annular ring per the test method and placed in the test

platform. The probe is brought into contact with the test sample and retracted at a set

speed. An electronic load cell measures the force, then feeds the information to a data

acquisition unit. The data acquisition unit collects the data from the load cell and stores

these data points in memory for use in calculating the maximum, minimum and average

values. This data can be downloaded through the USB connection port to an

appropriate receiving program on your PC.

POWER UP

Turn on the master power switch located on the back panel of the control cabinet next

to the power line receptacle.

WARNING: Operating temperature for this equipment is 32 to 122

degrees Fahrenheit (0 to 50 degrees Celsius). The equipment needs to be

completely free of condensation, inside and out, before applying power.

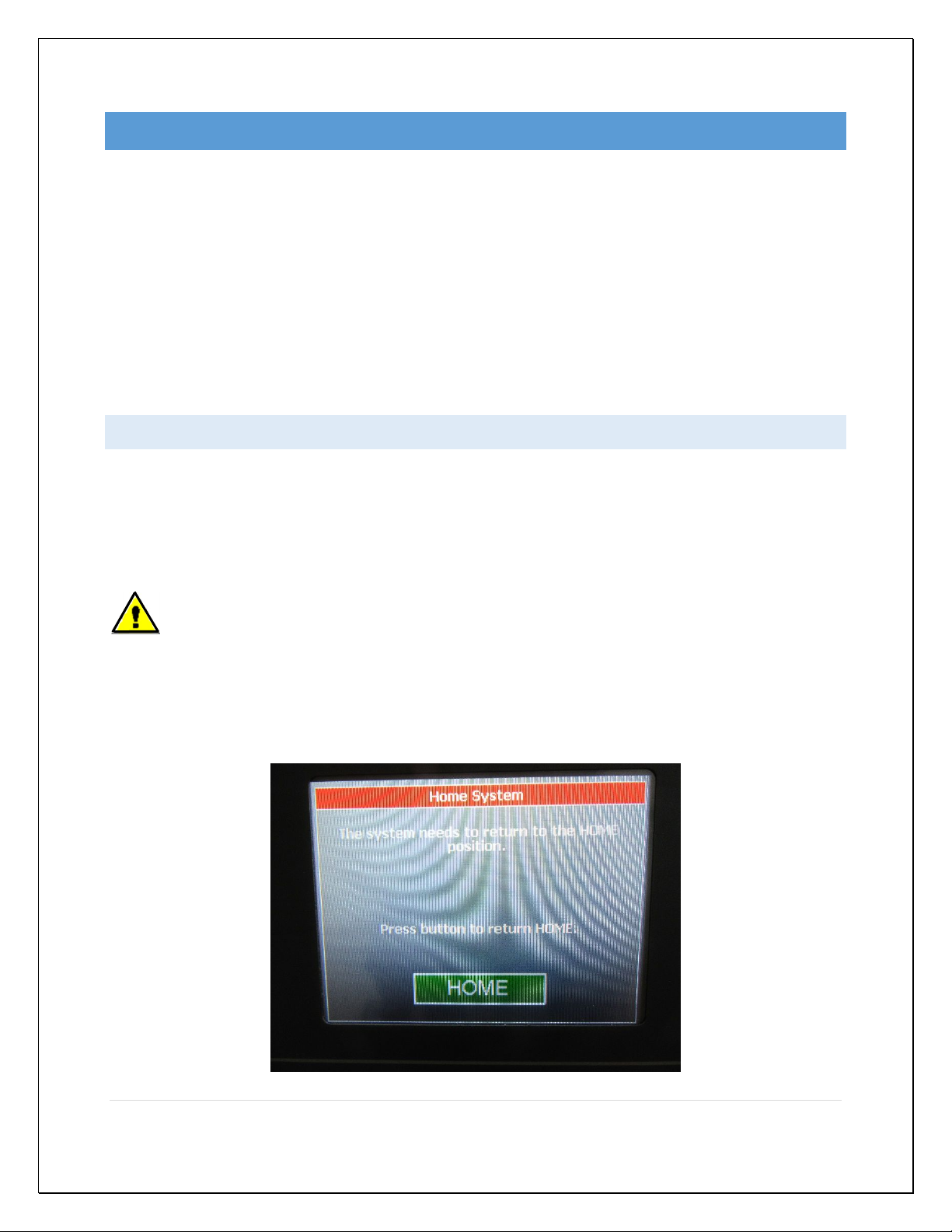

The following message will always appear on power up. The system must establish the

location of the home switch on power up. It will then go its starting position.

12 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

MACHINE SETUP

LOAD CELL CALIBRATION

It is important to calibrate the load cell to ensure that reliable data will be gathered. A

calibration procedure is built into the software of the Probe Tack Tester. This procedure

should be followed upon first use of the Probe Tack Tester and whenever necessary

thereafter. The following is the step-by-step procedure for calibrating the load cell.

Make sure that the Probe Tack Tester has been powered on for 30

minutes before proceeding with calibration.

The calibration sequence defaults to grams as the unit of measure. Make

sure that your calibration weights and entries are in grams.

LOAD CELL CALIBRATION PROCEDURE

1. Select SETUP from the main screen.

2. Select CALIBRATE LOAD CELL from the setup screen.

3. The first screen in the calibration process describes the 2 point calibration

process. Select OK to continue.

4. The next screen measures the low calibration value (typically 0). Make sure that

you do not have a weight hanging from the calibration wire and select OK.

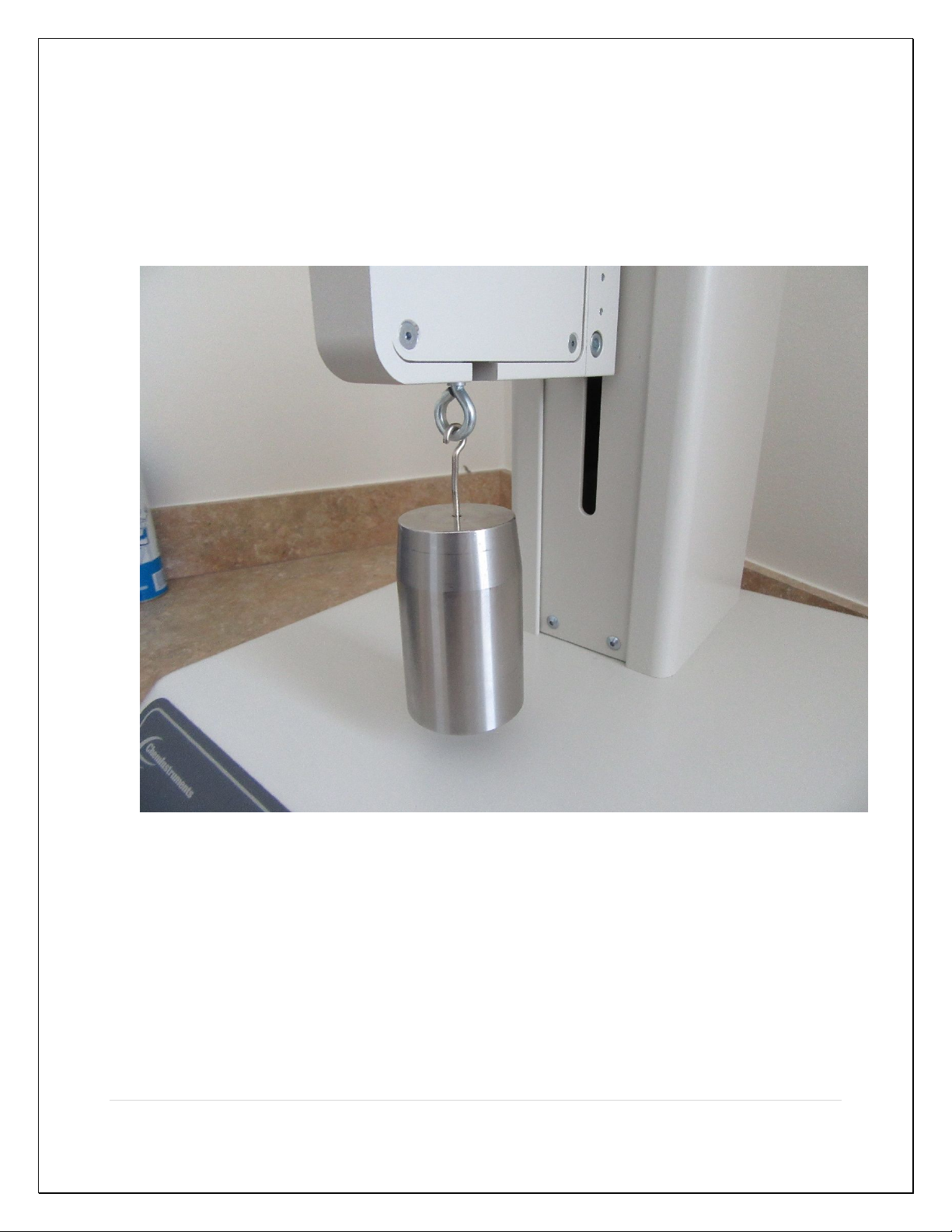

5. The next screen measures the high calibration value. This weight should be

close to the maximum rated load cell value. Hang the weight on the loop end of

the calibration wire making sure that the wire is able to move freely.

6. Set the high calibration value by selecting CHANGE and entering the value of the

weight in grams and select ENTER.

7. Make sure that the calibration weight is completely at rest and then select OK.

13 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

8. The display will show the main screen and the current reading of force will be

displayed under CURRENT LOAD.

9. Verify the calibration by hanging a different calibration weight on the calibration

wire.

10. Repeat the calibration procedure if necessary.

14 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

FORCE AND SPEED UNITS

Force and speed units can be changed with the following procedure.

1. Select SETUP from the main screen.

2. Select UNITS from the setup screen.

3. Select the desired units. Select OK to confirm the entered units.

SPEED

To perform a test correctly, it is necessary to set the test speed in accordance with the

selected test method. The following is a step-by-step procedure for setting the speed.

1. Select SETUP from the main screen.

2. Select SPEED from the setup screen.

3. Select CHANGE and enter the desired sled speed in the selected units and press

ENTER. Select OK to confirm the entered speed.

15 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

DWELL

The dwell time is the amount of time that the material will stay in contact with the probe

before it is pulled away. The following is a step-by-step procedure for setting the dwell

time.

1. Select SETUP from the main screen.

2. Select DWELL from the setup screen.

3. Select CHANGE and using the arrow buttons, select the desired dwell time and

select OK. Select OK again to confirm the entered dwell time.

MODE

The D 2979 test method mode will force the speed and dwell settings to match the test

specification. The user will not be able to change these 2 settings while this mode is

selected.

1. Select SETUP from the main screen.

2. Select MODE from the setup screen.

3. Select the appropriate mode and select OK to confirm.

16 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

QUALIFY OPERATION

Some of the hardware functions of the PT-2000 can be verified with the qualify

operation screen.

Current Load – displays the force currently measured by the load cell. It will be

displayed in the selected units.

Current Speed – displays the set speed of the test platform.

AD Reading – displays the hardware counts measured on the control board from

the load cell interface. Pulling on the load cell grip will display values greater

than 32000. Pushing on the load cell grip will display values less than 32000.

Test Speed – is a method of verifying the speed of the test platform. The test

platform will move 4 inches at the set speed and measure the amount of time

that it takes to travel 4 inches.

Verify Load Cell – will sample the load cell data for 10 seconds. A test can be

simulated with a weight sitting on the calibration pad to verify the load cell

calibration if necessary. The test platform will not move, the system will simply

measure the load cell and display a graph along with the statistics when the 10

seconds is complete.

17 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

RUNNING A TEST

Probe tack tests are conducted according to written test methods, such as ASTM,

PSTC, TLMI and others. These tests are performed to determine the tack adhesive

values of the selected PSA material as it is removed from a stainless steel test probe.

NOTE: Make sure the load cell has been calibrated before conducting a test.

TEST PROCEDURE

The ChemInstruments Probe Tack Tester is very simple to use. The following is the

correct procedure for running a Probe Tack Test. See pictures that follow this

procedure for clarification of terms.

1. Secure the test sample on the annular ring per the test method.

2. Press the CLEAN PROBE button from the main screen. The probe will be raised

to a position so that it can be cleaned with a cotton swab and the appropriate

solvent.

3. After cleaning the probe, press the START TEST button from the main screen.

The probe will be lowered so that the annular ring can be placed through the hole

and resting on the 3 studs.

4. After installing the annular ring, press the RUN TEST button from the main

screen. The probe will come up and make contact with the test material for 1

second. The probe will then retract while the load cell measures the test forces.

5. When the test is complete, the graph will be displayed along with the high, low

and average values recorded during the test.

6. The probe can be cleaned with a cotton swab and appropriate solvent when the

annular ring is removed.

7. Repeat the procedure for additional tests.

18 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

DWELL TIME MEASUREMENT

Dwell time is measured from the first data point that is less than -5 grams to the first

data point that is greater than 0 grams. Data points are collected every 1 millisecond.

19 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

EZ DATA SOFTWARE SYSTEM

EZ Data is a ChemInstruments program that runs on your computer and will allow you

to interface to your ChemInstruments machine in order to save test data files, save raw

test data to excel, graph and crop test data, tabulate test data files, and overlay test

data files. Please refer to the EZ Data manual for specific information on how to use the

EZ Data software system.

The PT-2000 can be connected to your computer with a Type A-B, Revision 2.0

Compliant, USB cable.

USB Connection

20 | P a g e

Probe Tack Tester Operating Instructions (PT-2000)

The following picture is the main screen of EZ Data with a PT-2000 connected. This

screen will show the current load as a value and a real time graph as data is collected

from the load cell. It shows the test setup parameters. It will also allow you to change

the test parameters.

The following picture shows the PT-2000 parameter setup.

Table of contents

Other ChemInstruments Test Equipment manuals

Popular Test Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 85056D User's and service guide

Agilent Technologies

Agilent Technologies 8960 Series 10 Reference manual

Macmesin

Macmesin MultiTest-xt Assembly and installation

KYORITSU

KYORITSU 4118A instruction manual

Keysight Technologies

Keysight Technologies N7015A Quick Start and Accessories Guide

Sonel

Sonel P-4 user manual