Electro-Sensors SA420 User manual

ENT

SA420

OUT%

VAR RATE

Description:

Electro-Sensor’s SA420 Signal Conditioner provides an analog signal

directly proportional to the speed of a monitored shaft. The 0-10 VDC

and 4-20 mA outputs can be sent to a chart recorder, digital display, PLC,

loop controller, drive speed controller, or other control or monitoring

devices. The wide voltage range and wave shape exibility of the

SA420’s sensor input circuitry allow it to translate signals from Hall-

Eect Sensors, proximity switches, magnetic sensors, and a wide variety

of other pulse generator devices into analog outputs.

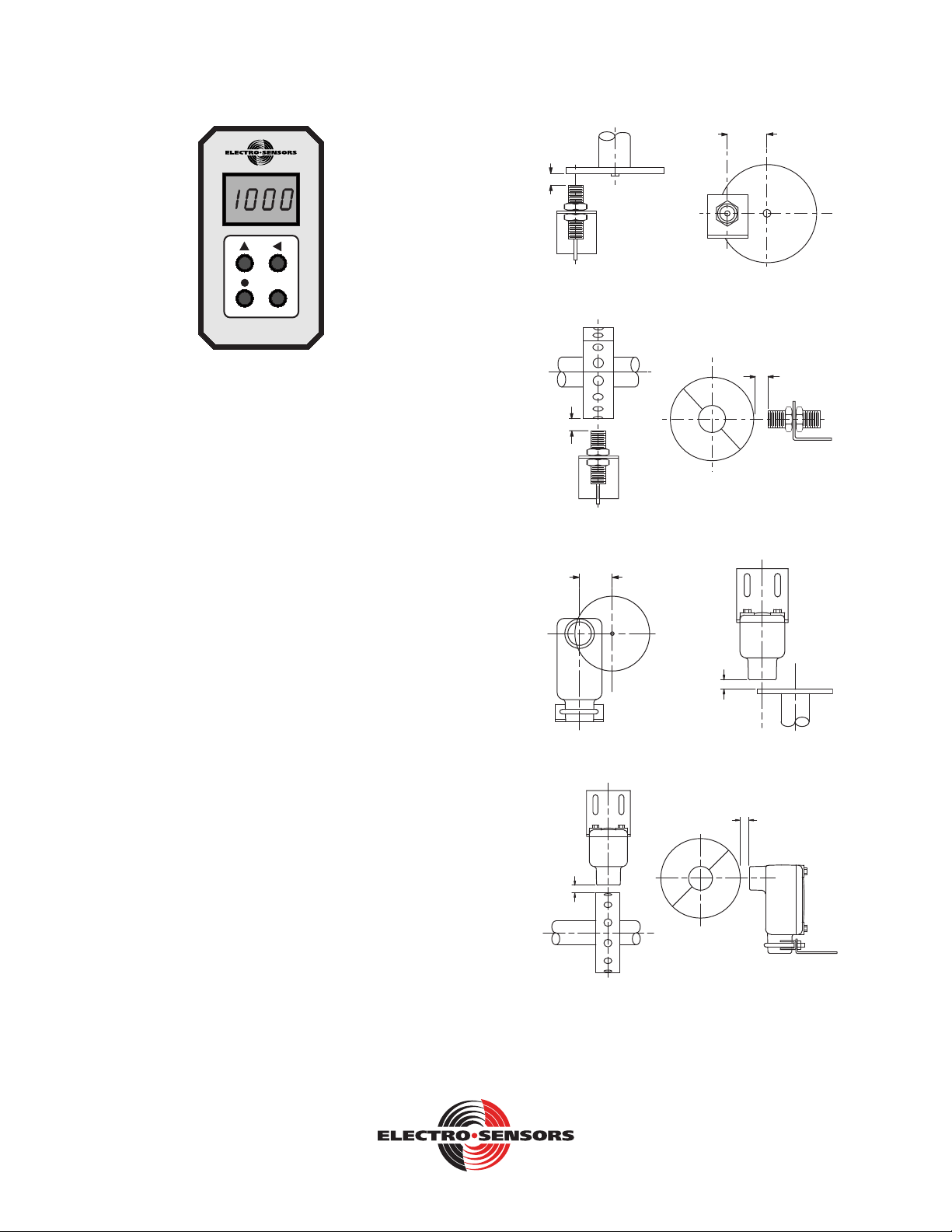

Sensor Installation:

The standard sensor is supplied with a mounting bracket and two jam

nuts. The explosion-proof sensor is supplied with a slotted mounting

bracket. Sensors should be installed so the centerline of the magnets

pass in front of the center of the sensor as the disc or wrap rotates. When

using the pulser disc, the center of the magnetized area of the disc,

shown as Dimension B in gures 1 and 3, is 1-3/4 inches from the center

hole of the disc. The gap distance between the sensor and the disc or

wrap, Dimension A In the diagrams, is 1/4-inch ±1/8 inch. To achieve

the proper gap distance, adjust the jam nuts holding the standard sensor

in the mounting bracket, or adjust the position of the explosion-proof

sensor using the slots on its mounting bracket.

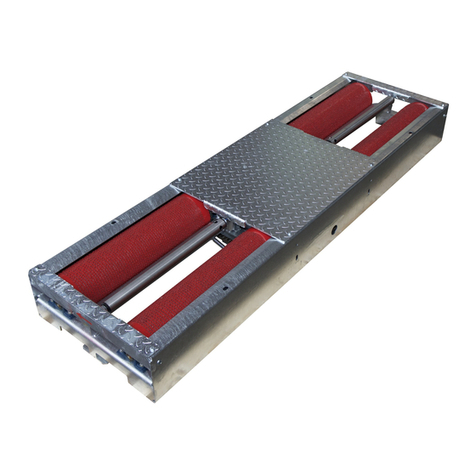

Pulser Disc:

The end of the shaft to be monitored must be center drilled to a depth of

1/2-inch with a No. 21 drill and tapped for 10-32UNF. After applying

Loctite™ or a similar adhesive on the threads to keep the pulser disc

tight, the pulser disc should be attached, decal side out, with the supplied

10-32UNF machine screw and lock washer.

Pulser Wrap (optional):

Pulser Wraps are custom manufactured to t the shaft they will be

mounted on. When the wrap is shipped, four Allen-head cap screws hold

the two halves of the wrap together. These screws must be removed so

that the wrap is in two halves. Place the halves around the shaft, reinsert

the screws and torque them to 5 foot-pounds max.

A

B

Figure 1: Standard Sensor with 255 Pulser Disc

A

A

Figure 2: Standard Sensor with optional Pulser Wrap

B

A

Figure 3: Explosionproof Sensor with 255 Pulser Disc

A

A

Figure 4: Explosionproof Sensor with Pulser Wrap

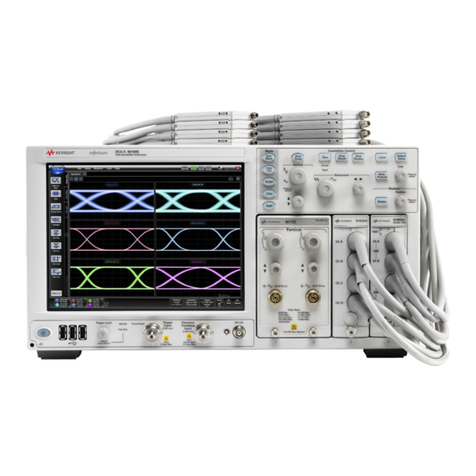

SA420 Signal Conditioner

6111 Blue Circle Drive

Minnetonka, MN 55343

Phone: 952.930.0100

Fax: 952.930.0130

ISO 9001:2015 Certied

Free Catalog and Application Assistance

1.800.328.6170

Visit Us Online

www.electro-sensors.com

990-001700 Revision I

SA420 Signal conditioner

For version 3 hardware with version 5.xx or later rmware

The SA420 now includes the following features:

• Quadrature (directional decoding)

• Bipolar voltage output (units now include +/- 5 VDC and +/- 10 VDC)

• Optional higher NPN input signal trip point (improves operation through IS barrier)

• Programmable lower analog output setpoint (Previously xed at 0 Hz, now includes forward and reverse osets) PR (00)

• Programmed to power up and display in the following units PR (04):

• Hz (default)

• Percent of maximum output

• User dened units

• Programmable minimum frequency cuto. PR (05) (This allows you to decide where the unit zeroes out for faster zeroing)

• More modes of operation:

• Single channel

• Quadrature 1X

• Single channel 2X (new)

• Quadrature 2X (new)

• Quadrature 4X (new)

• Security lock variables (viewable but not changeable while locked)

• Ability to improve calibration with user variables which alter the upper and lower calibration point of the analog

• Choice of new menu or revert to basic 3 variable menu for compatibility

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

2-8

Wiring Connections:

Sensor Wire connections:

Terminal

Model

906/

Old 907

All other

ESI

Sensors

Mag

Pickup

Logic

Level

ESI

Prox/

New 907

5 Supply Red Red N/C N/C Brown

6 Signal Black Clear + Signal Black

7 Ground Clr/Shd Blk/Shd - Common Blue

11 Signal B Green Green N/C N/C White

Power Connections:

Terminal 115 VAC

Standard

230 VAC

Optional

12 VDC

Optional

24 VDC

Optional

2 Hot L1 Hot (+)Positive (+)Positive

10 Neutral L2 Hot (-)Negative (-)Negative

Analog Output Connections:

Terminal 4-20 mA Terminal 0-10 VDC

3(+) High 9 (+) Positive

4 (-) Low 8 (-) Negative

Terminal Connection

8

765

4

9

1110 12

3

1No Connect

2 Hot +

34-20mA +

4 4-20mA -

5 Sensor Supply

6Sensor Signal A

7 Sensor Ground

80-10 VDC -

90-10 VDC +

10 Neutral -

11 Sensor Signal B

Figure 5: Terminal Block wiring

Frequency Calculations

Pertinent formula: Frequency (Hz) = (RPM * PPR)/60

Example: A customer has a motor rotating at 1200 RPM and wants the

SA420 to output 20mA at 1250 RPM using a Hall Eect sensor and an

ESI 255 disc.

Since the Hall Eect sensors turns on with a south eld and o with a

north eld, the 255 disc’s 16 alternating magnets (8 north and 8 south

elds) will produce 8 PPR (Pulses Per Revolution). Insert 8 into the

equation for PPR.

F = (1250 * 8)/ 60

F = 166.7 Hz [Value used in PR (01)]

Programming:

There are four buttons on the front panel used for calibration:

▲ Up Arrow Button is used to change the value of the position in focus

(ashing), while in the calibration mode. While in standard mode, this

button will toggle the display between frequency input (hertz) and output

percentage.

◄ Left arrow button is used to move the focus to the next position when

in the calibration mode of 4-20 mA or 0-10 VDC.

•Decimal Point Button is used to change the position of the decimal

point while in the calibration mode.

ENT Enter Button is used to enter or exit the calibration mode.

Programming The Unit:

Standard menu: To enter the calibration mode, push the ENT button

once. PR0 will be displayed. Press the ▲ (up) button to increment to

the desired variable. Press the ENT button at which time the value

of variable is displayed. The right most digit of the variable will be

ashing, which indicates that this digit has the focus and can be changed.

Pressing the ▲ (up) button will increment the ashing digit. The ◄

button will advance the focus to the next digit to be changed. The •

(DP) button will scroll the decimal point across the display from right

to left if that variable has the decimal point enabled. When the correct

value is programmed into the variable, press the ENT button to store the

variables value in memory. The display will show PRxx (the variable

you just updated). You can now ▲ (up) button to the next variable you

wish to change or continue until you’ve reached the end of variables and

exit to user mode.

Basic menu: To enter the calibration mode, push the ENT button once.

PR1 will be displayed for one second, and then the value of variable

1 is displayed. This is the Max frequency value. the right most digit

of variable 1 will be ashing, which indicates that this digit has the

focus and can be changed. Pressing the ▲ button will increment the

ashing digit. The ◄ button will advance the focus to the next digit to

be changed. The • (DP) button will scroll the decimal point across the

display from right to left. When the correct value is programmed into

the variable, press the ENT button to store the variable into memory and

access variable Pr02. Pr02 is the sensor type. You can now change Pr02

to match the sensor output type if necessary or press the ENT button and

advance to Pr03. Pr03 contains the input pulse buer. When the value

is correct press the ENT button to save value and to return to the user

mode.

ENT

SA420

OUT%

VAR RATE

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

3-8

Variable functions

PR (00) Analog Lower Setpoint*

Setpoint for 4mA and 0 VDC value. (-5 or -10VDC if selected). To

represent a reverse rate, increment the left most digit until the rate icon

ashes. **

PR (01) Analog Upper Setpoint*

Setpoint for 20mA and 10 VDC value. (5 VDC or 10 VDC if selected).

To represent a reverse rate, increment the left most digit until the rate

icon ashes. **

PR (02) Sensor Type and Level

Used to select your sensor output type. The default is set to 0.

Variable 2 Value Type of Sensors

0NPN*

1PNP

2 Magnetic Pickup

3Logic Level

4NPN 6.5V

5PNP 6.5V

*(All Standard ESI sensors are NPN open collector output.)

PR (03) Buer Size

Ring buer ltering up to 600 pulses. It is a rst-in-rst-out

conguration. Typically, you would put in the PPR of the sensor/target

combination or a supermultiple of the PPR.

Example: Customer using 906 sensor (Hall type with 1 PPR per 2

magnets) and a 255 disc (16 alternating magnets) would generate 8PPR.

Normally you would use 8, 16, 24, 32… for the buer size. Using higher

counts makes the output more stable but slows the response down. You

need to strike a balance between buer size and response.

PR (04) User Units

Value to be displayed when operating at PR (01) frequency. (FPM, RPM,

etc.) this is the value to display when operating at the frequency entered

in variable Pr01.

PR (05) Frequency Cuto

User can set the frequency cuto to zero the unit faster. Customers that

are reading higher speeds may want to raise the value entered here to

quickly zero the unit out. conversely customers that need to read lower

speeds may want to reduce this number, so it doesn’t zero out too soon.

PR (06) Analog Response

Some applications need slower analog response rates. This variable is

where you set the time required to slew from 10-90% analog output

PR (07) Signal Type**

Programming of PR (07) determines the way the signals are handled.

There are multiple choices for both single and quadrature operation. 1X

uses the rising edge of channel “A”. 2X uses the rising and falling edge

of channel “A”. the quadrature 4X uses both the rising and falling edges

of both the “A” and “B” channels. When using 2X or 4X congurations

the PPR calculations will be double or quadruple verses the 1X

conguration and the user needs to increase the Pr01 (Analog upper

setpoint) value upward accordingly.

PR (08) Voltage Output Type

Controls the type of voltage output from the unit. There are multiple

options see the table in the variable table on page 6.

PR (09) Menu Option

Controls what program menu is used. User can choice between the

current advanced menu or revert for compatibility to the basic menu

which has three variables.

All units will start in the new advanced menu unless the user programs

it to use the basic menu. A user can get it back to the advanced menu

which is the standard menu now by: holding down the decimal button

and left arrow button simultaneously while powering on the unit. Then

change PR (09) from (0000) to (0001) and press enter. The advanced

menu will remain afterwards when restarting the unit.

Keep in mind that advanced features will be retained if you switch from

the advanced menu back to the basic menu until you reset the unit. If you

change PR (09) to zero (0000) the variables will remain but only PR (01)

through PR (03) will be viewable.

PR (10) Display Option

User can set how the feedback is displayed. This enables the display of

user to set in user units

PR (11 thru 14) Reserved

PR (15) Security PIN

To advance past this point when going through the menu this PIN must

match the password. This will make the variable Read/Write rather than

read only.

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

4-8

PR (16) Security Password

User can lock variables. Making PR (15) dierent from PR (16) will lock

the variables and make PR (16) unviewable. It is important to remember

the number entered in PR (16).

PR (17) Cal: PIN

To advance past this point when going through the menu this PIN must

match the password. This will make the Cal variables accessible.

PR (18) CAL: Password

User can update variables 10-22 if the Cal pin matches the Cal password.

Making PR (17) dierent from PR (18) will lock the calibration variables

and make PR (18) unviewable. It is important to remember the number

entered in PR (18).

PR (19) CAL: Voltage oset value

Setting that allows the user to adjust the Voltage oset to obtain greater

accuracy.

Not implemented yet

PR (20) CAL: Voltage gain value

Setting that allows the user to adjust the Voltage gain to obtain greater

accuracy.

Not implemented yet

PR (21) Cal: Current oset value (4.000mA)

Setting PR21 allows the user to adjust the current oset to obtain greater

accuracy. The adjustment value is approximately 366nA (0.000366uA)

of deviation up or down per single count of change. Example

of changing this from 1000 to 980 results in the analog decreasing. It

will decrease (20 *0.000366uA) or -0.00732uA. When done after the

initial warm up of the unit, about 15 minutes, it can dramatically increase

the accuracy of the unit.

PR (22) Cal: Current gain value (20.000mA)

Setting Pr22 allows the user to adjust the current gain value to obtain

greater accuracy. The adjustment value is approximately 366nA

(0.000366uA) of deviation up or down per single count of change.

Example: Changing this value from 1000 to 1010 will result in the

analog output increasing. It will increase (10 * 0.000366uA) or

0.00366uA. When done after the initial warm up of the unit, about 15

minutes, it can dramatically increase the accuracy of the unit.

*Users can program the analog to go up or down as the frequency

increases by swapping the lower setpoint [PR (01)] with their upper

setpoint [PR (00)].

**Reverse numbers are represented by a ashing “rate” icon and cannot

be programmed until PR (07) is set for quadrature operation.

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

5-8

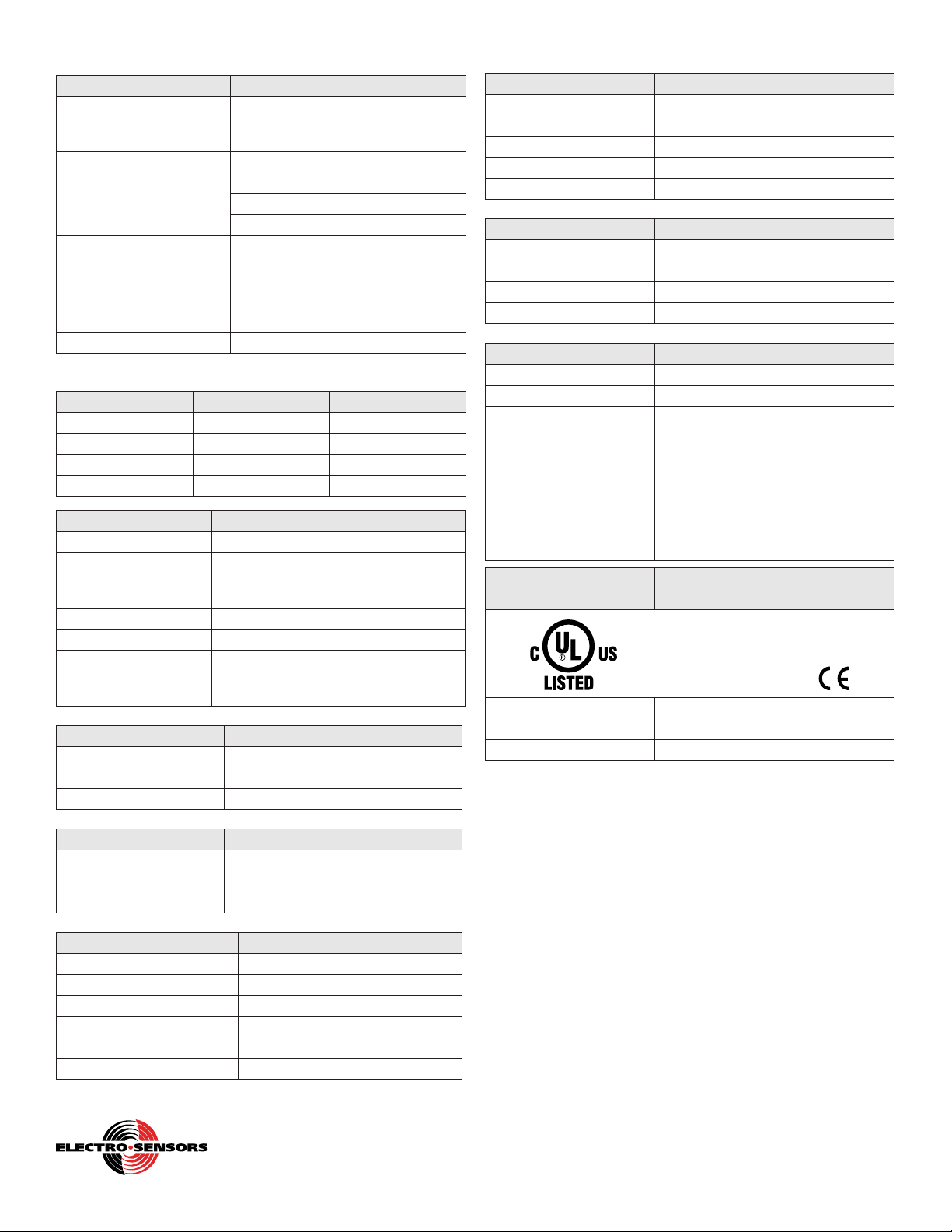

SA420 Advanced Mode Variables

Variable Number and Name Default

Value

Value

Range

Coded Number Table Move

Decimal

User Values

(00) ANALOG_LOWER_SP_VAR 0any number * Yes

(01) ANALOG_UPPER_SP_VAR 240.0 any number * Yes

(02) SENSOR_TYPE_VAR 0000 0-5 0 = NPN (2.5 VDC trip level)

1 = PNP (2.5 VDC trip level)

2 = Mag (75 mVDC trip level)

3 = Logic (2.5 VDC trip level)

4 = NPN (6 VDC trip level)**

5 = PNP (6 VDC trip level)**

No

(03) BUFFER_SIZE_VAR 8 0-16 No

(04) USER_UNITS_VAR 1800 any number * Yes

(05) FREQUENCY_CUTOFF_VAR 0.5 0.0-10.0 Hz No

(06) ANALOG_RESPONSE_VAR 00.00 00.00-20.00 Amount of time it takes the analog

output to change from 10% to 90%

Examples:

00.00 or 00.01 = 00.01 seconds

00.10 = 0.10 seconds

00.50 = 00.50 seconds

No

(07) SIGNAL_TYPE_VAR 0 0-4 0 = Single channel operation

1 = Quadrature operation

2 = Single channel 2X operation

3 = Quadrature operation 2X

4 = Quadrature operation 4X

No

(08) VOLTAGE_OUTPUT_TYPE VAR 10-3 0 = 0-5 VDC

1 = 0-10 VDC

2 = +/- 5 VDC

3 = +/- 10 VDC

No

(09) MENU_OPTION_VAR 1 0-1 0 = Basic menu

1 = Advanced menu (Standard)

No

(10) DISPLAY_OPTION_VAR 0 0-2 0 = Hz

1 = Percent output

2 = User units

No

(11) reserved for future use

(12) reserved for future use

(13) reserved for future use

(14) reserved for future use

No

(15) SECUR_PIN_VAR 0420 0000-9999 No

(16) SECUR_PASS_VAR 0420 0000-9999 No

(17) SECUR_CAL_PIN_VAR 0 0000-9999 No

(18) SECUR_CAL_PASS_VAR 0420 0000-9999 No

(19) CAL: VOLTAGE_OFFSET 1000 0000-2000 Currently not active No

(20) CAL: VOLTAGE_GAIN 1000 0000-2000 Currently not active No

(21) CAL: CURRENT_OFFSET 1000 0000-2000 No

(22) CAL: CURRENT_GAIN 1000 0000-2000 No

* When the ‘rate’ icon is ashing, the number being programmed is a reverse direction value. A value can only be displayed as a reverse direction

value AFTER the unit is programmed to operate in quadrature mode. This prevents errant reverse values from being entered into a single-channel

unit.

** Recommended quadrature setting for NPN or PNP.

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

6-8

SA420 Dimensional Drawings:

Dimensions in Inches

3.00

5.63

2.28

1.75

1.66

Figure 6: SA-420

2.28

1.18

1.34

0.85

1.44

6-32

1.66

Figure 7: Terminal Block

4.00

0.196

0.250

Figure 8: 255 Pulser Disc

2.00"

2.51"

2.00"

2.00"

1.25"

1.00"

1.00"

1.120"

Figure 9: Standard Sensor

2.38

5.53

1.16

3.38

1.00

1" NPT

1.63

3.75

1.88

Nut &

Lockwasher

0.56

1.25

4.63

Figure 10: Explosionproof Sensor

1.00

.43

0.13

2

.75 1.63

.32

.56

2.88

1.25

2.03.39

0.33

Figure 11: Explosionproof Sensor Bracket

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

7-8

Troubleshooting Guide

Problem Possible Solution

Unit Dead Check for proper supply at

terminals 2 and 10. See gure 5 on

page 3

No Analog out with zero

hertz displayed

Check for Sensor supply. It should

be Approximately 13.6 VDC

Check sensor Gap distance

Check Sensor Type (Variable 2)

Unit displays a

frequency but the analog

is incorrect

Check variable 1 for correct

frequency

Check your on the correct

analog output, voltage(VDC) or

current(mA)

Analog is unstable Check gap distance

SA420 General Specications:

Input Power Input Current Fuse Type (F2)

115 Vac, 60Hz (std) 2.5 VA Sloblo .032A 5X20

230 Vac, 60Hz (opt) 2.5 VA Sloblo .032A 5X20

12 Vdc (opt) 165 mA Sloblo .250A 5X20

24 Vdc (opt) 135 mA Sloblo .200A 5X20

Input Signal Parameters

Sensor Supply 12 VDC (unregulated) @50 mA max.

Programmable Types

Open collector NPN / PNP

Logic Level 5 V Nom. 3 V Min.

Magnetic Sensor +/- 75 MV Min.

Max. Amplitude 25 Vpk-pk Maximum

Frequency Range 0.01 Hz to 10 kHz

Minimum Input for

Full Scale Output

0.5 Hz = 3.8 RPM @ 8 PPR

(Lower full scale range is available,

consult Factory)

Analog Output Signal Parameters

Types 0 - 10 VDC, 4 - 20 mA with 500Ω

load max.

Accuracy (typical) 0.1% Linearity for both outputs

Step Response Time Parameters

50 Hz Input and above 10 to 90% = 50 ms.

Below 50 Hz Input 10 to 90% = 30 ms + 1/Hz Input

frequency

Physical/Envlronment Parameters

Mounting DIN rail mount or Stand alone

Operating temperature 0°C to +60°Cz

Storage temperature -65°C to +125°C

Electrical Connections 11 Position DIN rail terminal

block

DIN rail enclosure rating NEMA 1

Free Catalog and Application Assistance

1.800.328.6170

Website: www.electro-sensors.com

990-001700 Revision I

8-8

255 Pulser Disc (std.) Parameters **

Material Nylon 12 Std,

(opt; PVC, Alum, Stainless-Steel)

Dimensions 4-inch diameter x 1/4-inch thick

Operating Temperature -40ºC to +60ºC* (Nylon, PVC)

Operating Temperature -40ºC to +150ºC* (Alum, SS)

Pulser Wrap (optional) Parameters **

Material PVC Std.

(opt; Aluminum or Stainless-Steel)

Operating Temperature -40ºC to +60ºC* (PVC)

Operating Temperature -40ºC to +150ºC* (Aluminum, SS)

906 Sensor (Standard) Parameters **

Material Sensor Body Aluminum 3/4 - 16UNF thread

Material Mount Bracket Plate steel

Output Types NPN open collector current sinking

20 mA max

Signal Cable 3-conductor shielded, 10 feet length

std. (50 ft. or 100 ft. optional)

Operating Temperature -40ºC to + 60ºC*

Air Gap 1/4 inch +/- 1/8 inch with standard

255 Pulser disc (1/2” magnets)

907 Explosionproof

Sensor (optional)

Parameters **

Class I, Div 1, Group D

Class II, Div 1, Groups E, F, G

UL File: E249019

Mounting Bracket

Material

Plate Steel U-Bolt Assembly

Other Specications Similar to 906 standard sensor

Specications are subject to change without notice.

*For higher or lower temperature ranges, consult factory.

** For details on Discs, Wraps and Sensors, consult factory

or visit our website.

Table of contents

Popular Test Equipment manuals by other brands

Extech Instruments

Extech Instruments TK36 owner's guide

Amptec Research

Amptec Research 620A 4R Operation and maintenance manual

ACE INSTRUMENTS

ACE INSTRUMENTS WAVE operating manual

DeFelsko

DeFelsko PosiTector SST instruction manual

VOLTCRAFT

VOLTCRAFT VC64 operating instructions

IDEAL INDUSTRIES

IDEAL INDUSTRIES OTDR Technical manual