Chemtronics 22 User manual

Manual

Version 2.0 dated 06.11.2012

Absorption Turbidity Sensor

Model 22 (CSW)

Chemtronic Waltemode GmbH.

40789 Monheim Niederstr. 14

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007

Internet: www.chemtronic-gmbh.de

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 2

Content

Copyright ................................................................................................................................................. 3

Non-warranty........................................................................................................................................... 3

Warranty conditions................................................................................................................................. 3

Before installation and start-up................................................................................................................ 4

Installation guidelines.......................................................................................................................... 4

Safety instructions................................................................................................................................... 5

For ALL chemical liquids..................................................................................................................... 5

Electrical installation............................................................................................................................ 5

Maintenance........................................................................................................................................ 5

Storage.................................................................................................................................................... 6

Transport damage............................................................................................................................... 6

Shipment of the instrument................................................................................................................. 6

General.................................................................................................................................................... 7

What does Turbidity mean?................................................................................................................ 7

What Causes Turbidity?...................................................................................................................... 7

Turbidity Measurement ....................................................................................................................... 7

Principle of Absorbance Measurement............................................................................................... 7

Typical Turbidity Units............................................................................................................................. 8

The Dependencies on the Different Measurement Units.................................................................... 8

Concentration Measurement............................................................................................................... 8

Typical Ranges (depending by product).................................................................................................. 9

The absolute range of absorption sensors:......................................................................................... 9

Typical Applications................................................................................................................................. 9

Maintenance.......................................................................................................................................... 10

Replacement of measurement lamp................................................................................................. 10

Replacement of gaskets.................................................................................................................... 11

Replacement interval ........................................................................................................................ 11

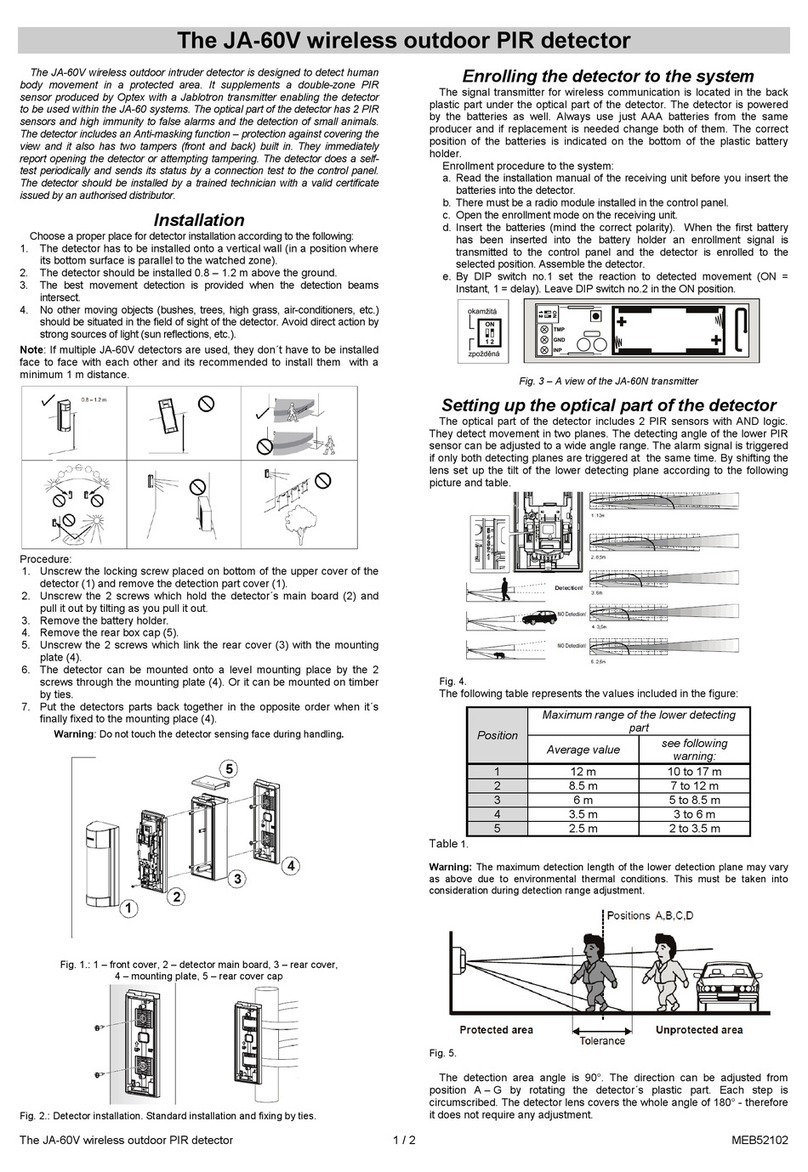

Components Model 22 (CSW) .............................................................................................................. 12

Spare Part List Model 22 (CSW)........................................................................................................... 13

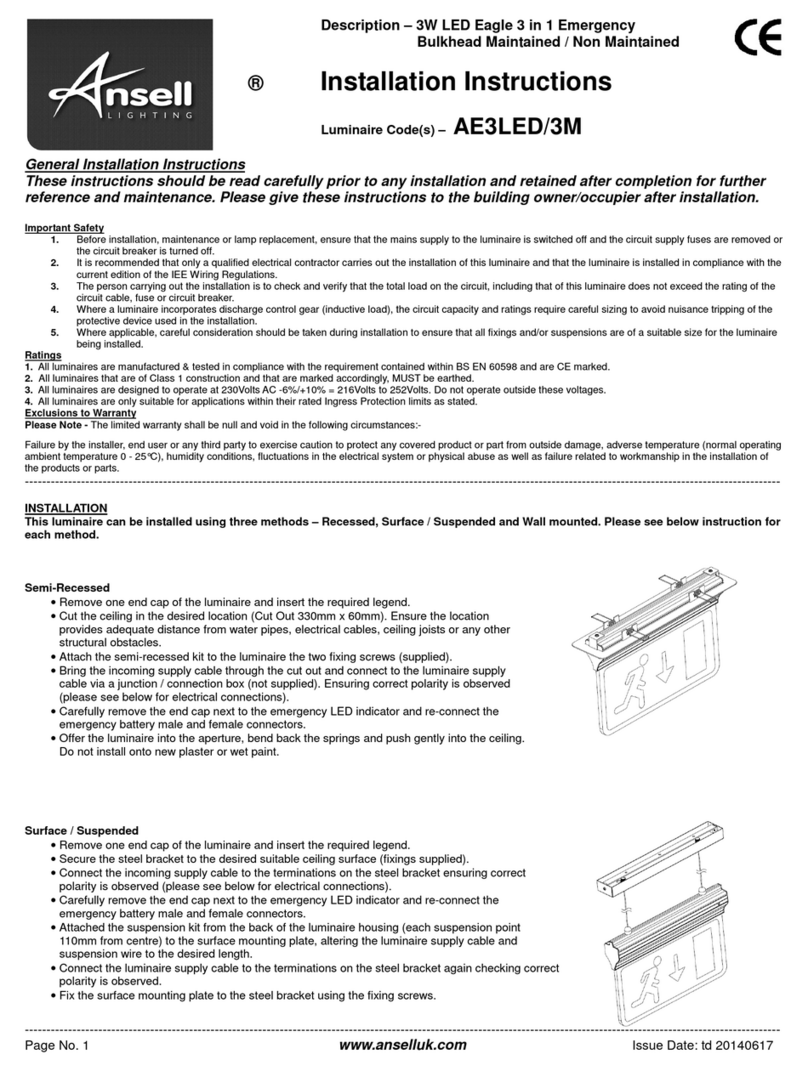

Wiring Diagram Model 22 (CSW) / Messenger (single Sensor)............................................................ 14

Wiring Diagram Model 22 (CSW) / Messenger (four Sensors)............................................................. 15

Wiring Diagram Model 22 (CSW) / CCAb ............................................................................................. 16

Dimensional Drawing Model 22 (CSW) DIN- Flange ............................................................................ 17

Dimensional Drawing Model 22 (CSW) ANSI- Flanges........................................................................ 18

Dimensional Drawing Model 22 (CSW) Milk Fittings............................................................................. 19

Dimensional Drawing Model 22 (CSW) TH- Flanges............................................................................ 20

Dimensional Drawing Model 22 (CSW) TH- Varivent Plates ................................................................ 21

Technical Data Model CSW (22)........................................................................................................... 22

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 3

Copyright

©2012 Chemtronic Waltemode GmbH

This manual including all of its parts are protected by copyright.

Any further use beyond the copyright laws is not allowed without the written approval

of Galvanic Applied Sciences.

There are no further reaching warranty claims to take because of the content of

existing document.

Non-warranty

Chemtronic Waltemode GmbH takes no responsibility or warranty for technical or

editorial mistakes or omissions in this document. The information in this publication

will be provided without warranty for their correctness.

Chemtronic Waltemode GmbH reserves all rights to make changes to this document

without announcement.

Chemtronic Waltemode GmbH is by no means liable for any consequential damages

or miscellaneous damages, which occur during the use or storage of the system.

Some countries do not allow the limitation of liability, so that this exclusion is possibly

not valid for you.

Warranty conditions

The warranty for this product takes place according to the legal provisions. As places

of warranty we explicitly name Chemtronic Waltemode GmbH, Niederstr. 14,

40789 Monheim am Rhein, Germany. In case of warranty service at the customer

site, we will charge additional expenses e.g. travel expenses, overnight cost, etc.

Consumable parts as well as wearing parts e.g. lamps, gaskets, etc. are not covered

by warranty. Improper use, gross negligence, use of the system outside of the

technical specifications, missing or improper maintenance will cause a loss of the

warranty claim. Please take notice to our general terms of contract.

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 4

Before installation and start-up

Installation guidelines

•The sensor is manufactured according to the customer’s application (variable line

size, flange type, cleaning jets, gasket material etc.).

•It is recommended to run the calibration of the system before installation of the

sensor.

•The location / installation of the sensor should be in a vertical standpipe.

•The process pressure should never exceed the specification of the delivered sensor.

•The process temperature should never exceed the specification of the delivered

sensor.

•Avoid air and gas bubbles inside the sensor, they cause disturbances. Air and gas

bubbles will cause noise and drift of the measurement signal. (The air bubbles are not

expected at pressures upwards of 2 bar in aqueous solutions).

•In case the process temperature should fall under the dew point or rise above 85 °C

purge the sensor optic housings with dry instrument air (approx. 10 l/h). Condensed

water and excessive temperatures can damage the sensor and cause inaccurate

measurements.

•Due to potential noise problems it is recommended not to extend the sensor cables.

•Due to potential noise problems use original parts only.

•In case the optional cleaning jets are being used, make sure the pressure of the

cleaning fluid is at least 50% higher than the process pressure.

Danger:

Exceeding the specified maximum pressure and /or the specified

maximum temperature will cause a very high safety risk.

Please read the additional safety instructions before installation and

start-up.

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 5

Safety instructions

Pay attention to the following general safety instructions during use and

operation of the system. Ignoring these instructions or special warnings inside

of this manual can damage the sensor, cause inaccurate measurements, and

possibly result in unsafe installations. Galvanic Applied Sciences will not take

any responsibility for consequences arising from ignoring the safety

instructions and warnings.

For ALL chemical liquids

The reagents or standards may be toxic or otherwise harmful to human

health. Observe appropriate precautions when handling and disposing the

reagents. Review the appropriate published material safety data sheets regarding the

safe handling and disposal of all reagents or standards.

Electrical installation

Qualified technical personnel must install the electrical installation of the system.

Hazardous area

DO NOT INSTALL the system in hazardous area without the optional Ex-proof

equipment.

Operation of non Ex- proof systems in hazardous area will cause a high risk.

Using the system in hazardous areas (Ex Zone I / Ex Zone II) will only

be safe with the installation of the optional special Ex-proof designs

including all required certifications.

Maintenance

Always disconnect the instrument from power during maintenance, replacement of

components, installation of additional components or any other operations at the

open instrument.

Only qualified technical personnel must perform this work.

Operating the instrument with open enclosure

Only qualified technical personnel should operate the instrument when the

enclosure is open (e.g. during calibration procedure). Be careful that no

moisture enters the enclosure.

Some components inside the instrument are energized with voltages, which

can cause lethal shocks in case of contact. Be careful during installation,

handling and operation of the instrument.

Improper installation / operation of the system

Warranty is void if the system is installed improperly, handled improperly, used

outside of the technical specifications (of the instrument), or damaged by gross

negligence.

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 6

Storage

Please inspect the instrument immediately after receiving for potential shipping

damages. In case the instrument has already been unpacked for inspection or

testing, or if the instrument has been removed from the process and it is not to be

installed or reinstalled for more than 1 day, the following procedure should be

observed:

1. If the instrument has been in service, the wetted portion should be thoroughly

cleaned (typically with clean water) and than thoroughly dried.

2. The instrument should be placed in the original packing material.

In case the original packing material is not available place the instrument in a

sealed heavy plastic bag with a desiccant added to assure clean dry storage.

3. The instrument should then be stored in a protected area until time of

installation.

Transport damage

Please inspect the instrument immediately after receiving for potential shipping

damages.

For any claims to the transportation insurance or warranty repair, it is absolutely

required to notify transportation damages immediately after receiving the instrument.

In case of obvious damages of the outer packaging, the carrier must give a receipt

for this damage to make demands for the insurance.

In case of a delayed announcement the insurance will not pay for damages and

Galvanic Applied Sciences will not assume liability for these damages.

Shipment of the instrument

Please clean the instrument carefully before shipment (e.g. for revision / repair).

Please use fixed packaging to protect the instrument against any shipping damages.

If at all possible the original packaging should be used.

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 7

General

What does Turbidity mean?

Turbidity is an optical impression, which describes the characteristic of a transparent

product, to scatter and absorb light. A focused light beam will be attenuated and

scattered in hazy products, so that this product can become practically opaque in

bigger layers.

What Causes Turbidity?

Turbidity is caused by particles in transparent products. A particle is defined as

something with a different refractive index as the carrier product. Some examples of

particles are, minerals, yeast cells , metals, oil drops in water, milk in water, gas

bubbles and aerosol’s.

Turbidity Measurement

Turbidity is not a clearly defined magnitude like e.g. temperature or pressure.

Turbidity is a subjective impression. For this reason turbidity measurement systems

will be typically calibrated by using a comparison's standard such as Formazin or

Diatomatious Earth.

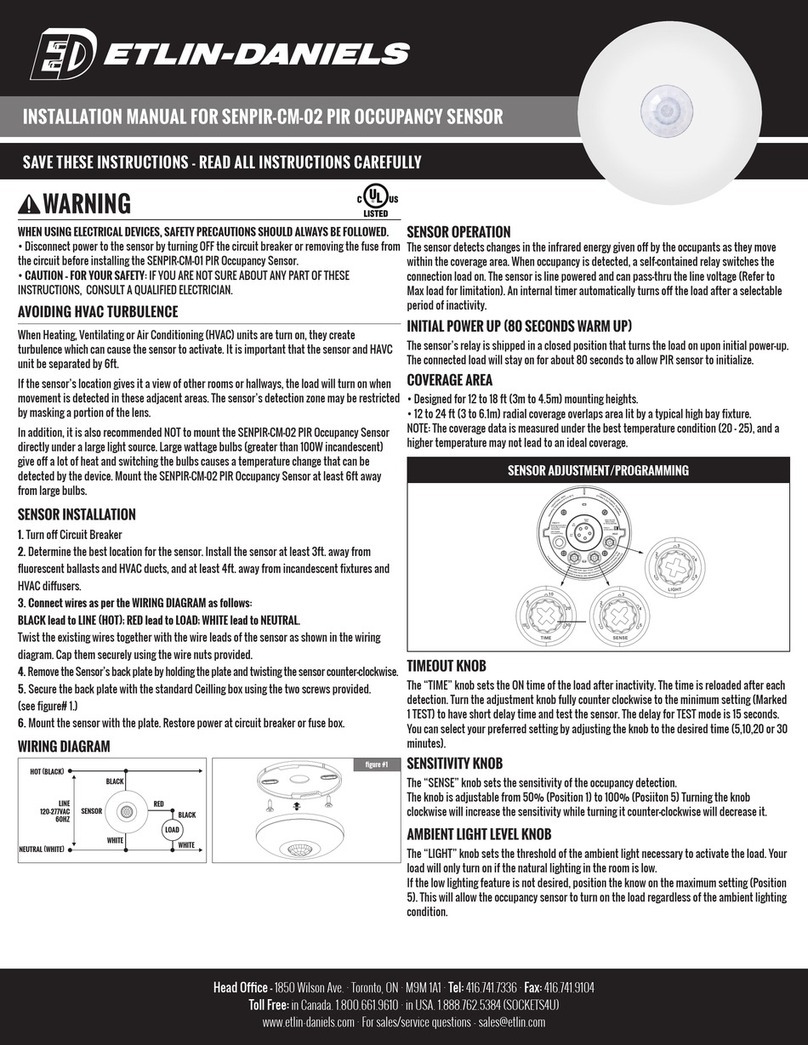

Principle of Absorbance Measurement

A light source and a detector are located parallel over against. The changing of light intensity, caused

by the product between lamp and detector, will be detected and displayed as measuring result.

The application is the measurement of concentrations (color or solids) in a liquid.

The basic measurement unit of an absorption photometer, is called AU (Absorption -

Unit).

Definition of AU:

1 AU = 90 % loss of light intensity

2 AU = 99 % loss of light intensity

3 AU = 99,9 % loss of light intensity

4 AU = 99,99 % loss of light intensity

5 AU = 99,999 % loss of light intensity

Absorption diagram

0,001

0,01

0,1

1

10

100

012345

Absorption AU

Lichtintensität %

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 8

Typical Turbidity Units

ppm: Parts per million FNU1: Formacine nephelometric

unit

FTU: Formacine Turbidity Unit mg/l: Milligram per liter

TEF: Trübungseinheiten Formazin (German for

FTU) gr/l: Gram per liter

EBC: European brewery convention % TS: Percent total solids

NTU1: Nephelometric turbidity unit AU Absorption unit

The Dependencies on the Different Measurement Units

1 FTU = 1 TEF = 1 NTU1 = 1 FNU1 = 0,25 EBC

1 Nephelometry describes the method of side scattered turbidity measurement, these units are used at 90° side scattered

turbidimeter only.

Based on comparisons measurements, by using a 12° forward turbidity measurement

system we have found the following dependencies.

1 FTU = 1 TEF = 0,25 EBC = 2,05ppm = 2,05 mg/l = 0,00205 g/l = 0,00000205 % TS

* At a specific particle weight of 1kg/dm, 1mg/l particles in 1kg of water will correspond to 1ppm.

Concentration Measurement

The sensitivity of a turbidity measurement system, based on the principle of light

absorption, is mainly dependent by two parameters.

1. The intensity of the light source, which is typically constant.

2. The optical path length (OPL1)

The optical path length is variable and can be changed to match the

requirements of specific applications.

To measure low concentrations, a large OPL is required. Otherwise there is not

enough change in light intensity, to get good measurement results.

To measure high concentrations, a small OPL is required. Otherwise there is not

enough light energy, to pass the product.

Large OPL = Low concentrations / high sensitivity

Small OPL = High concentrations / low sensitivity

1OPL [= optical path length] specifies the product slot between light source and detector

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 9

Typical Ranges (depending by product)

OPL lowest range highest range

3 mm approx. 0 - 2 g/l approx. 0 - 100g/l (10% TS2)

50 mm approx. 0 - 200 mg/l approx. 0 - 6 g/l

The OPL has to be specified according to the conditions of customers application.

Construction of sensor’s, and various measurement windows, allows for OPL’s, between 1/10“ (2

mm)

up to 20“ (500 mm).

The absolute range of absorption sensors:

•0 to 0.1 AU (lowest range)

•0 to 5 AU (highest range).

Typical Applications

The absorption measurement is the most common method to measure turbidity. This

measurement method can be used in various applications, due to a large

measurement range, and many different shapes of sensors (immersion probes,

insertion probes, flow cells, etc.).

•Measurement of lauter wort in breweries

•Measurement of yeast concentration

•Dosage systems (Yeast / Diatomatious earth)

•Concentration measurement of various products

•Freight measurement systems (in combination with a flow meter)

•Centrifuge control

•Oil in water

•Water in oil

•Monitoring of coatings inside of pipe systems

•Sludge concentration

•Sludge level

•Measurements in flotation- / sedimentation tanks

•Pulp and paper

•Retention at paper machines

2% TS [= total solids]

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 10

Maintenance

Replacement of measurement lamp

Introduction

Ignoring of the following hints will cause a loss of warranty

Qualified technical personnel must perform repair and maintenance.

Before beginning any work the sensor must be cleaned and flushed thoroughly.

Depending on customers’ application product residues can be very dangerous

(aggressive, poisonous). Please handle the system very careful due to possible

leakage etc.

Avoid pulling and twisting of the lamp cable.

Avoid applying excessive force during assembling and disassembling of the sensor.

Screw in all bolts and cable glands stalwart only.

Please work carefully during the replacement of the measurement lamp.

The lamp replacement should be done in a dry and clean location, to protect the

optical components from dirt.

Please be sure that no dust or other particles penetrates into the optical assembly.

Do not touch the lenses.

In case of dirty component please clean carefully by using fresh water and a cloth

(lint-free), dry all components by using instrument air.

Use suitable tools only.

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 11

Replacement of gaskets

Introduction

Ignoring of the following hints will cause a loss of warranty

Qualified technical personnel must perform repair and maintenance.

Before beginning any work the sensor must be cleaned and flushed thoroughly.

Depending on customers’ application product residues can be very dangerous

(aggressive, poisonous). Please handle the system very carefully due to possible

leakage etc.

Avoid pulling and twisting of the lamp cable.

Avoid applying excessive force during assembling and disassembling of the sensor.

Screw in all bolts and cable glands stalwart only.

Please work carefully during the replacement of the measurement gaskets.

The gasket replacement should be done in a dry and clean location, to protect the

optical components from dirt.

Please be sure that no dust or other particles penetrates into the optical assembly.

Do not touch the lenses.

In case of any dirty component please clean carefully by using fresh water and a cloth

(lint-free), dry all components by using instrument air.

Use suitable tools only.

Replacement interval

The interval to replace the gaskets depends on the specific application.

The replacement cycle depends on process pressure, process temperature, sealing

material and product characteristics. In worst case (high temperature, high pressure

and aggressive medium) the gaskets must be replaced every month. Under normal

conditions the gaskets should be replaced every year. The maximum lifetime in easy

applications can go up to 2 years.

We strictly recommend that the customer establishes a maintenance interval based

on local conditions. In case of further questions, or if you require more information

please contact Chemtronic Waltemode GmbH.

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 12

Components Model 22 (CSW)

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 13

Spare Part List Model 22 (CSW)

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 14

Wiring Diagram Model 22 (CSW) / Messenger (single Sensor)

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 15

Wiring Diagram Model 22 (CSW) / Messenger (four Sensors)

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 16

Wiring Diagram Model 22 (CSW) / CCAb

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 17

Dimensional Drawing Model 22 (CSW) DIN- Flange

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 18

Dimensional Drawing Model 22 (CSW) ANSI- Flanges

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 19

Dimensional Drawing Model 22 (CSW) Milk Fittings

Chemtronic Waltemode GmbH, 40789 Monheim am Rhein, Niederstr. 14, Germany

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007 Internet : www.chemtronic-gmbh.de E-mail: info@chemtronic-gmbh.de

Page 20

Dimensional Drawing Model 22 (CSW) TH- Flanges

This manual suits for next models

1

Table of contents

Other Chemtronics Security Sensor manuals

Popular Security Sensor manuals by other brands

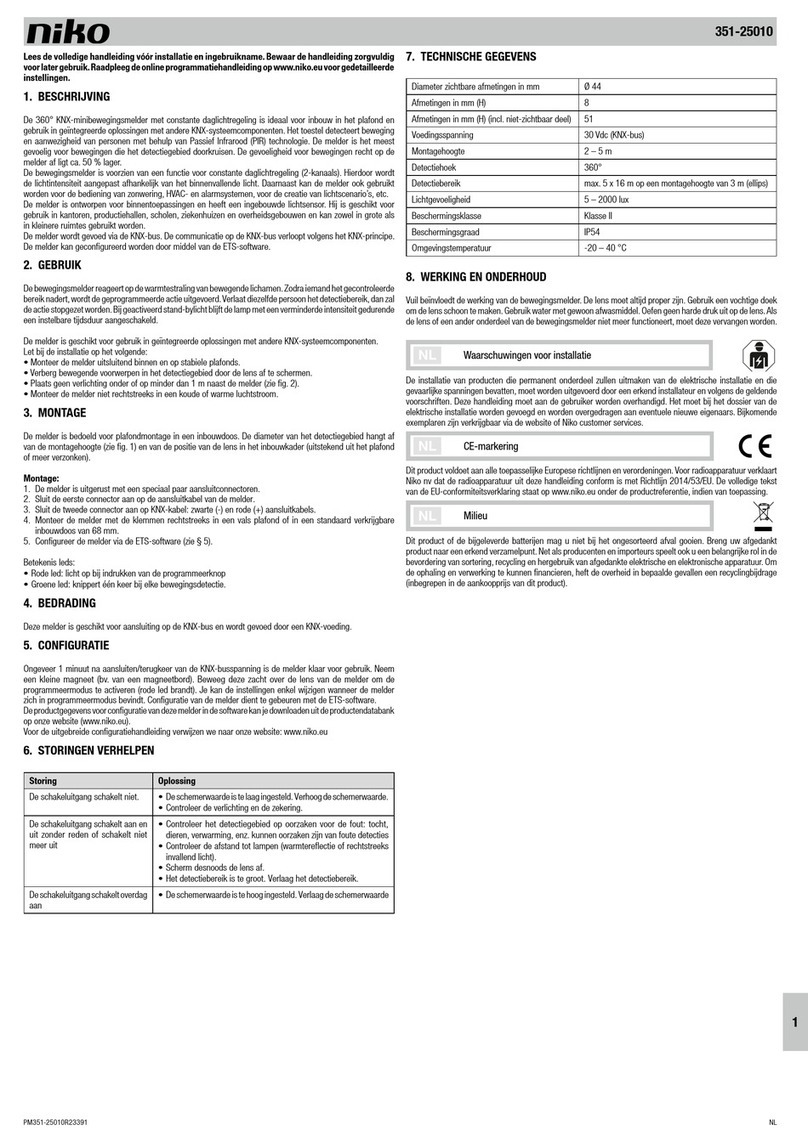

B.E.G. LUXOMAT

B.E.G. LUXOMAT PD2N-KNX-ST-FT Mounting instructions

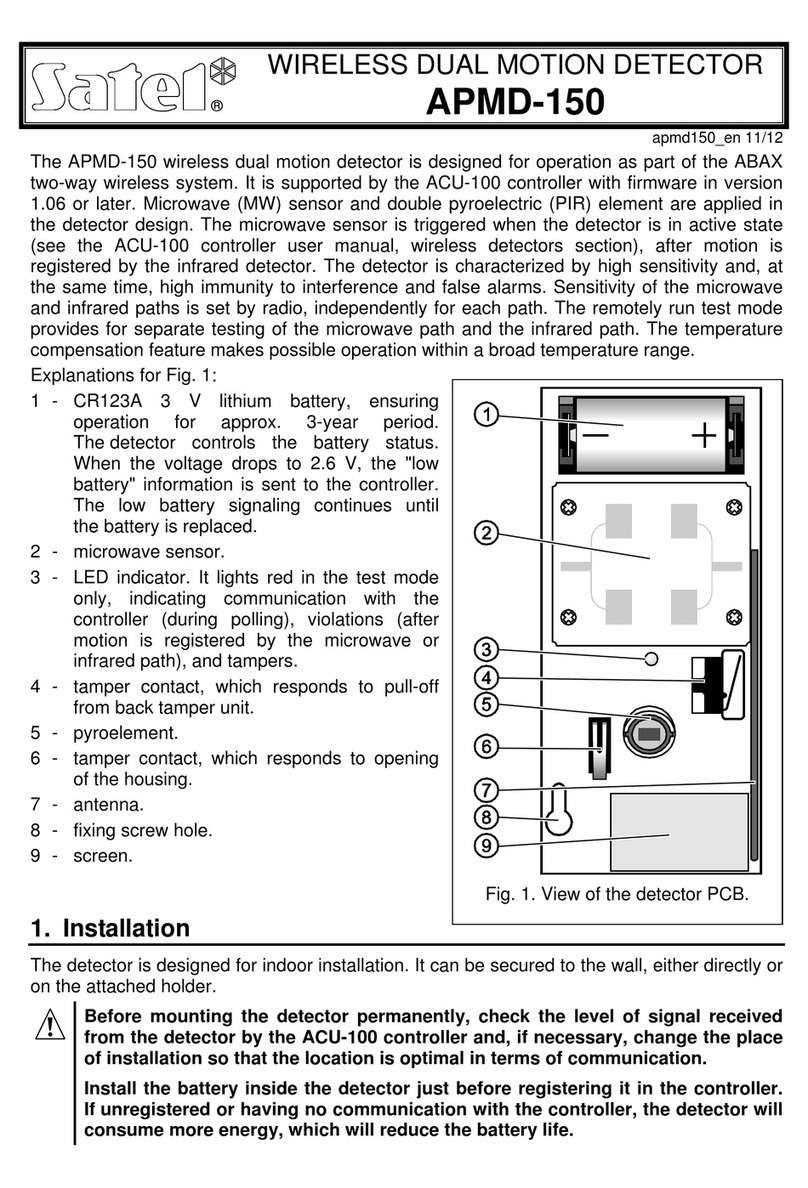

Satel

Satel APMD-150 manual

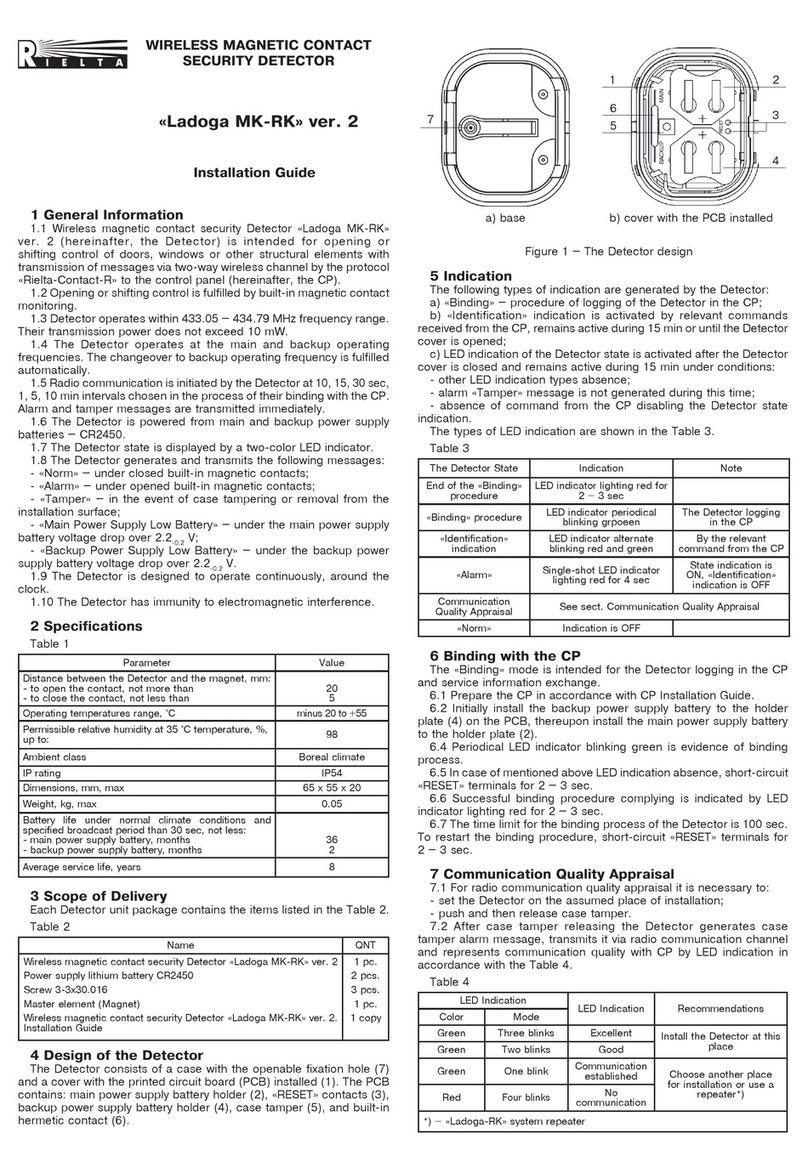

Rielta

Rielta Ladoga MK-RK installation guide

ITALIANA SENSORI

ITALIANA SENSORI 8058-ISR044 Installation, operation and maintenance manual

BW

BW GasAlert Quattro user manual

JFL Alarmes

JFL Alarmes IRA-360 user manual