IGM Vega FD 329-3-1 User manual

«IGM-Detector» Co Ltd

Address: 27 Engels Prospect,

building 5, litera A

Saint-Petersburg

194156, Russia,

Tel: 8 (800) 234-66-90

Website: www.igm-pribor.com

1

Flame detector

FD 329/330-3-1 «Vega»

User manual

MRBP.425241.001 UM

2022

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

2

Contents

Page

1. Introduction..............................................................................................................................3

2. Intended use ............................................................................................................................3

3. Technical specifications.......................................................................................................4

4. Contents of delivery...............................................................................................................6

5. Configuration and operation...............................................................................................7

6. Safety precautions...............................................................................................................10

7. Mounting.................................................................................................................................11

7.1 Mounting location.............................................................................................................11

7.2 Preparation.........................................................................................................................12

7.3 Cable requirements. Cable gland.................................................................................12

8. Detector connection ............................................................................................................13

8.1 Power source requirements...........................................................................................13

8.2 Detector connection.........................................................................................................13

Connecting a detector to digital channel RS-485...............................................................13

5.1 Connection diagrams ......................................................................................................14

9. Commissioning.....................................................................................................................18

Output signals and LED indicators description....................................................................19

9.1 Functionality check..........................................................................................................21

9.1.1 Manual mode.................................................................................................................. 21

9.1.2 Automatic mode............................................................................................................ 22

9.1.3 Detector setup test program...................................................................................... 22

9.2 Factory default...................................................................................................................23

10. Maintenance service........................................................................................................24

11. Troubleshooting................................................................................................................24

12. Packaging...........................................................................................................................25

13. Storage and transportation............................................................................................25

14. Storage ................................................................................................................................25

15. Marking and sealing.........................................................................................................25

16. Warranty..............................................................................................................................26

Appendix A......................................................................................................................................27

Appendix B. Ex-protection drawing.........................................................................................29

Revision history sheet.................................................................................................................30

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

3

1. Introduction

This user manual (UM) is intended to describe design, principle of operation and

operating routine of flame detectors «Vega» 329/330-3-1 (hereinafter FD 329/330-3-1

«Vega»). The UM contains basic technical data, guidelines for connection, maintenance

service, as well as other information, necessary for the correct operation, storage and

repair of flame detectors «Vega».

According to GOST R 53325 classification FD 329/330-3-1 «VEGA» belongs to:

а) by principle of operation –optical;

б) by region of the electromagnetic radiation spectrum –combined;

в) by power supply –powered by a separate wire;

г) by address setting possibility –addressable.

In terms of the functioning quality, FD 329/330-3-1 "VEGA" meets criteria A in

accordance with GOST R 53325 Appendix B.

Application scope:

explosive and fire hazardous areas of premises and outdoor installations at the

mounting sites of technological equipment of pumping stations of main oil pipelines,

tank farms, loading racks, etc., with the possible occurrence of an explosive and

flammable mixture of vapors of petroleum products, natural gas and other

hydrocarbons

explosive and fire hazardous facilities of the oil and gas as well as fuel and energy

complexes, including production sites, transport systems and storage facilities in the oil

and gas sector, tanks with oil, oil products, natural gas, etc.;

offshore oil production/refining platforms, ships and vessels;

as a part of fire protection and firefighting installations and complexes.

2. Intended use

FD 329/330-3-1 «VEGA» is a combined action detector, responding to electromagnetic

radiation in two spectral ranges –infrared (IR) and ultraviolet (IV).

Flame detector FD 329/330-3-1 «VEGA» is designed to detect fires of various

combustible materials indoors and outdoors and transmit a fire notification signal to fire

alarm control units, security and fire units and/or automatic fire fighting systems. It can be

used both as a separate device and as part of fire and security alarm systems.

FD 329/330-3-1 «VEGA» is placed at the process equipment mounting locations at oil

and gas production, transportation and storage facilities, in pumping stations of main oil

pipelines, on open areas, offshore platforms and tank farms, loading racks, etc. (electrical

equipment of subgroups IIA, IIB, IIC, IIIA, IIIB, IIIC temperature classes T1 - T6 according

to GOST IEC 60079-14-2013.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

4

3. Technical specifications

Housing material

- Aluminium

- Marine grade stainless

EX-marking

1 Ex d IIC T6…Т4 Gb Х; Ex tb IIIC T85°C

…135°C Db Х

Sign Х, following the ex-marking, means that

while mounting a detector you should use a

cable gland and a plug, certified according

to TR CU and having a marking according to

certificate.

Protection

IP 66/IP68

FD 329/330-3-1 «VEGA» overall

dimensions (with a mounting bracket)

not more than, mm

Ø266×166×99

FD 329/330-3-1 «VEGA» weight (with a

mounting bracket) not more than, kg

- 3,5 (aluminium),

- 6,0 (stainless)

Cable gland type

M 20

Ambient temperature range

-60 …+125 C for temperature class Т4

-60 …+90°C for temperature class Т5

-60 … +75 C for temperature class Т6

Ambient temperature range according to

transportation conditions

-50° C … +50°C

RH

Up to 95% (short-term exposure to 100%

humidity is allowed)

Supply voltage

Nominal: 24 VDC;

Range: 18 …32 VDC

FD 329/330-3-1 «VEGA» power

consumption

Stand-by mode –not more than 2 VA,

Alarm mode –not more than 3 VA.

With heating on –not more than 5,8 VA

FD 329/330-3-1 «VEGA» viewing angle,

not less than

120°

FD 329/330-3-1 «VEGA» responds

а) to radiation, generated by test sources

TP-5 иTP-6 according to GOST R 53325

Appendix A at a distance of at least 25 m

(detectors of the 1st class);

б) to radiation, created by test radiation

source.

Output signals

- analogue signal: 4..20 mA

- HART-interface

- digital signal in RS-485 standard with

Modbus RTU interface;

- actuation of relay contacts «Fire» and

«Failure».

FD 329/330-3-1 «VEGA» response time on

test flames TP-5 and TP-6 at a distance of

25 meters

not more than 5 s

Seismic resistance

FD 329/330-3-1 «VEGA» are earthquake-

resistant up to 9 points according to MSK-64

at the installation level above the zero mark

up to 10 m in accordance with GOST

30546.1-98.

MTBF

Not less than 100000 h

Specified lifetime

15 years

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

5

Shelf life and conservation of detectors

in the manufacturer's packaging

10 years

Warranty storage period

6 months since manufacturing

Warranty life

- 18 months from the day of commissioning;

- not more than 24 months since

manufacturing.

Exposure to sinusoidal vibration

group V2 GOST R 52931-2008,

corresponding to operation conditions

group F3 GOST R 52931-2008,

corresponding to transportation conditions

Resistance to atmospheric pressure

according to GOST R 52931-2008.

Group R1

Climatic category according to GOST

15150-69.

Boreal climate class 1

Seismic resistance according to GOST

30546.1-98

the impact of earthquakes with an intensity

of 9 points according to MSK-64 at an

installation level above the zero mark up to

10 m

Immunity to direct mechanical impact

with an energy of at least

1,9 J

Resistant to single shock pulses of a

half-sine waveform with peak

acceleration

with a pulse duration within

50 m/s2

10 - 20 ms

Immunity to nanosecond electrical

impulses propagating in the power

circuit and in the output circuits

Severity degree 4 according to GOST R

53325 Appendix B

Resistance to exposure to electrostatic

discharges of at least, kV:

contact –8;

air –15

Immunity to RF electromagnetic fields

with parameters

root-mean-square value of electromagnetic

field strength with amplitude modulation

depth of 80%, frequency 1 kHz, not less

than, V/m:

frequency range 0,1 …150 MHz –10;

frequency range 150 …500 MHz –5.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

6

4. Contents of delivery

Package includes:

Name

Identification

Number

Flame detector

FD 329/330-3-1 «VEGA»

1

User manual

MRBP.425241.001UM

1 in a set

Datasheet

MRBP.425241.001DS

1

Approval documentation

(certificates of

conformity, declarations

of conformity, permits

etc.)

-

1 package in a set,

delivered on a CD.

Paper copy –on

request.

Magnetic key

-

1 for 10 devices, but not

less than 1 in a set

Cable gland

-

On request

End plugs

-

On request

Sunshield

-

On request

Magnetic key allows to perform operability check in conditions of standard mounting

without disconnection from the external actuating alarm system.

Sunshield - protects the optical elements of the sensors from the adverse effects of the

environment at their mounting location.

The test radiation source is designed to test the detectors’ operability without

dismounting the latter from their workplaces.

Cable gland, designed for safe cable entry while mounting. Specify the model of the cable

gland when ordering. Not included in the delivery set, delivered on request.

End plug, is installed in a free hole for cable entry, to ensure the tightness and explosion

resistance of the gas detector. Specify the model of the end plug when ordering. Not

included in the delivery set, delivered on request.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

7

5. Configuration and operation

5.1 Appearance

Figure 1 –FD 329/330-3-1 «VEGA» appearance

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

8

5.2 Overall dimensions

Figure 2 - Overall dimensions of the detector with a mounting bracket

5.3 Construction

The detector housing is a flameproof enclosure, inside which all detector devices are

located, including sensitive elements that convert the electromagnetic radiation of the flame

into an electrical signal, electronic amplifiers and filters, digital-to-analog converters, a

microprocessor, display elements, optical elements for checking the operability of channels.

5.4 Principle of operation

The UV and IR sensors, when a flame is detected, convert electromagnetic radiation into

an electrical signal. Signals in digital form are processed in the microcontroller according to a

given algorithm to increase the reliability of the alarm output. The program highlights the

useful signal from the background, checks the correlation degree between UV and IR

channels. As a result of signal processing, a decision is made on the formation of output

signals: analog current output 4.20 mA, digital output in RS-485 standard with Modbus RTU

interface, “FIRE” relay contacts, “FAILURE” relay contacts.

FD 329/330-3-1 «VEGA» detector is equipped with a special self-testing function, that

performs correct operation check automatically every 30 minutes. It does not require the use

of an external control source of radiation (test lamp). Successful completion of the automatic

check does not cause the detector to switch to the ‘‘Fire” mode.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

9

FD 329/330-3-1 «VEGA» is resistant to false alarm. It doesn’t respond to UF radiation sources

other than flame, such as electric welding, artificial lighting, sunlight, lightning, high voltage

arc, X-rays and gamma rays, etc.

Notice: It is not recommended to operate FD 329/330-3-1 «VEGA» in places where combined

disturbance may occur (welding + radio station 5 W 100 MHz, welding + device vibration with an

acceleration > 10 g).

It is not recommended to use radio station in a distance less than 1 m away from FD 329/330-3-1

«VEGA» under conditions of continuous exposure to radiation from welding.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

10

6. Safety precautions

Any person who is familiar with the configuration, has studied this UM, has

been briefed on safety precautions when working with electrical installations

and have an electrical safety qualification group of at least III, including in

hazardous areas, is admitted to operate the flame detector.

FD 329/330-3-1 «VEGA» must have internal and external groundings

and grounding signs in accordance with GOST21130-75.

It is forbidden to operate the detector if the housing is damaged.

Equipment mounting in pumping stations should be carried out in

accordance with SNiP (construction rules and regulations) 3.05.05-84

"Technological equipment and process pipelines".

Detectors mounting must be carried out with the power supply switched

off.

Detector repair is allowed only to the personnel of the manufacturer's

enterprise or to persons authorized by the manufacturer to carry out repair

work.

FD 329/330-3-1 «VEGA» mounting at the control object must be carried

out in accordance with the duly approved project for the system placement,

which includes FD 329/330-3-1 «VEGA». Install detectors according to the

project, while FD 329/330-3-1 «VEGA» mounting it is necessary to follow:

Chapter 7.3 of the Electrical Installation Code;

Chapter 3.4 of the Operational Code for Electrical Installations

(OCEI);

Safety Rules for Operation of Customers' Electrical Installations;

This UM and maintenance documentation for co-used technical

equipment.

Electrical connections must be made in accordance with point

8Ошибка! Источник ссылки не найден..

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

11

7. Mounting

7.1 Mounting location

For the correct mounting of the detector, the following factors must be taken into

account:

The location of the detectors must ensure unobstructed control of the entire

protected area;

While detector’s positioning and targeting take into account the distance of

action and the viewing angle of the device;

Notice: Recognized that FD 329/330-3-1 «VEGA» has the highest sensitivity

along the central axis, which should be oriented to the place of a possible fire

(Figure 1);

Wrong orientation of the detector

Correct orientation of the detector

Figure 3 –Installation relative to the horizon.

It is necessary to visually estimate the area (viewing angle) controlled by the

detector. To do this, you can use the viewing angle indicator, which simplifies

the process of orienting the sensors while mounting in the field.

While mounting the detector should be oriented in such a way as to avoid direct

illumination from radiation powerful sources (sun, projector, etc.)

If there is a danger of mechanical damage to the detector, a protective structure

must be provided that does not intervene its performance and fire detection

efficiency;

Central axis direction

Central axis direction

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

12

Availability of a sufficient number of detectors to protect the controlled area;

The detector must be mounted on a rigid surface that is not subject to vibrations;

The detector must be easily accessible for periodic maintenance service;

While mounting take measures to prevent moisture from getting into the

electrical connections or components of the detector. Ensuring moisture

protection is necessary to keep the device in operation.

7.2 Preparation

Before FD 329/330-3-1 «VEGA» mounting a visual inspection is carried out. It needs to

pay attention to:

1) FD 329/330-3-1 «VEGA» ex-marking and a warning label;

2) zero damages;

3) presence of all the fasteners (bolts, nuts, washers) in accordance with FD

329/330-3-1 «VEGA» site placement project;

4) presence and integrity of the connecting wires (coming out of FD 329/330-3-1

«VEGA» insulation;

5) presence and integrity of the seal on the housing of FD 329/330-3-1 «VEGA».

6) It is recommended to connect FD 329/330-3-1 «VEGA» analogue outputs located

in the hazardous area with an external device located in the non-explosive area using a

control armored cable of the КВБбШв4х1,5 brand according to GOST 1508-78. The

КВБбШв cable can be used in hazardous areas of any class, including indoors, outdoors, in

channels, tunnels, ground (trench) in an aggressive environment, in places exposed to stray

currents.

7) While FD 329/330-3-1 «VEGA» mounting it is necessary to check the condition of

the ex-proof parts subjected to disassembly for compliance with the requirements of the EX

protection drawing (appendix B).

8) Check the availability of cable gland seals and plugs.

9) The external grounding conductor must be carefully stripped, and its connection

to the grounding clamp must be protected from corrosion by applying grease.

10) Upon mounting completion, the grounding device resistance must be checked

and must not exceed 4 Ohm.

7.3 Cable requirements. Cable gland

It is recommended to connect FD 329/330-3-1 «VEGA» analogue outputs located in

the hazardous area with an external device located in the non-explosive area using a

control armored cable of the КВБбШв4х1,5 brand according to GOST 1508-78. The

КВБбШв cable can be used in hazardous areas of any class, including indoors, outdoors,

in channels, tunnels, ground (trench) in an aggressive environment, in places exposed to

stray currents.

Use certified cable glands M20 while mounting.

The cable sealing on the cable gland must be carried out in every manner, since the

explosion-resistance of the entry compartment depends of this.

Notice: If it is necessary to connect piping to a cable gland with a ¾’ NPT thread, the

connection is made using a transitional threaded sleeve:

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

13

8. Detector connection

8.1 Power source requirements

Before connection it is necessary to:

- Calculate the total power consumption rate of the gas detection system in watts,

taking into account cold start.

- Select a power source with the appropriate power for the calculated load.

- Make sure the selected power source provides a regulated 24 VDC output voltage

for the entire system, taking into account allowable ripples. It is recommended to use

of a battery backup power supply to improve system reliability.

Notice: If it is required to be able to turn off the power supply, then a separate method

of turning it off must be provided.

8.2 Detector connection

To connect the detector:

-fix the mounting bracket at the FD 329/330-3-1 «VEGA» workplace, install a base on

it and fix it with a screw and a lock nut. The detector with a mounting bracket and its overall

dimensions are shown in figure 2;

-separate the base with cable gland from the detector housing;

-install the connecting cable in the cable gland исоединить проводники с

соответствующими клеммами,and connect the conductors to the corresponding terminals

located on the backplane:

Figures 4 and 5 show examples of connecting the detector to fire alarm control panels;

Figures 6 and 7 show diagrams of connecting the detector to fire alarm control panels

in the analogue signal using and digital output using mode;

Figures 8 and 9 show diagrams of connecting two detectors to fire alarm control system

via RS-485 interface with and w/o terminal box;

-install the FD 329/330-3-1 «VEGA» housing on the base and tighten the 3 screws;

-turn the detector for correct targeting;

-after applying power to the detector, it is necessary to control the internal IR and UV

radiation test sources, powered by a pulsed voltage. This radiation falls on the optical

sensitive elements of the IR channels (IR channel test lamp blinking at a frequency of 4-5

hertz for 1.5-2 seconds) and the UV channel (UV channel test lamp lighting once for 0.5

seconds), which allows the FD 329/330-3-1 «VEGA» to carry out a self-test every 30 minutes.

After successful passing of the test, at the FD 329/330-3-1 «VEGA» output a «slow»

alternate red LEDs blinking appears in the window of the FD 329/330-3-1 FD 329/330-3-1

«VEGA» IR channel, which corresponds to the detector entering «Standard»mode.

Detector connection to RS-485 digital channel

1. It is recommended to connect the detectors to the bus via a terminal box. Detectors

connection to a terminal box is carried out by a cable with a recommended length of

not more than 0,5m. Cable must meet the cable gland requirements on the FD

329/330-3-1 «VEGA» housing and terminal box. For the connection from terminal box

to the bus an armored cable with pairs of shielded twisted pairs can be used.

2. For the correct power supply network organization note that the supply voltage at the

terminals of the devices must be not less than 18 V and not more than 32 V, taking

into account the FD 329/330-3-1 «VEGA» consumption.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

14

3. The information network organization must be carried out in a way that the voltage drop

on the –24 V wire between the central processor and the detector does not exceed 8

V.

4. It is recommended to connect the detectors in a branch line from the main interface line.

Branches should be formed by installing repeater-splitters with galvanic isolation of the

type at the nodal points of the line. Each branch must serve a separate tank. Extension

of the main line beyond 1200 m must be carried out by inserting an interface repeater into

the line.

5. It is advisable to power the FD 329/330-3-1 «VEGA» according to the beam scheme -

each tank has its own cable.

Allowable line length is determined by the formula:

L(km) = 25 ΔU(V) S (mm2) / Imax(mA),

where ΔU(V) –allowable line voltage drop;

Imax(mA) –max current consumption;

(Imax(mA)FD 329/330-3-1 «VEGA» = 150 mA N(pcs.)

Notice: FD 329/330-3-1 «VEGA» digital output protocol parameters are shown in Appendix

A.

5.1Connection diagrams

Figure 4 –Connection diagram for an explosion-proof detector EEx

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

15

Figure 5 –Connection diagram for an ultra-explosion-proof detector EEx de.

Figure 6 –Connection diagram for a detector with uninsulated output 4-20 mA

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

16

Figure 7 –Connection diagram for an explosion-proof detector

ЕЕх via RS-485 interface

Figure 8 –Connection diagram for two explosion-proof detectors EEx via RS-485 interface

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

17

Terminal box

Figure 9 –Connection diagram for two detectors and a digital channel RS-485 via terminal

box

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

18

Notice: 250 Ohm is necessary to ensure the correct operation of the HART interface, in

case of 4-20 mA controller low resistance, it is not necessary to install resistance at the FD

329/330-3-1 «VEGA» output, it can be installed at the controller input.

Figure10 –Three-wired connection diagram FD 329/330-3-1 «VEGA» using 4-20mA and

HART

Notice: 250 Ohm is necessary to ensure the correct operation of the HART interface, in

case of 4-20 mA controller low resistance, it is not necessary to install resistance at the FD

329/330-3-1 «VEGA» output, it can be installed at the controller input.

Figure 11 –Four-wired FD 329/330-3-1 «VEGA» connection diagram using 4-20mA and

HART

9. Commissioning

PROHIBITED:

1 OPERATION OF THE DETECTORS IN CONDITIONS AND MODES

DIFFERENT FROM THOSE, MENTIONNED IN THIS UM!

2 OPERATION OF THE DETECTORS WITH DAMAGED ELEMENTS, SEALS

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

19

AN OTHER MALFUNCTIONS!

3.OPEN THE DETECTORS IN A HAZARDOUS AREA WITH POWER ON

Detector’s housing must be grounded.

Output signal and LED indicators description

FD 329/330-3-1 «VEGA» generates the following output signals:

-analogue signal with the following meanings:

a) 1.9…2.1 mA –«Failure»;

b) 3.9…4.1 mA –«Standard»;

c) 17.9…18.1 mA –«Fire»;

d) 4.1 mA –«Testing».

-digital signal via standard communication channel RS-485 with MODBUS protocol;

- actuating of the «dry» contacts of two relays «Fire» and «Failure». Relays are

designed for switching current 1 A at a voltage of 30 VDC.

FD 329/330-3-1 «VEGA» is equipped with LED indicators, displaying the current

operation mode of the detector.

Table 1 lists output signals, states of the relay contacts and indicator LEDs for FD

329/330-3-1 «VEGA» different states. Table 1

№

FD 329/330-3-1

«VEGA» state

«Fire»relay

contacts state

«Failure»relay

contacts state

Output

signal, mA

LED indicators state

NC

NO

1

No supply

voltage

Closed

Open

Open

0

Off

2

Dirty optics or

failure

Closed

Open

Open

2

Cycles: every 30 s

flashing with

different frequency:

first: 4 times

within 0.25 s

with a period 0.5 s

second: 3 times

within 0.5 s

with a period 1s

3

Standard

Closed

Open

Closed

4

Cycles: every 30 s

flash 3 times

alternately

within 0.5 s

with a period 1 s

4

Fire

Open

Closed

Closed

18

Continuous glow of

the both LEDs during

the «Fire»signal

5

IR-channel

Closed

Open

Closed

4

Continuous glow of

the IR LED during the

IR channel threshold

exceeding

6

UV-channel

Closed

Open

Closed

4

Continuous glow of

the UV LED during

the UV channel

threshold exceeding

7

Checking mode

(with a

magnetic key

on)

Closed

Open

Open

2

Yellow –when putting

on a magnet, red –

when illuminated with

a test lamp

It is possible to fix the output signal "Fire" after the end of the alarm cause.

MRBP.425241.001 UM version 1.1 01.05.2022 FD 329/330-3-1 «Vega»

20

It is possible to change the sensitivity and signal processing time to reduce the effect of

interference when identifying a fire or a nearby location of the alleged fire site («far/near» and

«fast/slow»modes).

This manual suits for next models

1

Table of contents

Other IGM Security Sensor manuals

Popular Security Sensor manuals by other brands

Abus

Abus Security-Center FU5130 installation guide

Tinker & Rasor

Tinker & Rasor AP/W instructions

Multitech

Multitech RBS3010NA08BN00 user guide

C.P. Electronics

C.P. Electronics MWS5-AD-SA-C installation guide

ACU-RITE

ACU-RITE 06039 instruction manual

Green Brook

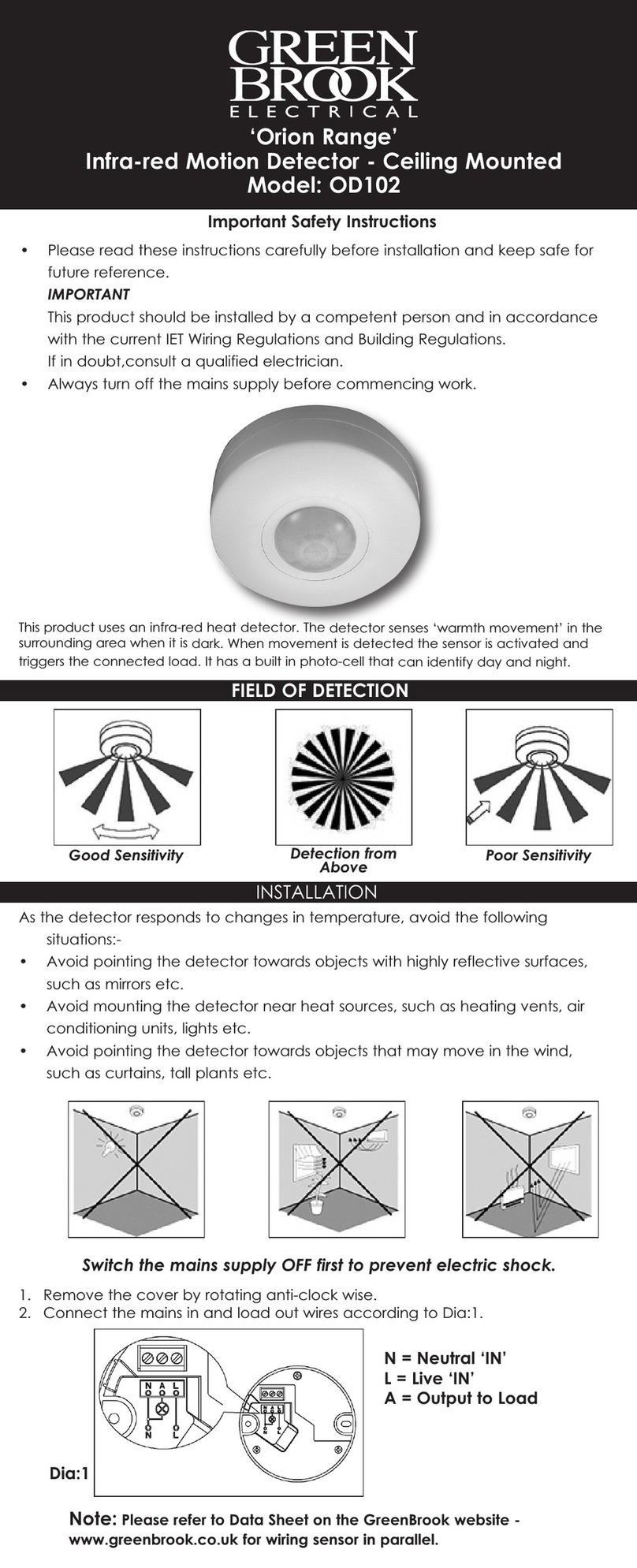

Green Brook Orion Range OD102 Important safety instructions

C.P. Electronics

C.P. Electronics MWS6-DD installation guide

HIK VISION

HIK VISION Pyronix XDH10TT-WE quick start guide

Green Brook

Green Brook Orion Series quick start guide

Suresafe

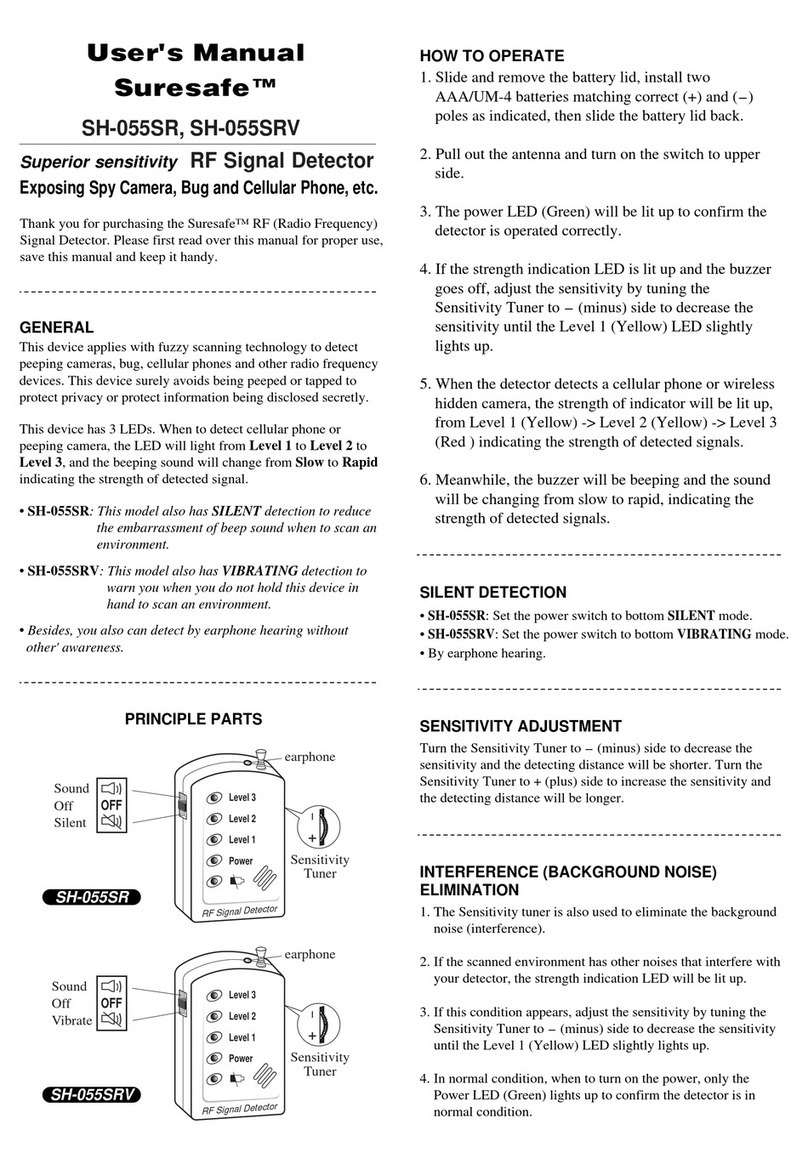

Suresafe SH-055SR user manual

DigiSpec

DigiSpec VMD-1001 Operation manual

Powerfix Profi

Powerfix Profi 40111 Operation and safety notes