Chemtronics MoniTurb-F User manual

Chemtronic Waltemode GmbH

Sales- & Service Partner for Your MONITEK Products.

40789 Monheim am Rhein , Niederstr. 14

Phone: +49-(0)2173-57007 Fax: +49-(0)2173-56007

E-mail: info@chemtronic-gmbh.de

Internet: www.chemtronic-gmbh.de

Manual

Version 09.03.2015

Universal Transmitter Model

Messenger

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 2

Transportation Damages!

Please inspect the instrument immediately after receiving for potential

shipping damages.

For any claims to the transportation insurance or warranty repair, it is

absolutely required to notify transportation damages immediately after

receiving the instrument. In case of obvious damages of the outer

packaging, the carrier must give a receipt for this damage to make

demands for the insurance. In case of a delayed announcement the

insurance will not pay for damages and Chemtronic Waltemode GmbH will

not assume liability for these damages.

Manufacturer and owner of all rights model Messenger:

Galvanic Applied Sciences Inc., Lowell MA, USA

Revised manual by Chemtronic Waltemode GmbH

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 3

Content

TRANSPORTATION DAMAGES! ................................................................................................................................................. 2

COPYRIGHT.................................................................................................................................................................................. 5

WARRANTY CONDITIONS........................................................................................................................................................... 5

Shipment of the instrument......................................................................................................................................................... 5

SAFETY INSTRUCTIONS ............................................................................................................................................................. 6

BEFORE INSTALLATION AND STARTUP .................................................................................................................................. 7

System Inspection ....................................................................................................................................................................... 7

General Installation guidelines ................................................................................................................................................... 7

GENERAL INFORMATION ........................................................................................................................................................... 8

Introduction .................................................................................................................................................................................. 8

SPECIFICATIONS:........................................................................................................................................................................ 9

DIFFERENT VERSIONS: MESSENGER TRANSMITTER ............................................................................................................ 9

DIMENSIONAL DRAWINGS ....................................................................................................................................................... 10

WIRING DIAGRAM (MESSENGER TRANSMITTER) ................................................................................................................. 11

Main Board.................................................................................................................................................................................. 11

Optional Relay Board................................................................................................................................................................. 11

JUMPER POSITIONS MODEL MESSENGER ............................................................................................................................ 12

Jumper Positions (Gain Setting)............................................................................................................................................... 13

SOFTWARE INSTALLATION (MESSENGER GRAPH) ............................................................................................................. 14

RS-232 Interface ......................................................................................................................................................................... 17

RS-485 Pins – at Messenger...................................................................................................................................................... 17

INTERCONNECTIONS TO PC / LAPTOP (RS 232) ................................................................................................................... 18

Turn Messenger and PC / laptop back on................................................................................................................................ 18

Messenger RS232 Wiring Diagram ........................................................................................................................................... 18

INTERCONNECTIONS TO PC / LAPTOP (USB)........................................................................................................................ 19

Using the optional USB to RS485 Interface Converter Model USB Nano.............................................................................. 19

MENU LAYOUT AND OPERATION............................................................................................................................................ 20

MENU LAYOUT AND OPERATION............................................................................................................................................ 20

Messenger Software Navigation Tree (Operator) .................................................................................................................... 20

Messenger Software Navigation Tree (Technician) ................................................................................................................. 21

Messenger Software Navigation Tree (Factory Level) ............................................................................................................ 22

SETUP AND CALIBRATION....................................................................................................................................................... 23

Field Calibration and Curve Fitting........................................................................................................................................... 23

Access Levels and Codes ......................................................................................................................................................... 24

Analog Outputs and Alarms...................................................................................................................................................... 27

Display Units .............................................................................................................................................................................. 28

Data Trending Display and RS-232 Output. ............................................................................................................................. 28

Self-Cleaning Interval................................................................................................................................................................. 29

SYSTEM AND TROUBLESHOOTING ........................................................................................................................................ 30

View Channel Output Display ................................................................................................................................................... 30

Factory Calibration .................................................................................................................................................................... 30

Toggling Between Factory and User Calibration .................................................................................................................... 31

Default parameters:.................................................................................................................................................................... 31

Error and Warning Messages.................................................................................................................................................... 31

SOFTWARE UPGRADING.......................................................................................................................................................... 34

Firmware ..................................................................................................................................................................................... 34

PC Version (Messenger Graph Software) ................................................................................................................................ 34

OPTIONAL LAMP control board ............................................................................................................................................... 36

EXTERNAL LAMP CONTROL CONNECTOR PIN OUT: ........................................................................................................... 36

INTERNATIONALIZATION.......................................................................................................................................................... 38

Select Language......................................................................................................................................................................... 38

ON-LINE HELP MENUS AND RELATED CONTENTS ............................................................................................................... 38

MAIN MENU ................................................................................................................................................................................ 38

SET CALIBRATION MENU ......................................................................................................................................................... 39

Process Calibration.................................................................................................................................................................... 40

Build Calibration ........................................................................................................................................................................ 40

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 4

View / Edit Calibration................................................................................................................................................................ 41

Fit Data ........................................................................................................................................................................................ 41

Copy Factory Table .................................................................................................................................................................... 42

Build Calibration ........................................................................................................................................................................ 42

View / Edit Calibration................................................................................................................................................................ 42

SETUP RESULTS ....................................................................................................................................................................... 43

Setup Results Nametag (Panel PC version only) .................................................................................................................... 43

Setup Results Equation ............................................................................................................................................................. 44

Setup Sensor Equation.............................................................................................................................................................. 44

Setup Numerical Display (Panel PC version only) .................................................................................................................. 45

Setup Graphical Display (Panel PC version only) ................................................................................................................... 45

Set Results Units (Panel PC version only) ............................................................................................................................... 46

Setup Data Logging ................................................................................................................................................................... 46

Setup Storage Size..................................................................................................................................................................... 46

Bubble Reject Threshold........................................................................................................................................................... 47

Set Results Offsets (manual zero adjust)................................................................................................................................. 47

SETUP INPUTS / OUTPUTS MENU............................................................................................................................................ 48

Set LCD Display (Version with LCD- display only) .................................................................................................................. 48

LCD version, Enter nametag, measurement unit and decimal resolution............................................................................. 48

Set Analog Outputs.................................................................................................................................................................... 49

Assign Digital Inputs.................................................................................................................................................................. 49

Set Alarms................................................................................................................................................................................... 50

Set Messenger Unit ID ............................................................................................................................................................... 51

DIAGNOSTIC MENU ................................................................................................................................................................... 52

File Menu..................................................................................................................................................................................... 52

Save Parameters to File ........................................................................................................................................................ 52

Load Parameters from File ................................................................................................................................................... 52

View Channel Outputs ............................................................................................................................................................... 53

Adjust Hardware Settings.......................................................................................................................................................... 53

Zero Dark Current ...................................................................................................................................................................... 54

Optimize Channel Signal Auto .................................................................................................................................................. 54

Optimize Channel Signal Manual.............................................................................................................................................. 55

Calibrate Analog Outputs .......................................................................................................................................................... 56

ADC-GAIN Manual...................................................................................................................................................................... 56

Hardware Test............................................................................................................................................................................. 57

Test Relays ................................................................................................................................................................................. 58

CLEAR/RESET MENU ................................................................................................................................................................ 59

Clear Process Calibration.......................................................................................................................................................... 59

Clear Factory Calibration........................................................................................................................................................... 59

Reset Alarms .............................................................................................................................................................................. 59

Software Revision ...................................................................................................................................................................... 59

SET CLEANING EVENT.............................................................................................................................................................. 60

SET ACCESS CODE ................................................................................................................................................................... 61

SET ACCESS LEVEL.................................................................................................................................................................. 61

MEASUREMENTS SCREEN (PANEL PC VERSION ONLY!) .................................................................................................... 62

Graph Settings (Panel PC Version only) .................................................................................................................................. 67

SENSOR LIST FOR MODEL MESSENGER ............................................................................................................................... 69

TECHNICAL DATA...................................................................................................................................................................... 70

DECLARATION OF CONFORMITY (CE).................................................................................................................................... 71

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 5

COPYRIGHT

2015 Chemtronic Waltemode GmbH

This manual including all of its parts are protected by copyright.

Any further use beyond the copyright laws is not allowed without the written approval of Chemtronic Waltemode

GmbH. There are no further reaching warranty claims to take because of the content of existing document.

Manufacturer and owner of all rights model Messenger:

Galvanic Applied Sciences Inc., Lowell MA, USA

Revised manual by Chemtronic Waltemode GmbH

WARRANTY CONDITIONS

The warranty for this product takes place according to the legal provisions. As places of warranty we explicitly

name Galvanic Applied Sciences Inc. (Lowell USA) or Chemtronic Waltemode GmbH, Monheim am Rhein

(Germany). In case of warranty service at the customer site, we will charge additional expenses e.g. travel

expenses, overnight cost, etc. Consumable parts as well as wearing parts e.g. lamps, gaskets, etc. are not covered

by warranty. Improper use, gross negligence, use of the system outside of the technical specifications, missing or

improper maintenance will cause a loss of the warranty claim. Please pay attention to our general terms of contract.

Non-warranty

Chemtronic Waltemode GmbH takes no responsibility or warranty for technical or editorial mistakes or omissions in

this document. The information in Chemtronic Waltemode GmbH reserves all rights to make changes to this

document without announcement. Chemtronic Waltemode GmbH is by no means liable for any consequential

damages or miscellaneous damages, which occur during the use or storage of the system. Some countries do not

allow the limitation of liability, so that this exclusion is possibly not valid for you.

Improper installation / operation of the system

Warranty is void if the system is installed improperly, handled improperly, used outside of the technical

specifications (of the instrument), or damaged by gross negligence.

Storage

Please inspect the instrument immediately after receiving for potential shipping damages.

If the instrument has already been unpacked for inspection or testing, or if the instrument has been removed from

the process and it is not to be installed or reinstalled for more than 1 day, the following procedure should be

observed:

1. If the instrument has been in service, the wetted portion should be thoroughly cleaned than thoroughly dried.

2. In case the original packing material is not available place the instrument in a sealed heavy plastic bag with a

desiccant added to assure clean dry storage.

3. The instrument should then be stored in a protected area until time of installation.

Shipment of the instrument

Please clean the instrument carefully before shipment (e.g. for revision / repair). Please use fixed packaging

material to protect the instrument against any shipping damages.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 6

SAFETY INSTRUCTIONS

Pay attention to the following general safety instructions during use and operation of the system.

Ignoring these instructions or special warnings inside of this manual can damage the sensor, cause

inaccurate measurements, and possibly result in unsafe installations. Chemtronic Waltemode GmbH will

not take any responsibility for consequences arising from ignoring the safety instructions and warnings.

For all chemical liquids

The product you measure is may be toxic or otherwise harmful to human health. Observe appropriate

precautions when handling and disposing the liquid. Review the appropriate published material safety

data sheets regarding the safe handling and disposal of all reagents or standards.

Electrical installation

Qualified technical personnel must install the electrical installation of the system. This instrument

requires an input of 90-260VAC at 50-60 Hertz (unless otherwise specified). A 24VDC/AC power supply

is optional.

Hazardous area

DO NOT INSTALL the system in hazardous area without the optional Ex-proof equipment. Operation of

non Ex- proof systems in hazardous area will cause a high risk.

Using the system in hazardous areas (Ex Zone I / Ex Zone II) will

only be safe with the installation of the optional special Ex-proof

designs including all required certifications

Maintenance

Always disconnect the instrument from power during maintenance, replacement of components,

installation of additional components or any other operations at the open instrument. Only qualified

technical personnel must perform this work.

Operating the instrument with open enclosure

Only qualified technical personnel should operate the instrument when the enclosure is open. Take care

that no moisture enters the enclosure.

Some components inside the instrument are energized with

voltages, which can cause lethal shocks in case of contact. Be

careful during installation, handling and operation of the

instrument.

Improper installation / operation of the system

Warranty is void if the system is installed improperly, handled improperly, used outside of the

technical specifications (of the instrument), or damaged by gross negligence.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 7

BEFORE INSTALLATION AND STARTUP

System Inspection

Check to ensure that all components of the instrument have arrived safely. Included should be: the Messenger Transmitter, the

Sensors and the cable sets and Manual.

The Messenger versions without display and with LCD include typically additional a Cd- Rom with Messenger Graph

Software and an Interface adapter Model USB-Nano.

If there is any damage to the equipment or if anything is missing please contact us immediately. Save the packing

material for future system storage or shippingI

Please read the additional safety instructions before installation and start-up!

General Installation guidelines

1. Transmitter and Sensors are sensitive components, do not drop and handle with care.

2. Follow the wiring diagram (pay attention to sensors manual) during installation of the system.

3. The process temperature and pressure cannot exceed the specification of the delivered Sensor.

4. Avoid air and gas bubbles inside the sensor, they cause disturbances. Nois

e and drift of the measurement would be the result (th

bubbles are not expected at a pressure upwards of 2 bar in aqueous solutions).

5. Please do not use the system in case of any visible mechanical damages!

6. The Messenger enclosure fits IP65 / Nema 4x protection class we recommend a dry / dust free area.

7. The ambient temperature for the transmitter must be in a range of -10°C to 50°C (use dry purge air above 40°C)

8. AC power consumption of the Messenger Transmitter is less than 50 Watts

9. Transmitter relay ratings for alarms and external devices are 2 A at 250V~ maximum

10. Do not operate with open enclosure. Exposed electronics will promote the risk of electrical shock and might cause damage to t

he

11. Do not alter cable length. The instrument was calibrated

with a specified cable length. Altering cable length can cause unstable s

and void instrument calibration.

12. Ship the instrument in the original packing material to avoid damage to the sensor or transmitter.

13. Mishandling of the system is not covered under warranty. Do not disconnect the interior wiring of the sensor.

14. Proper instrument grounding: The instrument must be grounded to avoid electrical shock hazards to person

nel, damage to the un

erroneous operation.

WARNING: MAKE SURE THE AC POWER MAINS ARE SWITCHED OFF OR OTHERWISE

DISCONNECTED BEFORE YOU BEGIN WIRING THE SYSTEM TO AVOID THE POSSIBILITY OF ELECTRICAL

SHOCK. IT IS A GOOD PRACTICE TO INSTALL A MAIN POWER CUTOFF SWITCH NEAR THE SYSTEM WITH

EXTERNAL MAIN FUSES.

THE SYSTEM REQUIRES AN AC-GROUND (EARTH GROUND) AND ALL SENSORS CONNECTED TO

THE TRANSMITTER MUST BE GROUNDED

Please note. The following points are important to avoid damages of the Sensors at

high temperature applications:

•Please connect purge air (cooling) before process insertion (dry, oil- & dust free instrument air )

•Leave air output open

•Do not interrupt the air cooling

•

Remove the Sensor immediately from the process in case air purge is not guarantied!

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 8

General Information

Introduction

Monitek Messenger is a compact, highly efficient, and expandable system that is designed to interface

to a broad range of Monitek / Galvanic / Chemtronic sensors. It also has the capability to interface with

multiple and different sensors at the same time. It’s modular design approach enables several

applications to be customized for a variety of measurements, such as Turbidity, Suspended solids,

Color and % Concentration using optical in-line Sensors. The Messenger may be linked with Personal

Computer, Laptop or Netbook operating Windows XP / Vista / 7 or a Panel PC (also called a TPC), the

GUI (Graphical User Interface) offers completely menu-driven screens that are easy to understand and

also has online help. The GUI interface is designed to allow three access levels (Operator, Technician

and Factory) to prevent an unskilled operator from changing any critical parameter in the setup of the

transmitter. The interface is intuitive with no need for programming codes or program numbers. The

system also includes some self-check operations as well as the ability to access the basic

measurement values without the use of a multi-meter or even physically accessing the electronics. The

system includes the ability to perform field calibrations while the instrument is installed in the process

and is operating. It comes factory pre-configured to your application. For most accurate setup we

recommend that the user calibrate on his process sample condition. Please refer to Process calibration

Icons used in this User’s Manual

Important notice!

Cautions indicate situations that could damage the Monitek Messenger or

sensor. Cautions are printed in mixed case characters in boldface font

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 9

Specifications:

Sensors: MoniTurb-F, MoniTurb-FS, MoniSpec-AD, AP2, LAS, MoniSpec A, MoniTurb-S, TS2,

Model 22, Model 25 Probes (includes CSK, CSH, CSS), Model 450, 210 with external

power supply, more …..

Number of Sensors: 1 to 4 sensors. Each sensor may be linked to a separate 8 points Calibration table with 1st

order or Curve fit linearization technique.

Area Classification: General Purpose (optional Hazardous area Zone 1 & 2)

Environmental:

Operating Temp:

-14 °F to 122 °F (-10 °C to 50 °C), air purge required for cooling above temperatures of 104°F (40°C)

Humidity: 0 to 95% RH, non condensing

User Interface:

Alarms: Low High Alarms and General Fault Alarm are user programmable, latching or non-

latching, energized or de-energized with alarm delay and hysteresis.

Display: Optional, 4 lines by 20 Characters backlight LCD.

Programming: Using PC, Laptop, Netbook or touch screen Panel PC.

Analog Outputs: 2x 0/4-20mA Isolated. Optional 2additional outputs 0 to 1000 Ohm

Internal Relays: Optional, 4 relays fully programmable rated 2A/250VAC

Digital Inputs: Four Digital Inputs, fully programmable with activate levels of 5 to 24 VDC

Digital Output: RS-232 or RS-485 using Modbus RTU protocol.

Input Power: 90 to 260 VAC 50/60 Hz optional 24V

Power consumption: less than 50 watts

Case Material: 304 Stainless Steel

Approvals CE / CSA

Different versions: Messenger Transmitter

Version without display Version with alpha

numeric LCD Version with Panel PC

(TPC)

A PC / Laptop or Netbook is required for configuration / calibration of the

versions without display and with LCD- display.

The Panel PC (TPC) version allows configuration and calibration without

external equipment. The operation is will be done via touch screen of the

Panel PC.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 10

Dimensional Drawings

Messenger (without display)

Messenger (with numeric LCD)

Messenger (with Panel- PC / TPC)

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 11

Wiring Diagram (Messenger Transmitter)

Main Board

Optional Relay Board

See additional wiring instructions in your sensors manual!

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 12

Jumper Positions Model Messenger

All jumpers are typically factory configured according to sensor and application.

Please contact our service before you change any jumper position!

Some components inside the instrument are energized with voltages, which can

cause lethal shocks in case of contact. Be careful during installation, handling

and operation of the instrument. Disconnect from supply power.

Firmware

(JP10)

Figure 128

This jumper (JP10) is used to unlock the hardware for a firmware update.

Firmware updates should be done by Service personal only!

•Standard jumper position (JP10) = not jumpered (open)

Signal Gain (JP1 to JP8)

•Jumper positions (JP1 to JP8) = depending on application, see next page for details.

Lamp current (JP11 & JP12)

Position for lamp

current 1A

Position for lamp

current 350mA & less

Read chapter „

Sensor List for Model Messenger” before changing JP11, JP12

jumper position!

Only qualified technical personnel must perform this work.

•Jumper positions (JP11 & JP12) = depending by Sensor

System Reset (JP9)

Only qualified technical personnel must perform this work. This Jumper allows a complete

system reset by hardware, take notice al user programmed settings will be lost!

•Standard jumper position (JP9) = not jumpered (open)

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 13

Jumper Positions (Gain Setting)

Only qualified technical personnel must perform this work.

Please contact our service before you change any jumper position!

Some components inside the instrument are energized with voltages, which

can cause lethal shocks in case of contact. Be careful during installation,

handling and operation of the instrument. Disconnect from supply power.

You can change the hardware gain of the Messenger transmitter in case the “optimize signal”

values are to high or to low. See chapter “Optimize Signal”.

Jumper Positions „low gain“

Jumper Positions „high gain“

Jumpers are located directly behind the connectors for the signal inputs.

See wiring diagram at Page 13

Each signal input can be configured individually:

JP1 and JP5 = 1. Signal Input

JP2 and JP6 = 2. Signal Input

JP3 and JP7 = 3. Signal Input

JP4 and JP8 = 4. Signal Input

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 14

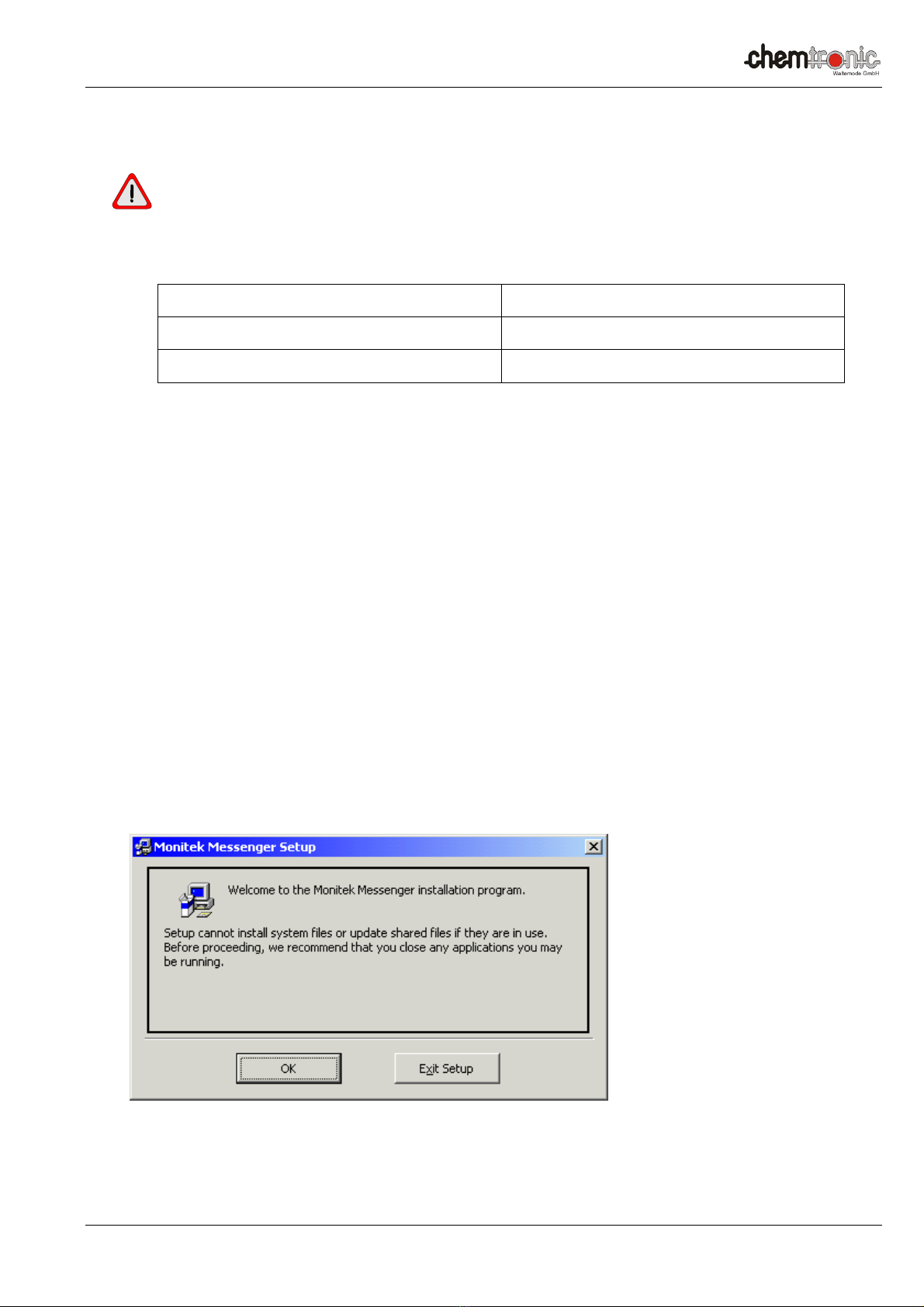

Software Installation (Messenger Graph)

The Software Installation is not required at Panel PC (TPC) version of the

Transmitter. Panel PC version arrives with installed Software!

System Requirements

Supported Operating Systems Windows XP, Vista, 7

RAM 32MB

Hard Disk Space 5MB

.

Installation procedure Messenger Graph Software

I. Close any open programs that are running on your computer before starting the installation.

II. Double click on setup.exe.

III. As the installation progresses, follow the instructions on the screen. Some Windows system files

will be updated to newer versions during installation of Messenger software. If these updates are

done, you will be required to reboot your PC. If so, repeat steps 1 through 2 of the installation

procedure to continue with the installation. Once the installation of Messenger software is

complete, you will be required to restart your computer once again for proper functioning of the

software.

IV. Welcome screen shown below will appear, Click OK to continue the installation process. To abort

the installation process click Exit Setup.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 15

V. Choose the Destination location.

VI. To change the default destination location click on Change Directory. Choose new

destination location using the following screen.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 16

VII. Choose the program group under which the application has to appear.

VIII. Click Continue.

IX. Dialog showing the status of the files being copied will be displayed.

X. On Completion of Installation Process Message “Installation process complete” will appear.

XI. Click on OK to finish the installation process.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 17

RS-232 Interface

RS-232 Pins - at Messenger

Messenger Pins PC / Laptop

16 DSR (-) 4 DTR

17 TX (Out) 2 RX (In)

18 RX (In) 3 TX (Out)

19 GND 5 GND

Reference Pins RS232 - at PC / Laptop / Netbook (9 Pin Sub-D)

Pin Signal Dir Funktion

1 DCD/RLS

D IN Carrier Detect

2 RXD IN Receive Data

3 TXD OUT Transmit Data

4 DTR OUT Data Term

Ready

5 GND Ground

6 DSR IN Data Set

Ready

7 RTS OUT Request to

Send

8 CTS IN Clear to Send

9 RI IN Ring Indicator

RS-485 Pins – at Messenger

Messenger Pin PC / Laptop

13 (-) -- --

14 (+) -- --

15 GND -- --

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 18

Interconnections to PC / Laptop (RS 232)

Install the software “Messenger Graph” to your computer

Turn Messenger and PC / Laptop off.

Connect the RS232 cable according to wiring diagram.

Connect your PC / Laptop via the RS232 jack to Messenger the transmitter.

Turn Messenger and PC / laptop back on.

Messenger RS232 Wiring Diagram

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 19

Interconnections to PC / Laptop (USB)

Using the optional USB to RS485 Interface Converter Model USB Nano

An interface converter USB to RS232 can not be used to configure or calibrate

the transmitter model Messenger! Using this type of converter will cause a

crash of the Messenger Graph Software!

The interface converter USB- Nano is used to configure / calibrate the Transmitter via USB-

interface. Please do not access the menu “Measurements Screen” if you use this converter this

may crash of the Messenger Graph software!

1. Install the software “Messenger Graph” to your computer.

2. Connect the RS485-converter to the USB- interface of your computer.

3. Install the driver software of the RS485- converter model USB- Nano.

Take notice:

Restart your computer before you proceed with item 3 otherwise you may get problems with

configuration.

4. Start the Windows Control Panel and select System, Hardware, Device Manager, COM and LPT.

5. Assign a COM port, COM1, COM2, COM3 or COM4 to your interface converter (we recommend COM1).

6. Close Device Manager and Control Panel.

7. Connect transmitter mod. Messenger to Interface converter model USB- Nano.

USB- Nano connector A: to terminal 13 model Messenger

USB- Nano connector B: to terminal 14 model Messenger

USB- Nano Shield: to terminal 15 model Messenger

8. Start the software „Messenger Graph“.

9. Call up the “Main Menu” and select the sub- menu

Inputs/Outputs – Set COM Port. Please proceed directly with step 10 in case your COM port is assigned to

COM1.

10. Enter the in item 4 selected Port (COM-COM4) and enter:

Baud 57600, Modbus- Normal. Please proceed directly with step 10 in case your COM port is assigned to

COM1.

11. Return to the START/EXIT-Menu and select „GO ONLINE”.

Background of button „GO ONLINE” and the dot in the upper right corner, change to green color.

Some Windows Installations may come up with the message:

„Invalid procedure call or argument“.

Confirm the Message with the OK button.

Take notice, the dot in the upper right corner has to stay green.

Chemtronic Waltemode GmbH, Niederstr. 14, 40789 Monheim am Rhein, Germany / Sales & Service Partner of Galvanic Applied Sciences Inc.

Phone +49-(0)2173-57007 Fax: +49-(0)2173-56007 E-mail: info@chemtronic-gmbh.de Internet: www.chemtronic-gmbh.de Page 20

Menu layout and Operation

Messenger Software Navigation Tree (Operator)

Start/Exit Menu

Setup Inputs/

Outputs

Measurement

Screen

Previous

Data

Set Access

Level

Set Cleaning

Event

Select Messenger

Main Menu

Select Language

Graph

Settings

Copy Data

Diagnostic

Menu

Online

Data

Copy Image

Save As Bmp

Set Alarms

Soft are Revision

Clear/Reset Menu

Functions

Reset Alarms

This manual suits for next models

5

Table of contents