CHESTER U.K. B-Super 3-in-1 User manual

ModelBSuper3in1

InstructionManual

ChesterUKLtd

ClwydClose,HawardenIndustrialPk

Hawarden,NrChester

Flintshire.CH53PZ

Tel:01244531631

Email:sales@chesteruk.net

www.chesteruk.net

IMPORTANT

SAFETYFIRST

ALLMACHINESAREDANGEROUS

1.Usethecorrecttoolforthejobathandnevermakeamachinedoajobitwasnotdesignedfor.

2.Neverforcethe toolinthemachineitwilldothequickerandsaferatthecorrectrate.

3.Alwaysuseclampsorvicestosecurework– yourhandisnotstrongenough!

4.Whenchangingtoolsorworkpiecesalwaysdisconnectthemachinefirst.

5.Servicethemachineregularly;acorrectlyoperatingmachineisasafermachine.

6.Alwaysreplacebeltcoversbeforestartingthemachine.

7.Understandthemachinefullybeforeoperationandalwaysreadthemanual.

8.Gettoknowthemachineslimitationsandapplications.

9.Ensurethatthemachineissecurelyboltedtothebenchandthatthebenchissecurelyboltedtothe

ground.

TAKEGREATCAREWHENOPERATINGTHISMACHINETOPROTECTYOURBODY

1.Alwayswearsafetyglasses–everydayglassesarenotsuitable.

2.Dustcanbecausedwhenmachiningcertainmaterials,alwayswearamask.

3.Makesureyouarenotwearinganylooseclothingsuchasties,rings,braceletsthatmaygetcaughtin

themovingpartsofthemachine.

4.Keepaproperfootingandbalancewhilstoperatingthemachine.

5.Neverleavecleaningrags,etconornearthemachine.

ChesterUKModelB

1.

SAFETYFIRST

ELECTRICS

1.Allelectricaltoolsmustbeearthed.

2.Neveruseelectricaltoolsindamporwetenvironment.

3.Makesurethemachineisintheoffpositionbeforeswitchingonatthemains.

4.Alwaysimmobilisethemachinebeforeservicingorsettingupworkinthemachine.

5.Greatcareshouldbetakenwhenusingcoolantfluidwithmachinetools.

6.Ensurethemachineiscorrectlyconnectedandafuseoftheproperratingisused.

CHILDREN

1.Keepchildrenawayfrommachines,ifnecessaryfitsafetylockstothemachineandmainsswitches.

2.Neverusemachinerywhilsttalkingtovisitors,alwaysconcentrateonthejobinhand!

REMEMBERALLMACHINESARE

DANGEROUSIFNOTUSED

CORRECTLY!

ChesterUKModelB

2.

LIFTINGMACHINE

TheModelBrequirestheuseofliftingequipmentsuchasaforklift,enginehoistorboomcrane.Donot

liftmachinebyhand.Seethewarningbelow.Usedinconjunctionwithliftingstrapsandfollowingsafe

liftingproceduresasdetailedbythemanufacturesofthese liftingdevices,thelathe/ millcanbesafely

liftedoffofthepalletandplacedonasturdyworkbench.

Donotliftthemachinefromanyotherpointsthanthosepicturedin Figure2.

ChesterUKModelB

3

IDENTIFICATION

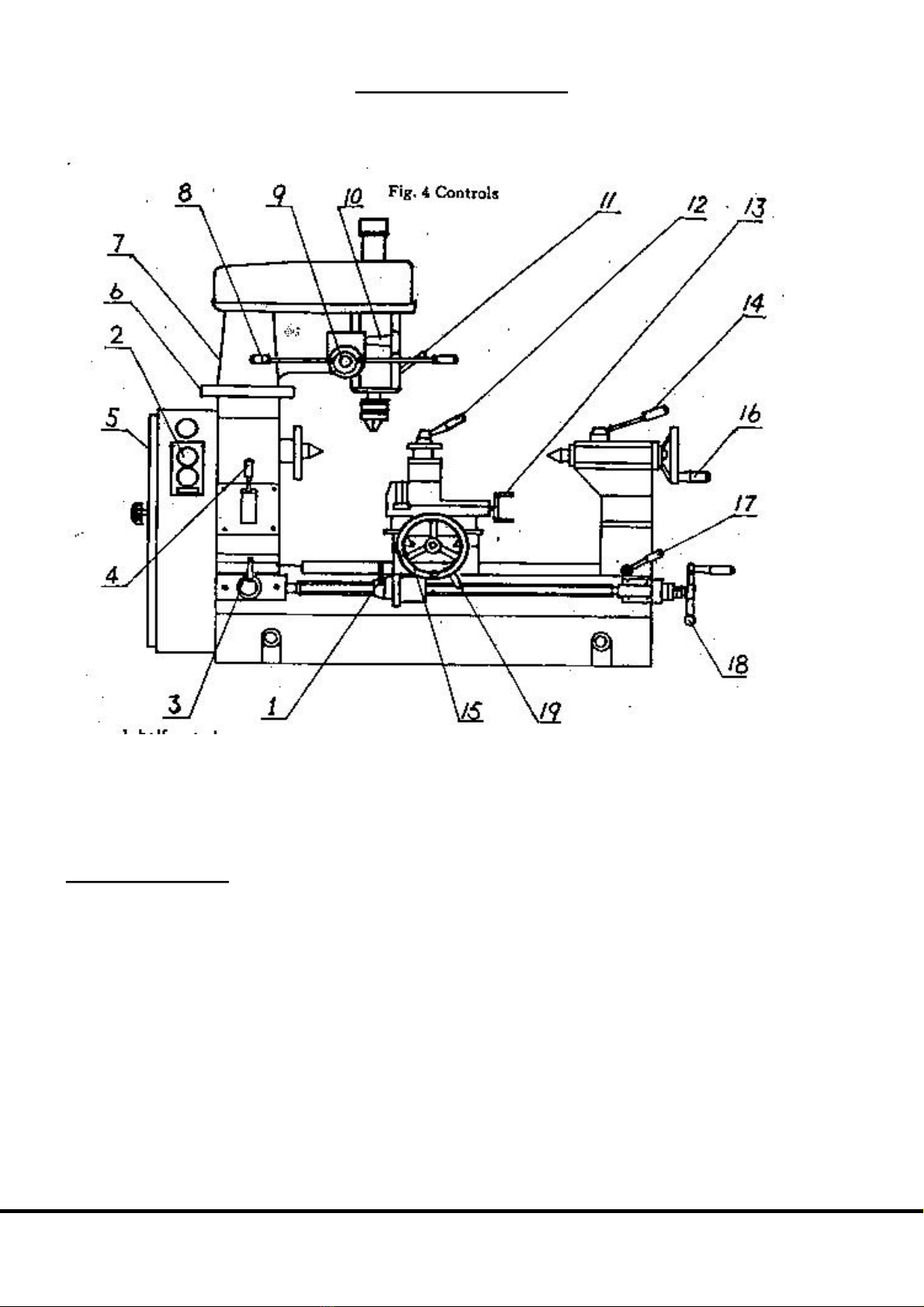

Figure4.ThefollowingisalistofcontrolsandcomponentsontheModelB.Pleasetaketimetobecome

familiarwitheach item and its location.These terms will beused throughoutthemanual andknowing

them will aid in comprehension. Most of these terms will be shown in italics (italics) throughout the

manual.

MACHINETERMS

1.Halfnutslever 10.Microfeedhandle

2.Powerswitch 11.Drillingmillingclamplever

3.Screwclutchlever 12.Toolpostlocklever

4.Speedchangelever 13.Machinevicehandle

5.Clutchhandle 14.Tailstockbarrelclamplever

6.Thedrillingmillingunit 15.Transversemotionhandle

updownhandle 16.Tailstockbarrelhandwheel

7.Theunitlocklever 17.Tailstocklocklever

8.Drillingoperatinglever 18.Longitudinalmotionhandle

9.Clutchhandle 19.Carriagelocklever

ChesterUKModelB

4

ASSEMBLY&SETUP

Thissectionwillcoverthebasicsinassemblyandsetup.Werecommendyoucompleteassemblyinthe

orderinwhichitispresentedtoachievethebestresults.

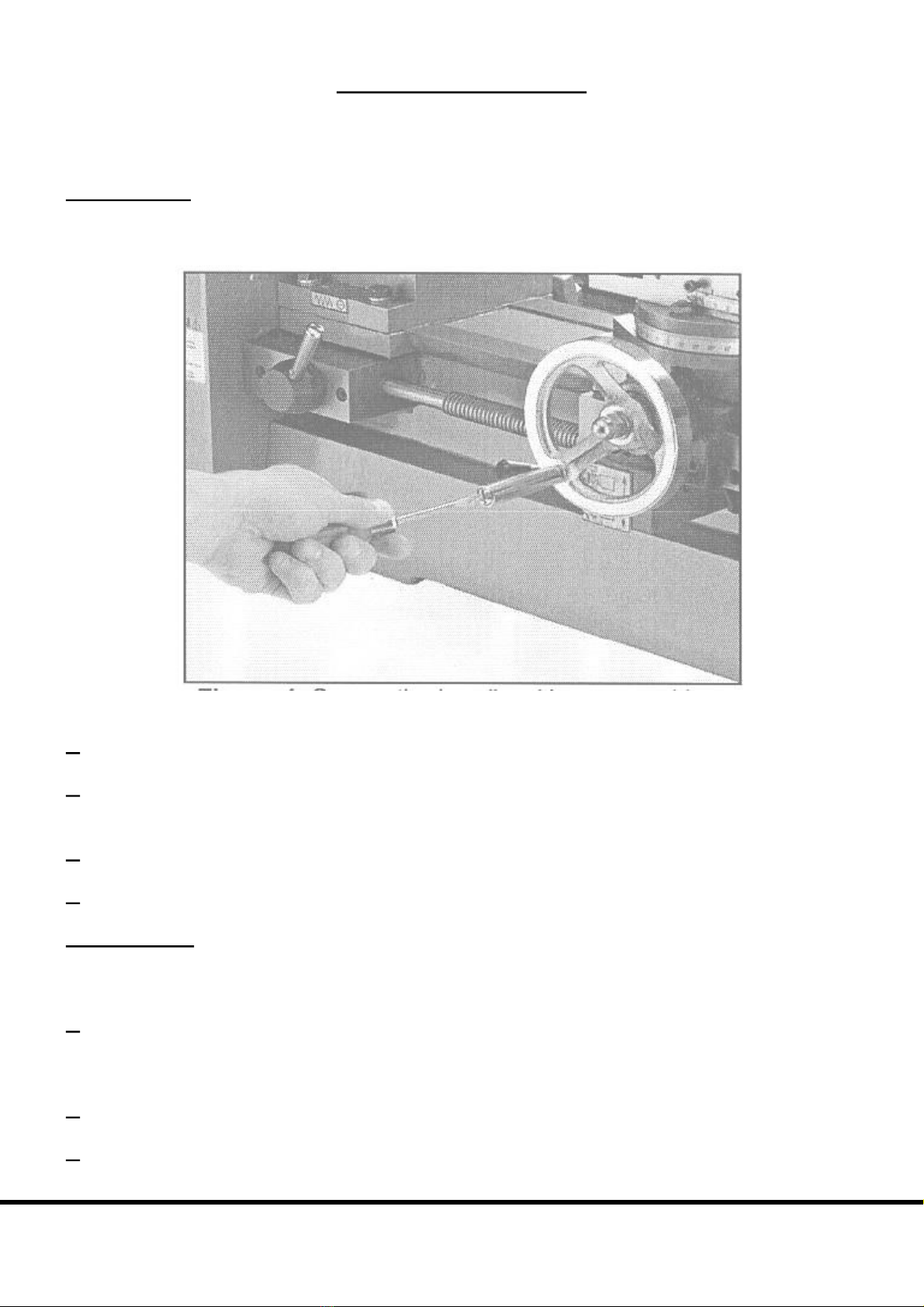

HANDWHEEL

Thehandwheelfortheapronmustbeinstalled.

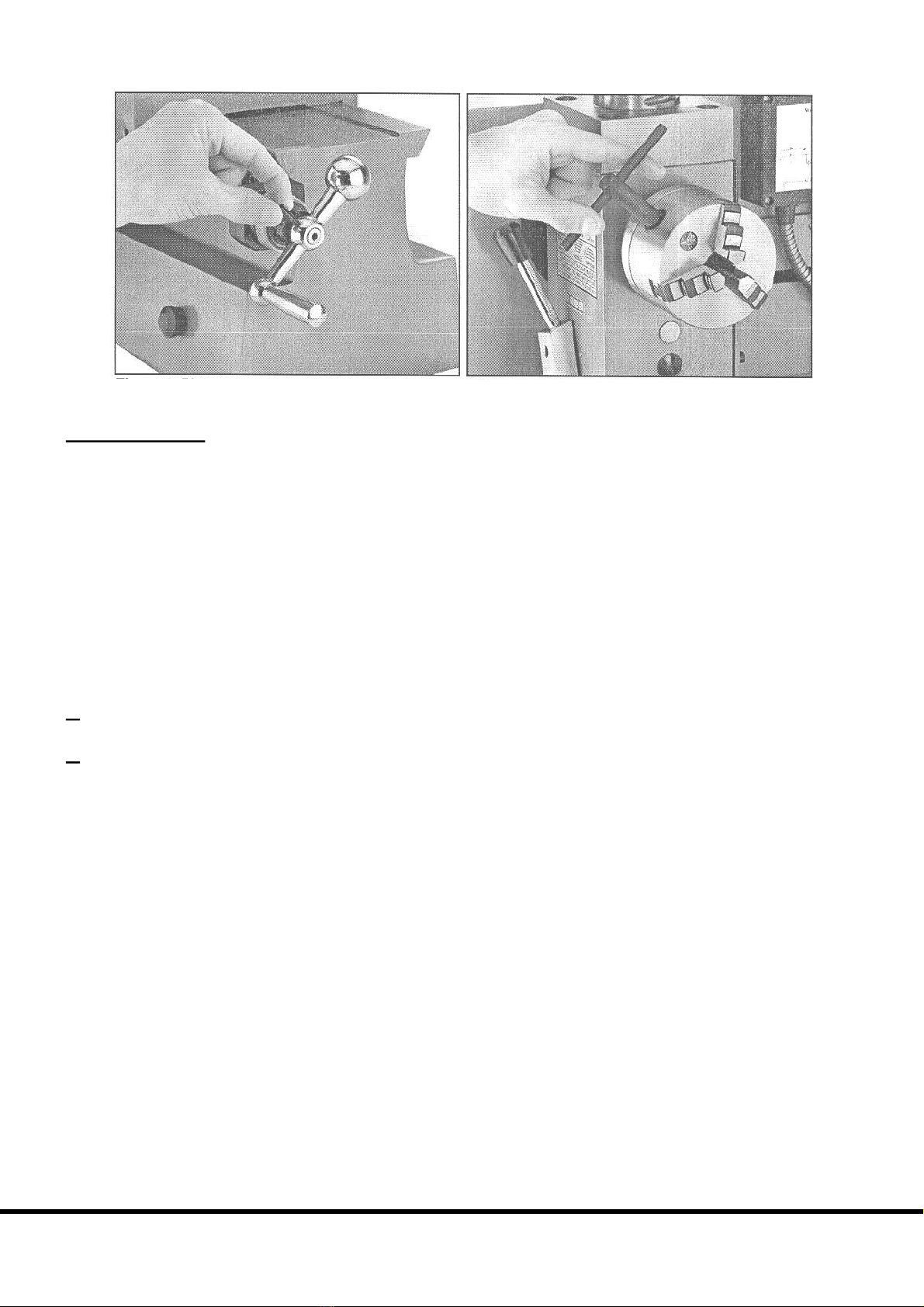

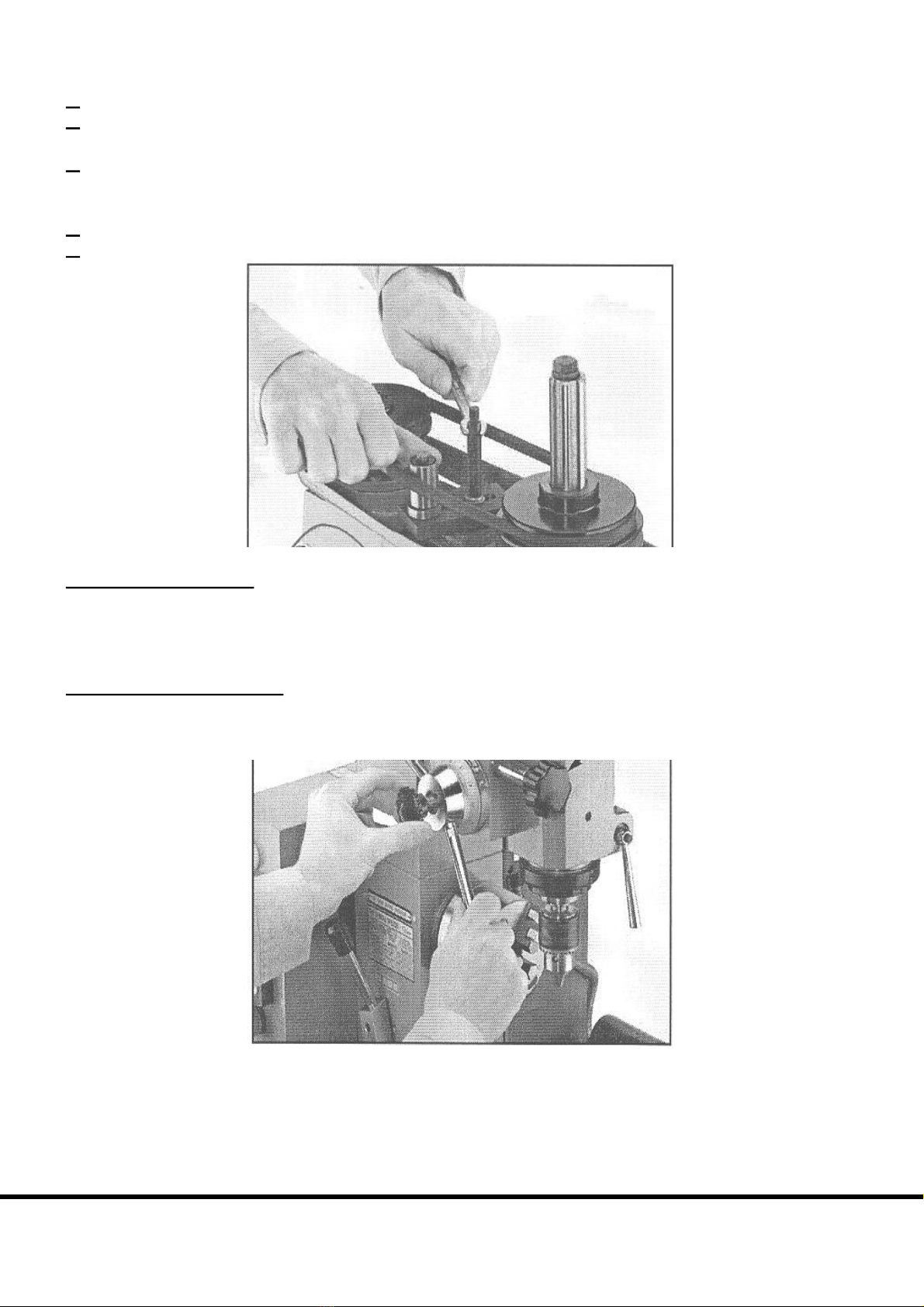

Figure5.Securethehandlewithascrewdriver.

1.RemovetheacornnutandwasherfromthecrossfeedLeadScrew.

2. Slide the handwheel onto the cross feed Lead Screw. Note the key way that is in the bore of the

handwheelandorientitsoitalignswiththekeyonthecrossfeedLeadScrew.

3.Securethehandwheelwiththeacornnutandwasher.

4.SecurethehandleforthehandwheelwithascrewdriverasinFigure5.

HANDCRANK

Thehandcrankforthelongitudinalmanualfeedmustbeinstalled.

1. Theendofthe LeadScrew has asmall holethat iscrossdrilled near itsend.The handcrank has a

similarholedrilled intotheedgeofthecentreball.Orienttheseholestoeachotherandslidethehand

crankontotheendoftheshaft.

2.Rotatethehandcrankontheshaftuntiltheholesalign.

3.Placethe4mmrollpinintotheholeasin Figure6anddriveitinwithahammer.

ChesterUKModelB

5

Figure6.PlacerollpininholeandtapwithhammerFigure7.Rotatechuckkeytoopen/closejaws

LATHECHUCK

TheModelBLathe/Millcomesequippedwitha3jaw(alreadyinstalled).

The3jawchuckisascrolltypechuck,meaningthatallthreejawsmoveinunisonwhenadjustmentsare

made. Most 4jaw chucks, on the other hand, feature jaws which are adjusted independently. A 4jaw

chuckcanbeusedtoholdsquareorrectangularstock.

The3 jaws,ona3JawChuck,openandcloseusingthechuckkeyprovided.Pleasereferto Figure7.

Rotatingthekeyclockwiseclosesthejaws.

Tousethismountingplate:

1.Fastentheplatetothe4jawchuckusingthescrewsprovidedwiththechuck.

2.Fastentheplattothespindleusingthe3screwsthatwereremovedfromthe3jawchuck.

DONOTmountchucksmeasuringlargerthan5”indiameteronthisspindle.

Some4jawchucksmaynotreadilymounttothebackplateprovided.Itmaybenecessarytodrillnew

mounting holes and/or resurface and shoulder the plate so the chuck may be mounted accurately and

safely. Should you have questions regarding this, please consult your local technical school, trained

expertorothertraderesources.

ChesterUKModelB

6

LATHECHUCKREMOVAL

Toremoveachuck:

1.Placeapieceofplywoodacrossthelathebedandpositionitjustunderthechuck.Theboardshouldbe

atleast8”wideand10”long.

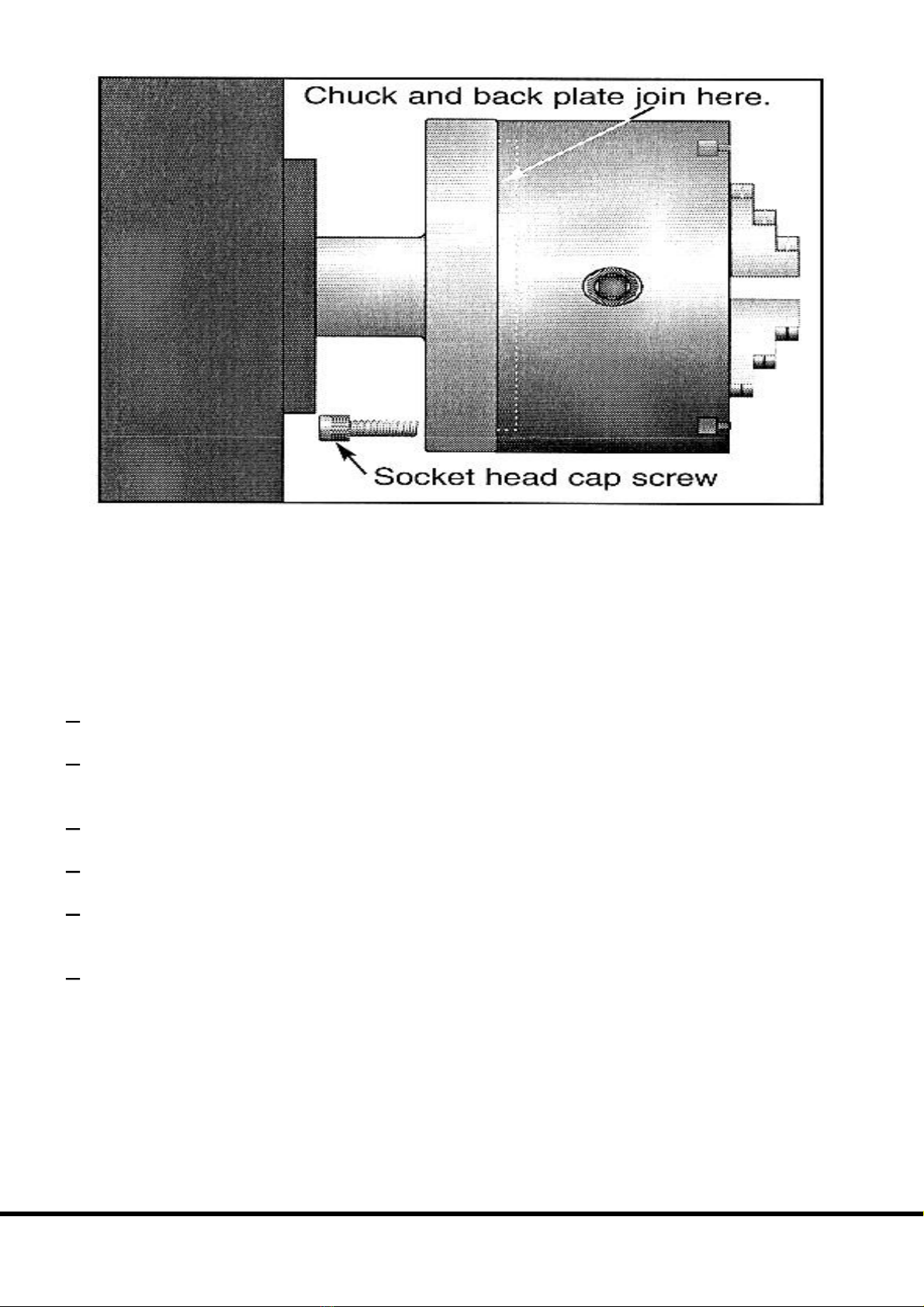

2.Locatethe3socketheadcapscrewsonthebackofthebackplateandremove2ofthem.Pleasesee

Figure8.

3.Removethelastscrew,whilstmakingsuretosupportthechuckwithonehand.Thechuckmaycome

offasthelastscrewisremoved,soitisimportantthatyouarereadytosupportitsweight.

4.Removethechuck.

ChesterUKModelB

7

Ifthechuckisstilltightonthespindle:

Taptheedgeofthechuckwitharubberorwoodenmalletwhilesupportingthebottomofthechuckwith

yourfreehand.Ifthechuckdoesnotimmediatelycomeoff,rotatethespindleapproximately60ºandtap

again.

Toinstallachuck:

1.Placeapieceofplywoodacrossthelathebedandpositionitjustunderthespindle.

2.Placeasocketheadscrewintooneoftheholesinthebackplate.Liftthechuckuptothespindleand

alignthethreadedholeinthebackofthechuckwiththescrew.

3.Whilesupportingtheweightofthechuck,turnthescrew3turns.Donottightenatthistime.

4.Rotate thespindleandrepeatstep3 onthelasttwoscrews.

5.Returntothefirstscrewandtightenitalittlemore.Tightentheotherscrewsaswellbutonlyenough

thatthegapbetweenthechuckandthebackplateremainseven.

6.Finally,tightenallthreescrewsuntilthegapbetweenthechuckandthebackplateisclosed.

ChesterUKModelB

8

DEADCENTRE

The dead centre is used to support stock that is too long to be supported by the chuck alone. Stock

protrudingmorethan2½timesitsdiameter,shouldbesupportedbyadeadorrollingcentre.

Figure9.Deadcentreinstalledintailstock.

Thetailstockbarrelandcentrehavea MorseTaper#3.Beforeassemblingthese, insurethatthemating

surfaces are“white glove” clean. Cleanthe matingsothey are freeofdirt and oil. Theseparts will last

longerandremainaccuratewhenproperlycleanedbeforeassembly.Morsetaperswillnotinterlockwhen

dirtoroilarepresentonthemountingsurfaces.

Insert the end of the centre into the tailstock bore until it seats. The force of the centre contacting a

mountedworkpiecewillfullyseatthetaperwhenthehandwheelistightened.

When using a centre, the tailstock barrel should protrude about ½” and not more than 1¼” out of the

tailstockbody.SeeFigure9.

Toremovethelivecentre,backthetailstockbarrelallthewayintothecastingbyturningthehandwheel,

on the end of the tailstock, counterclockwise. The live centre will pop out. Besure to hold it before it

comesoutlestitdroponthelathebed.

ChesterUKModelB

9

TOOLPOST

TheModelB comes supplied with a4 wayturret tool post. It isdesignedto accept upto 14tool bits.

OtherdevicesandholdersmaybeinstalledintothetoolpostandarrangedasinFigure10.Whenmore

thanonetoolissecuredintothetoolpost,changingfromonetooltoanotherisquicklydonebyloosening

thelock lever(5)androtatingtheposttothedesiredtool. Aspringloadedcatchisinstalledbelowthe

toolpost.Thisallows motioninonlythecounterclockwisedirection.Thecatchcausesthetoolpostto

stop at the same rotational point for each tool placement. This feature can be used for some types of

machiningsetups.Pleasenotethatthesecurenessofthetoolpostisnotdependentuponthecatch.Thus,

thetoolpostcanbepositionedatanyrotationallocationandproperlysecuredwiththelocklever.

If using tool bits that require shimming, be sure to use steel shims as opposed to aluminium or brass

shims.Softshimsmaygive,allowingthetoolbittobecomeloose!

Figure10.Fourtoolsmountedintothetoolpost:

1.BoringBar 2.LeftCuttingToolBit

3.ThreadingToolBit 4.RightTurningToolBit

5.LockLever

Whensecuringatoolbitintothetoolpost,alwaysremembertheserules:

· Securethetoolbitwithatleast2boltsonthetoolpost

· Make sure the top of the tool bit is at the lathe spindle centre line or just below. The tailstock

centrecanbeusedasin Figure11.

· Neverextendthetoolbitmorethan2½timesitsthicknessfromedgeofthetoolrest,i.e.a3/8”

toolbitshouldonlyextend15/16”pastthebottomofthetoolrest.Lessisbest!

· Alwaysusesharptoolbits.

Figure11.Usingacentretochecktoolbitheight.

ChesterUKModelB

10

DRILLCHUCK

TheModelBcomessuppliedwithadrillchuckandarborthatcanbeusedinthetailstockonthelatheor

inthespindleforthepress.Thearboranddrillchuckareassembledandinstalledintothespindleforthe

drillpressspindleatthefactory.

DRILLCHUCKREMOVAL

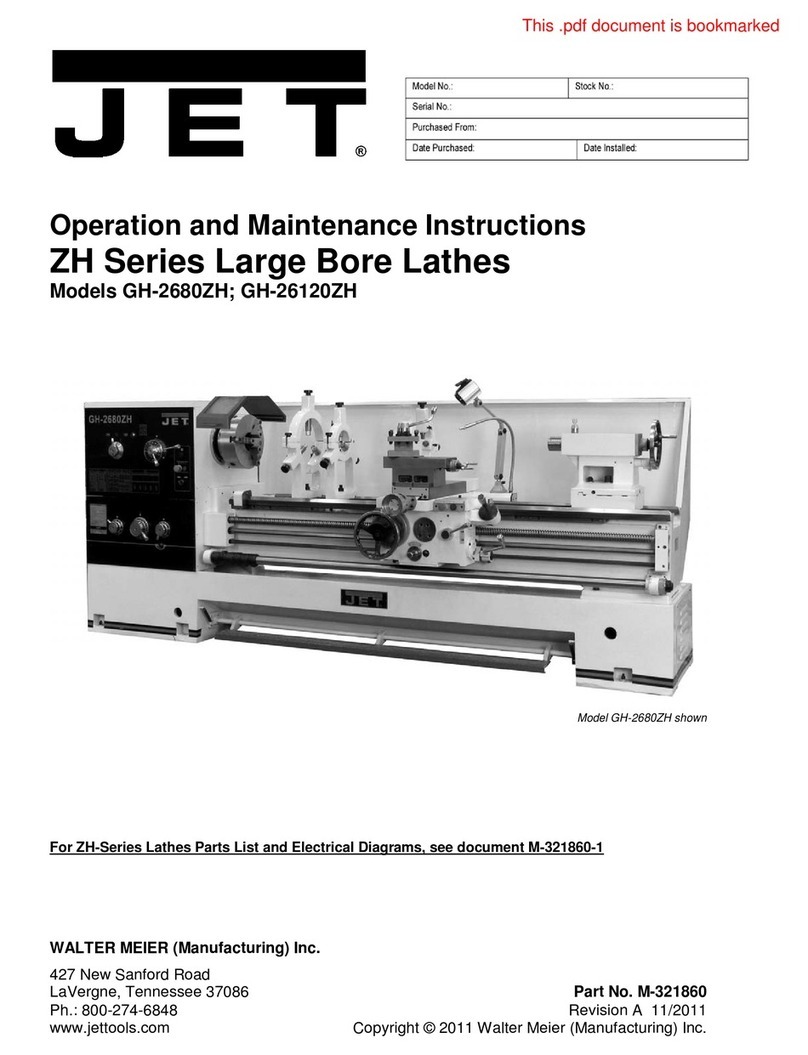

Toremovethedrillchuckfromthedrillpress:

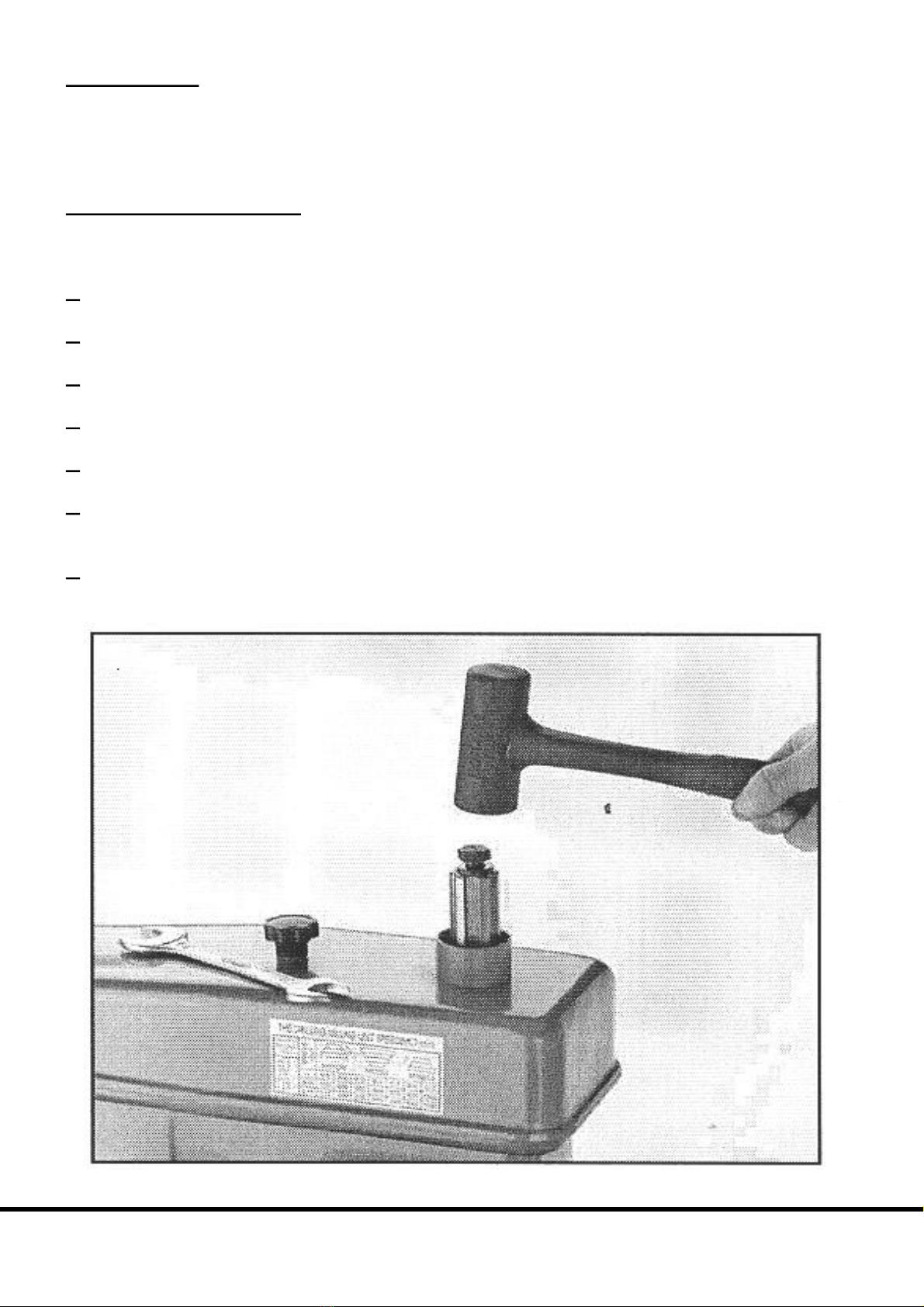

1.Unplugthemachine.

2.Returnthespindletothehighestposition.

3.Removethesmallplasticcapontopofthebeltguard.

4.Graspthedrillchuckwithonehandandunscrewthedrawbar3 turnswiththeother.

5.Securethequillwiththequilllock.

6.TapontheendofthedrawbarwithasoftfacedmalletasinFigure12.Donotuseasteelhammer!

Damagetothedrawbar,suchaschipping,mayoccur.

7.Oncethearborhasbecomeloose,holdthedrillchuckwithonehandwhileunthreadingtheremainder

ofthedrawbolt.

Figure12.Removingdrillchuck

ChesterUKModelB

11

DRILLPRESSMOUNTING

Tomountthedrillchuckintothedrillpress:

1.Removethesmallplasticcapontopof thebeltguardandslidethedrawbaroutofthespindlethrough

thetop.

2.Insertthearborhalfwayintothedrillpressspindle,thenquicklyslideitinplace.

3.Replacethedrawbarandthreaditintothearbor.Donotovertighten!Thedrawbaronlyneedstobe

lightlytightened.Tighteninganyfurtherwillmakeitdifficulttoremovethearbor!

LATHEMOUNTING

Priortomountingthedrillchuckintothetailstockwipetheinsideofthetailstockbarrelandarbordown

withacleanclothandinspectthemfornicksorscratches.Anyirregularitiesonthesurfaceofthearboror

inside thetailstock barrel will hinder thelocking capabilityofthetaper andshould bedressed smooth

withafinefile.

Tomountthedrillchuckintothetailstockofthelathe,slidethearborintothetailstockbarrelaboutone

halfoftheway.Withaquickmotion,finishslidingthechucktherestoftheway.Thisshouldseatitwell

intothetailstockbarrel.

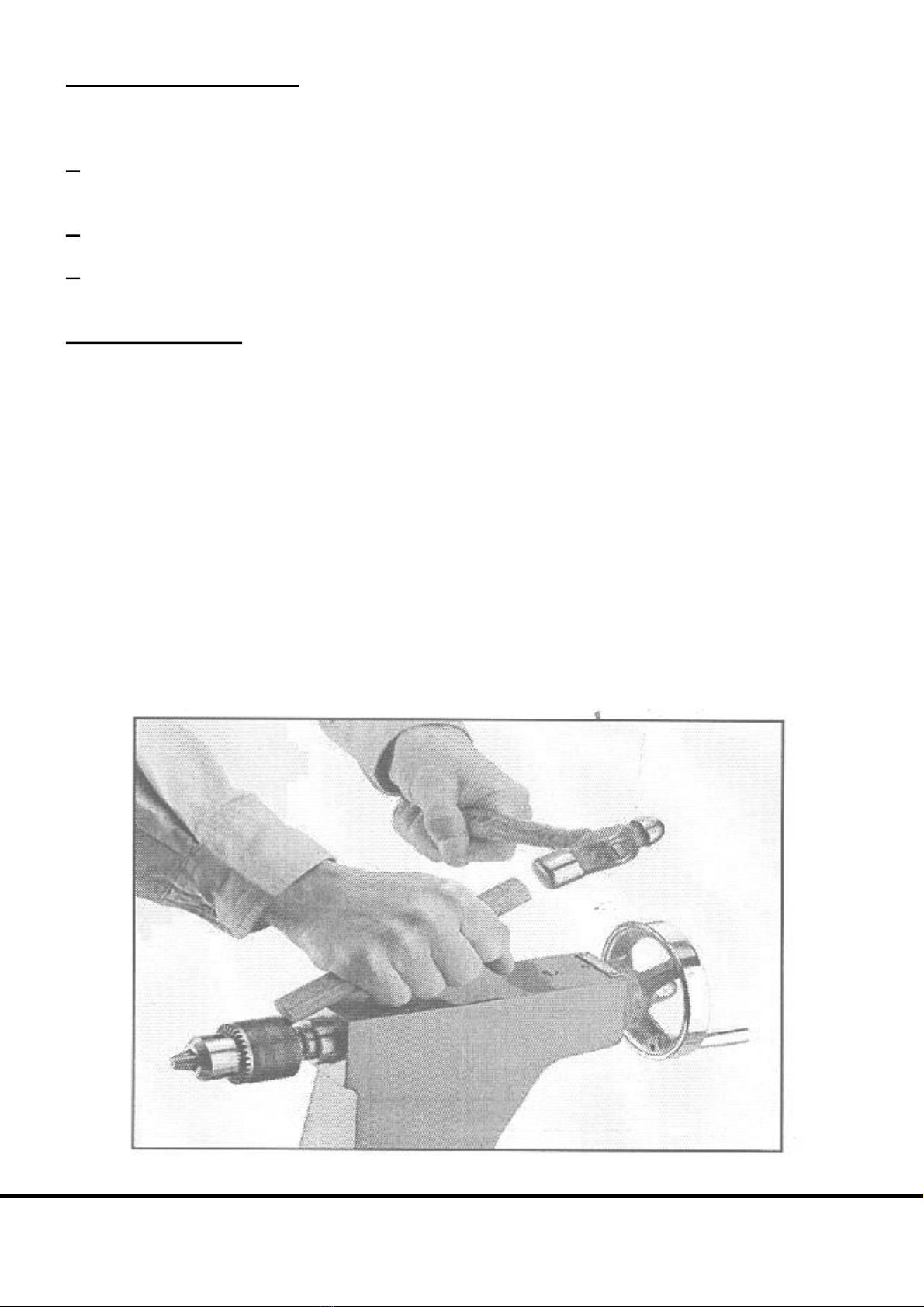

Becausethedrill chuckarbor isthreadedon thesmall end, removalrequiresthe use of amallet and a

woodendowelasinFigures13.Tapalongthebackedgeofthedrillchuckontheleftandthentheright.

Thedrillchuckandarborwillpoploosefromthetailstockbarrel.

Drillchuckarbors withastandardtang(or flat)onthesmall endallow theoperatortosimplyturnthe

tailstock handwheel counterclockwise until the drill chuck and arbor pop loose. Chester UK offers a

varietyofchucksandarbors.Pleaseseeourcurrentcatalogueformoreinformation.

Figure13.Seatingthearboranddrillchuck.

ChesterUKModelB

12

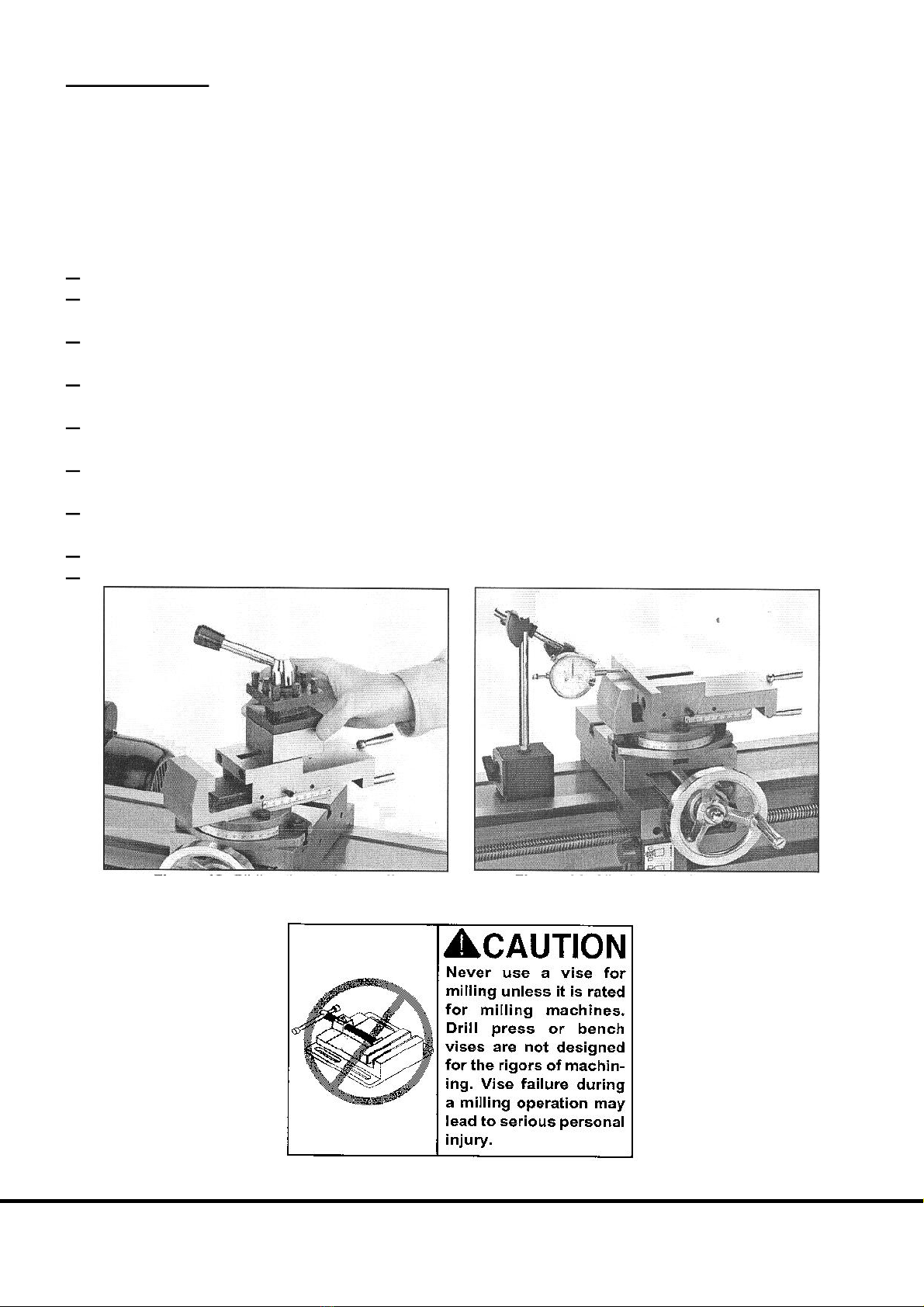

MACHINEVICE

TheModelBcomessuppliedwithamillingvicethatalsoservesasthecompoundforthelathe.The4

waytoolpostmustberemovedbeforeusingthevice.Loosenthelockhandleandslidethetoolpostoffof

thecompound/viceasFigure14.

Themillingvicecanbealignedto1ofthe2axisofthelatheoratanyangledesired.Caremustbegiven

tosettingthevice ifaprecisionangleisneeded.Thefollowinginstructionsaregiventomakethejaws

paralleltothetravelofthecrossslide.

1.Removethetoolpostasdescribedabove.

2.Loosentheswivelboltsonthecompound/vicesoitcanswivelfreely.Pivotthecompound/viceso

thejawsoftheviceareroughlyalignedwiththecrossslide.

3.Mountthedrillchuckintothemillingspindleandsecureanindicatorintoitor,placeadialindicator

mountedtoamagneticbaseonthebedasin Figure15.

4.Positionthecrossslideandapronsotheindicatorpointcontactsthestationaryvicejaworaparallel

mountedintothevice.

5.Movethecrossslidewiththehandwheelandwatchthedial.Notethedirectiontheneedleismoving

onthedialandbyhowmuch.

6.Whenthevicehasmovedsotheindicatorisattheotherendoftheparallel,pivottheviceonehalfthe

amountofmotiondetectedin step6.

7. Move the vice to the starting position and note the difference. Again, pivot the vice one half the

difference.

8.Repeatsteps6 through 8untilthedialremainsstationarywhentheviceismoved.

9.Tightenthepivotboltsonthebaseofthecompound/vice.

Figure14.Slidingthetoolpostoff. Figure15.Aligningviceforprecision.

ChesterUKModelB

13

LATHECONTROLS

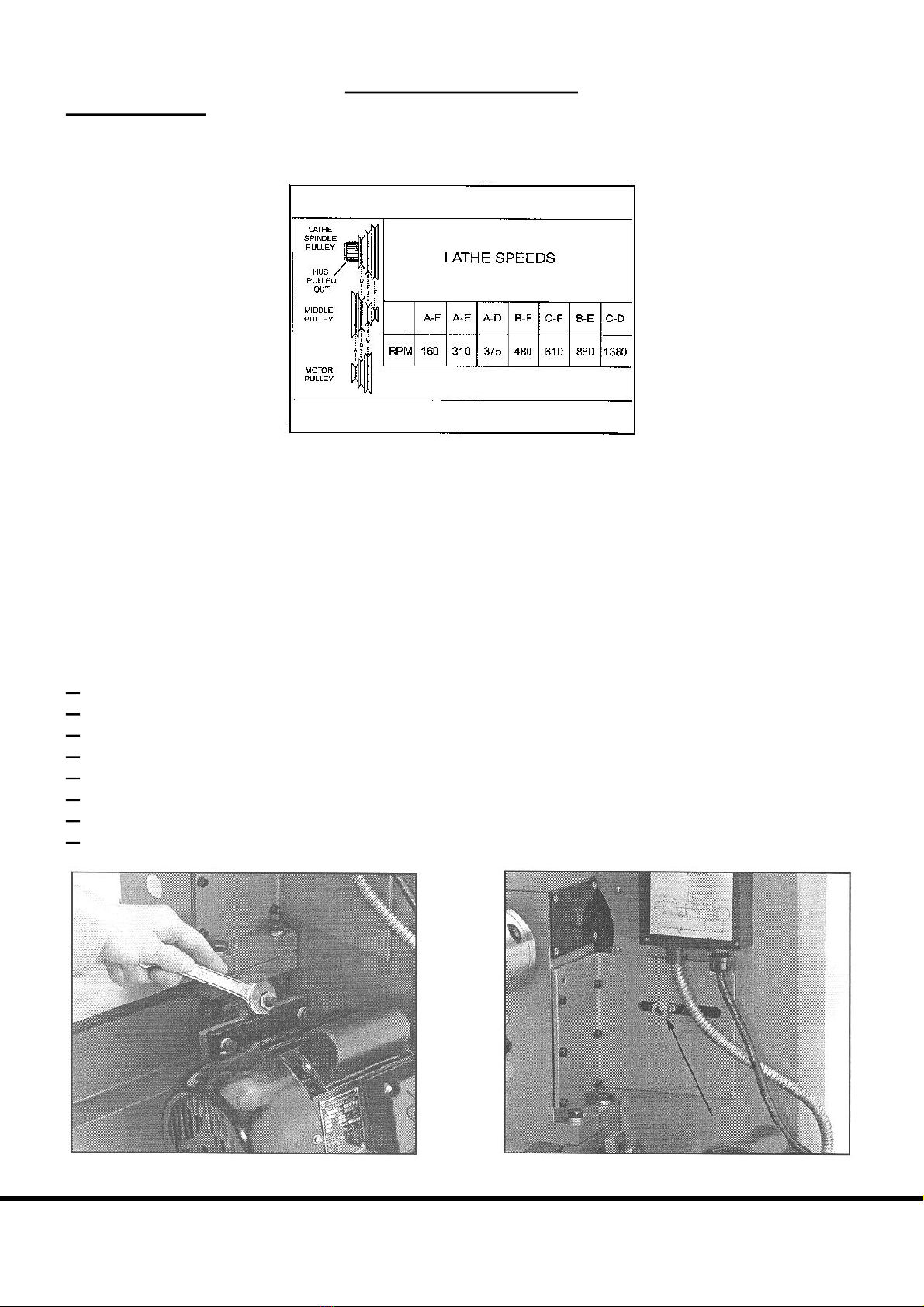

LATHESPEEDS

Beforeusingthelathe,thehubontheendofthelathespindlemustbepulledoutasshowninFigure16.

Toeaseengagementofthishub,slowlyrotatethespindlebyhandwhilegentlypullingthehub.

Figure16.Speedchart

Thespeedof the lathe is controlled by the position of thebelts onthepulleys.Thechart inFigure16

showsthevariouscombinationsofbeltpositionsforachievingarangeof6speeds.

Example:

Toselectaspindlespeedof310R.P.M.,placeabeltonthe3

rd sheave(fromtheoutermostsheave)ofthe

middlepulleyandthe2

nd sheaveofthespindle pulley. Place abelt fromthe first sheaveonthemotor

pulleytothefirstsheaveofthemiddlepulley.

Tochangebeltposition:

1.Unplugthemachine.

2.Loosenthetensioningnutlocatedjustabovethemotor.SeeFigure17.

3.Loosenthenutonshaftforthemiddlepulley.SeeFigure18.

4.LiftthemotorandremovethelowerbeltfromtheModelBmotorpulley.

5.Placetheupperbeltinthedesiredposition.

6.Placethetensionbeltinthedesiredpulleys.

7.Pulltensionontheupperbeltwiththemiddlepulleyandtightenthenutloosenedin step3.

8.Tightenthetensioningnutjustabovethemotoruntilthereis¼”deflectionwithmoderatepressure.Do

notovertighten.

Figure17.Tensionnutshown Figure18.Loosenthisnuttoadjustpulley.

ChesterUKModelB

14

FEEDSELECTION

Nevermovethefeedrateleverwhilethemachineisrunning.

TheModelBLathe/Millhas2feedcontrolleverswhichmustbeengagedinordertousethepowerfeed

orthreading feature.TheFeedRateLever,showninFigure19,controlsinternalgearsthatchangethe

feedratebyafactorof2.Turningthelevertoposition“l”willcausetheLeadScrewtoturnattwicethe

rateas whenit isinposition“ll”. Whenthis lever is straight up,thegearing is in neutraland no power

feedisavailable.

Figure19.Feedrateselectionlever

Important

Do not force any lever on the machine. If the lever will not engage, rotate the chuck by hand while

keepinglightpressureontheselector.Asthechuckrotatesitalignsthegearteethinsidetheselectorbox

andtheselectorwillengage.

Figure20.FeedLeverindicatedbyarrow

FEEDLEVER

While the Lead Screw can be placed in neutral with the feed selection lever, another lever allows the

powerfeedingfeatureofthelathetobeturnedonandoff.Whenturnedtotheleft,asinFigure20,the

FeedLeverconnectspowertotheapron.Whenturnedtotheright,theaproncanebefedmanuallyand

thehandcranknolongerturnsbyitself.TheaproncannotbemovedmanuallyunlesstheFeedRateLever

isinneutralortheFeedLeveristurnedtotheright.Pleaseseethecautionbelow.

ChesterUKModelB

15

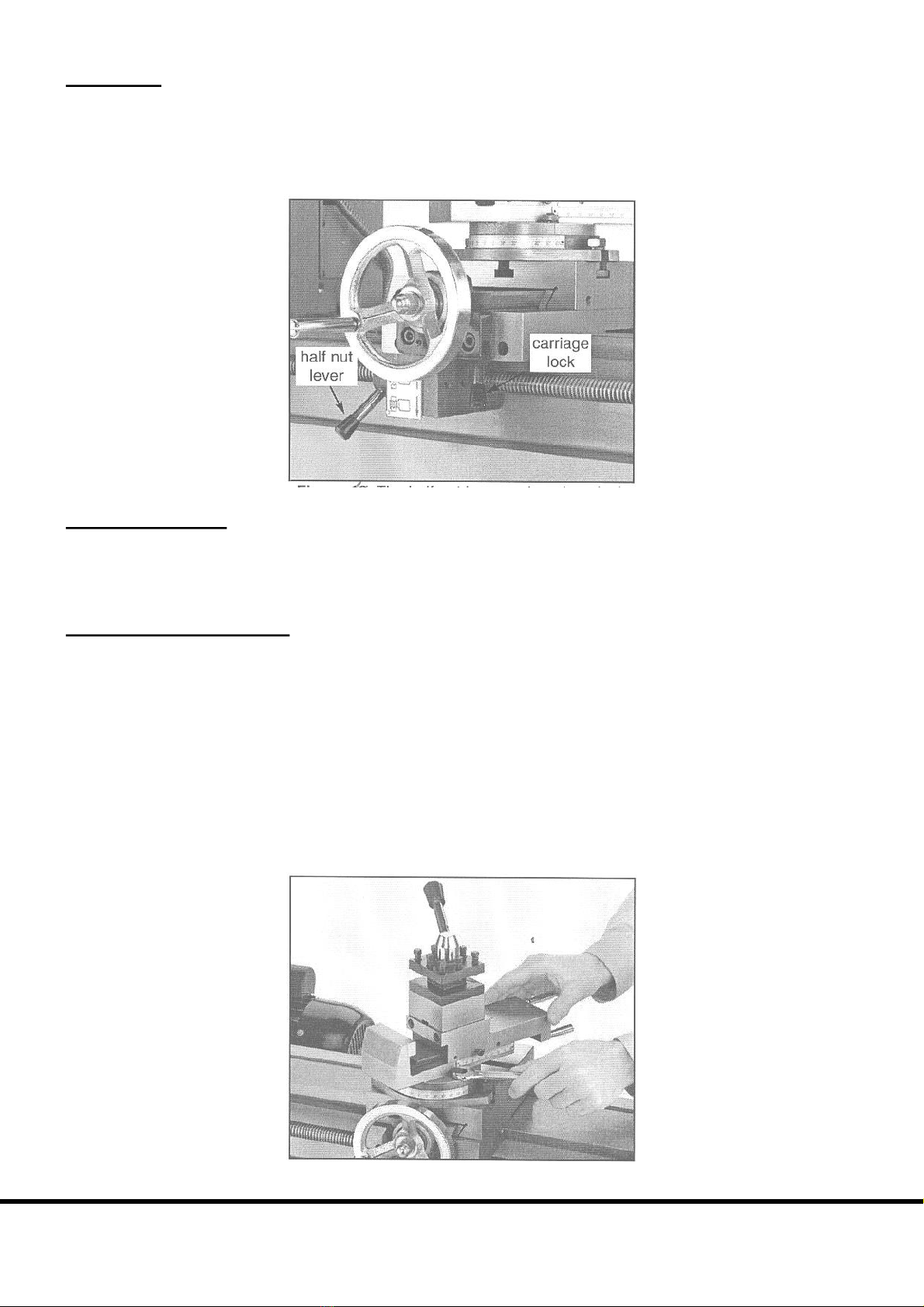

HALFNUT

ThehalfnutleverislocatedunderthelefthandsideapronasshowninFigure21.Thishandlemaybe

engagedanddisengagedwhilethemachineisstillrunningandwhilemakingacut.Movethelevertothe

downpositionandthehalfnutisengaged.BecausethethreadsofthenutandLeadScrewwillnotalways

bealigned,engagingthehalfnutmayrequirewaitinguntiltheyare.Donotforcethehandle.Applylight

pressuretothehandleandwhenthethreadsarealignedthehandlewillengage.

Figure21.Thehalfnutleverandcarriage

CARRIAGELOCK

The carriage lock lever is located under the right hand side of the apron as shown in Figure 21. This

allowsthecarriagetobelockedinplaceforprecisionfacingoperationswhileusingthelatheortomakea

setinamillingoperationmorerigid,amongotherthings.

CARRRIAGECONTROLS

Thelathehas3handlesformanualcontrolofthetoolbitduringmachiningoperations.Onefullturnon

thecrossslideorlongitudinalhandcrankswillproduce0.100”(onetenthofaninch)ofmotion.Thecross

slide and apron crank have dials with divisions showing relative motion. The compound has a direct

readingscaleonitssidewhichiscalibratedin1millimeterincrements.Thefollowingisadescriptionof

eachslideandtheirmeasuringcharacteristics.

Compound Slide – This slide is adjustable to any angle. By loosening the bolts at the swivel base as

shownin Figure22,thecompoundmaypivottoanyanglerelativetotheturningaxisofthelathespindle.

Thisfeatureallowstaperedcutstobeproducedonaworkpiece,andwhensetto60º,ishelpfulincutting

threads, etc. The scale on the side of the slide has divisions in millimeters and is 80 millimeters long.

Eachlinemarks1millimeter(orabout0.03937”).Thetoolpostismountedtothetopofthecompound

slideandwhenremovedallowstheslidetobeusedasavice.

Figure22.Changingtheangleoncompound.

ChesterUKModelB

16

CrossSlide–Thehandwheelmovesthecompoundslideacrossthelathebed.Turningthedialclockwise

movestheslideawayfromtheoperator.Themotionofthisslideisusedforfacingaworkpieceandwhen

advancing a cut for reducing a diameter. The dial has 100 divisions with each division representing

0.001”(onethousandthsofaninch)ofmotionfortheslide.Thelabelabovethedialreportsthateachline

represents0.002”.Itisbesttothinkofthisastheamountofreductionindiameteronthepartperlineon

thedial.Therefore,rotatingthedial10markswillmovetheslide0.010”andmultiplyingthisamountby

0.002”equals0.020”.Therefore,thediameterofthepartwillbereducedby0.020”

Apron–Thelongitudinalmotionoftheaproniscontrolledbythehandcrankattheendofthelathebed.

SeeFigure23.Themotionofthisslideisusedwhencuttingalongthelengthofaworkpiece.Thisslide

canalsobeoperatedwiththepowerfeedfeature.

Figure23.Handcrankfortheapron,

GraduatedDials–Eachdialcanberotatedwithoutturningthehandcrank.Thisishelpfulbecausethe

dialcanbesettozeroafterthetoolbittouchesthepartandthelocationoftheslideandtoolbitwillbe

known.Thegraduateddialcanbeadjustedbyholdingthehandcrankwithonehandandturningthedial

withtheother.

TAILSTOCKCONTROLS

Thetailstockcomessuppliedwithahandwheelwithgraduateddial,barrellock,tailstocklockandoffset

feature.Figure24showsthelocationsofeach.

Tailstock Handwheel – Turning the handwheel advances or retracts the barrel in the tailstock. The

graduateddialonthehandwheelisadjustable.

BarrelLockLever –Thisleverlocksthetailstockbarrelinplace.

TailstockLockLever –Thisleverlocksthetailstockinplaceonthelathebed.

Offset Mechanism – Loosening these bolts allows the tailstock to be offset from centre by turning a

screw.Thisfeaturewillallowtaperturningwhenaworkpieceisheldbetweencentres.

Figure24.Detailoftailstockcontrols

1.TailstockHandwheel 2.BarrelLockLever

3.TailstockLockLever 4.OffsetMechanism

ChesterUKModelB

17

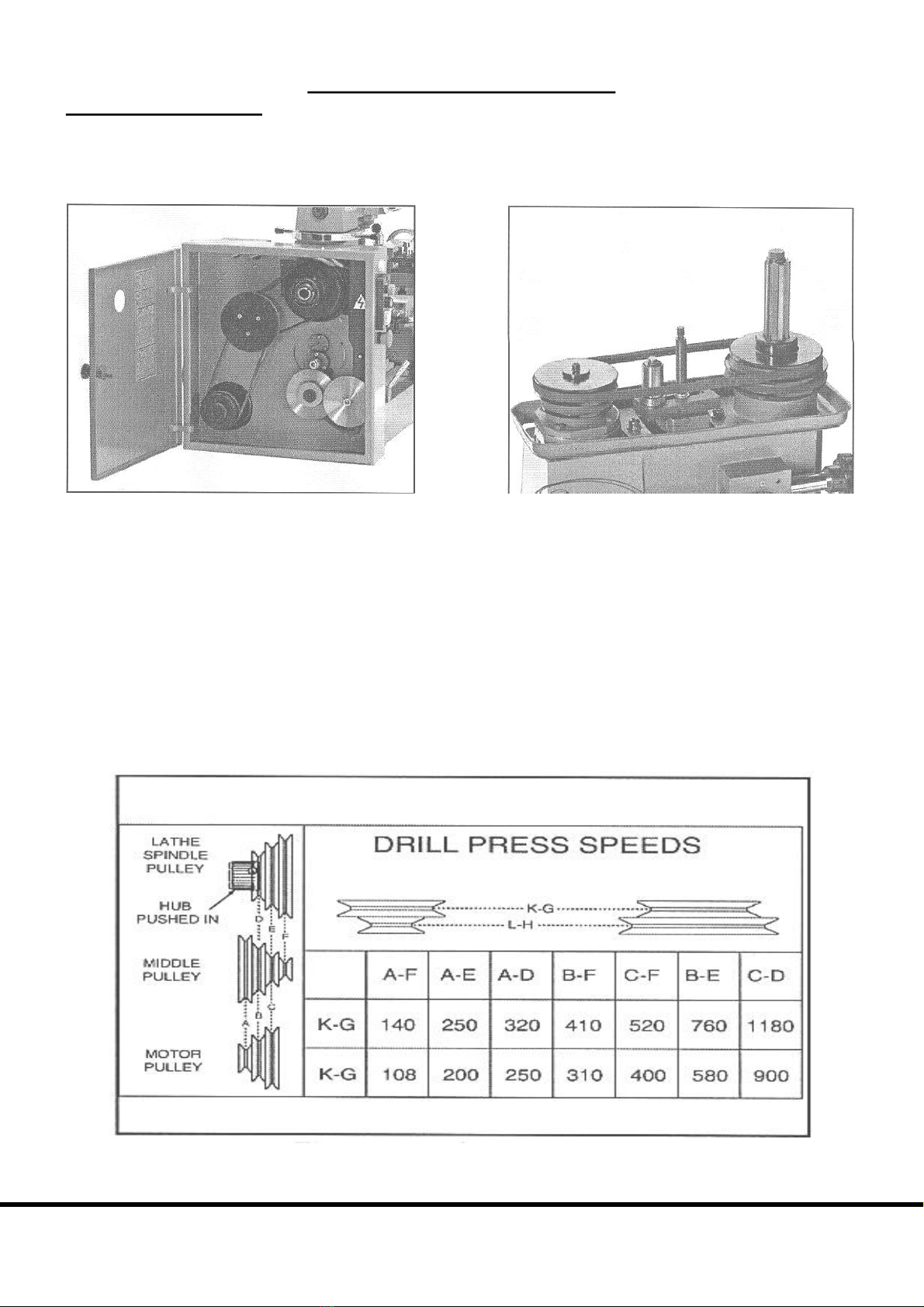

DRILLPRESSCONTROLS

DRILLPRESSSPEEDS

Thespeedofthedrillpressspindleiscontrolledby2groupsofbeltsandpulleys.Thebeltpositionson

theendofthelathecontrolonespeedrange.See Figure25.Thebeltsandpulleysabovethedrillpress

controltheotherrange.SeeFigure26.

Figure25.Lowerpulleysforspeedchanges Figure26.Upperpulleysforspeedchanges

Unplug the Lathe/Mill! Before using the drill press, the hub at the end of the lathe spindle must be

adjusted to the “in” position. See Figure 27. To ease engagement of this hub, slowly rotate the drill

spindlebyhandwhileapplyingpressuretothehub.

Thechartalsoshowsthevariouscombinationsofbeltpositionsforachievingadesiredspeed.

Example:

Toselectaspindlespeedof310R.P.M.,startbymovingthebeltsattheendofthelathe.Movethelower

belttothe“B”position.Movetheupperbelttothe“F”position.Followthebeltchangingproceduresin

thesectiontitledLatheSpeeds.Next,movethebeltlocatedabovethedrillpresstothe“KG”position.

Figure27.Speedchart.

ChesterUKModelB

18

Tochangebeltposition:

1.Unplugthemachine.

2.RemovetheUpperBeltGuard,loosenthecoversecuringthestudandpivotthebelttensionertorelax

tensiononthebelt.SeeFigure28.

3.Whileslowlyturningapulley,rollthebeltupordowntothedesiredsheave.Itisalwayseasiertoroll

offofthelargerpulleyontoasmallerpulley.Donotallowfingerstobecometrappedbetweenbeltand

pulley.

4.Pivotthebelttensioneruntilthebeltistightandsecurethetensionerbytighteningthestud.

5.Replacebeltguard.

Figure28.Loosenstudtopivotbelttensioner.

QUILLLOCKLEVER

TheheightofthespindlecanbelockedwiththeQuillLockLever.SetthedesiredheightwiththeQuill

Leverandturntheleverdown.ThelevercanbeclearlyseenonthebottomrighthandcornerofFigure

29.

FINEFEEDDOWNFEED

TheupanddownmotionofthedrillpressspindleiscontrolledjustlikeanyotherdrillpresswithaQuill

Lever.Butunlikemostdrillpresses,theModelBissuppliedwithaFineDownFeedKnob,indicatedby

thearrowin Figure29.

Figure29.Movethehandlewhiledepressingknob.

Toactivatethisfeature,rotatetheQuillLeverwhiledepressingtheblackknobinthemiddleofthecentre

ofthehubas inFigure29. Theknobwill engage and thespindlewill no longer moveusingtheQuill

Lever.RotatingtheFineDownFeedknobinaclockwisedirectionwillcausethespindletogodown.To

disengagethis feature, rotatetheFineDownFeed knobandpull ontheknob in thecentre ofthe hub.

Rotatingthehandwheelwillalwaysaidinengaginganddisengagingthisfeature.

ChesterUKModelB

19

Table of contents

Other CHESTER U.K. Lathe manuals

Popular Lathe manuals by other brands

IGM

IGM LAGUNA Revo 1836 operating instructions

Bochi Machine Tool Group Co.

Bochi Machine Tool Group Co. CS6140 Series Operator's manual

LNS

LNS HYDROBAR SPRINT 555 Troubleshooting and Spare Parts Manual

Jet

Jet ZH Series Operation and maintenance instructions

Teknatool

Teknatool NOVA DVR XP instruction manual

MiniMax

MiniMax T 124 instruction manual